Patents

Literature

139results about How to "Fully solid solution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low cost yield strength 700MPA level non-tempering processing high strength steel plate and manufacturing method thereof

ActiveCN101768698AImprove plasticityImprove toughnessTemperature control deviceManufacturing convertersSteel platesSheet steel

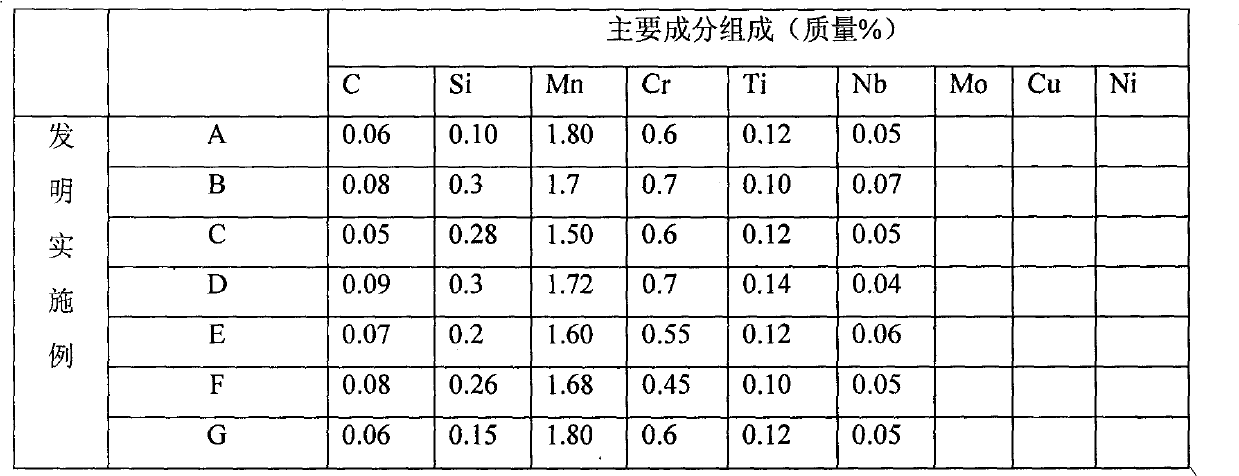

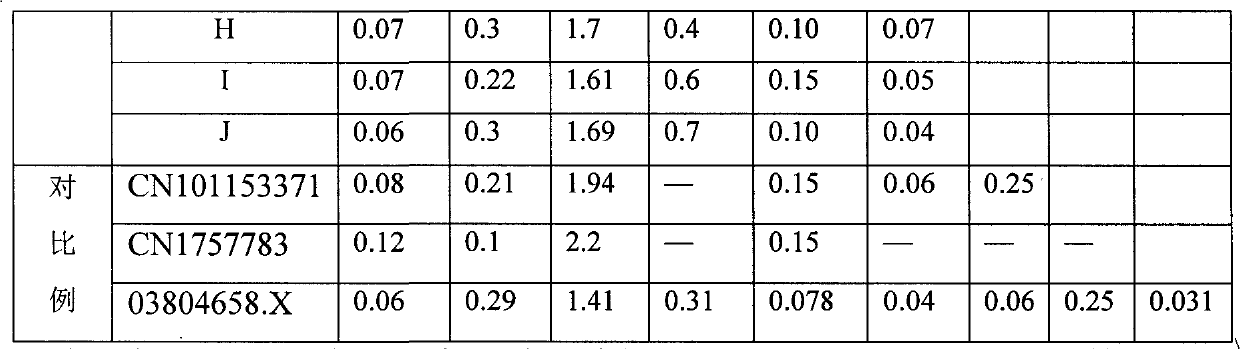

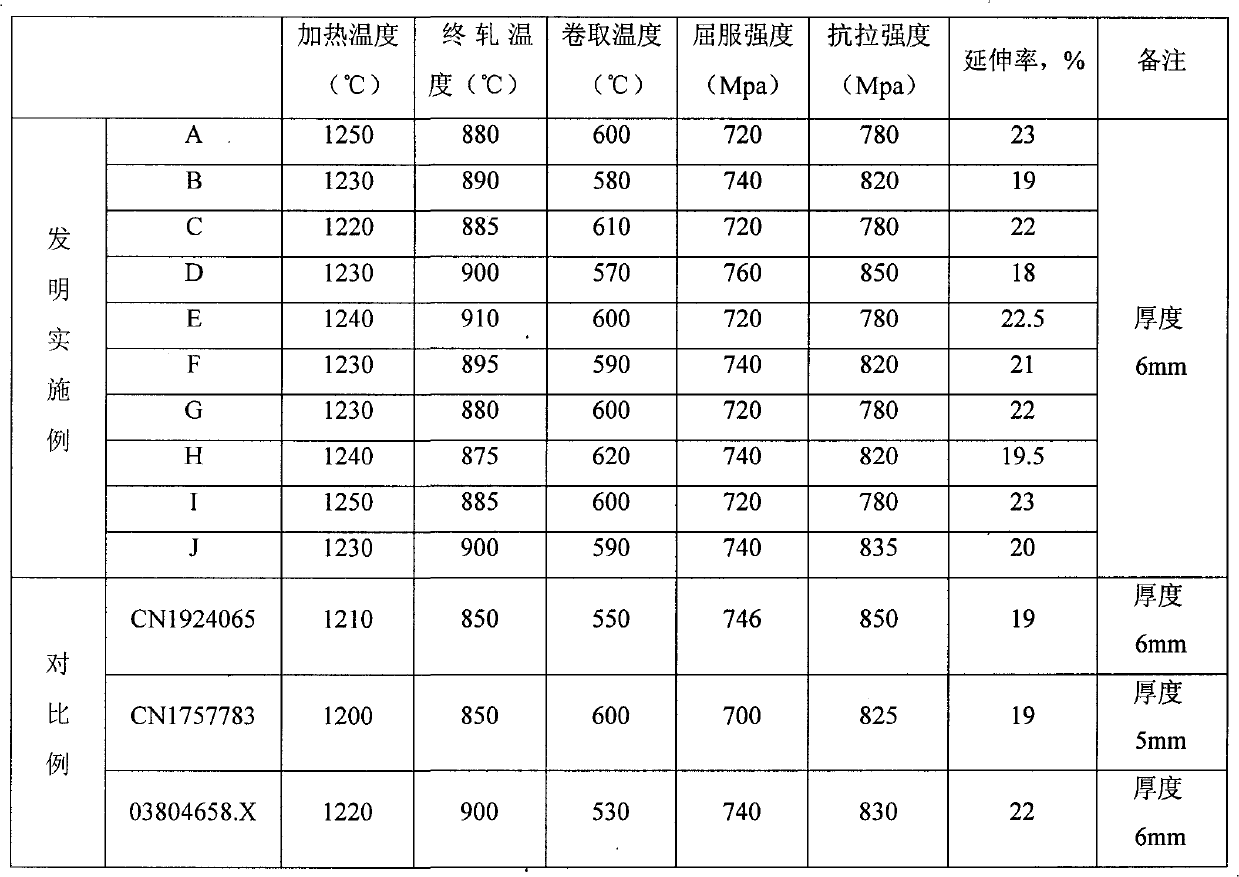

The invention discloses a low cost yield strength 700MPA level non-tempering processing high strength steel plate, which is characterized by, in terms of mass, comprising 0.05-0.10% of C, 0.1-0.4% of Si, 1.5-2.0% of Mn, less than 0.015% of P, less than 0.01% of S, 0.3-0.8% of Cr, 0.09-0.15% of Ti, 0.04-0.08% of Nb, less than 0.005% of N, less than 0.002% of O, and balance of Fe and unavoidable impurities. The manufacturing method of the steel plate comprises technological steps of smelting, rough rolling, fine rolling, reeling and cooling to obtain the steel plate with yield strength of 700-780MPa, tensile strength of 800-860MPa and elongation Delta larger than or equal to 18%. The yield strength 700MPA level non-tempering processing high strength steel plate simultaneously has abrasive resistance and better low temperature toughness, toughness and crispiness transition temperature is at around negative 40 DEG C, specific energy of shock at normal temperature can reach as high as 120J.

Owner:SHANDONG IRON & STEEL CO LTD

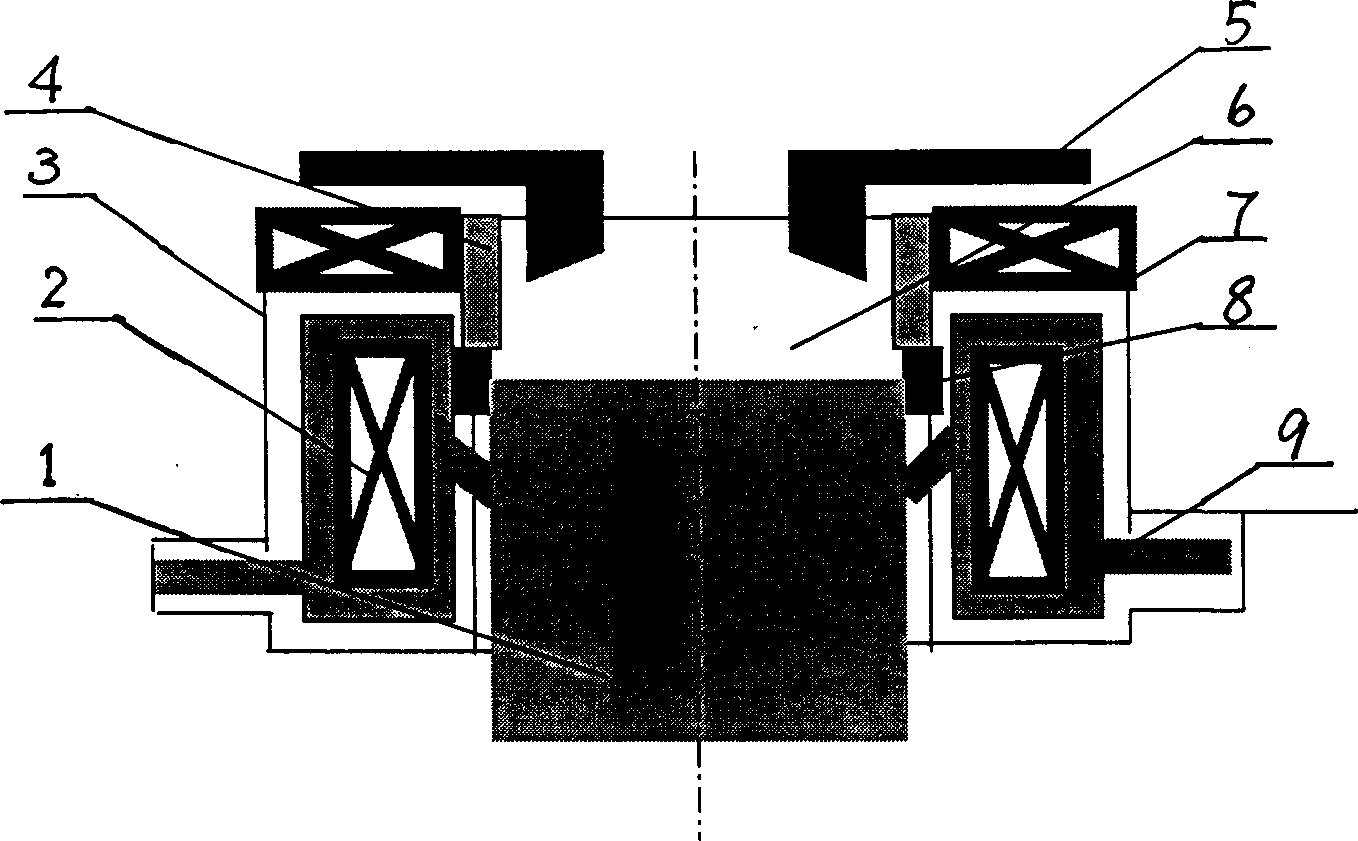

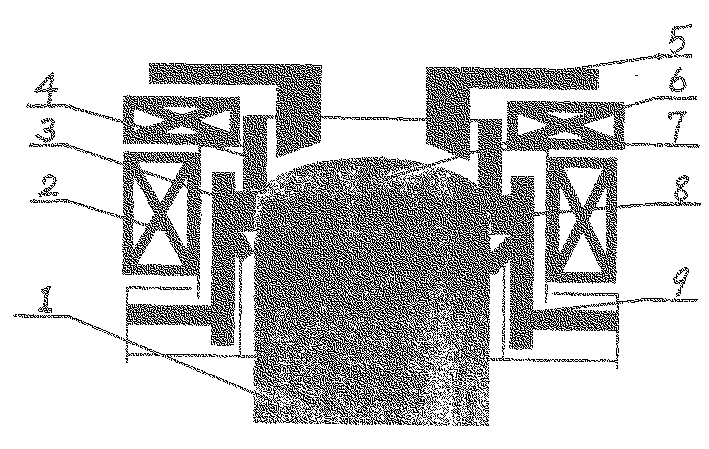

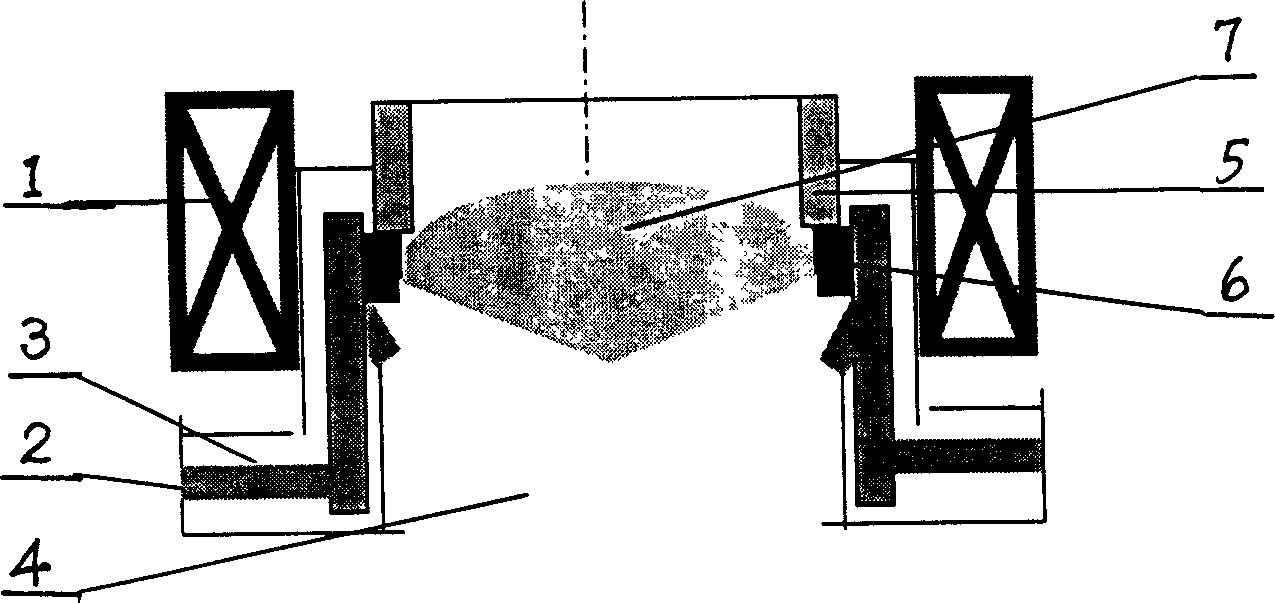

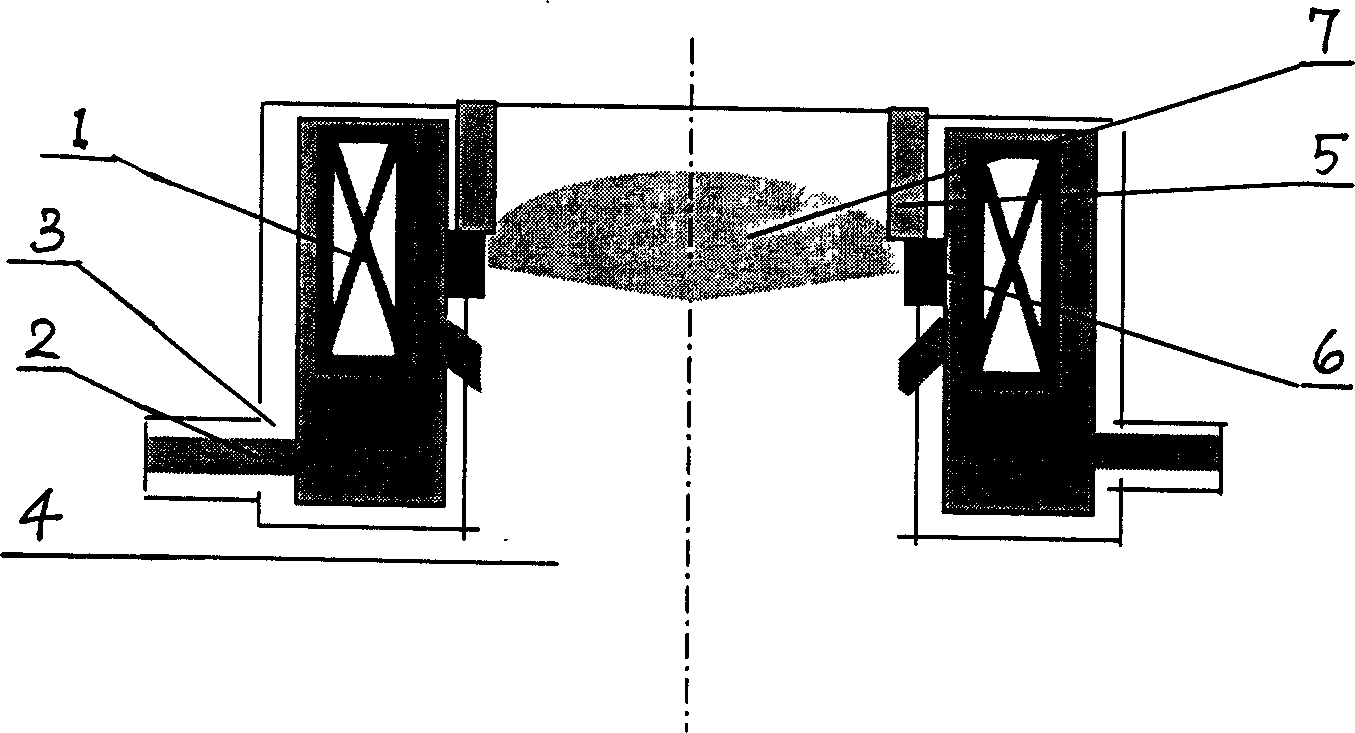

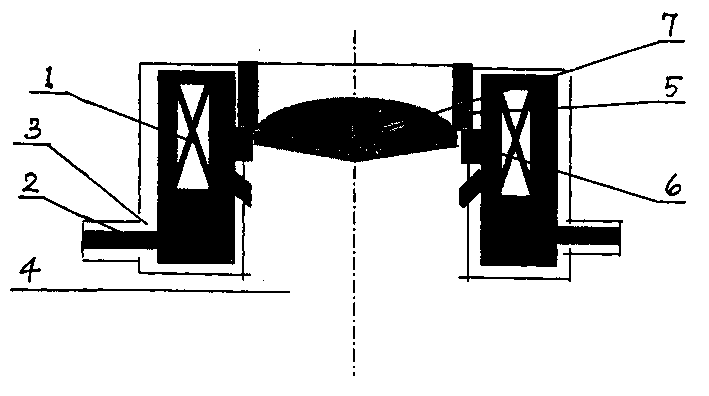

Aluminium alloy low frequency electromagnetic oscillation semicontinuous casting crystal grain fining method and device

