High thermal conductivity heat radiator aluminum profile, preparation method thereof and heat radiator

A heat sink and high thermal conductivity technology, which is applied in the field of aluminum alloy, can solve the problems of limited application and high cost, and achieve the effect of reducing lattice distortion and internal stress, reducing internal stress and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

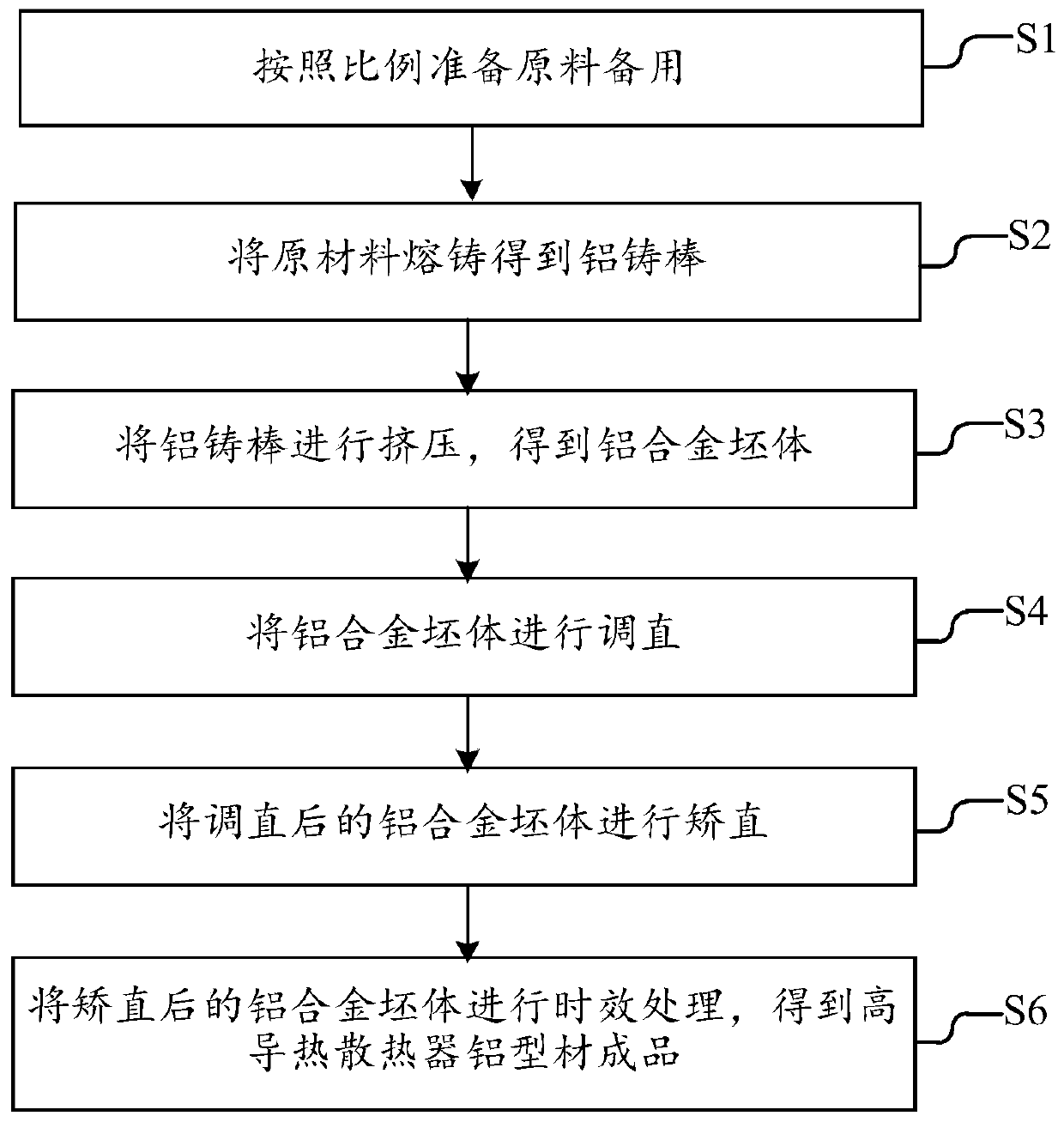

[0036] refer to figure 1 , the invention discloses a method for preparing an aluminum profile of a high thermal conductivity radiator, which comprises the following steps:

[0037] S1: Prepare raw materials according to the ratio for use;

[0038] Wherein, the raw material formula in weight percentage is as follows:

[0039] Si 0.4-0.5%, Fe≤0.25%, Cu≤0.1%, Mn≤0.03%, Mg 0.45-0.6%, Cr≤0.03%, Zn≤0.1%, Ti≤0.1%, and the balance is aluminum.

[0040] Some functional elements are usually added to aluminum alloys to improve the mechanical properties and processing properties of aluminum alloys. These elements will replace Al atoms. Due to the difference in diameter between impurity elements and Al atoms, it will cause lattice distortion and form internal stress. At the same time, some elements will form new phases and exist in the aluminum alloy, causing lattice distortion. The heat conduction is realized through the movement of electrons in the aluminum alloy, and during the movem...

Embodiment 1

[0075] This embodiment provides a high thermal conductivity radiator aluminum profile, the preparation method of which is:

[0076] (1) Raw materials are prepared according to the ratio for subsequent use, wherein the formula is:

[0077] Si 0.4%, Fe 0.25%, Cu 0.1%, Mn 0.05%, Mg 0.45%, Cr 0.03%, Zn 0.1%, Ti0.1%; the balance is aluminum.

[0078] (2) melting and casting raw materials to obtain aluminum cast rods;

[0079] (3) Extruding the cast aluminum rod to obtain an aluminum alloy blank; wherein, the extrusion temperature is 490° C., and the extrusion speed is 2 m / min;

[0080] (4) straightening the aluminum alloy body, wherein the straightening amount is 0.8%;

[0081] (5) Straightening the straightened aluminum alloy;

[0082] (6) Aging treatment is performed on the straightened aluminum alloy body to obtain a finished aluminum profile for a heat sink with high thermal conductivity; wherein, the aging treatment temperature is 200° C. and the time is 5 hours.

Embodiment 2

[0084] This embodiment provides a high thermal conductivity radiator aluminum profile, the preparation method of which is:

[0085] (1) Raw materials are prepared according to the ratio for subsequent use, wherein the formula is:

[0086] Si 0.5%, Fe 0.1%, Cu 0.03%, Mn 0.03%, Mg 0.6%, Cr 0.03%, Zn 0.03%, Ti0.03%; the balance is aluminum.

[0087] (2) melting and casting raw materials to obtain aluminum cast rods;

[0088] (3) Extruding the cast aluminum rod to obtain an aluminum alloy blank; wherein, the extrusion temperature is 550° C., and the extrusion speed is 10 m / min;

[0089] (4) straightening the aluminum alloy body, wherein the straightening amount is 3%;

[0090] (5) Straightening the straightened aluminum alloy;

[0091] (6) Aging treatment is performed on the straightened aluminum alloy body to obtain a finished aluminum profile for a heat sink with high thermal conductivity; wherein, the aging treatment temperature is 240° C. and the time is 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com