Set milling integrated sand bailing device and application method thereof

A technology of sleeve milling and outer sleeve, which is applied in earth-moving drilling, wellbore/well components, etc., can solve the problems of serious sand sticking in the well, affecting the production cycle, etc., and achieve the effect of high transportation efficiency and strong transportation capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

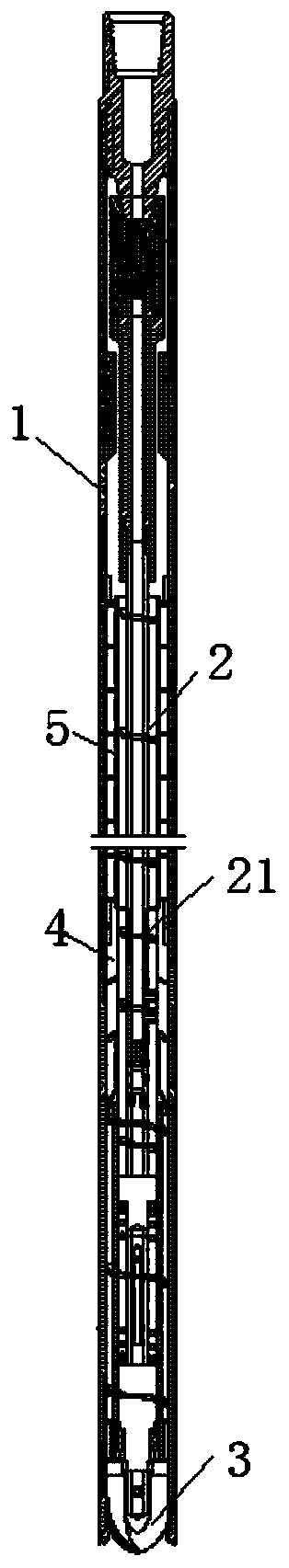

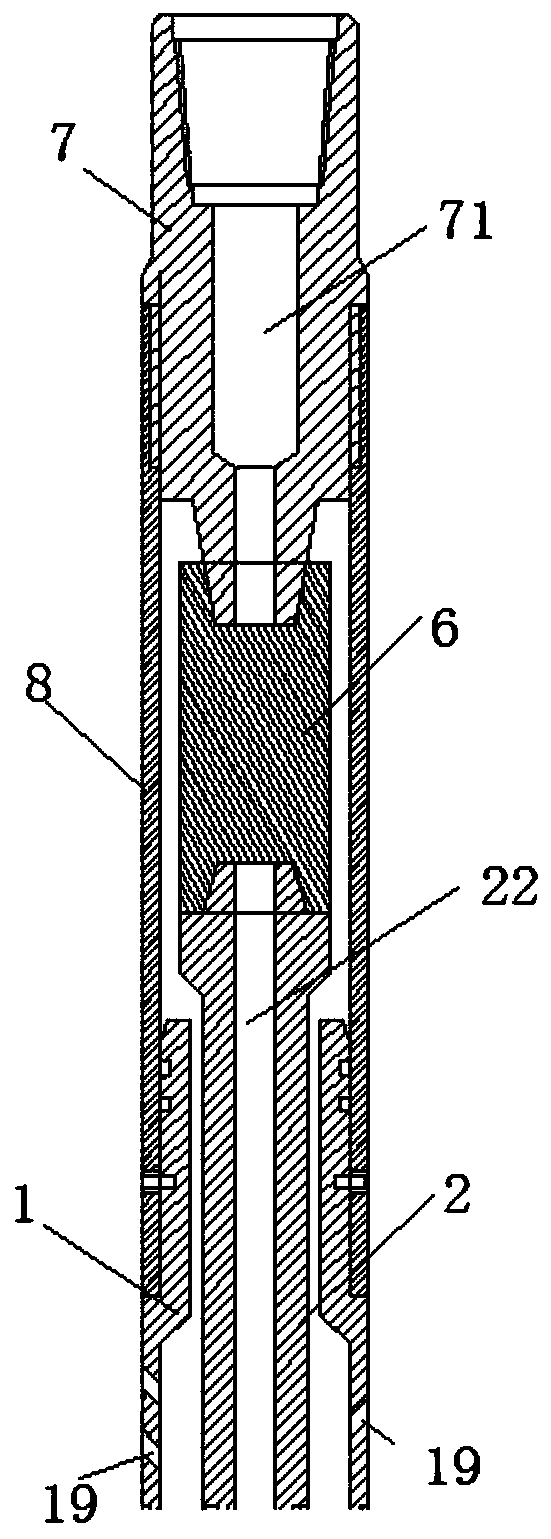

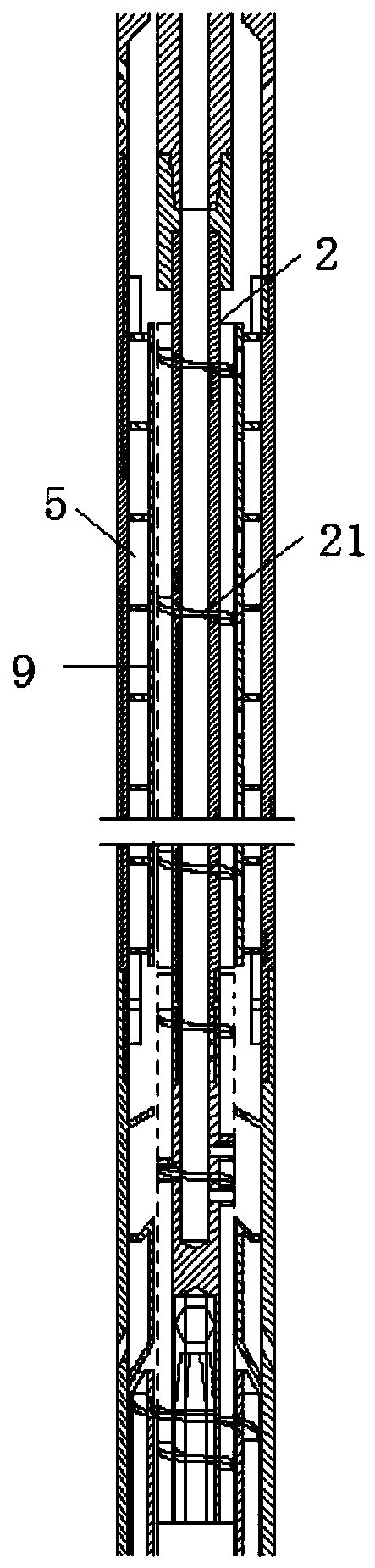

[0020] as attached Figure 1~6 The shown casing-milling integrated sand fishing device and its usage method: it includes an outer sleeve 1 and a central rotating shaft 2, the central rotating shaft 2 is sleeved in the outer sleeve 1, and the top end of the central rotating shaft 2 A screw motor 6 is arranged at the position, and a mud channel 22 is arranged at the middle part of the central rotating shaft 2, and the outlet of the screw motor 6 communicates with the mud channel 22; an upper joint 7 is arranged above the screw motor 6, and the upper A feed chamber 71 is provided in the joint 7, and the feed chamber 71 is communicated with the inlet of the screw motor 6; by pressing the mud liquid into it from the feed chamber of the upper joint, the mud liquid will press the hydraulic pressure at the screw motor. Converted into mechanical energy, so as to ensure the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com