Method for adding oxygen and iron in titanium alloy

A technology for titanium alloys and alloying elements, applied in the field of co-addition of oxygen and iron in titanium alloys, can solve problems such as low iron addition, damage to alloy service performance, uneven micro-area, etc., to achieve quality improvement, low input cost, and method Effects in simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

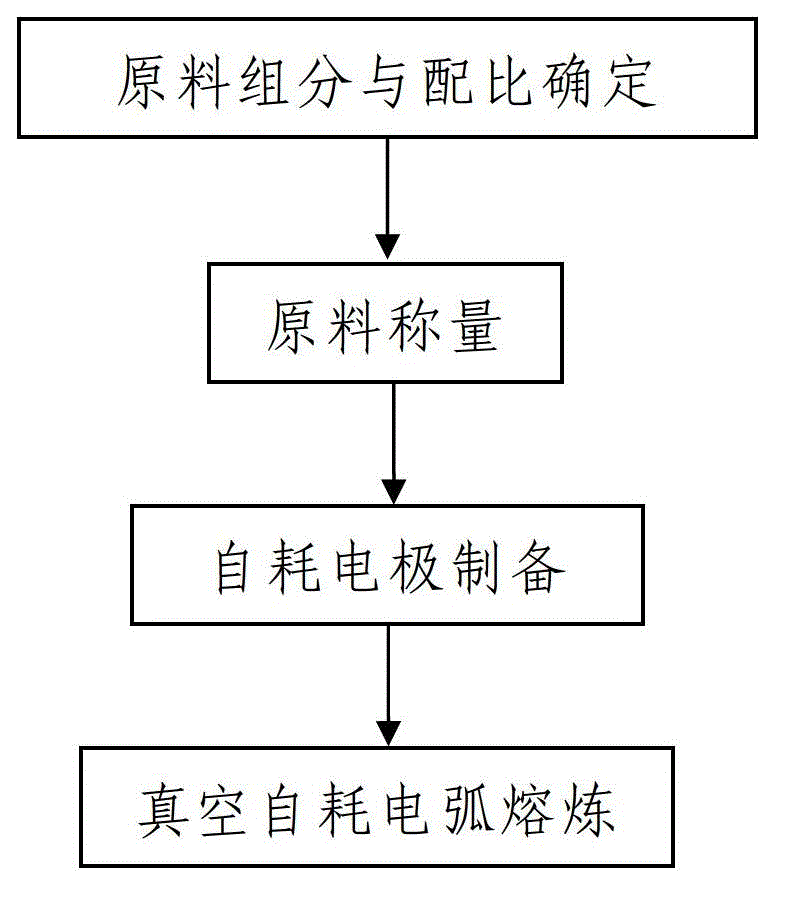

[0058] In this embodiment, the method for adding oxygen and iron in the titanium alloy comprises the following steps:

[0059] Step 1. Determination of raw material components and proportions: according to the nominal chemical composition of the titanium alloy to be prepared, the components of the raw materials used to prepare the titanium alloy and the proportions of each component are determined;

[0060] The raw materials include titanium sponge, mixed powder for adding oxygen and iron elements and materials for adding other alloy elements.

[0061] When carrying out raw material component and proportioning to determine in step 1, its determination process is as follows:

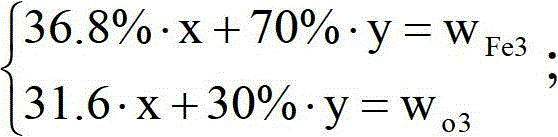

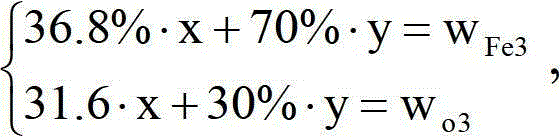

[0062] Step 101, determining the alloy elements of each component: according to the nominal chemical composition of the titanium alloy to be prepared, calculate the content of the alloy elements of each component, including the content of oxygen element w O1 and iron content w Fe1 , the content of oxyge...

Embodiment 2

[0084] In this embodiment, the difference from Example 1 is that the nominal chemical composition of the titanium alloy to be prepared in step 101 is Ti-6Al-4V-0.15Fe-0.18O, that is, Al: 6.0% by weight percentage, V: 4.0%, Fe:0.15%, O:0.18%, the balance is Ti and unavoidable impurity; In step 102, the materials used to mix other alloying elements include Al-85V intermediate alloy and aluminum beans; wherein Al-85V intermediate The alloy is fine particles, and its particle size is below 4mm; the selected sponge titanium is grade 1 sponge titanium, and the content of O element in the selected sponge titanium raw material is 0.07%, and the content of Fe element is 0.05%; The B component is TiO 2 powder, that is, the mixed powder consists of FeTiO 3 Powder and TiO 2 The powder is uniformly mixed, and the particle size of the mixed powder is 80 mesh; therefore, the raw materials used include Al-85V master alloy, aluminum beans, 0-grade sponge titanium and FeTiO 3 Powder and TiO ...

Embodiment 3

[0092] In this embodiment, the difference from Example 1 is that the nominal chemical composition of the titanium alloy to be prepared in step 101 is Ti-6Al-4V-0.25Fe-0.15O, that is, Al: 6.0% by weight percentage, V: 4.0%, Fe:0.25%, O:0.15%, the balance is Ti and unavoidable impurity; In step 102, the material used to mix other alloy elements includes Al-85V intermediate alloy and aluminum beans; wherein Al-85V intermediate The alloy is fine particles, the content of O element in the selected sponge titanium raw material is 0.07%, and the content of Fe element is 0.05%; the selected sponge titanium is grade 1 sponge titanium, and the particle size of the sponge titanium is below 4mm ; The selected B component is Fe 2 o 3 powder, that is, the mixed powder consists of FeTiO 3 Powder and Fe 2 o 3 The powder is uniformly mixed, and the particle size of the mixed powder is 80 mesh; therefore, the raw materials used include Al-85V master alloy, aluminum beans, 0-grade sponge tit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com