The present invention belongs to the field of material processing technology. The equipment includes one crystallizer, one coil over the crystallizer with DC current passing through, one magnet over the DC coil to introduce the DC magnetic field into the melt in the upper part of the crystallizer, one coil outside the crystallizer with low-frequency current passing through. It has low-frequency electromagnetic field frequency of 15-30 Hz, DC magnetic field strength of 0.01-0.06 T, and AC magnetic field strength in the margin inside the crystallizer of 0.01-0.06 T. The semi-continuous low-frequency aluminium alloy casting process has casting temperature 680-750 deg.c, casting speed 50-150 mm / min and cooling water pressure 0.06-0.12 MPa. The present invention has fined cast ingot structure, isometric crystal grains, low cost internal stress, improved surface quality and hgh ingot quality.

Owner:NORTHEASTERN UNIV

Alumium alloy low frequency electromagnetic semi-continuous casting method and device

The present invention belongs to the field of material processing technology. The equipment includes one crystallizer, one coil outside or inside the crystallizer with low-frequency current passing through. The semi-continuous aluminium alloy casting process in low-frequency electromagnetic field has electromagnetic field frequency of 15-50 Hz, casting temperature 680-750 deg.c, casting speed 50-150 mm / min and cooling water pressure 0.06-0.12 MPa. The present invention has fined crystal grains, full solid dissolving of alloy elements inside the crystal, no crack, no segregate, improved surface quality and high ingot quality.

Owner:NORTHEASTERN UNIV

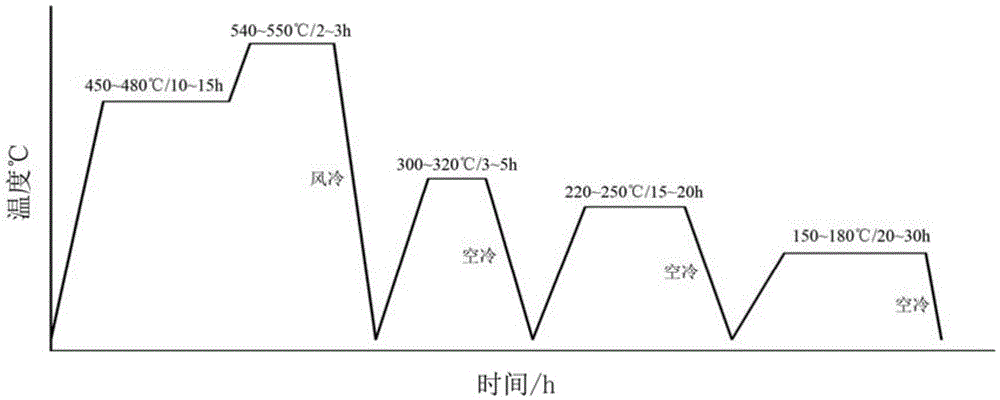

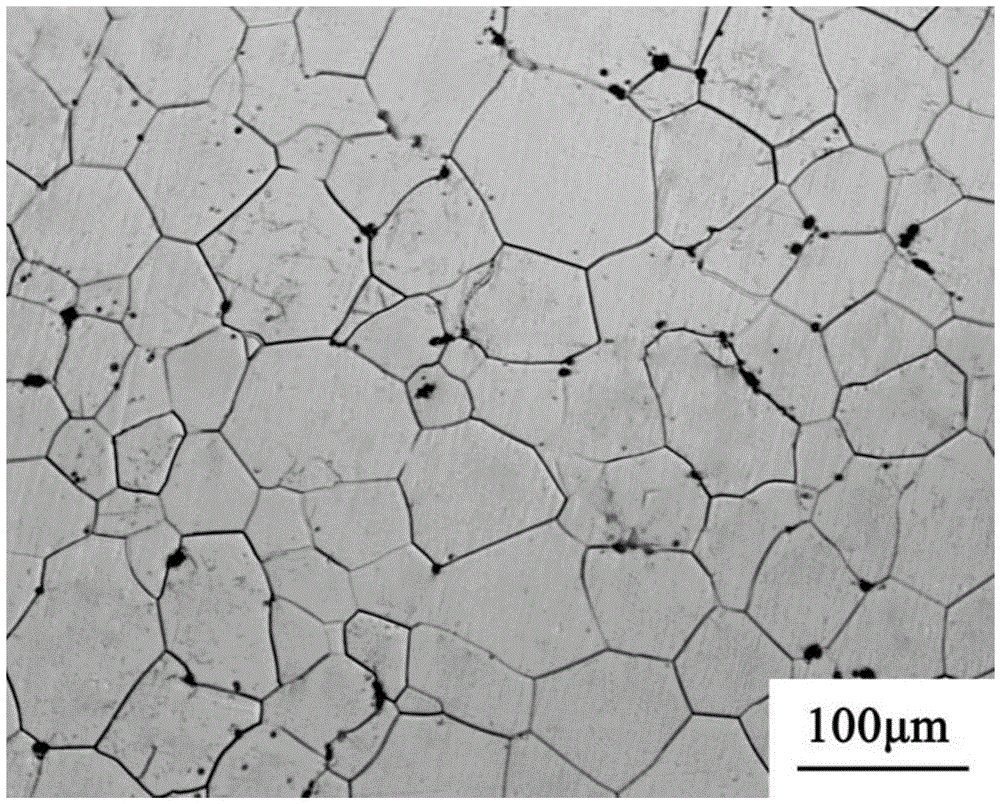

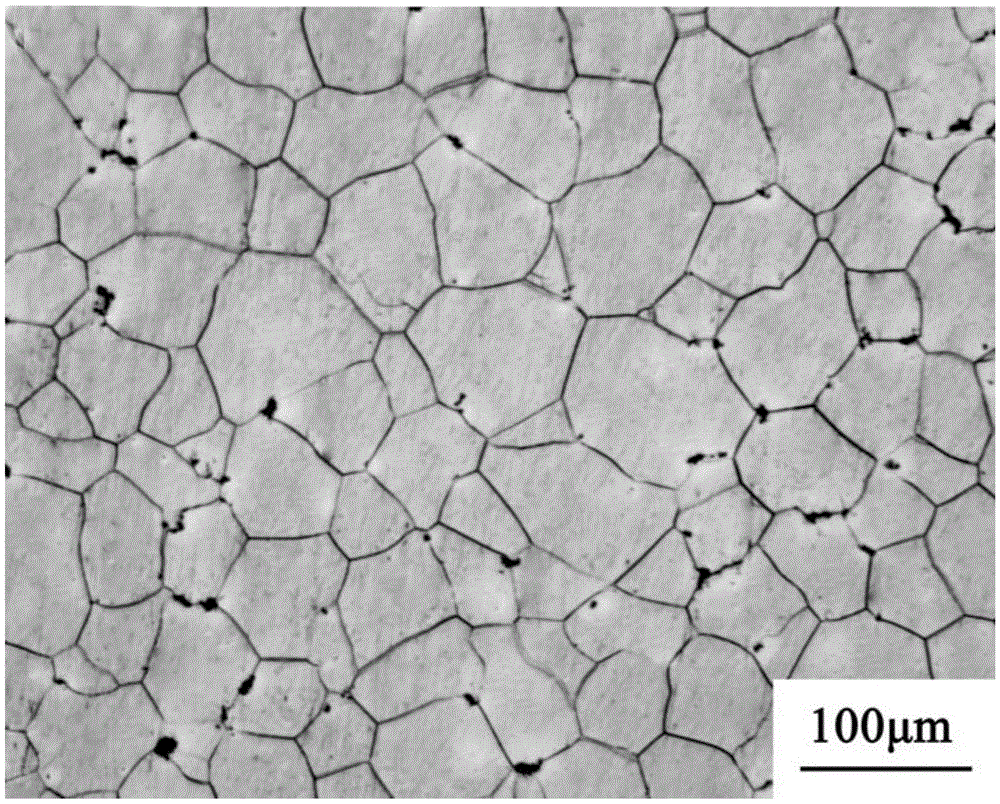

Heat treatment technology for improving mechanical properties of rare earth magnesium alloy castings

A heat treatment technology for improving mechanical properties of rare earth magnesium alloy castings is a heat treatment method which is used for carrying out staged solution and staged aging on Mg-Y-Nd magnesium alloy castings. Solution and aging are regarded as a whole body, namely, after being heated and subjected to primary solution and secondary solution sequentially, the castings are subjected to tertiary artificial aging sequentially, solution temperature, insulating time, aging temperature and insulating time are controlled, in a process of aging precipitation of strengthening phases containing Nd, a Y element is in a solution state, in a process of aging precipitation of a compound containing Y, a compound containing Nd cannot grow, the number of the strengthening phases subjected to aging precipitation is large, the strengthening phases are tiny, growth of crystal grains in a solution process is also avoided, and the mechanical properties of the alloys are improved. The heat treatment technology is simple, existing heat treatment equipment is not required to be modified, the mechanical properties of the obtained alloys are greater than those of alloys treated by a conventional method by at least 10%, industrial production is easy to implement, and a simple and efficient effective way is provided for improving the mechanical properties of the large-size rare earth magnesium alloy castings.

