Homogenized sextupole magnet of permanent magnet beam

A homogenization, pole magnet technology, applied in the direction of electromagnets, accelerators, electrical components, etc., can solve the problems of poor uniformity and uneven beam current, and achieve the effect of good homogenization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

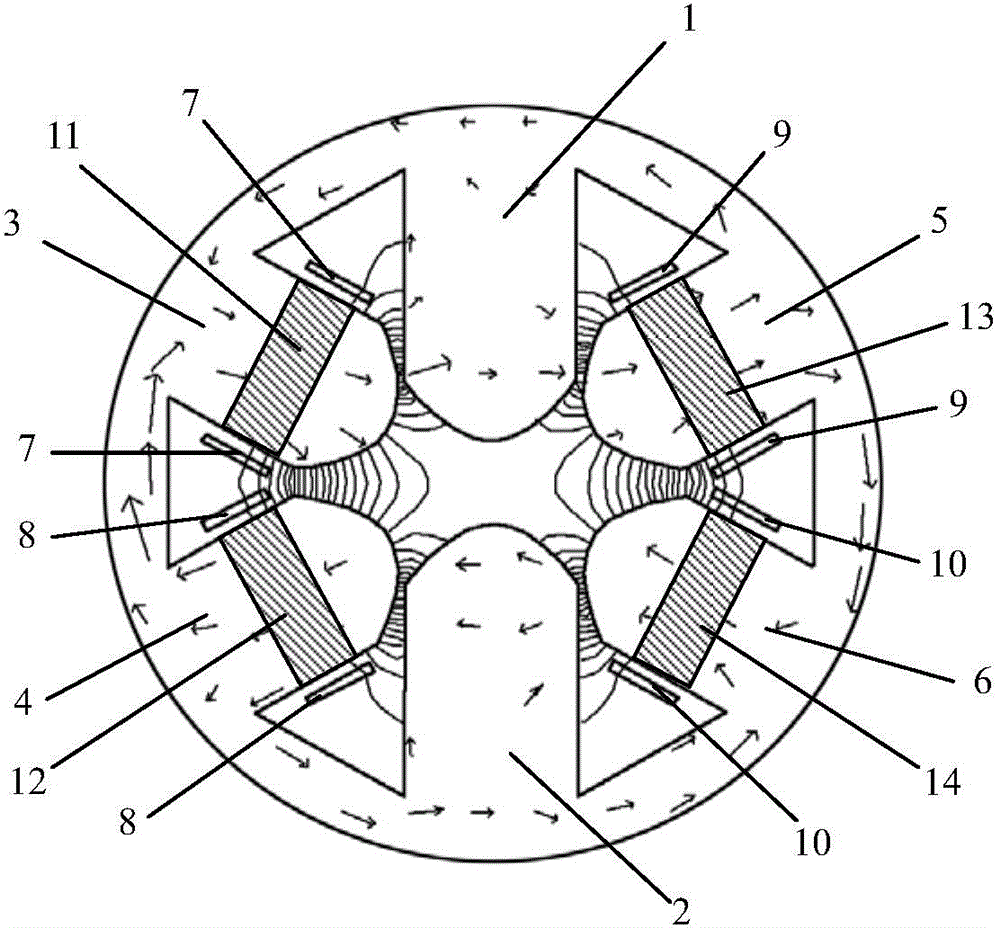

[0025] The pole distance of the six-pole magnet provided by the present embodiment is as follows: figure 1 As shown, the distance between poles 3 and 6 is the same as the distance between poles 4 and 5, which is 5cm, the distance between poles 1 and 2 is 1.1cm, and no magnetic field excitation components are set on poles 1 and 2. Magnetic field excitation components are arranged on the remaining magnetic poles 3, 4, 5, and 6. The direction of the magnetic field generated in the opposite magnetic poles 3,6 of the two magnetic field excitation assemblies 7,10 is opposite to the direction of the magnetic field generated in the opposite magnetic poles 4,5 of the other two magnetic field excitation assemblies 8,9, and the opposite magnetic poles 3,6 (or 4, 5) the direction of the magnetic field generated in the same, so as to form a symmetrical magnetic field distribution with respect to the center line of the magnet. The magnetic field excitation assembly includes permanent magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com