Sapphire crystal growth method

A sapphire crystal and growth method technology, which is applied in the field of single crystal sapphire crystal growth, can solve the problems of long time required for high temperature crystal growth, crystal quality and size limitations, and high cost, and achieves saving crystal growth time, reducing thermal stress and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

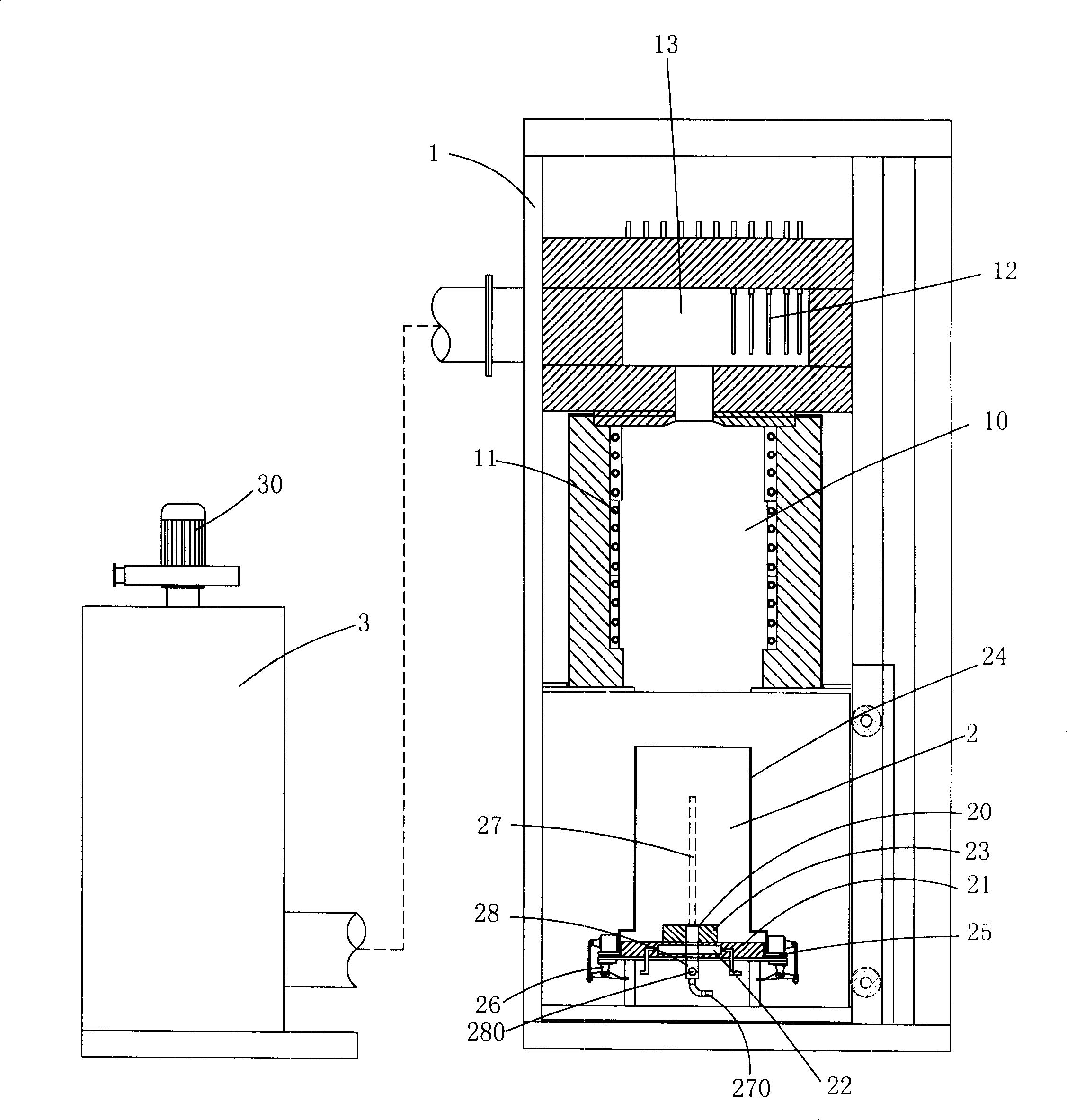

Image

Examples

Embodiment Construction

[0021] The steps that sapphire crystal growth method of the present invention implements are as follows:

[0022] Grinding: aluminum oxide (Al 2 o 3) powder is pulverized and ground with chemical aids to ultrafine powder particles, such as ultrafine powder particles of tens of nanometers. Crushing and grinding are an indispensable small step in the powder production process. Crushing is often the preliminary work of grinding, or coarse grinding, and grinding is generally referred to as the step of obtaining a particle size below a millimeter. For crushing, there are many types of pulverizers; for grinding, ball milling is generally used as a means. For traditional ceramic powders, crushing and grinding operations are the only way to obtain this powder. However, for the new generation of ceramic powders, the crushing and grinding operations may have many purposes, including: breaking up aggregates, reducing aggregates, or making the powders that make up the powder into termi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com