Owner:CENT SOUTH UNIV

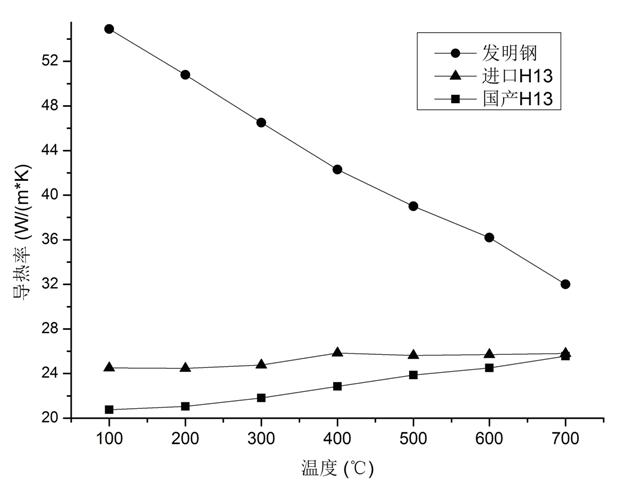

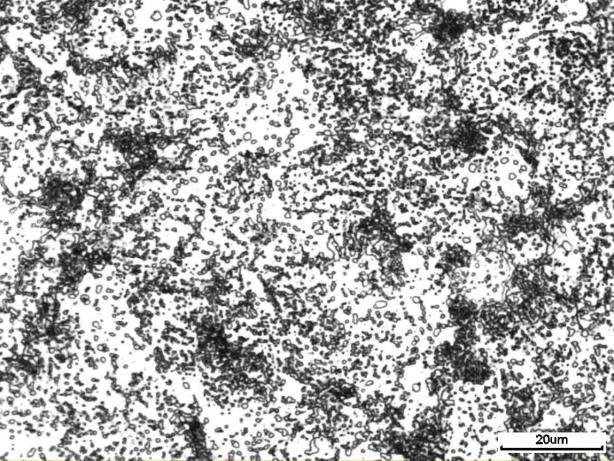

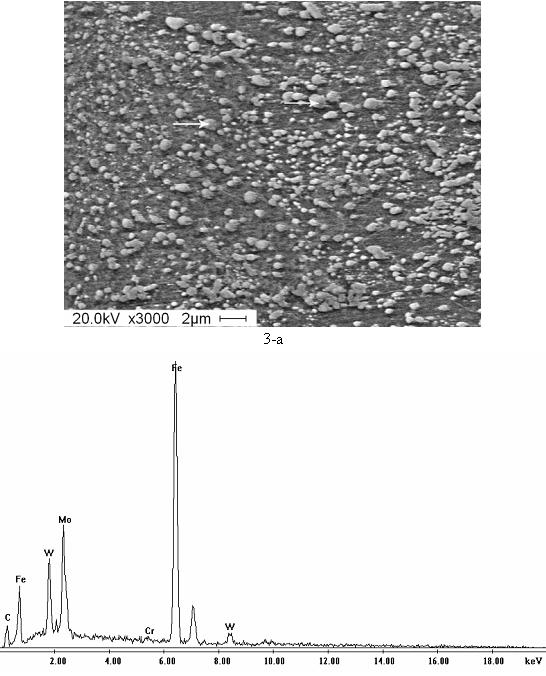

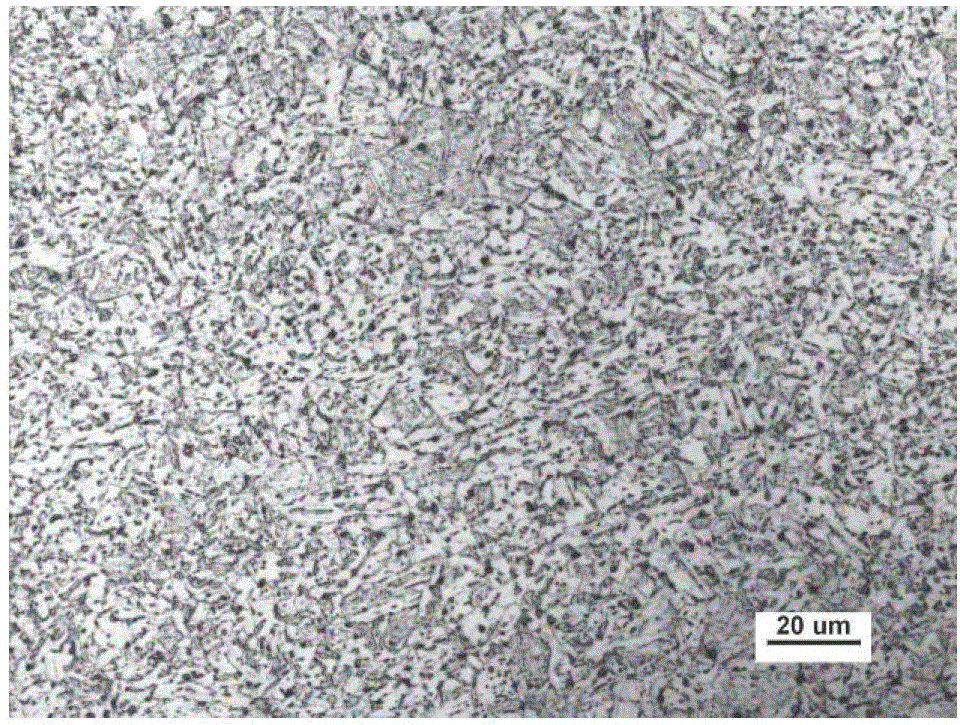

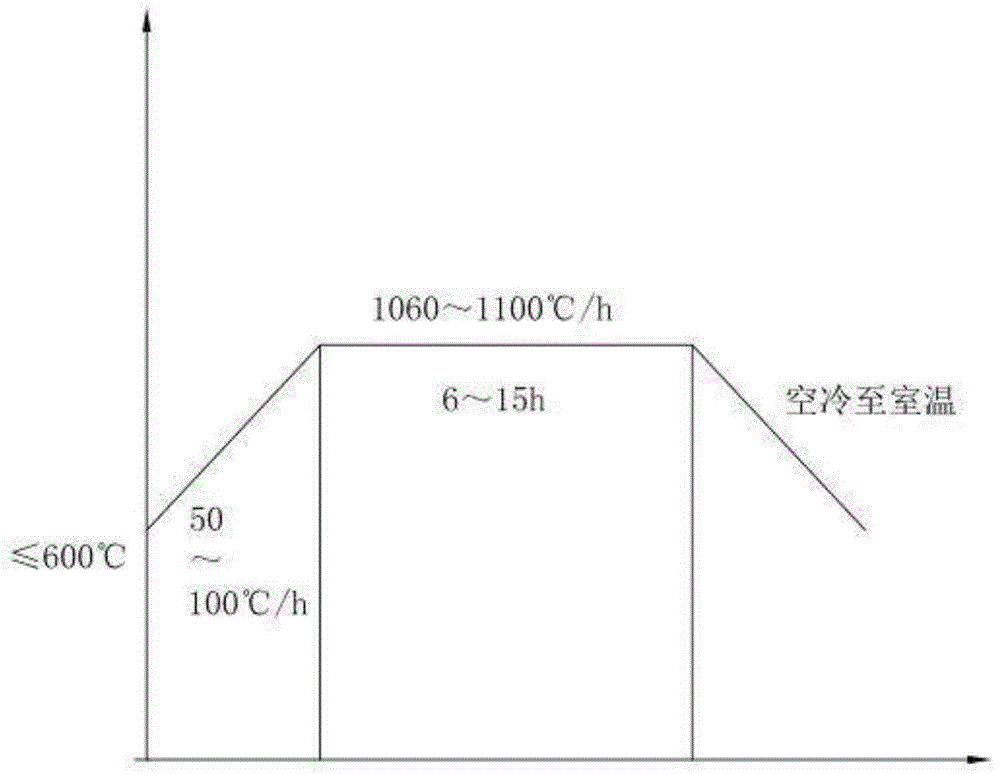

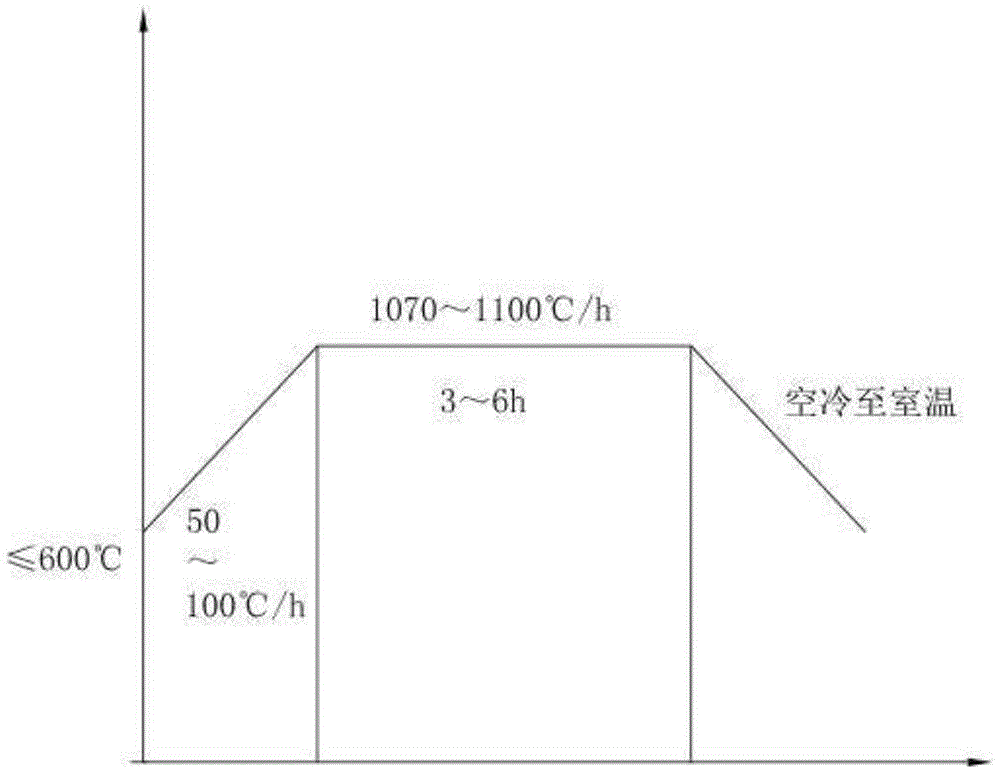

Steel with ultra-high thermal conductivity for hot-stamping die and preparation method of steel

The invention relates to a novel material with ultra-high thermal conductivity for a hot-stamping die. The steels in the market for the hot-stamping die are mainly various types of improved H13 and H11 high-alloy hot work die steels. The steel in the invention comprises the following compositions in percentage by mass: 0.150-0.35% of C, less than or equal to 0.25% of Si, 0.08-0.20% of Mn,1.0-2.0% of W,2.0-4.5% of Mo, less than or equal to 0.30% of Cr,less than or equal to 0.02% of V and the balance of Fe and inevitable impurity elements, wherein S in the impurity elements is less than or equal to 0.005%, P in the impurity elements is less than or equal to 0.01 and O in the impurity elements is less than or equal to 30 ppm (parts per million). The invention is characterized in that simple elements i.e. C, Mo and W are used as the main elements, and proper proportion of carbide is adopted; the contents of Mn and Cr are maintained low, and the content of Si is maintained ultra-low; the steel has superior machining property after being subjected to electro-smelting, electro-slag remelting, annealing, high-temperature homogenization, forging and annealing; through thermal treatment (1060-1100 DEG C quenching and high-temperature annealing), the toughness of the steel can reach the toughness of common hot-stamping die steel such as H13, and the hardness, annealing stability and the fatigue property of the steel are more superior; particularly, the steel with lower coefficient of thermal expansion and ultra-high thermal conductivity is more suitable for hot stamping.

Owner:SHANGHAI UNIV

Economic-type pipe fitting steel with high strength and low yield ratio and production method thereof

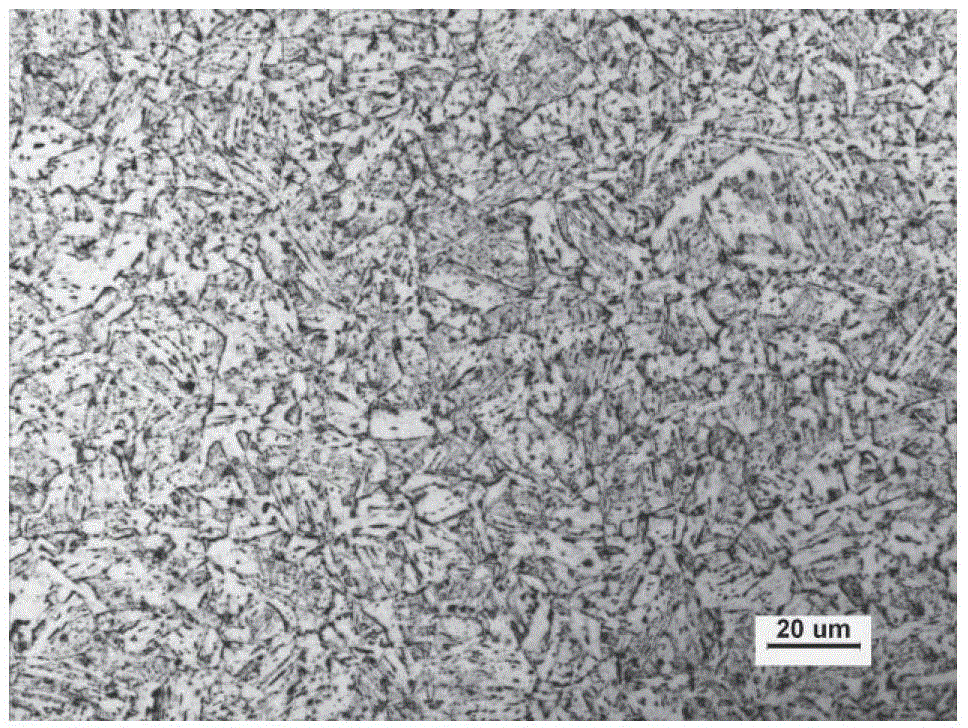

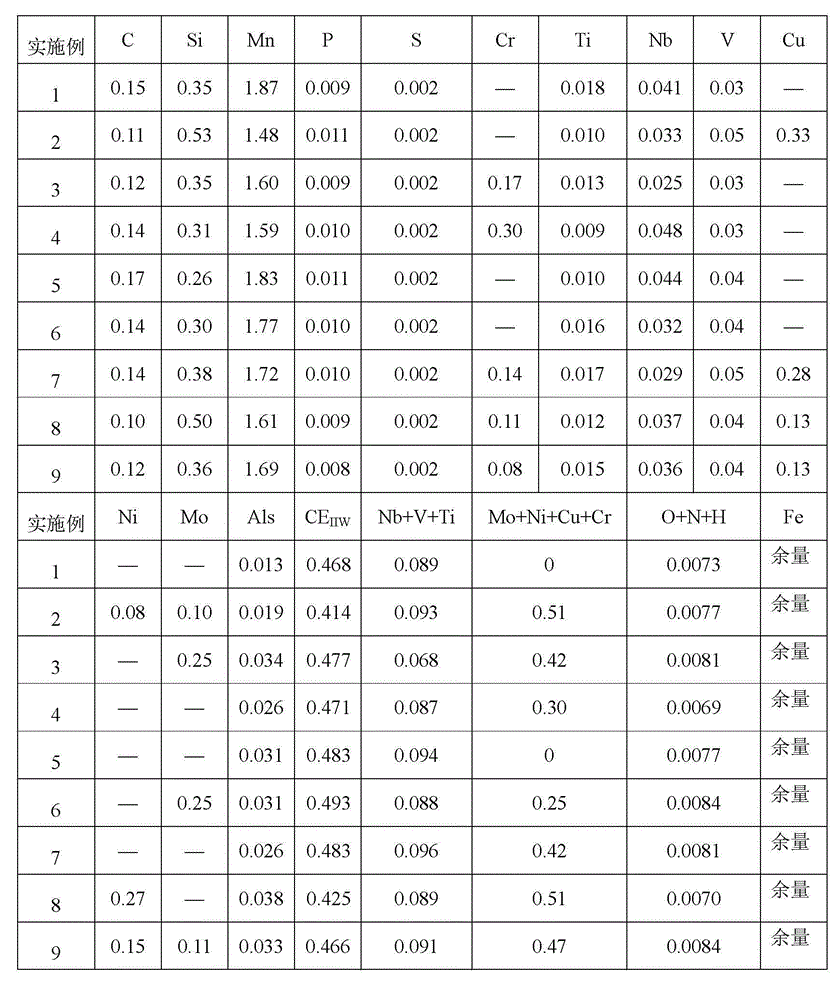

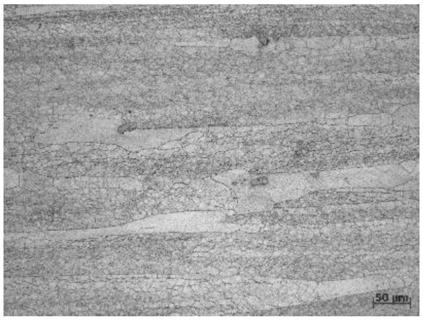

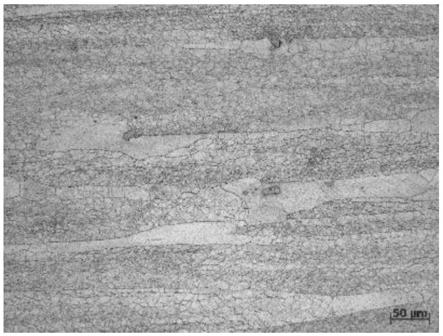

The invention discloses an economic-type pipe fitting steel with high strength and low yield ratio, which comprises the following elements: 0.10%-0.18% of C, 0.25%-0.55% of Si, 1.40%-1.90% of Mn, 0.02%-0.05% of Nb, 0.008%-0.020% of Ti, 0.02%-0.05% of V, 0.010%-0.040% of Als, smaller than or equal to 0.10% of Nb, V and Ti, 0-0.25% of Mo, 0-0.30% of Ni, 0-0.35% of Cu, 0-0.30% of Cr, smaller than or equal to 0.55% of Mo, Ni, Cu and Cr, and the balance of ferrum and unavoidable impurities. The yield strength after heat treatment can reach more than 630MPa or 690MPa, the tensile strength reaches more than 775MPa or 870MPa, the yield ratio is lower than 0.85, the impact ductility at minus 46 DEG C is not lower than 80J, and the technical requirements for X90 level and X100 level pipe fitting steel are completely satisfied.

Owner:ANGANG STEEL CO LTD

Machining method for 7-series aluminum alloy thick plates

The invention belongs to the technical field of aluminum alloy production, and relates to a machining method for 7-series aluminum alloy thick plates. Aluminum alloy ingots comprise the following components in percentage by mass: Si not more than 0.20%, Fe not more than 0.25%, 1.2-2.1% of Cu, 1.2-2.2% of Mg, 5.0-7.0% of Zn, 0.02-0.15% of Ti, 0.02-0.15% of Zr, Ti+Zr not more than 0.15%, single impurity not more than 0.05%, total impurity not more than 0.15%, and the balance of Al. The machining method for the aluminum alloy thick plates adopts a mode of multi-pass hot rolling, and adopts double-stage solid solution and double-stage aging to enable the finally prepared 7-series aluminum alloy thick plates to achieve excellent strength and rupture toughness.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

High-strength austenitic stainless steel for automobile frames and manufacturing method thereof

