Ore soil raw material storage used for bentonite production

A technology of bentonite and raw material storage, which is applied in the direction of mixed material pretreatment, screening, grille, etc., which can solve the problems of inability to filter out large particles, influence, and unfavorable homogenization effect of ore raw material storage, and achieve good homogenization effect , Improve work efficiency, improve the effect of homogenization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

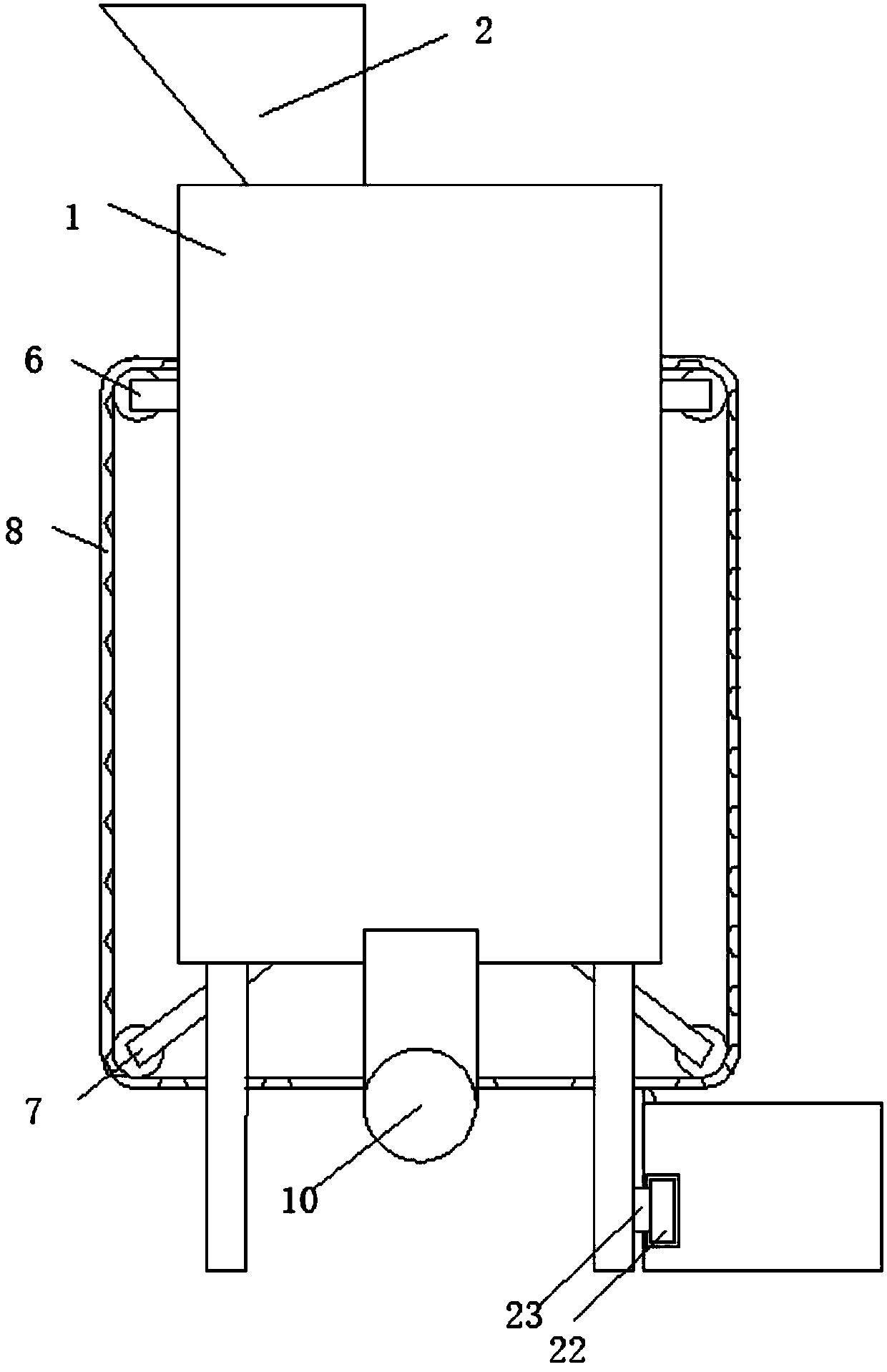

