Special screw for single-screw plastic extruding machine

A plastic extruder and single screw technology, applied in the field of extruder screw, can solve the problems of large influence of plasticization and molding effect, material overheating, large motor power consumption, etc., to improve extrusion efficiency and final product High quality, strong material conveying ability and ideal homogenization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

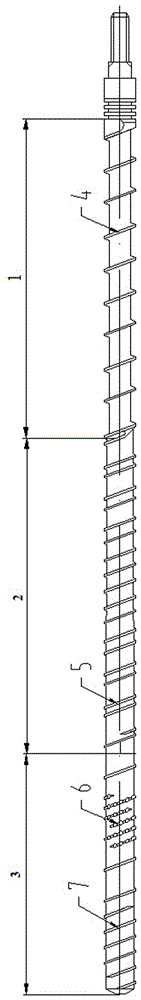

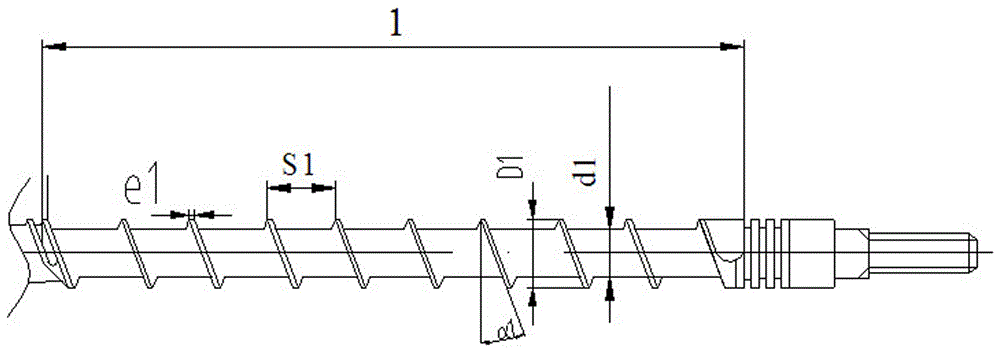

[0016] Such as figure 1 , 2 , 3, 4 It can be seen that in this embodiment, the special screw for the single-screw plastic extruder includes feeding section 1——length is 1065mm, melting section 2——length is 3740mm, metering section 3——length is 1145mm , the main thread 4 is set on the whole process of the screw, and the feeding section 1 is equidistant and equal in depth, that is, the screw root diameter d of the feeding section 1 1 , main thread top diameter D 1 constant, in this embodiment, the screw root diameter d of feeding section 1 1 106mm, main thread top diameter D 1 is 125mm. The lead angle α1 of the main thread 4 of the feeding section 1 is 21°, and the flight width e1 of the feeding section 1 is 15mm.

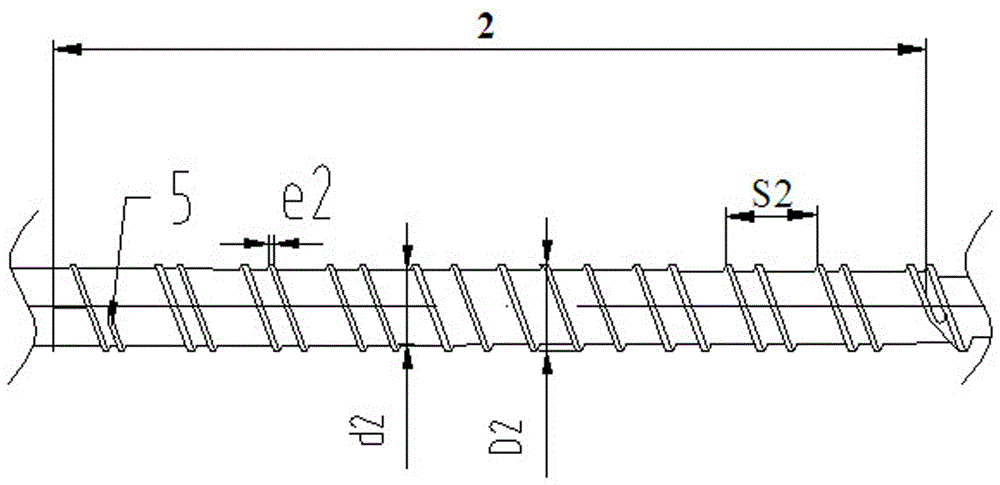

[0017] The root diameter of the screw increases to d at the beginning of the melting section 2 2 , in this example, d 2 =125mm, the top diameter of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com