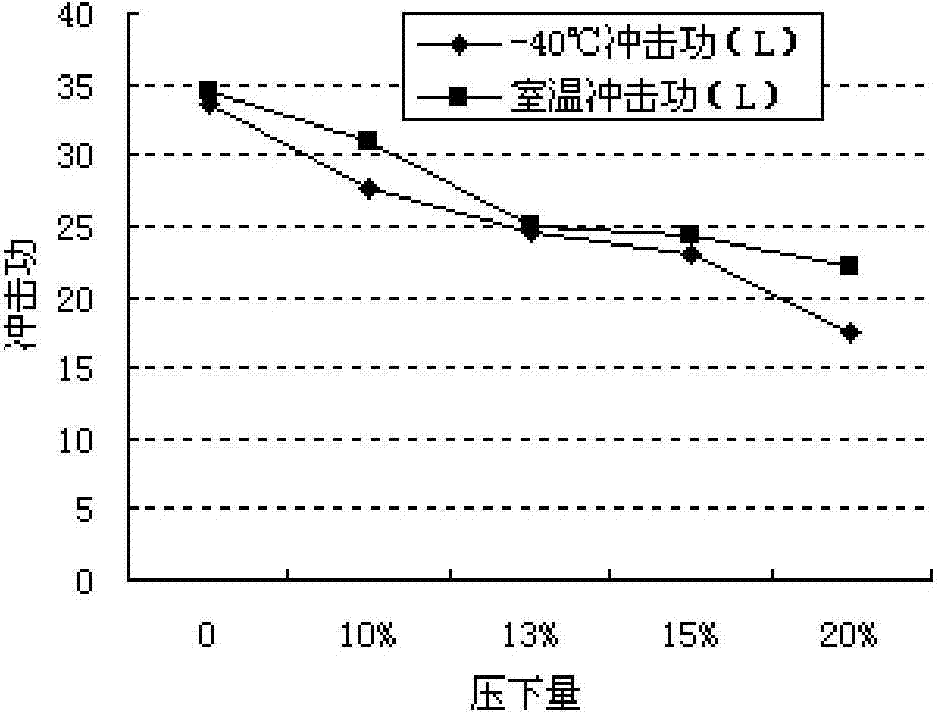

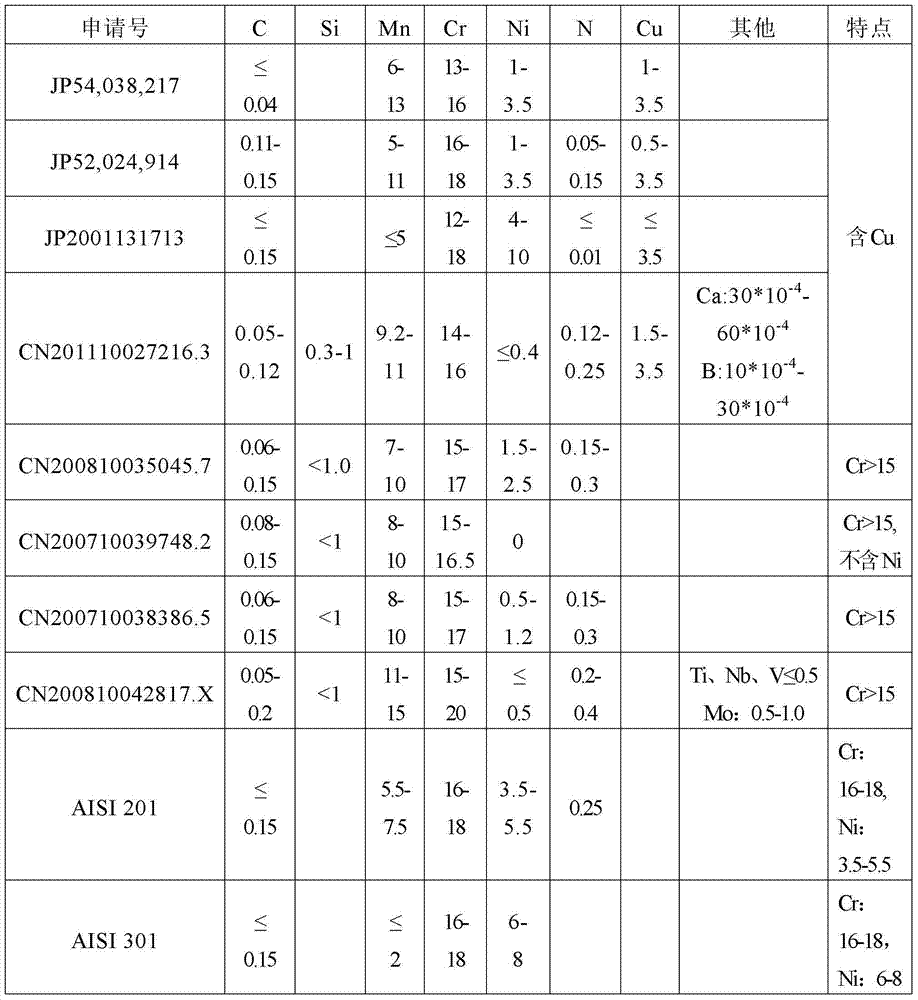

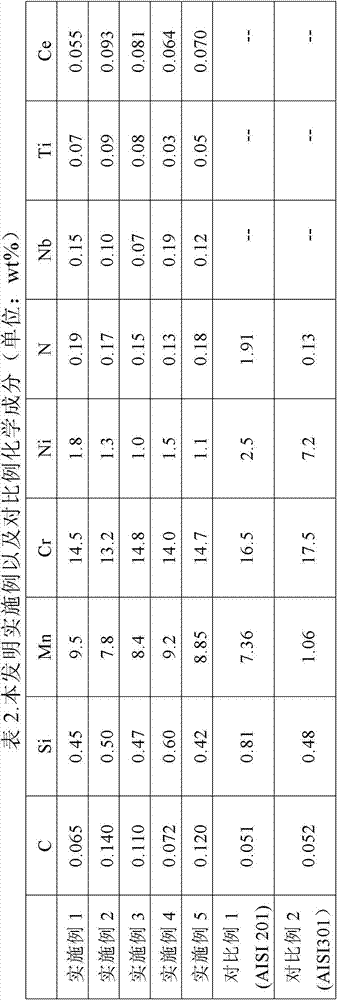

The invention relates to a high-strength austenitic stainless steel for automobile frames and a manufacturing method thereof. The austenitic stainless steel comprises the following chemical components in percentage by weight: 0.05-0.15% of C, 0.4-1% of Si, 7-10% of Mn, at most 0.03% of P, at most 0.01% of S, 13-15% of Cr, 1-2% of Ni, 0.1-0.2% of N, 0.05-0.2% of Nb, at most 0.1% of Ti, 0.05-0.1% of Ce, and the balance of Fe and inevitable impurities, wherein 0.1%<=Nb+Ti<=0.25%.In order to ensure the comprehensive mechanical properties to satisfy the requirements, the austenitic stainless steel manufacturing method adopts two different production techniques for producing high-strength stainless steel with different thicknesses. The yield strength of the finished austenitic stainless steel can reach 600 MPa above, the tensile strength is up to 1000 MPa above, and the elongation percentage is up to 28% above. The austenitic stainless steel is suitable for manufacturing automobile frames, anti-collision beams and other high-strength parts as well as other new-energy vehicle structural members.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

Aluminum alloy panel for aviation and production method of aluminum alloy panel

The invention provides an aluminum alloy panel for aviation and a production method of the aluminum alloy panel, relating to the production field of aluminum alloy panels. The production method comprises the steps of carrying out smelting, casting, dual-stage homogenization treatment, hot roll treatment and dual-stage solution treatment on aluminum alloy raw materials, and stretching, wherein the dual-stage homogenization treatment comprises the steps of heating an aluminum alloy cast ingot to 460-470 DEG C in a temperature increase rate of 10 DEG C / h-40 DEG C / h, maintaining the temperature for 20-25 hours, continuing to heat to 475-480 DEG C, maintaining the temperature for 6-8 hours and carrying out air cooling, and the aluminum alloy raw materials include the following raw materials in percentage by mass: 25%-35% of solid aluminum, 40%-50% of waste aluminum and 15%-35% of electrolyte. By virtue of the production method, the comprehensive performance of the produced aluminum alloy panel for the aviation is beneficially improved and is relatively uniform, and the strength is relatively high. Besides, the aluminum alloy panel produced by virtue of the production method is high in strength and durability, strong in damage tolerance and good in comprehensive performance.

Owner:SHANDONG NANSHAN ALUMINUM +1

Economical low-yield-ratio steel for pipe fittings for oil and gas transmission and method for producing economical low-yield-ratio steel

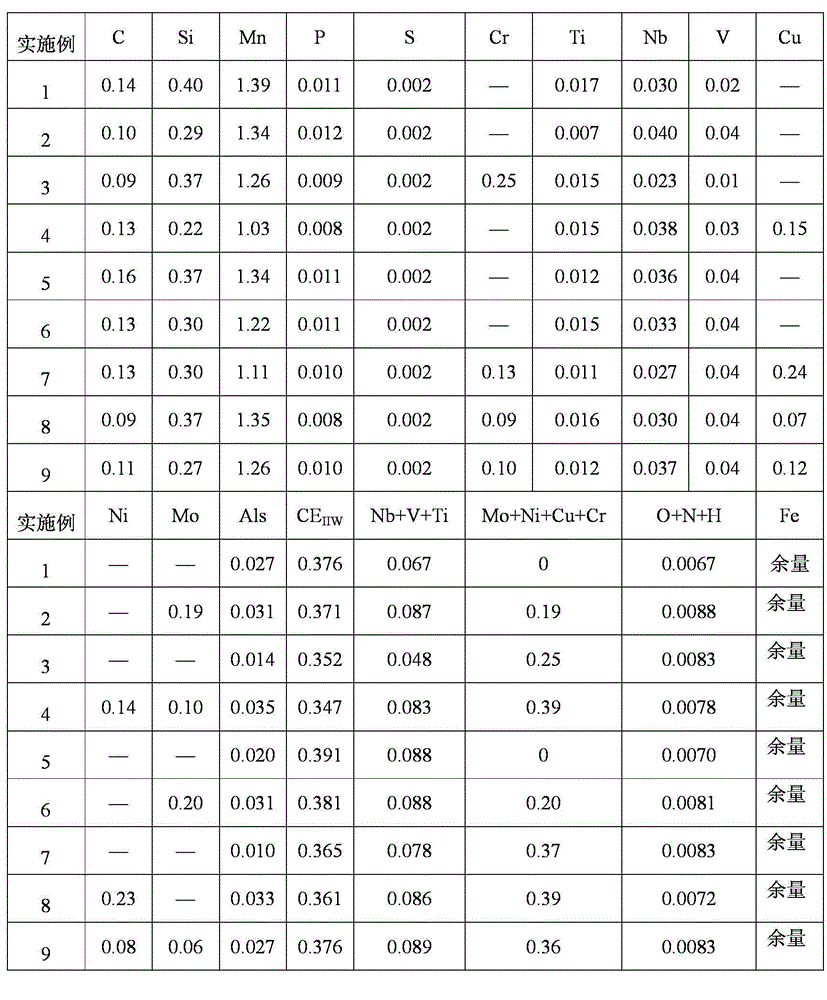

The invention discloses economical low-yield-ratio steel for pipe fittings for oil and gas transmission and a method for producing the economical low-yield-ratio steel. The economical low-yield-ratio steel comprises from 0.09% to 0.16% of C, from 0.20% to 0.40% of Si, from 1.00% to 1.39% of Mn, from 0.01% to 0.04% of Nb, from 0.005% to 0.018% of Ti, from 0.01% to 0.04% of V, from 0.008% to 0.035% of Als, from 0% to 0.20% of Mo, from 0% to 0.30% of Ni, from 0% to 0.30% of Cu, from 0% to 0.25% of Cr, the balance iron and inevitable impurities, wherein the total content of the Nb, the V and the Ti is lower than or equal to 0.09%, and the total content of the Mo, the Ni, the Cu and the Cr is lower than or equal to 0.40%. After the economical low-yield-ratio steel is subjected to heat treatment, the yield strength of the economical low-yield-ratio steel for the pipe fittings can be higher than 490MPa or 560MPa, the tensile strength of the economical low-yield-ratio steel can be higher than 670MPa or 720MPa, the yield ratio of the economical low-yield-ratio steel is lower than 0.80, the impact toughness of the economical low-yield-ratio steel at the temperature of minus 46 Celsius degrees is not lower than 80J, and technical requirements of X70-grade steel for pipe fittings and X80-grade steel for pipe fittings are met completely.

Owner:ANGANG STEEL CO LTD

Thick-gauge hot continuous rolling steel belt with excellent ultralow temperature CTOD (Crack Tip Opening Displacement) performance and production method of thick-gauge hot continuous rolling steel belt

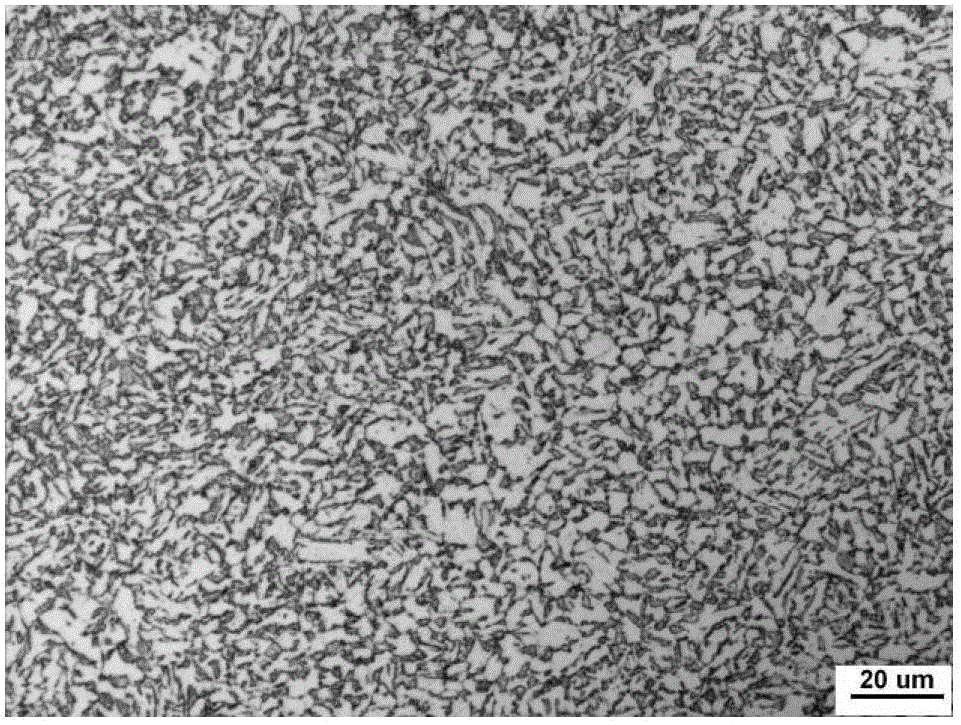

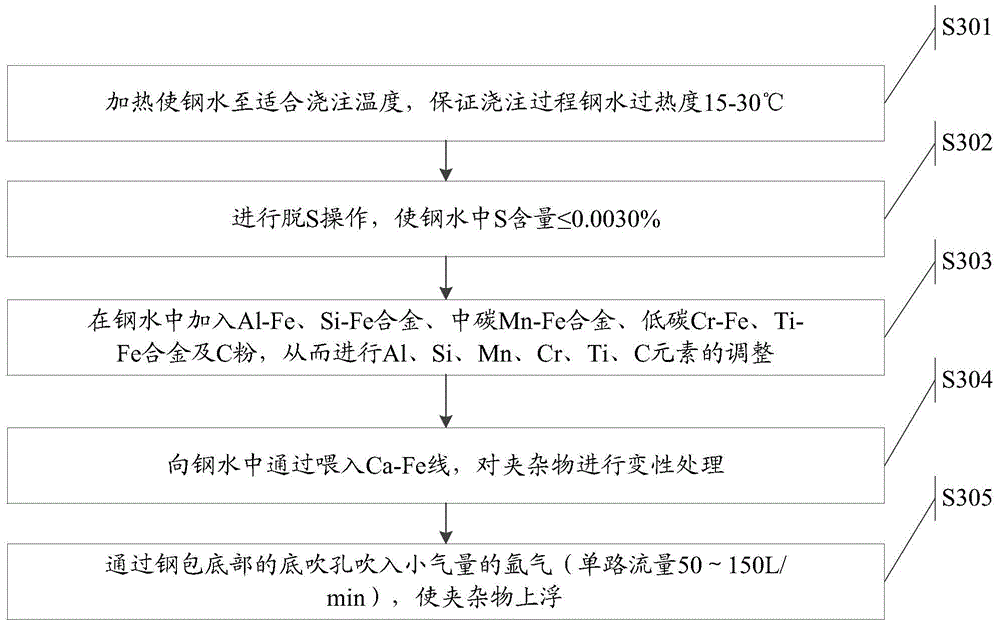

ActiveCN104561486AGuaranteed surface qualityImprove purityCrack tip opening displacementHeating furnace

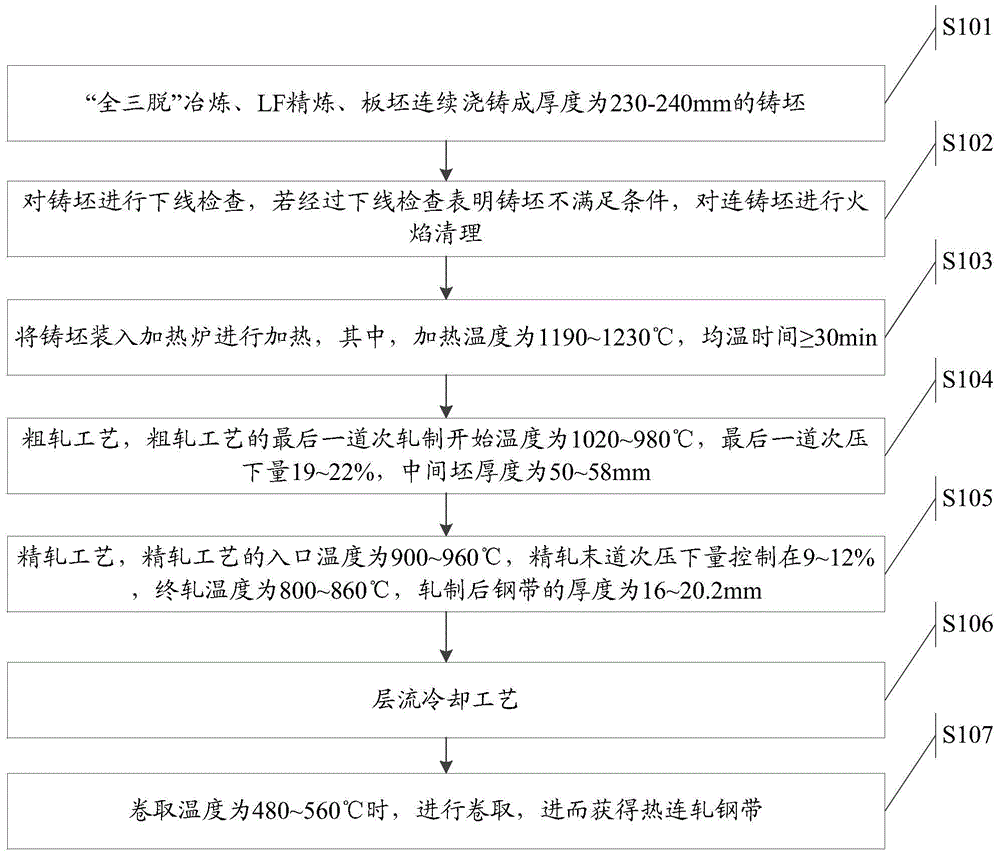

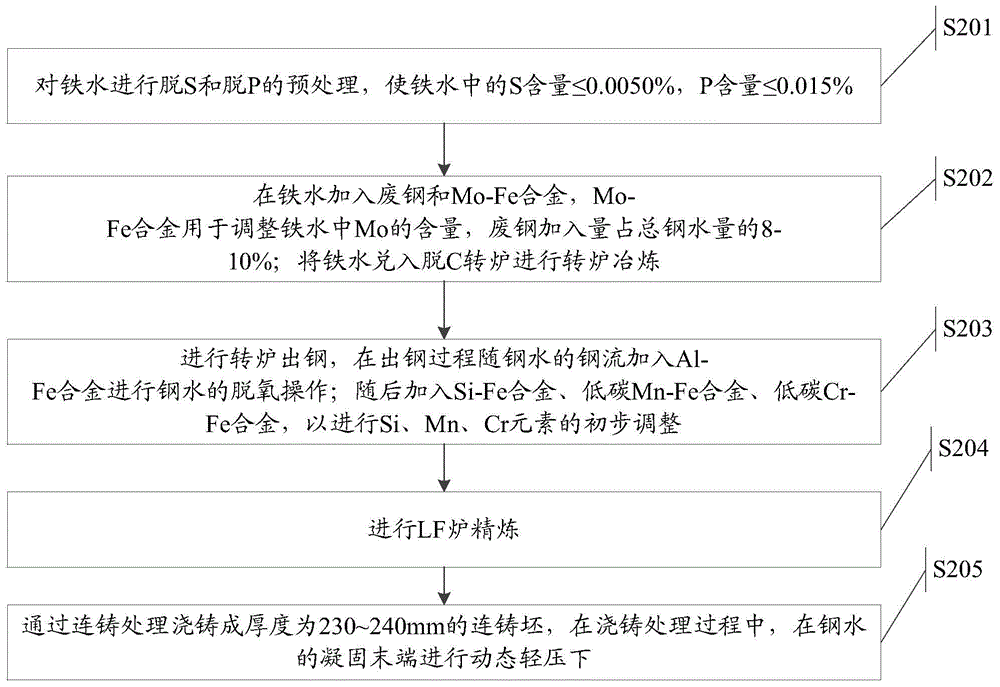

The invention relates to the technical field of hot continuous rolling steel belts for use in submarine oil / gas transmission pipelines and provides a thick-gauge hot continuous rolling steel belt with excellent ultralow temperature CTOD (Crack Tip Opening Displacement) performance and a production method of the thick-gauge hot continuous rolling steel belt. According to the thick-gauge hot continuous rolling steel belt and the production method, the technical problem of high technical difficulty in the production of the thick-gauge hot continuous rolling steel belt with the excellent ultralow temperature CTOD performance in the prior art is solved. The production method comprises the following steps: (1) continuously casting a plate blank into a casting blank with the thickness of 230mm-240mm by virtue of 'complete pretreatment' smelting and LF refining; (2) carrying out offline detection on the casting blank; (3) putting the casting blank in a heating furnace, and heating, wherein the heating temperature is 1190-1230 DEG C, and the temperature equalizing time is more than or equal to 30 minutes; (4) carrying out a rough rolling process; (5) carrying out a precision rolling process, wherein the thickness of the rolled steel belt is 16mm-20.2mm; (6) carrying out a laminar flow cooling process; and (7) reeling at the temperature of 480-560 DEG C. The production method can be used for producing the thick-gauge hot continuous rolling steel belt with the excellent ultralow temperature CTOD at relatively low difficulties.

