Low-cost 460MPa-grade hot-rolled H-shaped steel with excellent low-temperature toughness and production method thereof

A technology of low temperature toughness and production method, applied in the direction of metal rolling, etc., can solve the problems of poor welding performance, large alloy types and additions, and high production cost, and achieve the improvement of weldability, reduction of carbon equivalent and welding crack susceptibility index. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

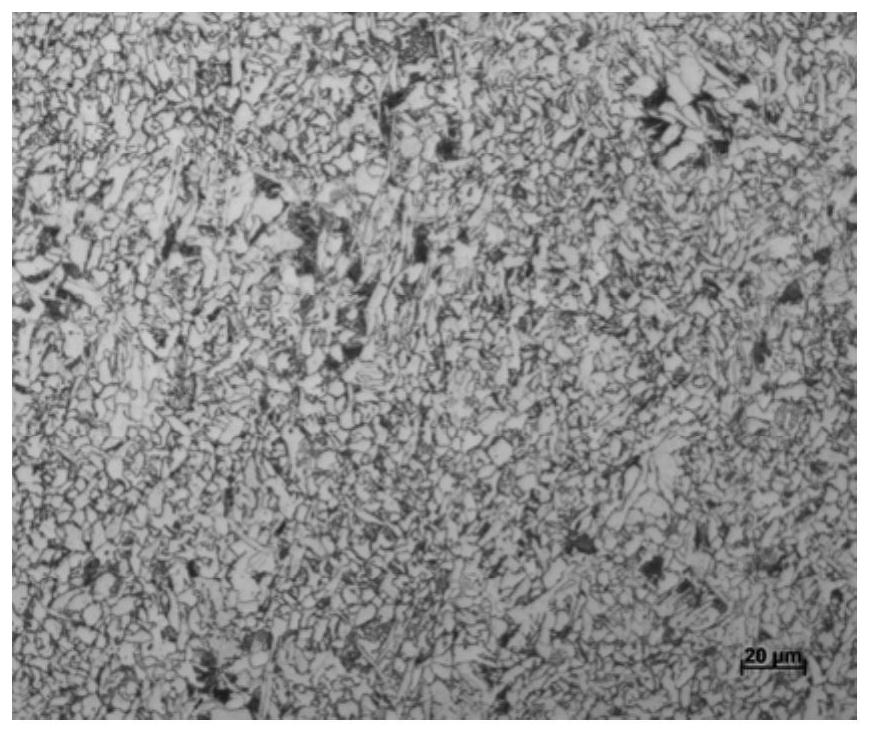

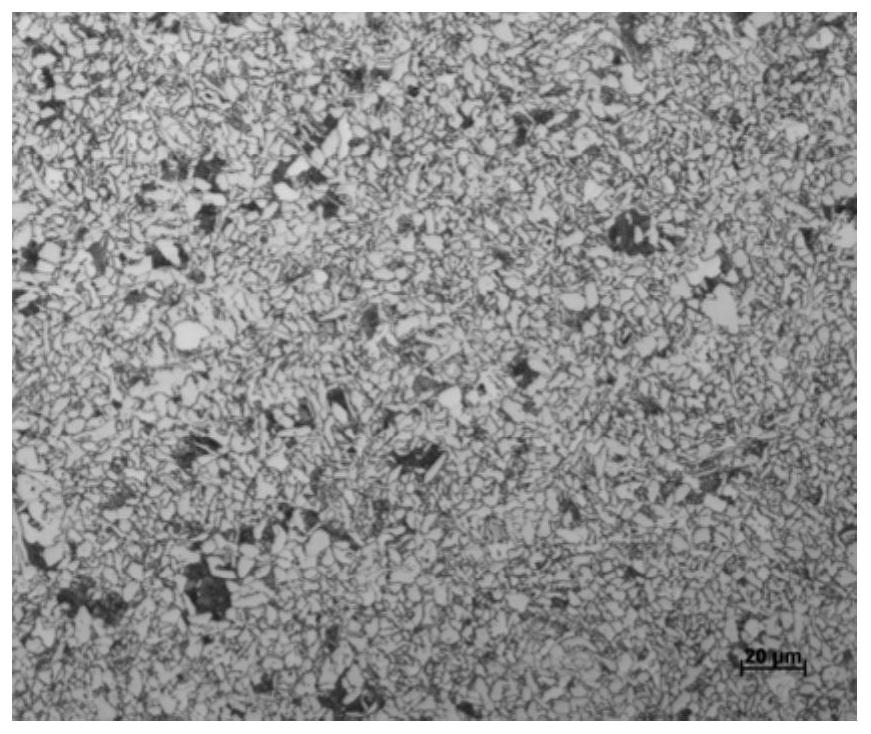

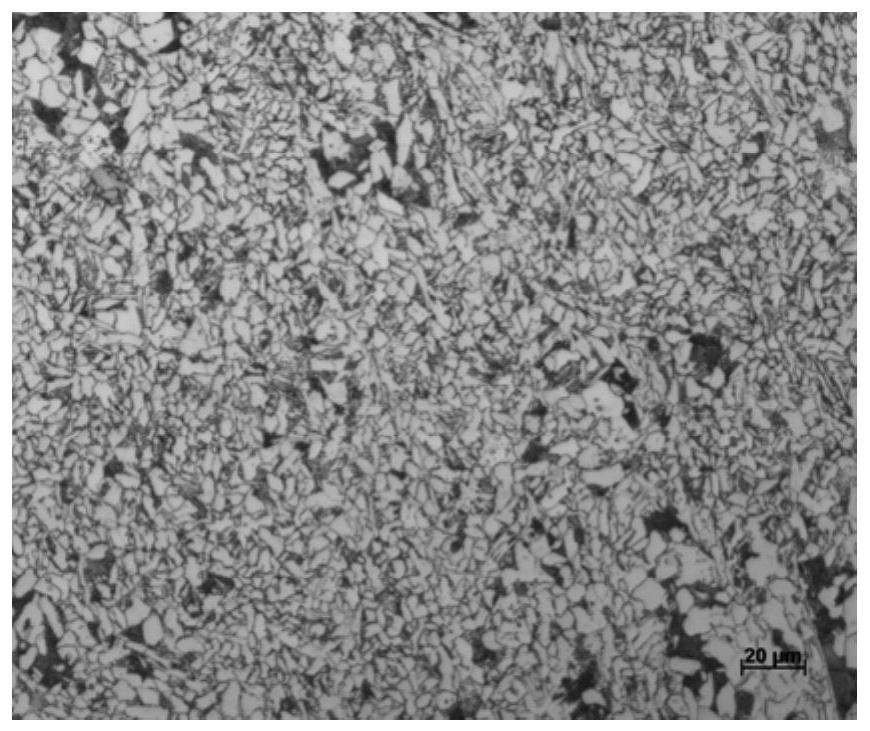

[0048] A low-cost 460MPa grade excellent low-temperature toughness hot-rolled H-shaped steel of this embodiment includes the following components in weight percentage: C: 0.03%, Si: 0.20%, Mn: 1.55%, P: 0.007%, S: 0.00: 3%, V: 0.08%, Ni: 0.10%, Cr: 0.20%, N: 0.01%, and the rest is Fe and unavoidable impurities. This embodiment mainly adopts economical alloy composition design, cooperates with 460MPa level excellent low temperature toughness hot rolled H-beam austenite strengthening phase transformation technology, realizes microstructure refinement, through fine grain strengthening + solid solution strengthening + precipitation strengthening + phase transformation Combined strengthening methods such as strengthening have improved the comprehensive mechanical properties of H-beams. Specifically, it adopts the composition design of low C+V+low Ni and low Cr to realize the role of the second phase particles in fine grain strengthening, solid solution strengthening and precipitati...

Embodiment 2

[0063] A low-cost 460MPa grade excellent low-temperature toughness hot-rolled H-shaped steel of this embodiment is basically the same as that of Embodiment 1, except that it includes the following components in weight percentage: C: 0.04%, Si: 0.23%, Mn : 1.4%, P: 0.01%, S: 0.004%, V: 0.086%, Ni: 0.15%, Cr: 0.20%, N: 0.0095%, and the rest is Fe and unavoidable impurities. In this embodiment, the content ratio of V to N is 9:1; the sum of Ni+Cr is 0.35%, and the ratio of Ni:Cr is 1:1.3.

