Anaerobic fermentation system

A technology for anaerobic fermentation and extraction of tubes, which is applied in the field of anaerobic fermentation systems, can solve the problems of reducing methane power generation benefits, achieve the effect of reducing the generation of scum and reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to allow examiners and those skilled in the art to fully understand the effects of this application, the preferred embodiments of this invention are described as follows with reference to the figures and figure numbers. The directional terms mentioned in the following embodiments, such as: up, down, left, right, front, back, inside or outside, etc., are only referring to the directions attached to the drawings. Accordingly, the directional terms used are for illustration and not for limitation of the application.

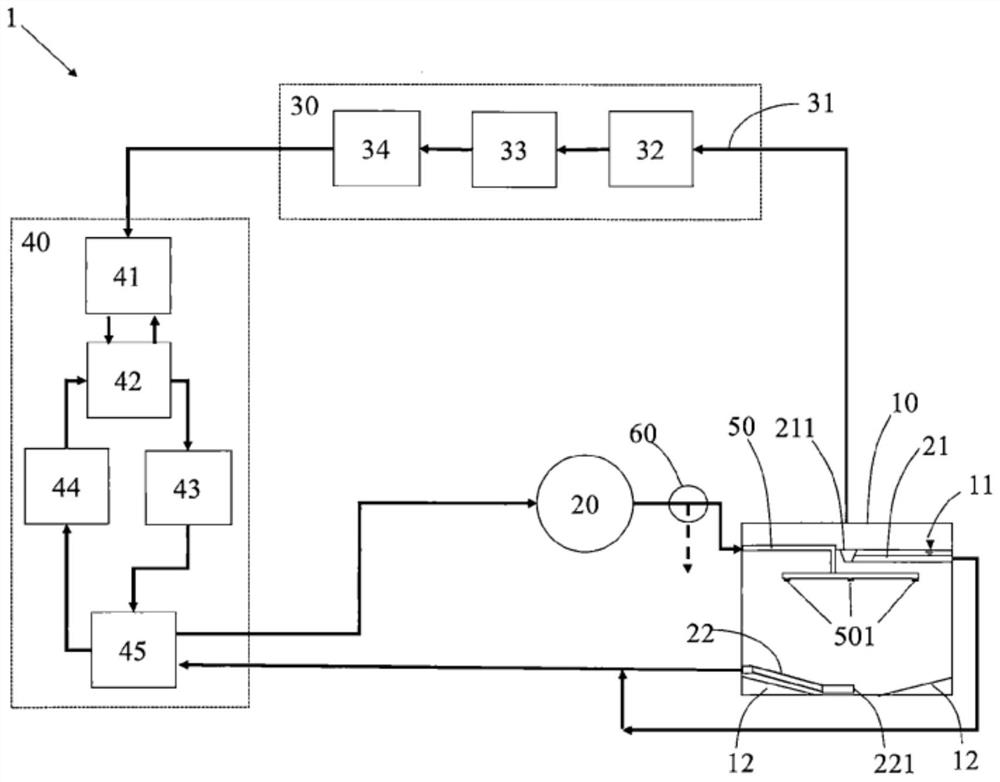

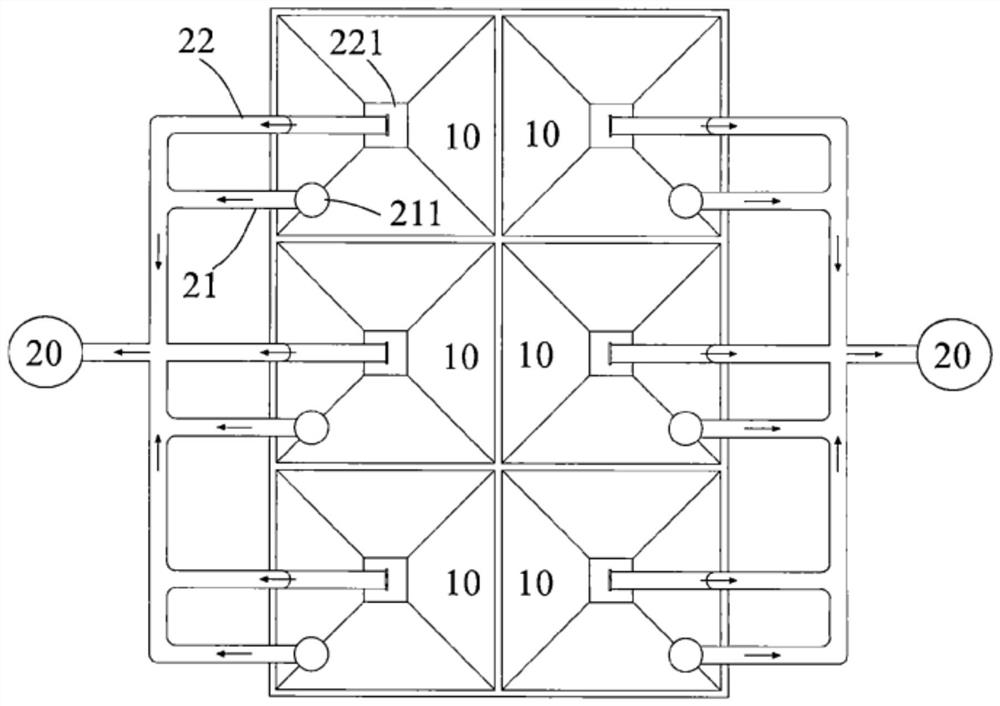

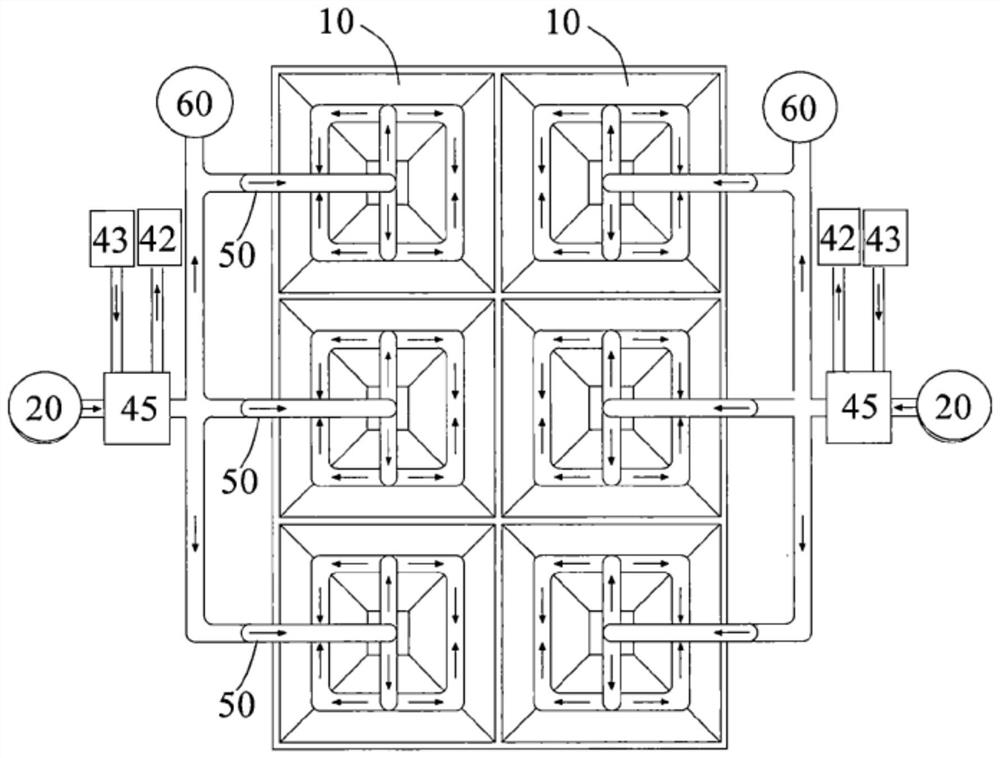

[0049] The application provides an anaerobic fermentation system 1 such as figure 1 As shown, it includes: an anaerobic fermentation tank 10, which is used to contain and decompose an organic waste to generate a fermentation gas; an external circulation pump 20, which is connected to the anaerobic fermentation tank 10, and passes through a floating A slag extraction pipe 21 and a sludge extraction pipe 22 respectively extract a scum and a solid-cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com