Owner:SHOUGANG CORPORATION +1

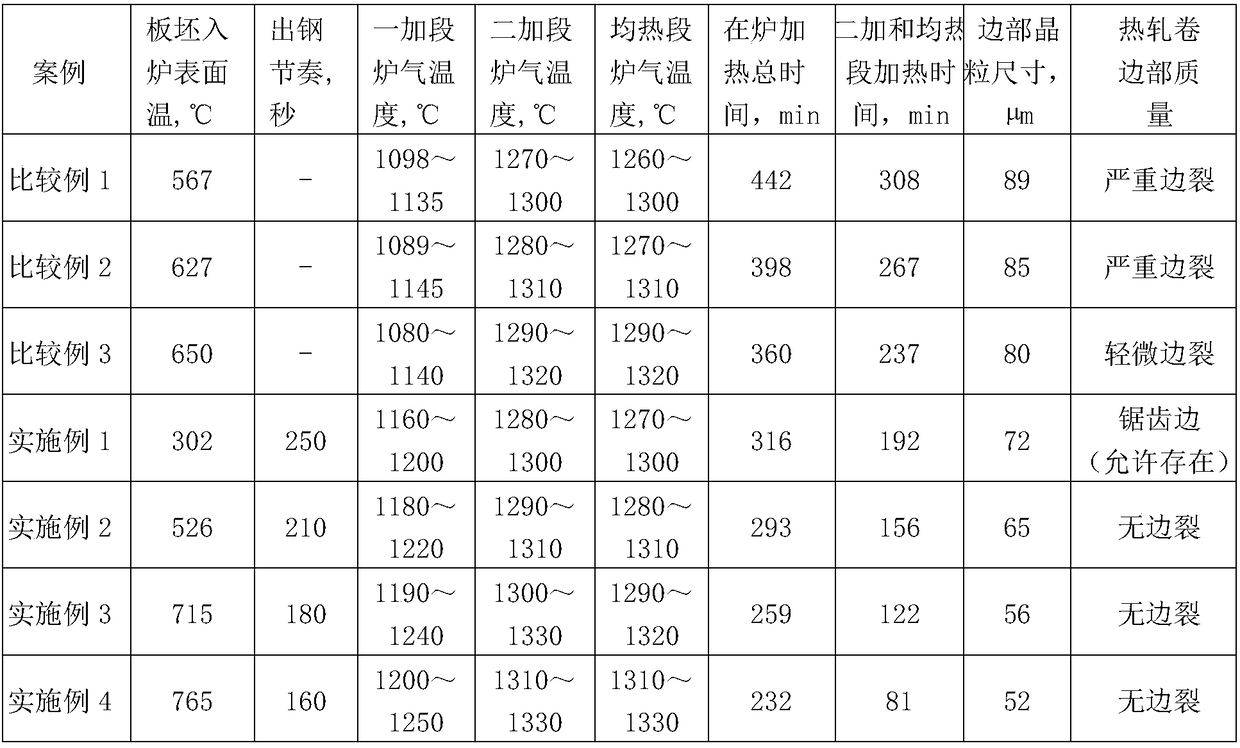

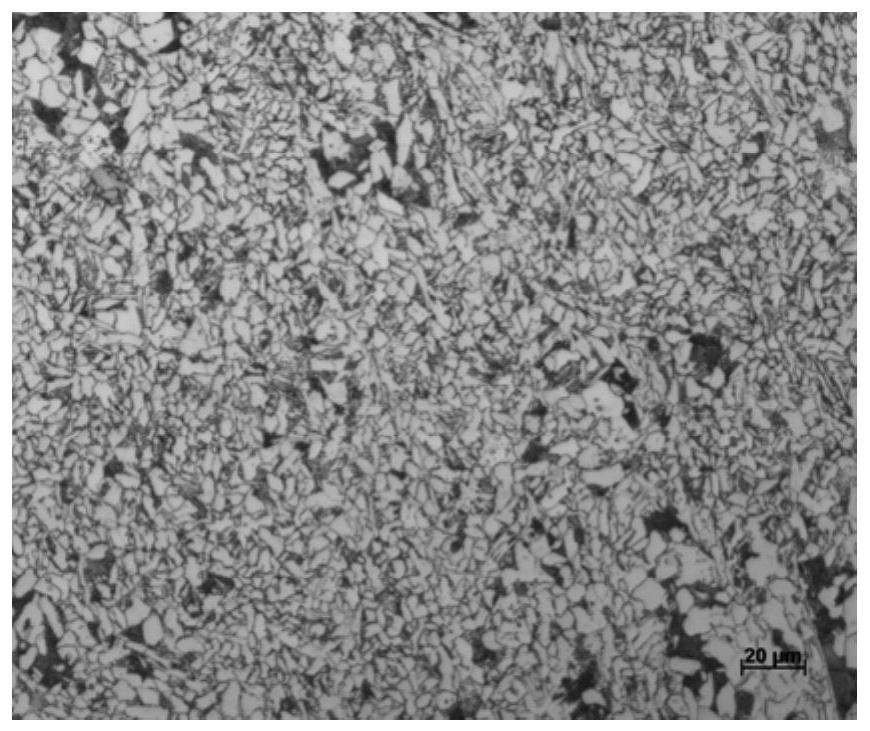

Process for preventing hot-rolling edge cracking of oriented silicon steel

ActiveCN108193037AFully solid solutionTemperature control deviceHeat treatment process controlHeating timeHeating furnace

The invention discloses a process for preventing hot-rolling edge cracking of oriented silicon steel. The process comprises the steps that the surface temperature of a plate blank is no smaller than 300 DEG C before the plate blank enters a heating furnace; the furnace gas temperature of a first heating section is 1160-1250 DEG C; the furnace gas temperatures of a second heating section and a soaking section are each 1270-1330 DEG C, the heating time is 80-200 minutes, and the standing time is no longer than 30 minutes; the average grain size of the edge of a hot-rolled finished product is nolarger than 72 [mu]m; the final rolling temperature of finish rolling is 880-960 DEG C; the coiling temperature is 500-620 DEG C; and tension of a seven-rack finish rolling unit is reasonably controlled. On the premises that sufficient solid solubility of an oriented silicon steel inhibitor is ensured and electromagnetic performance of the finished product meets the target requirement, the problems that the edge of the plate blank is decarburized or the plate blank is locally decarburized when the heating time of the second heating section and the soaking section is too long or when the standing time is too long, grains grow excessively, and edge cracking occurs in the hot-rolling process are avoided.

Owner:新余钢铁股份有限公司

Preparation method of composite ceramic powder material for high-temperature-resistant sintering thermal barrier coating

InactiveCN103304234AHigh phase structure stabilityStrong resistance to high temperature sinteringElectron beam physical vapor depositionChemical reaction

The invention discloses a preparation method of a composite ceramic powder material for a high-temperature-resistant sintering thermal barrier coating. The powder material is prepared by codoping ZrO2 in three rare earth oxides Y2O3, Yb2O3 and Gd2O3 in a chemical reaction method, and Y2O3, Yb2O3, Gd2O3 and ZrO2 are completely solidified and compounded. The composite ceramic power material subjected to ball milling, agglomeration and granulation and sintering can be used for preparing a thermal barrier coating through plasma spraying or can be compressed into a bar material to prepare a thermal barrier coating by electron beam physical vapor deposition. The thermal barrier coating is high-temperature sintering resistant, is stable in phase structure, is low in heat conductivity, can achieve the working temperature of 1450 DEG C, and can be used for high-temperature thermal-insulation protection of aircraft engines and hot end parts of ground surface combustion gas turbines.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

Steel bar for high-ductility and superhigh-strength pre-stressed concrete and machining method thereof

ActiveCN103484789AReduce intensityImproved resistance to hysteresis fractureUltra high pressurePre stress

The invention discloses a steel bar for high-ductility and superhigh-strength pre-stressed concrete and a machining method of the steel bar. The steel bar comprises, by weight, 0.3-0.5% of C, 0.3-1.8% of Si, 0.6-1.5% of Mn, 0.02-0.2% of Nb, 0.01-0.1% of V, 0.01-0.2% of Ni, 0.1-0.5% of Cr, 0.01-0.1% of Mo, 0.001-0.005% of B and the balance Fe, wherein the Ceq is smaller than 0.8%. Because an online continuous superhigh-pressure quenching control technology is adopted, the strength of the steel bar can be larger than 1860MPa or even larger than 2000MPa; because an online continuous quenching heat insulation and control technology is adopted, the ductility of the steel bar can be larger than 7%, the structural state of few ultra fine ferrites and tempered troostite is kept, and the steel bar has the advantages of being good in ductility and resistant to delayed fractures.

Owner:江苏森林建筑新材料股份有限公司

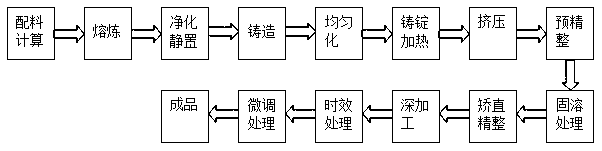

Aluminum alloy variable section extruded profile for spaceflight and preparation method of aluminum alloy variable section extruded profile

The invention discloses an aluminum alloy variable section extruded profile for spaceflight and a preparation method of the aluminum alloy variable section extruded profile. The profile consists of the following elements of, in percentage by weight, 5.0%-6.0% of Zn, 1.0%-2.0% of Cu, 0.04%-0.1% of Mn, 2.0%-3.0% of Mg, 0.15%-0.25% of Cr, 0.35%-0.42% of Fe, less than or equal to 0.25% of Si, and thebalance Al. During preparation, a finished product is obtained after being subjected to smelting, purifying, standing, casting, homogenizing treatment, ingot heating, extrusion, pre-finishing, solution treatment, straightening finishing, deep machining, aging treatment and fine adjustment treatment. According to the method, by setting specific alloy composition and the preparation process, the aluminum alloy variable section extruded profile formed by once is obtained, the strength, fatigue resistance, corrosion resistance and stress corrosion resistance of the aluminum alloy profile are greatly improved, comprehensive performance requirements of a carrier rocket launcher on the variable section aluminum alloy profile can be met, the bottleneck of extrusion forming of the variable sectionprofile at present is broken, various indexes of the aluminum alloy profile are ensured to meet standards and use requirements, and material guarantee is provided for research of new carrier rockets in China.

Owner:西北铝业有限责任公司

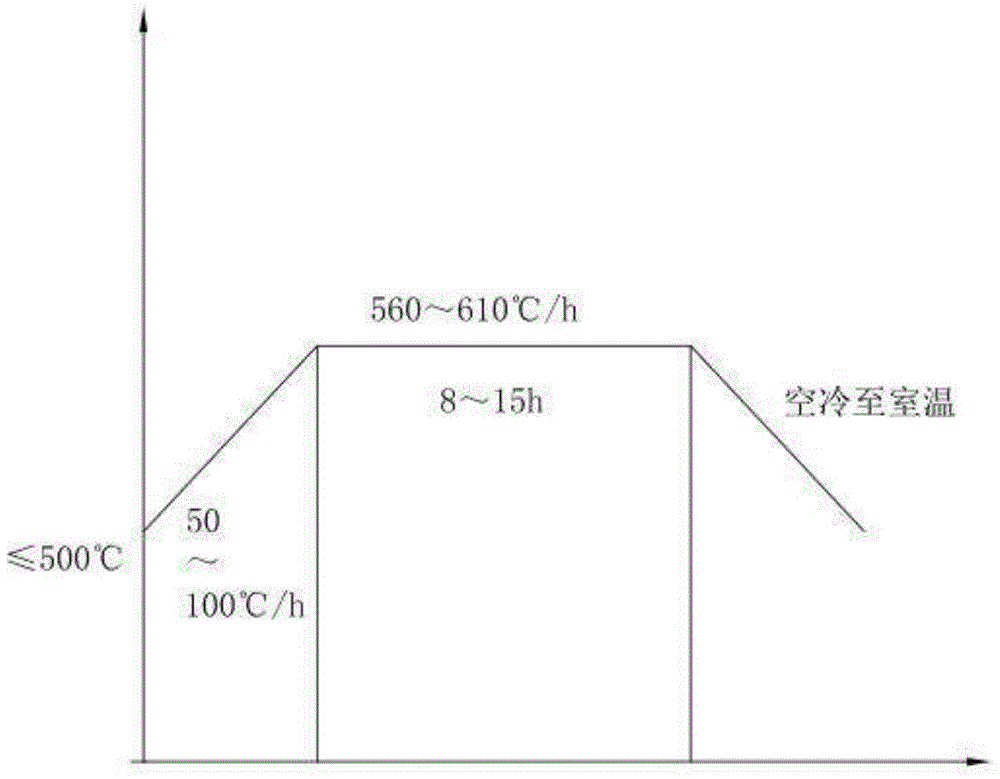

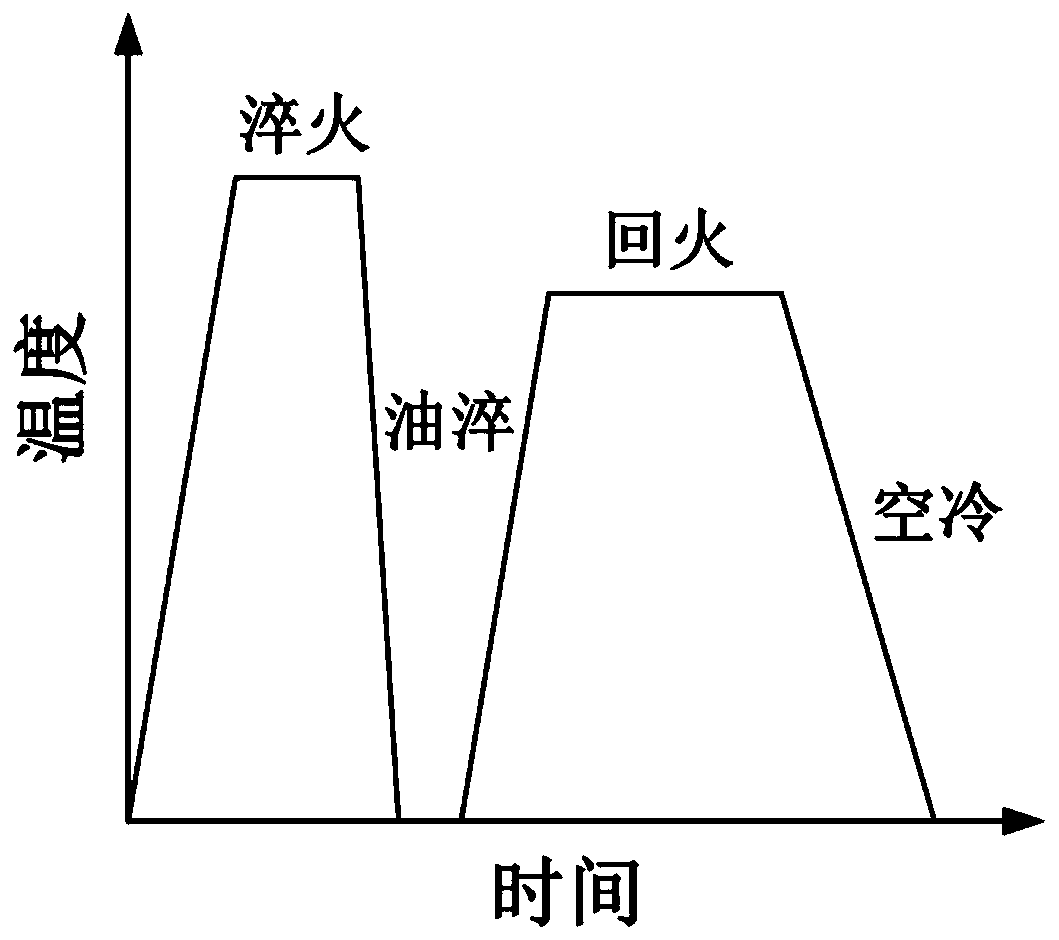

High-toughness cold-hot-fatigue-resistant cast steel for high-speed train brake disc and preparation method thereof

ActiveCN111360198AMatch mechanicsMatching cold and heat fatigue resistanceFoundry mouldsFurnace typesBrakeMetallic materials