[0064] The carbon equivalent CEV of the finished H-shaped steel in this embodiment is 0.35%, and the welding crack sensitivity index Pcm is 0.14%. The structure of the H-shaped steel flange is ferrite, pearlite and bainite, the grain size of the structure is 11, the volume of ferrite accounts for 72% of the total volume, and the volume of bainite accounts for 13% of the total volume.

[0065] In this embodiment, the thickness of the flange of the H-shaped steel is 30 mm, the yield strength of...

Embodiment 3

[0069] A low-cost 460MPa grade excellent low-temperature toughness hot-rolled H-shaped steel of this embodiment is basically the same as that of Embodiment 1, except that it includes the following components in weight percentage: C: 0.04%, Si: 0.26%, Mn : 1.56%, P: 0.008%, S: 0.005%, V: 0.07%, Ni: 0.13%, Cr: 0.25%, N: 0.008%, and the rest is Fe and unavoidable impurities. In this embodiment, the content ratio of V to N is 8.8:1; the sum of Ni+Cr is 0.38%, and the ratio of Ni:Cr is 1:1.9.

[0070] The carbon equivalent CEV of the finished H-shaped steel in this embodiment is 0.37%, and the welding crack sensitivity index Pcm is 0.15%. The structure of the H-shaped steel flange is ferrite, pearlite and bainite, the grain size of the structure is 10, the volume of ferrite accounts for 75% of the total volume, and the volume of bainite accounts for 15% of the total volume.

[0071] In this embodiment, the thickness of the flange of the H-shaped steel is 42 mm, the yield strength ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Flange thickness | aaaaa | aaaaa |

| Flange thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com