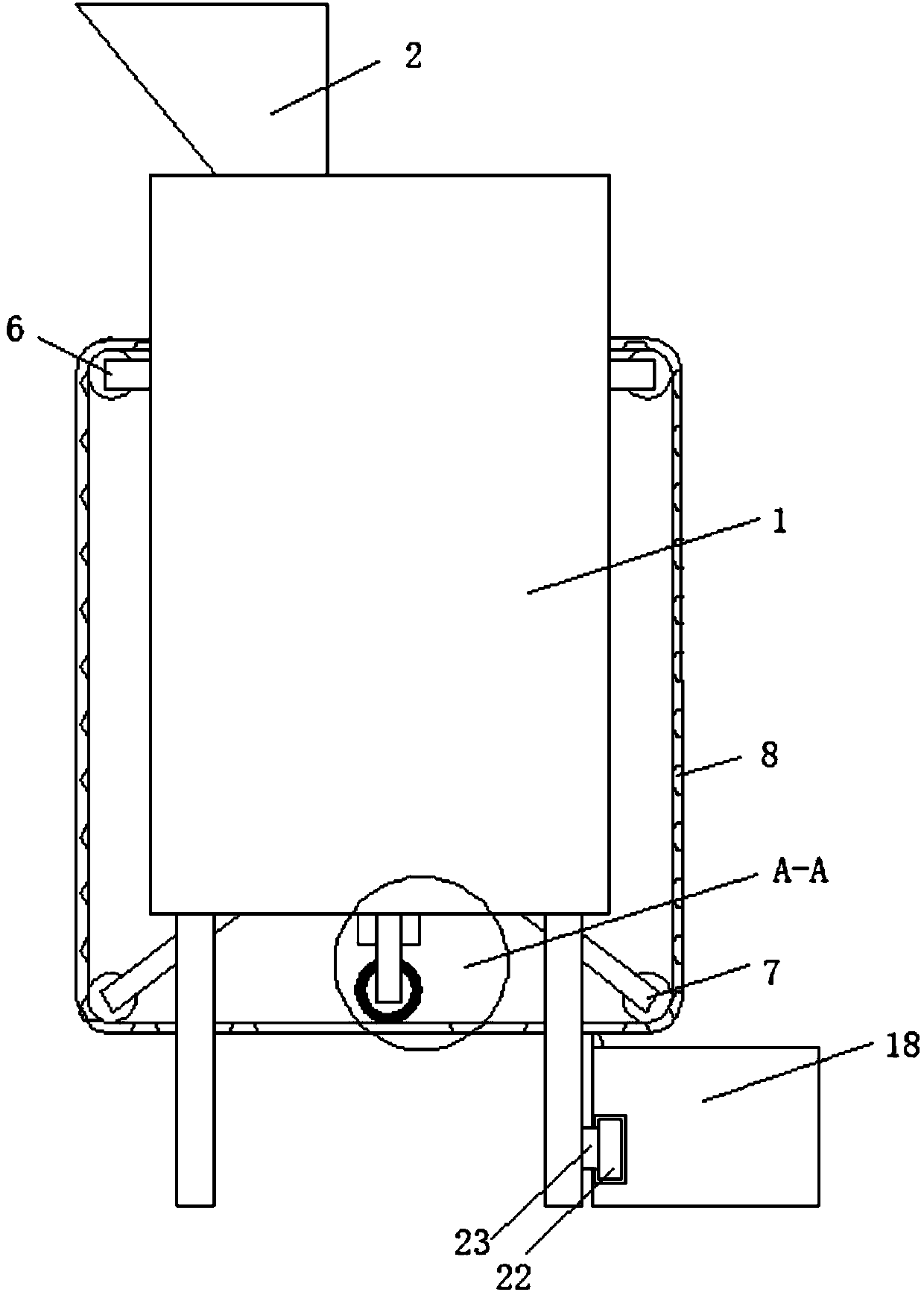

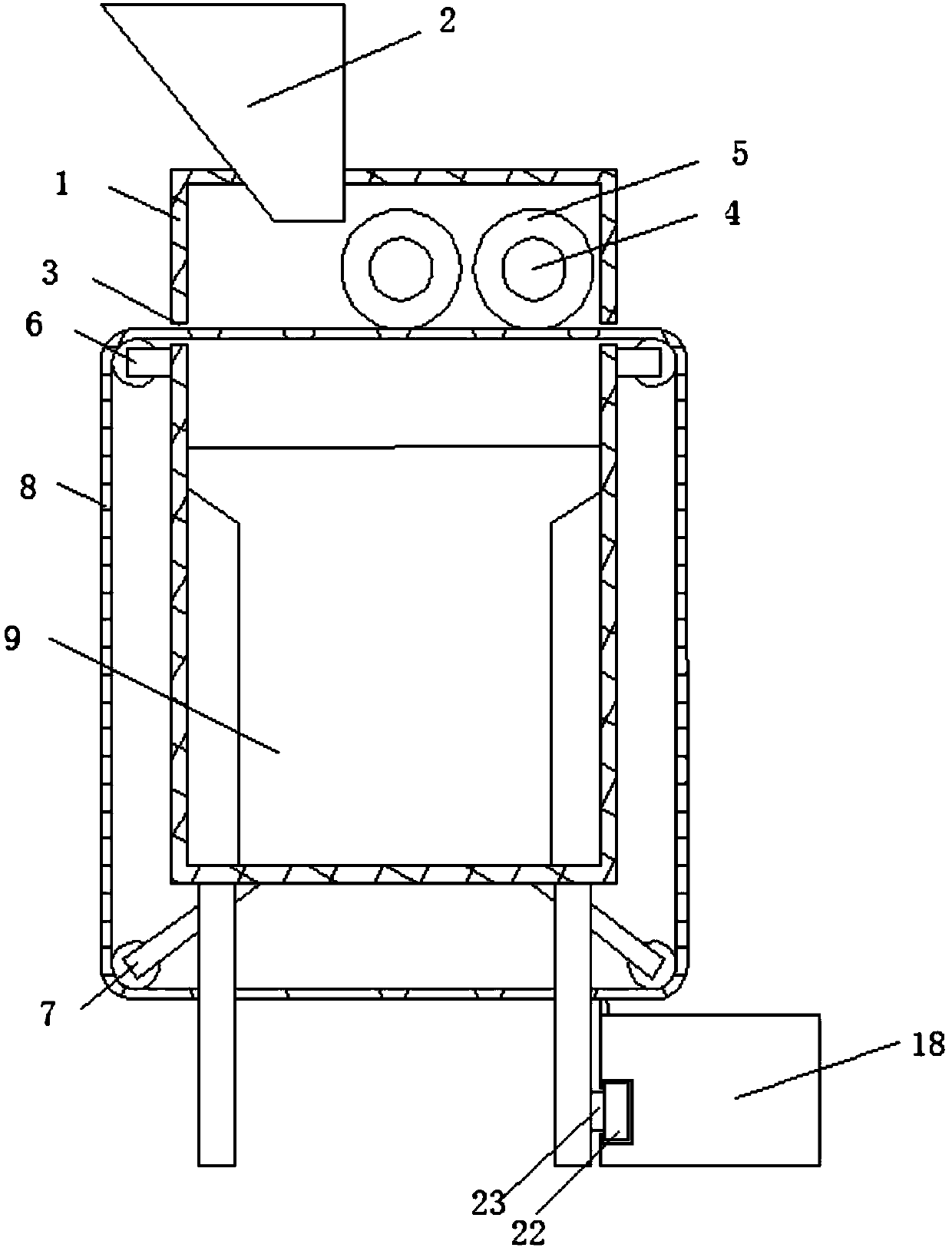

[0023] refer to Figure 1-5 , present embodiment proposes a kind of ore soil raw material storehouse that is used for bentonite production, comprises raw material storehouse 1, and the top side of raw material storehouse 1 is equipped with the feeding hopper 2 that is connected with raw material storehouse 1, two sides of raw material storehouse 1 A through hole 3 is symmetrically opened on the side inner wall, and a plurality of electric shafts 4 located above the through hole 3 are installed inside the raw material bin 1 along a horizontal straight line. And the outer side of each electric rotating shaft 4 is provided with a rubber sleeve 5, and both sides of the raw material bin 1 are rotatably installed with a first roller 6 located below the through hole 3, and the bottom of the raw material bin 1 is rotatably installed with two symmetrical rollers. The second turning roller 7 provided, two second turning rollers 7 and two first turning rollers 6 are connected with the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com