The invention relates to high-toughness cold-hot-fatigue-resistant cast steel for a high-speed train brake disc and a preparation method thereof, belongs to the field of metal materials and preparation thereof, and solves the problem of matching of room-temperature toughness, high-temperature mechanical properties and cold and hot fatigue failure resistance of the cast steel for the high-speed train brake disc in the prior art. The high-toughness cold-hot-fatigue-resistant cast steel for the high-speed train brake disc comprises the following chemical components, in percentage by mass, of 0.20%-0.40% of C, 0.30%-0.70% of Si, 0.50%-2.00% of Mn, 0.50%-2.00% of Cr, 0.50%-2.00% of Ni, 0.40%-1.80% of Mo, 0.01%-0.30% of V, smaller than or equal to 0.015% of P, smaller than or equal to 0.010% ofS, smaller than or equal to 0.010% of O, smaller than or equal to 0.015% of N, and the balance Fe and inevitable impurities, wherein the total content of the Mn, the Cr and the Ni is 2.00%-6.00%, andthe total content of the Mo and the V is 0.41%-2.00%. Through reasonable composition, organization structure and preparation process regulation and control, excellent room-temperature toughness, high-temperature mechanical property and cold and hot fatigue failure resistance of the cast steel are matched, the requirements for comprehensive mechanical property and long service life of the cast steel brake disc of a high-speed train are met, and the cast steel is suitable for being used as a material for the cast steel brake disc of the high-speed train.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

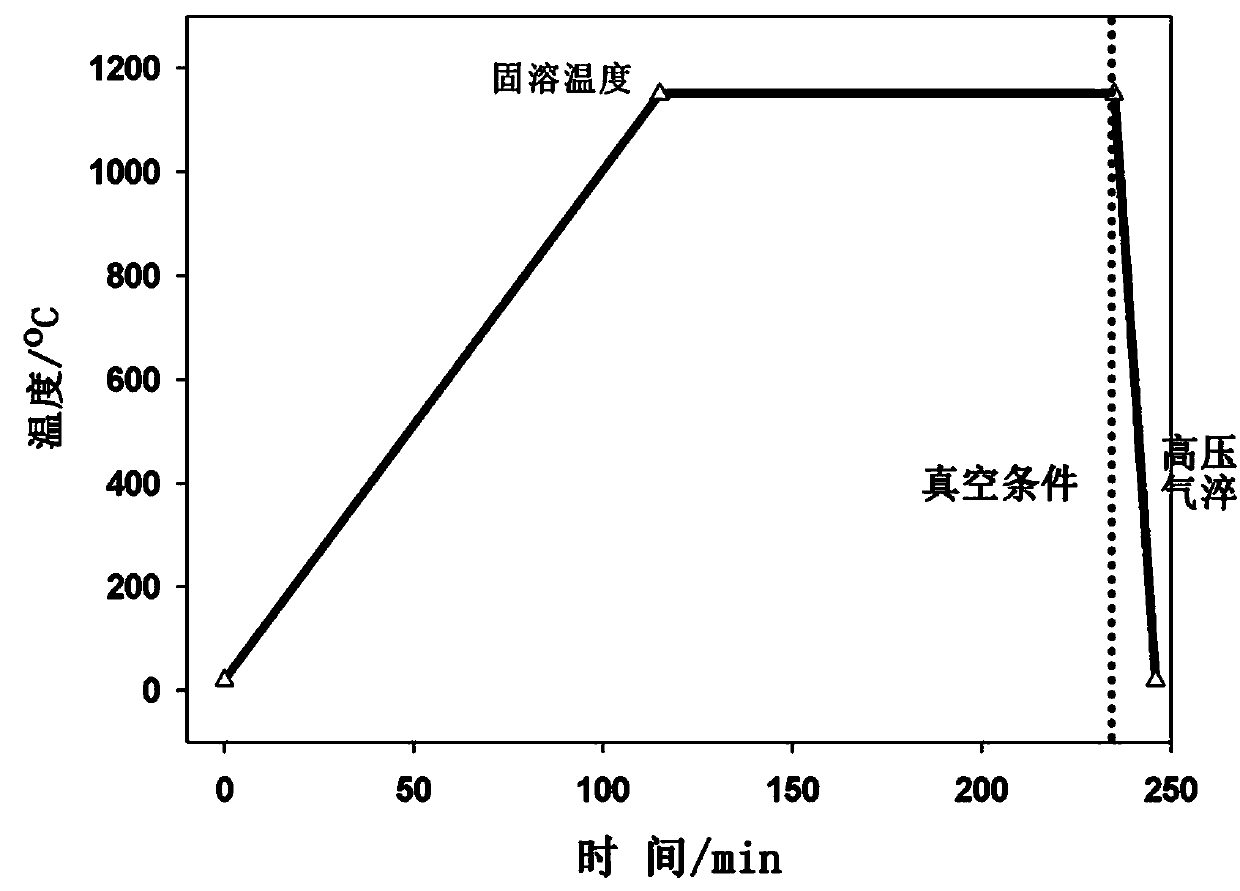

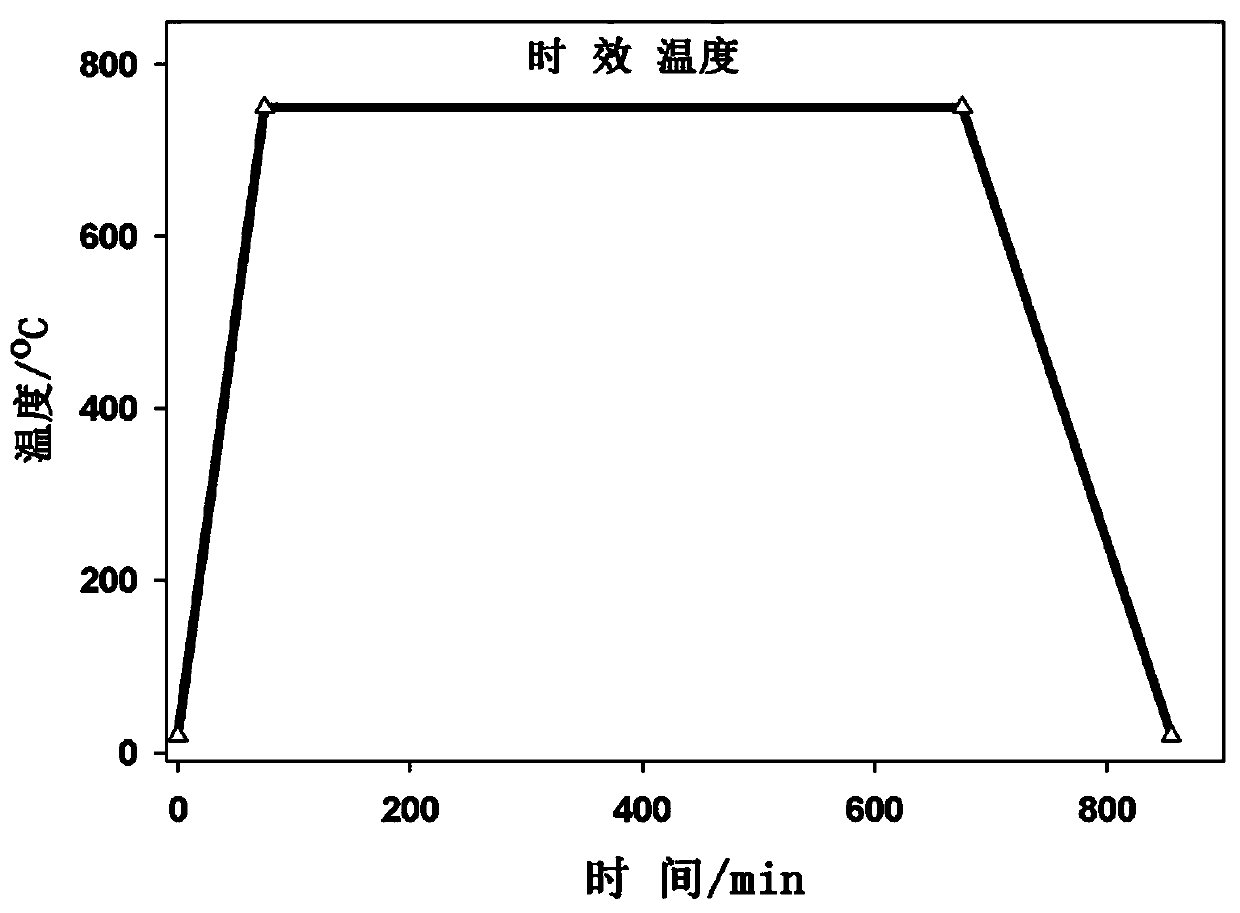

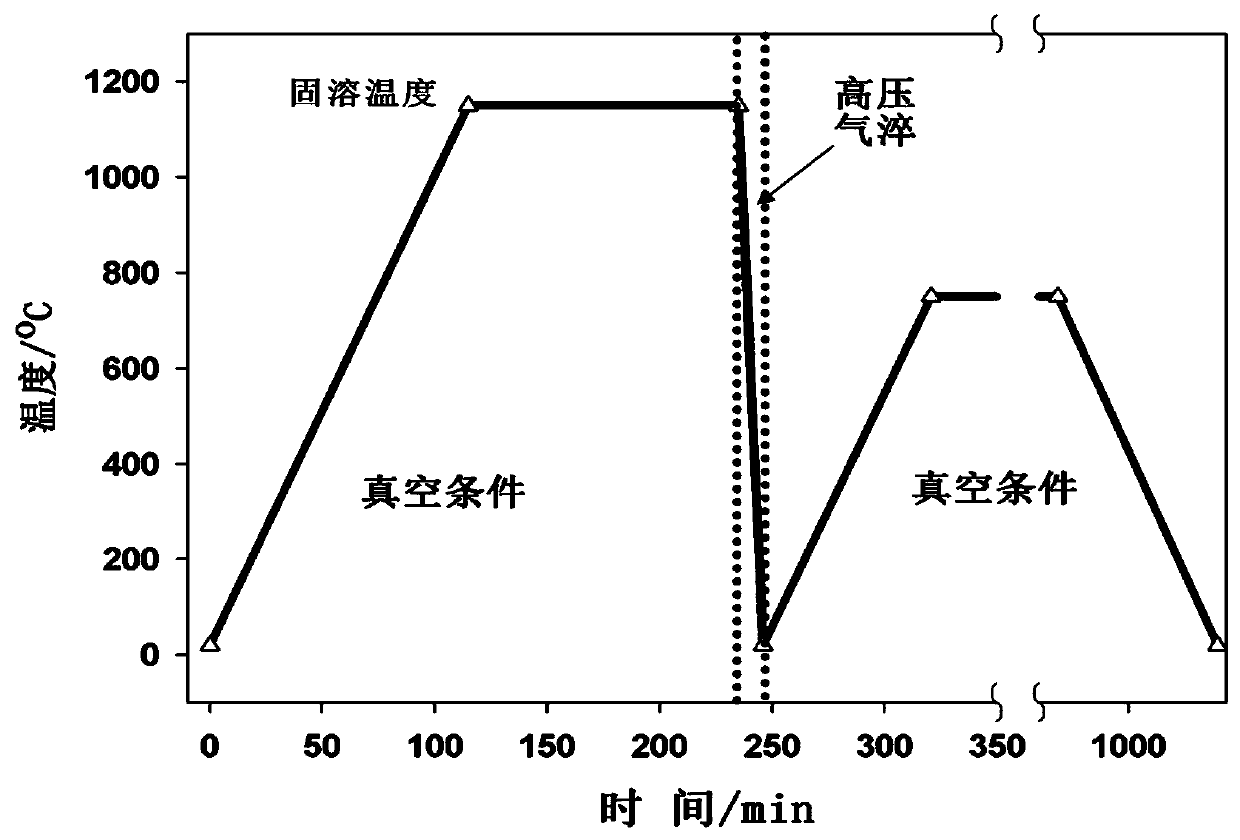

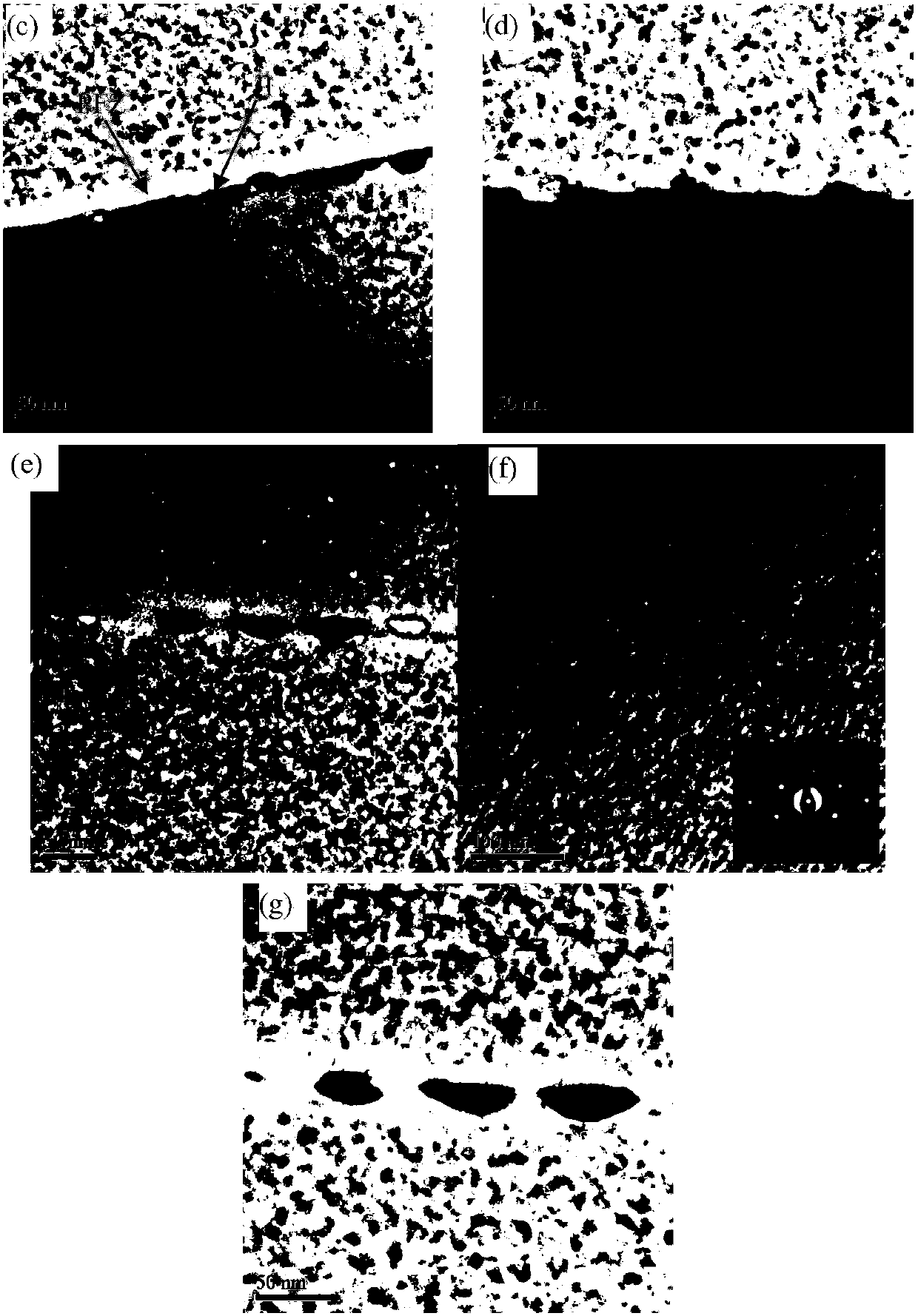

Heat treatment method of WC-Co-Ni3Al hard alloy

The invention discloses a heat treatment method of a WC-Co-Ni3Al hard alloy. The heat treatment method sequentially comprises the following steps: heating the WC-Co-Ni3Al hard alloy to a solid solution temperature of 1000-1300 DEG C under a vacuum condition of lower than 1 Pa at a speed of not less than 10 DEG C / min, and then, preserving the temperature for 10-120 minutes to carry out a solid solution treatment; introducing high pressure N2 or Ar after the temperature maintaining treatment, and cooling the hard alloy to the room temperature at a cooling speed of not less than 100 DEG C / min; heating the hard alloy to 600-900 DEG C under a vacuum condition of lower than 1 Pa at a speed of not less than 10 DEG C / min, preserving the temperature for not less than 10 h to carry out an aging treatment; and then, slowly cooling the hard alloy to the room temperature to obtain the WC-Co-Ni3Al hard alloy with obviously increased gamma'(Ni3Al) phase precipitation amount; compared with an alloy without heat treatment, the precipitation amount of the gamma' phase in the heat treated alloy disclosed by the invention is obviously increased, the strengthening effect is more obvious, the bending strength of the alloy is further improved, obviously, and meanwhile, stress generated in an early stage gas quenching rapid cooling process can be eliminated; moreover, the heat treatment method is simple in process, simple and convenient to operate, efficient and environment-friendly.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

High strength steel bar for pre-stressed concrete and production technology thereof

ActiveCN104404380AImproved resistance to hydrogen-induced delayed fractureAvoid inhalationSpinningChemical composition

The invention discloses a high strength steel bar for pre-stressed concrete. The steel bar is composed of the following chemical components in percentage by weight: 0.20 to 0.25% of C, 1.50 to 1.85% of Si, 0.20 to 0.50% of Mn, 0.07 to 0.09% of Cr, 0.30 to 0.35% of Mo, 0.25 to 0.35% of V, 0.05 to 0.08% of Nb, 0.42 to 0.61% of Ti, 0.15 to 0.25% of Ni, 0.25 to 0.40% of Ca, not more than 0.025% of S, not more than 0.025% of P, not more than 0.20% of Cu, 0.15 to 0.30% of composite rare earth, and the balance being Fe. The invention further discloses a production technology of the steel bar. The production technology comprises the following steps: smelting to obtain a steel blank, rolling the steel blank, cooling the rolled steel blank, rolling the steel blank for a second time, carrying out a thermal treatment and a stabilizing treatment, performing a gas nitrogenation treatment, spinning, winding, bundling, and storing the bundles in a warehouse.

