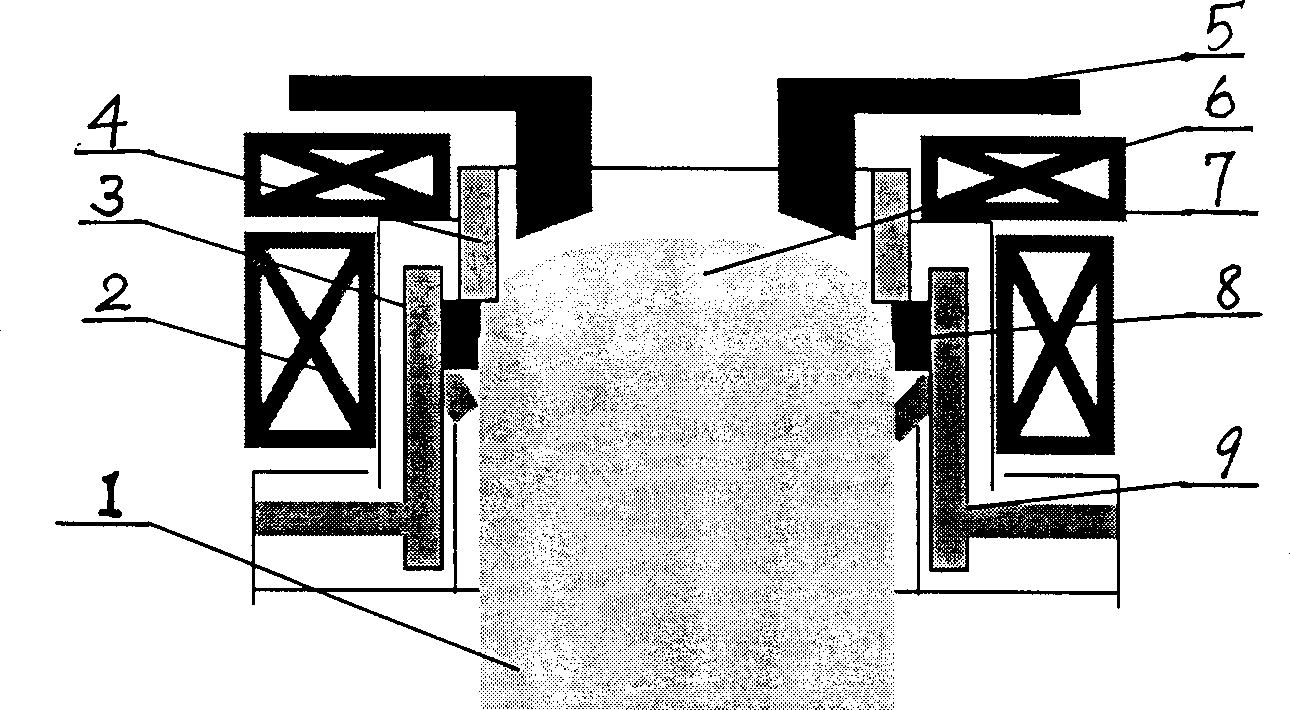

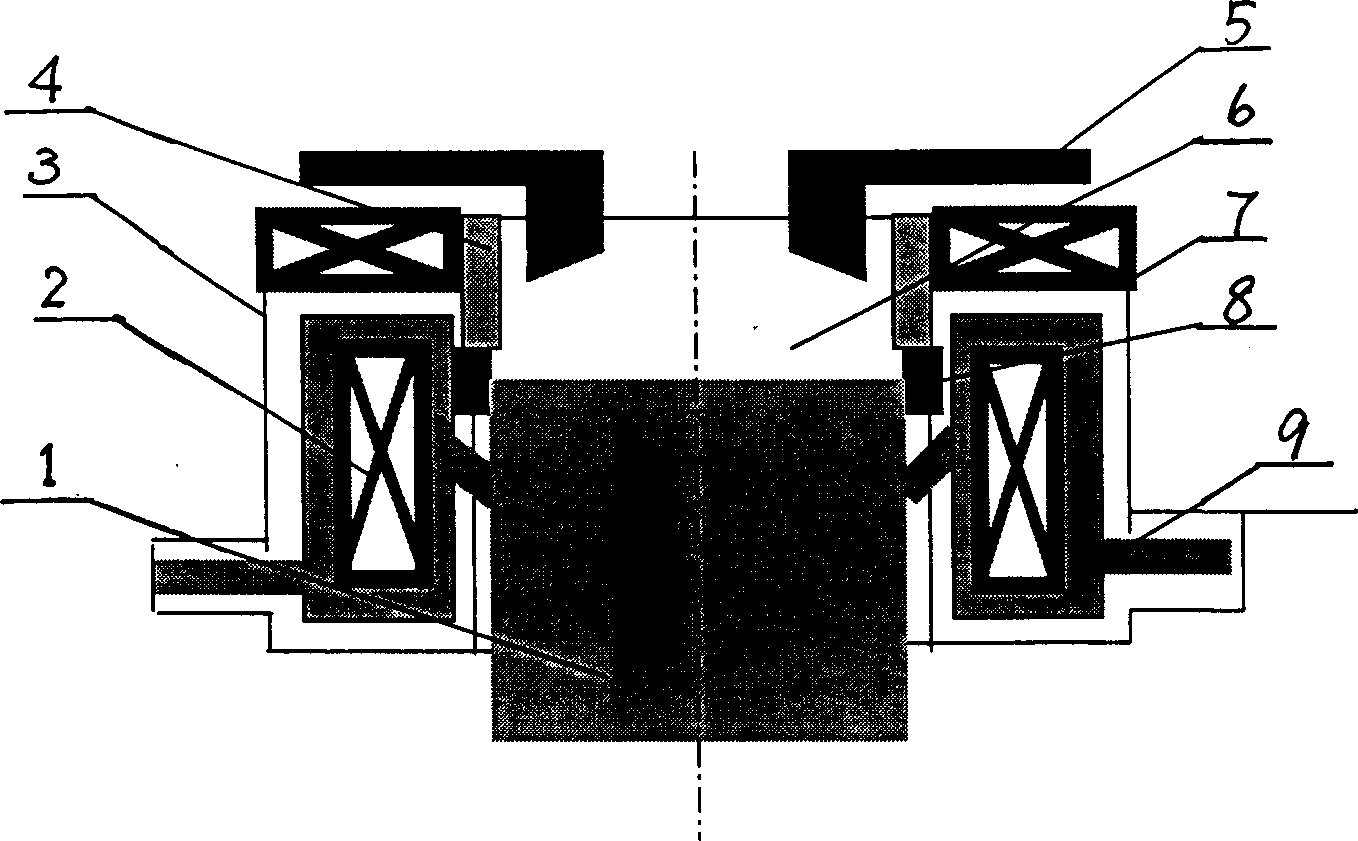

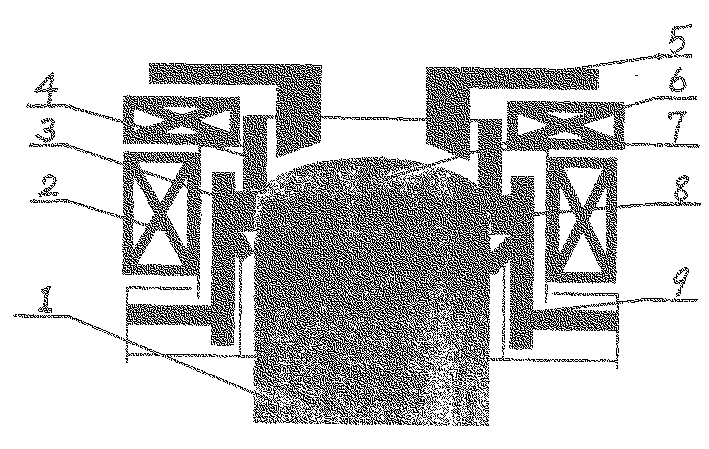

Aluminium alloy low frequency electromagnetic oscillation semicontinuous casting crystal grain fining method and device

A technology of electromagnetic oscillation and grain refinement, applied in the field of material processing, can solve the problems of limited penetration capacity and poor intragranular solidification effect, and achieve the effects of eliminating segregation nodules, reducing internal casting stress and improving yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0056] Example 1. Pure aluminum:

[0057] Ingot size: 200

[0058] Casting conditions: casting temperature 680-700°C, casting speed: 100mm / min, cooling water pressure: 0.08Mpa, aluminum alloy dummy rod, no bottom laying.

[0059] to cast

example 27075

[0060] Example 2.7075 alloy low-frequency electromagnetic oscillation semi-continuous casting:

[0061] 7075 aluminum alloy chemical composition Zn Mg Cu Cr Mn Fe Si Al5.1~6.1 2.0~3.0 1.2~2.0 0.16~0.3 ≤0.15 ≤0.5 ≤0.5 balance

[0062] Ingot size: 200

[0063] Casting conditions: casting temperature 680-720°C, casting speed: 80mm / min, cooling water pressure: 0.08Mpa, aluminum alloy dummy rod, no bottom laying.

[0064] Electromagnetic field conditions: AC frequency 30Hz, realized on an external crystallizer, electromagnetic field strength: DC magnetic field: 10000At, AC magnetic field: 20000At

[0065] to cast

make

party

Law

Grain

size

mm

Grain

shape

Intragranular Zn

Content %

Zn

view

Partial

analysis

Rate

%

#

Mg

view

Partial

analysis

Rate

%

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com