Owner:溧阳市万兴特种建材有限公司

Manufacturing method of super austenitic stainless steel seamless steel pipe with large diameter

The invention discloses a manufacturing method of a super austenitic stainless steel seamless steel pipe with the large diameter, and relates to the technical field of production of seamless steel pipes with the large diameters. The manufacturing method comprises the steps that first a super austenitic stainless steel hollow ingot cylindrical tube blank is prepared by adopting an electroslag remelting technology, then surface treatment of an inner circle and an outer circle, heating, diameter enlarging and perforation and skew rolling are conducted, then intermediate heat treatment, cold rolling, intermediate heat treatment and cold rolling again, and heat treatment of a finished product are conducted, and finally, finishing is conducted. According to the manufacturing method of the superaustenitic stainless steel seamless steel pipe with the large diameter, the electroslag remelting technology is utilized to manufacture the hollow blank, and intermediate casting, forging and mechanical punching processes are reduced; and the perforation difficult problem that the center of the blank cannot form the Mannesmann effect during perforation of super austenitic stainless steel is solvedby using the hollow blank for perforation, the yield is high, the finished steel rate is more than 85%, the production cost is reduced, and the production efficiency is high.

Owner:YANGZHOU CHENGDE STEEL PIPE

Heat treatment method for achieving T77 three-stage aging and aviation aluminum alloy panel

The invention relates to a heat treatment method for achieving T77 three-stage aging and an aviation aluminum alloy panel, and relates to the field of aluminum alloy panel production. The heat treatment method for achieving T77 three-stage aging includes the steps that a heating zone is heated to 120 DEG C to 140 DEG C, heat preservation is carried out for 20 min to 30 min, an aluminum plate to besubject to aging is fed into the heating zone, and first-time heating and heat preservation are carried out for 20 h to 25 h; the temperature of a heat preservation zone is increased to 180 DEG C to195 DEG C with the rate larger than 3-5 DEG C / min, and second-time heating and heat preservation are carried out for 30 min to 60 min; the aluminum plate in the heating zone is fed into a quenching zone, and water quenching is carried out to obtain the room temperature; and the aluminum plate in the quenching zone is blown to be dry and is fed into an aging furnace to be subject to third-time aging. According to the heat treatment method for achieving T77 three-stage aging, sufficient alloy solid solution can be achieved, an oversaturation solid solution object is formed, wee and even separation exists in crystals, and grain boundaries are coarsened. A prepared aviation aluminum alloy panel is high in strength and is strong in durability and damage tolerance.

Owner:SHANDONG NANSHAN ALUMINUM +3

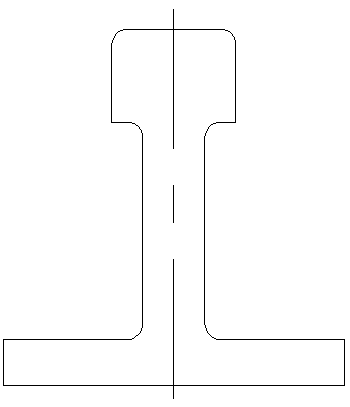

Low-cost 460MPa-grade hot-rolled H-shaped steel with excellent low-temperature toughness and production method thereof

ActiveCN112410666AImprove mechanical propertiesImprove surface qualityMetal rolling arrangementsToughnessWeldability

The invention discloses low-cost 460MPa-grade hot-rolled H-shaped steel with excellent low-temperature toughness and a production method thereof, and belongs to the technical field of steel smelting.The H-shaped steel comprises the following components of, in percentage by weight, 0.03%-0.06% of C, 0.20%-0.40% of Si, 1.40%-1.60% of Mn, less than or equal to 0.01% of P, less than or equal to 0.005% of S, 0.07%-0.09% of V, 0.10%-0.25% of Ni, 0.10%-0.25% of Cr, 0.008%-0.010% of N and the balance Fe and inevitable impurities, wherein the content ratio of V to N is 8:1-10:1. According to the low-cost 460MPa-grade hot-rolled H-shaped steel with excellent low-temperature toughness and the production method thereof, based on actual production of the hot-rolled H-shaped steel, the 460MPa-grade hot-rolled H-shaped steel with flange thickness of 30mm-50mm, high strength, high-low-temperature toughness, excellent weldability and thickness direction performance is developed through a reasonable component proportion and a full-flow TMCP technology.

Owner:MAANSHAN IRON & STEEL CO LTD

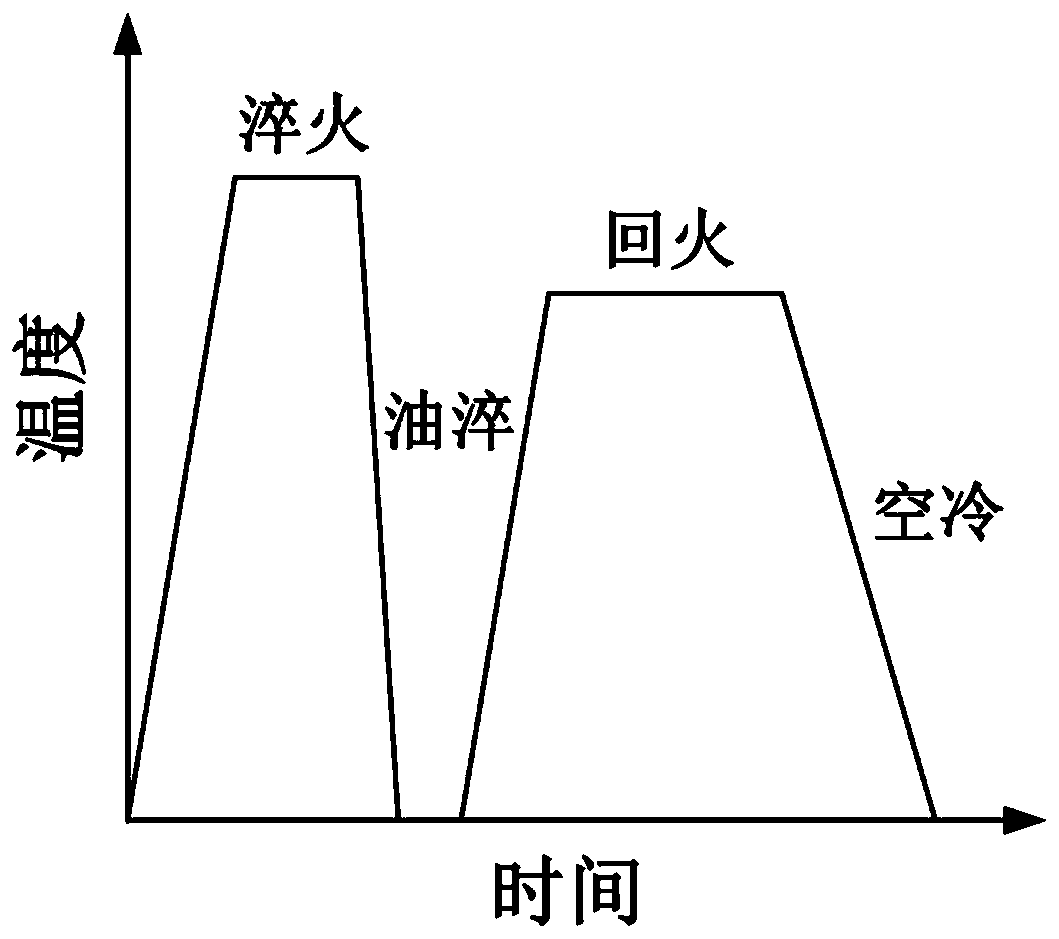

Processing method of above-600MPa-grade high-strength steel bar connection sleeve

ActiveCN103643124AImprove toughnessIncrease elasticityBuilding reinforcementsRebarMechanical engineering

The invention discloses a processing method of an above-600MPa-grade high-strength steel bar connection sleeve. The sleeve selects No.45 round steel as a raw material, and the No.45 round steel comprises 0.38-0.43wt% of C, 0.8-1.1wt% of Cr, 0.75-1.0wt% of Mn, 0.15-0.25wt% of Mo, 0.15-0.3wt% of Si, below 0.035% of S, below 0.035wt% of P, below 0.035wt% of N, and the balance Fe. The designed processing method of the above-600MPa-grade high-strength steel bar connection sleeve substantially improves the tensile strength and the elongation rate, guarantees the external diameter dimension and fineness of a steel tube, and reduces the friction stress between a tap and the inner wall of the sleeve.

Owner:江苏森林建筑新材料股份有限公司

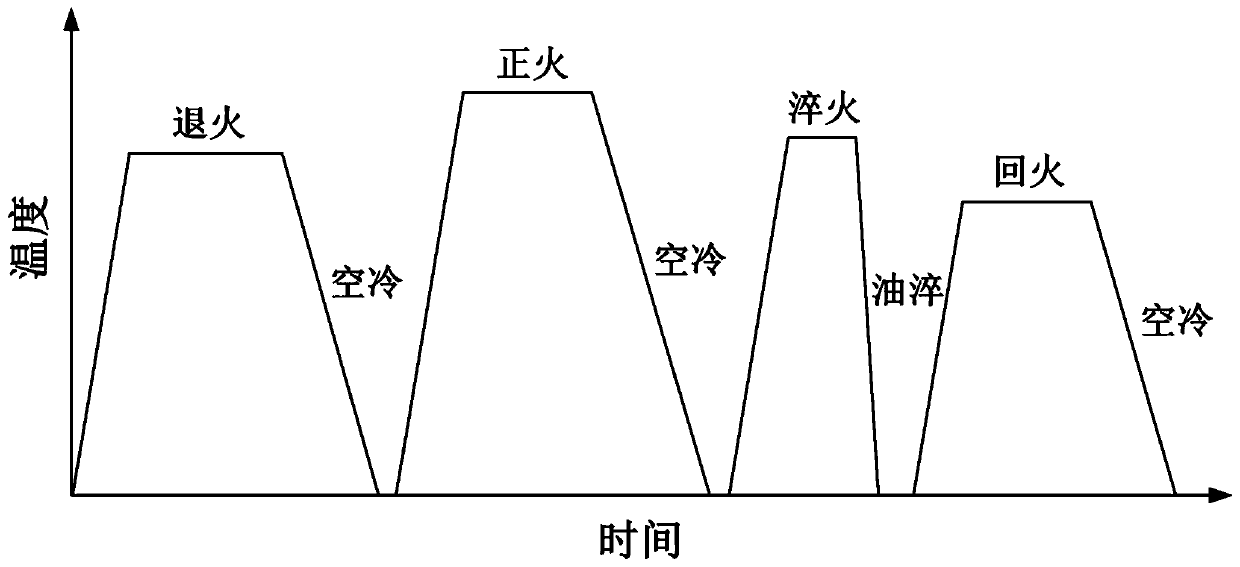

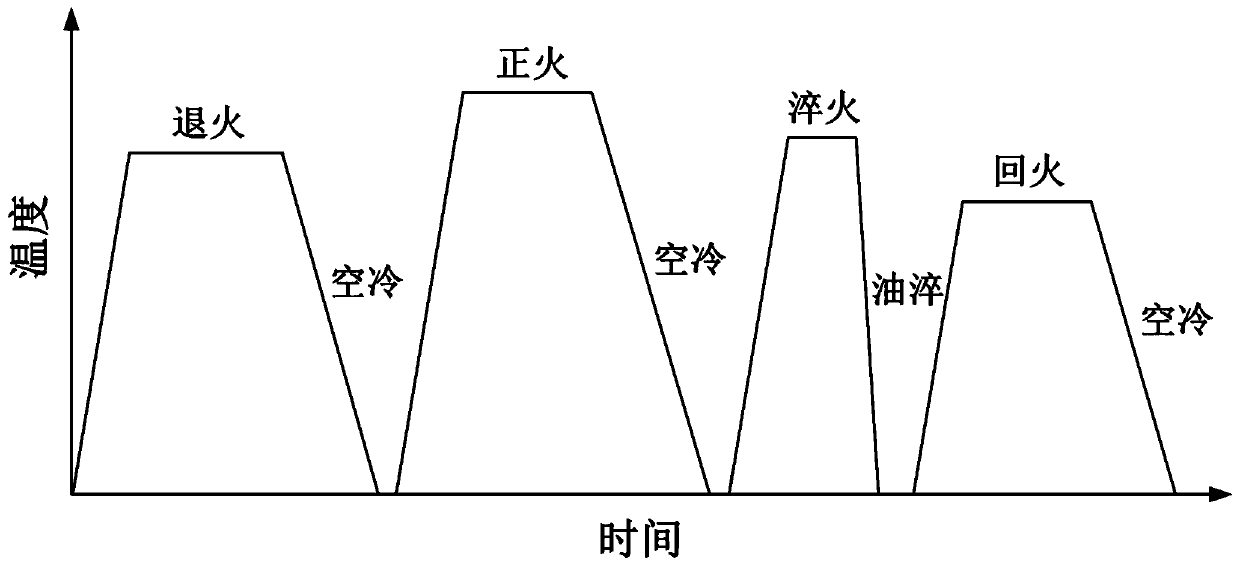

Thermal processing method improving impact resistance of 13Cr9Mo2Co1NiVNbNB forged piece

InactiveCN105063291AGood condition for liquid feedingReduce porosityQuenchingMartensitic microstructure

The invention relates to a thermal processing method improving impact resistance of a 13Cr9Mo2Co1NiVNbNB forged piece. It is guaranteed that carbonitride and elements are in sufficient solid solution through high-temperature normalizing, the elements are evenly diffused, and the evenness of the tissue of the forged piece is greatly improved. In the quenching process, a water-dissolving medium or oil is adopted, and the forged piece is effectively prevented from being cooled rapidly during quenching. After the forged piece is quenched and the medium is cooled to 250-350 DEG C, the medium is discharged for air cooling, and a martensite transformation zone is prevented from being cooled rapidly; then, air cooling is carried out on the forged piece to reach the room temperature, the tissue of the forged piece is sufficiently converted, the retained austenite of the forged piece is reduced, and the uniform austenite tissue is obtained. The first-time tempering is carried out on the forged piece to eliminate the tissue and thermal stress produced through quenching, and fine carbonitride is precipitated. During second-time tempering, the stress produced during first-time tempering can be eliminated, and the martensite newly generated through the first-time tempering is tempered. The moulding of the forged piece is improved. The carbonitride can be sufficiently precipitated, and the performance of a base body is improved.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

Nickel-chromium alloy powder-coated steel bar manufacturing method

ActiveCN103643086AHigh strengthImprove safety and reliabilityMolten spray coatingNickel Chromium AlloysHeating furnace

The present invention discloses a nickel-chromium alloy powder-coated steel bar manufacturing method, which is characterized in that (1) the chemical components of the nickel-chromium alloy powder comprise, by weight, 0.2-3.3% of Re, 45-55% of Ni, 16-33% of Cr, 1.5-5.0% of Si, 0.25-0.5% of S, 0.2-1.5% of C, 10-16% of Fe, 0.8-10% of Mn, and 1-2% of composite rare earth; (2) the smelted steel bar is conveyed into a heating furnace to heat to achieve a temperature of 900-1000 DEG C; (3) the nickel-chromium alloy powder mixed according to a certain ratio is uniformly sprayed on the steel bar surface through a spraying gun; (4) the heated steel bar is conveyed into a quenching device; (5) the quenched steel bar is heated through a tempering heating furnace to achieve a temperature of 450-480 DEG C; and (6) the tempered steel bar is naturally cooled to achieve a room temperature. According to the invention, the nickel-chromium alloy is coated the steel bar surface so as to increase the wear resistance.

Owner:TIANSHUN GROUP

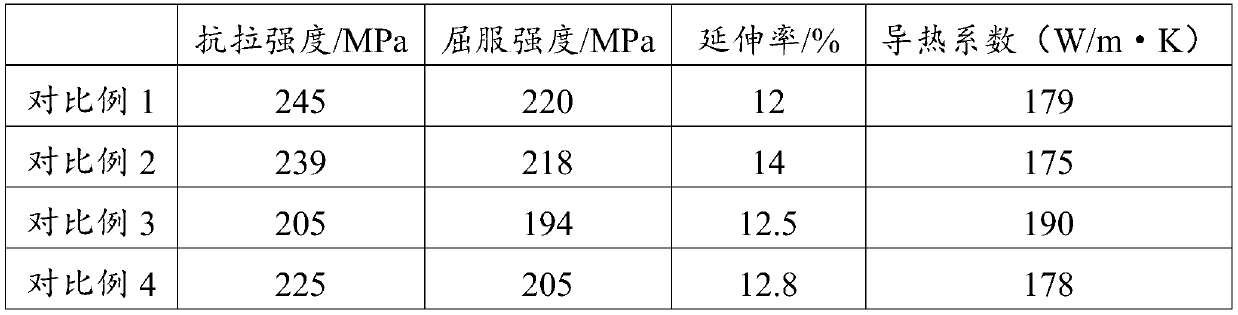

High thermal conductivity heat radiator aluminum profile, preparation method thereof and heat radiator

ActiveCN110358949ALow elemental contentImprove thermal conductivityHeat exchange apparatusInternal stressElectron

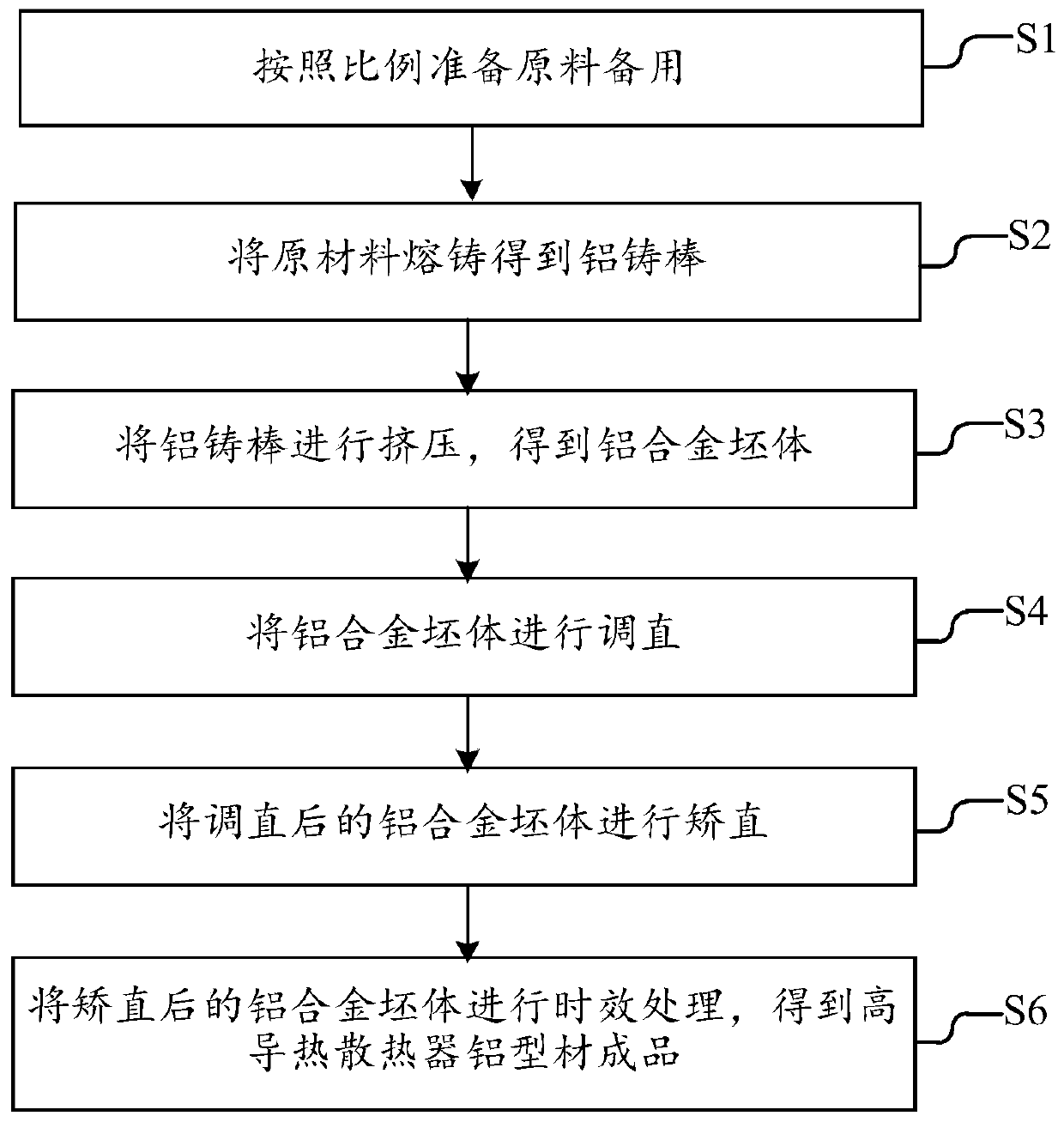

The invention discloses a preparation method of a high thermal conductivity heat radiator aluminum profile. The preparation method of the high thermal conductivity heat radiator aluminum profile includes: (1) preparing raw material for standby application according to a proportion; (2) performing fusion casting on the raw materials to obtain an aluminum cast rod; (3) squeezing the aluminum cast rod to obtain an aluminum alloy blank body; (4) aligning all parts of the aluminum alloy blank body, wherein alignment rate is 0.8%-3%; (5) straightening the aluminum alloy blank body after being aligned; (6) performing aging treatment on the aluminum alloy blank body after being straightened, and then obtaining the high thermal conductivity heat radiator aluminum profile finished product. Correspondingly, the invention further discloses the high thermal conductivity heat radiator aluminum profile and a heat radiator. By regulating and controlling the formula and process of aluminum alloy, the preparation method of the high thermal conductivity heat radiator aluminum profile reduces lattice distortion, reduces internal stress, and reduces scattering to free electrons, thereby raising the heat conductivity coefficient of the aluminum alloy, and meanwhile guaranteeing good mechanical performance and processing performance.

Owner:GUANGDONG JMA ALUMINUM PROFILE FACTORY GRP +1

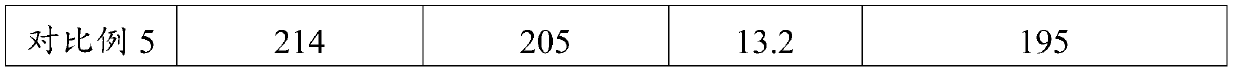

High-hardness and high-toughness metal ceramic and preparation method and application thereof

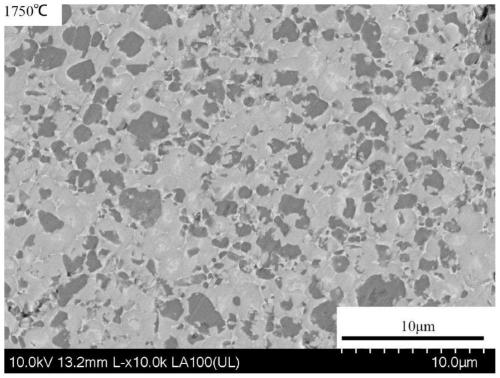

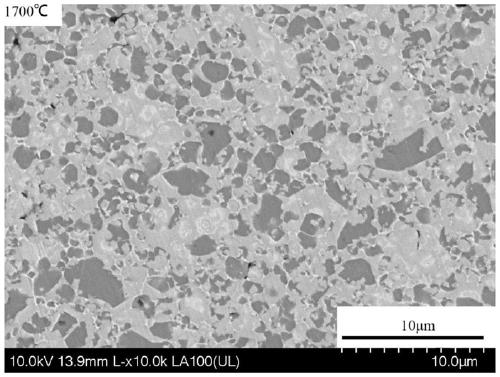

The invention belongs to the technical field of cutting tools, and discloses high-hardness and high-toughness metal ceramic and a preparation method and application thereof. According to the metal ceramic, TiC<0.7>N<0.3>, WC, Ni, Co, Mo<2>C and NbC are mixed, and then WC cemented carbide balls and anhydrous ethanol are added for ball milling; and mixed slurry is dried at 80-100 DEG C, a forming agent polyvinyl alcohol is added for granulation, granulated powder is pre-pressed for forming, plasma sintering is adopted, 25-30 Mpa of pressure is applied, and the temperature is raised to 1,700-1,800 DEG C for sintering to obtain the metal ceramic. Ti(C, N) is a hard phase of the metal ceramic, the density of the metal ceramic is improved and the thickness of a ring phase is controlled, the structure and performance of the ring phase are further improved, NbC is a grain inhibitor and can be used for inhibiting the growth of crystal grains in the sintering process, the mechanical properties of the metal ceramic are improved, and the red hardness and thermal shock resistance of the metal ceramic are improved.

Owner:GUANGDONG UNIV OF TECH

Erosion-resistant zirconium oxide nozzle bricks and preparation method thereof

The invention discloses erosion-resistant zirconium oxide nozzle bricks and a preparation method thereof, and belongs to the technical field of refractory materials. The zirconium oxide nozzle bricksare prepared from the following raw materials in percentage by weight: 93 to 96 percent of electrically fused zirconia, 2 to 4 percent of lanthanum oxide fine powder and 2 to 3 percent of an adhesive.The preparation method comprises the following steps: (1) crushing the electrically fused zirconia sand, mixing the crushed electrically fused zirconia sand with the lanthanum oxide fine powder, finely grinding the mixture, and pressing the mixture to obtain green bricks; (2) performing preliminary calcining on the green bricks under a nitrogen atmosphere at 1,300 to 1,400 DEG C in a temperaturepreservation manner for 2 to 3 hours; (3) crushing the calcined green bricks, mixing the crushed calcined green bricks with 2 to 3 percent of the adhesive, finely grinding the mixture till 2,000 to 3,000 meshes are achieved, pressing the mixture into green bricks, and performing secondary calcining under the nitrogen atmosphere at 1,650 to 1,670 DEG C in a temperature preservation manner for 2 to4 hours, thereby obtaining final products which are the zirconium oxide nozzle bricks. According to the zirconium oxide nozzle bricks and the preparation method thereof which are provided by the invention, by calcining under the nitrogen atmosphere through a two-step method, impurity iron can be converted into iron nitride in situ, and the erosion resistance of the zirconium oxide bricks is enhanced, and the service life of the zirconium oxide bricks is prolonged.

Owner:JIANGSU JIANAI HIGH TEMPERATURE MATERIAL

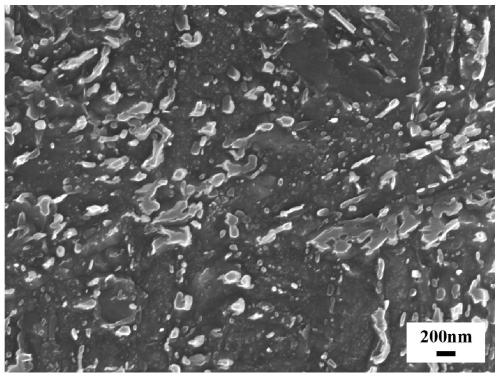

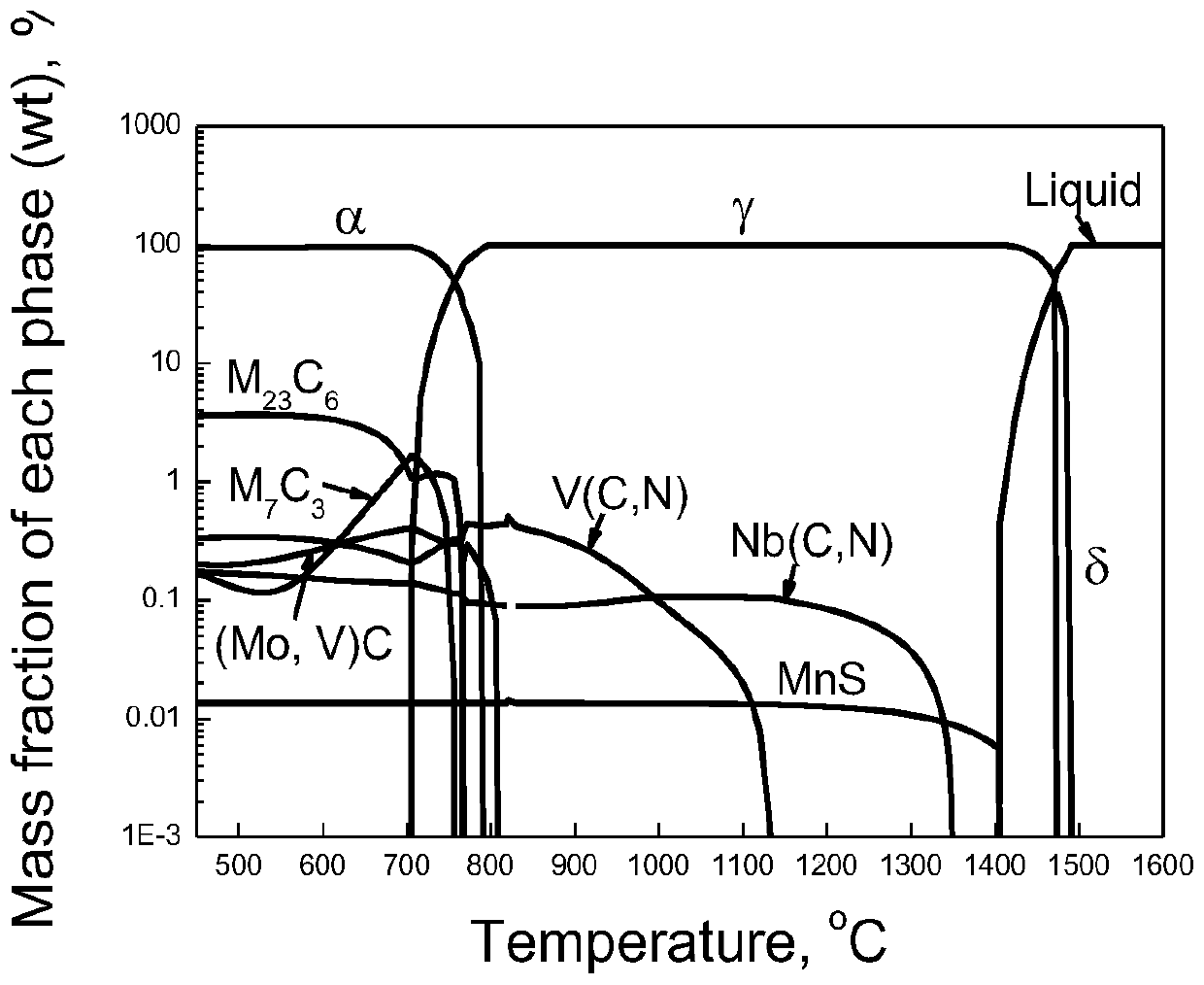

MC-MX containing precipitated phase high-speed train brake disc cast steel and preparation method

ActiveCN111304556ARaise room temperatureImprove mechanical propertiesMetallic materialsThermal stability

The invention discloses MC-MX containing precipitated phase high-speed train brake disc cast steel and a preparation method, and belongs to the fields of metal materials and preparation thereof. The problem of matching between room temperature toughness and high temperature mechanical properties of cast steel for high-speed train brake discs in the prior art is solved. The high-speed train brake disc cast steel comprises the chemical components of, by mass percent, 0.20-0.40% of C, 0.30-0.80% of Si, 0.50-2.00% of Mn, 0.50-2.00% of Cr, 0.50-2.00% of Ni, 0.40-1.60% of Mo, 0.01-0.30% of V, 0.01-0.20% of Nb, 0-0.015% of P, 0-0.010% of S, 0-0.010% of O, 0-0.015% of N and the balance Fe and inevitable impurities, wherein the total amount of Mn, Cr and Ni is 2.00-6.00%, and the total amount of Vand Nb is 0.02-0.40%. Through reasonable component design, organization structures and technology control, MC and MX precipitated phases which are fine, in dispersed distribution and excellent in heatstability are obtained, room temperature and high temperature mechanical properties of the high-speed train brake disc cast steel are comprehensively improved, the comprehensive requirements for theroom temperature and high temperature mechanical properties of the cast steel under the condition of high speed pure air emergency braking of a high-speed train are met, and the cast steel is suitablefor being used as cast steel brake discs of a high-speed train high in speed grade per hour.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

Making method of alloy coat coated prestressed steel wire

ActiveCN103643196AImprove machinabilityReduce rust generationMolten spray coatingFurnace typesHeating furnaceAlloy coating

The invention discloses a making method of an alloy coat coated prestressed steel wire. The method comprises the following steps: 1, preparing an alloy coat which is powdery; 2, sequentially carrying out pickling treatment phosphatization treatment and surface drying treatment of a prestressed steel wire rod; 3, sending the above obtained treated prestressed steel wire into a drawing machine, drawing to obtain the prestressed steel wire having required specifications and dimensions, and cleaning the prestressed steel wire; 4, sending the prestressed steel wire into a hot spraying device, uniformly spraying the surface of the prestressed steel wire with the prepared alloy powder by a spray gun, allowing the sprayed prestressed steel wire to an intermediate frequency heating furnace, and heating the prestressed steel wire to 550-570DEG C within 5-8s; and 5, allowing the prestressed steel wire to enter a quenching cooling device, cooling through a second cooling operation, air-cooling to room temperature, allowing the prestressed steel wire to a take-up machine, examining, and warehousing to obtain the alloy coat coated prestressed steel wire. The method increases the strength of the prestressed steel wire, further improves the wear resistance and the corrosion resistance of the prestressed steel wire, and prolongs the service life of the prestressed steel wire.

Owner:TIANSHUN GROUP

Silicon carbide product with high Sialon phase and preparation method thereof

The invention discloses a silicon carbide product with high Sialon phase and a preparation method thereof. The method comprises the following steps: premixing and grinding high-activity monatomic silicon powder, high-activity metallic aluminum powder, high-activity alpha-aluminum oxide powder and silicon carbide fine powder in a ball grinding mill for 25 to 30 minutes, so as to obtain ground powder, weighing different silicon carbide particles according to grading, the ground powder and a binding agent in proportion, mixing the mixture on a wet grinding mill for 25 to 30 minutes, pressing themixture into a blank body, and performing nitridation firing at 1450 to 1500 DEG C. The method produces the silicon carbide product with a high Sialon phase content through high-activity graded ram materials and a special technocal method, and the content of beta-Sialon phase can reach to 21 to 27 percent.

Owner:REFRACTORY MATERIAL OF SINOSTEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com