Method capable of giving consideration to laser melt injection efficiency, composite layer depth and metallurgical quality

A technology of laser melting injection and laser spot, which is applied in the direction of coating, metal material coating process, etc., can solve the problems of inability to take into account the efficiency of melting injection, so as to avoid prolonged residence time of molten pool, improve strength and wear resistance, and high Effect of melt injection efficiency and cladding depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

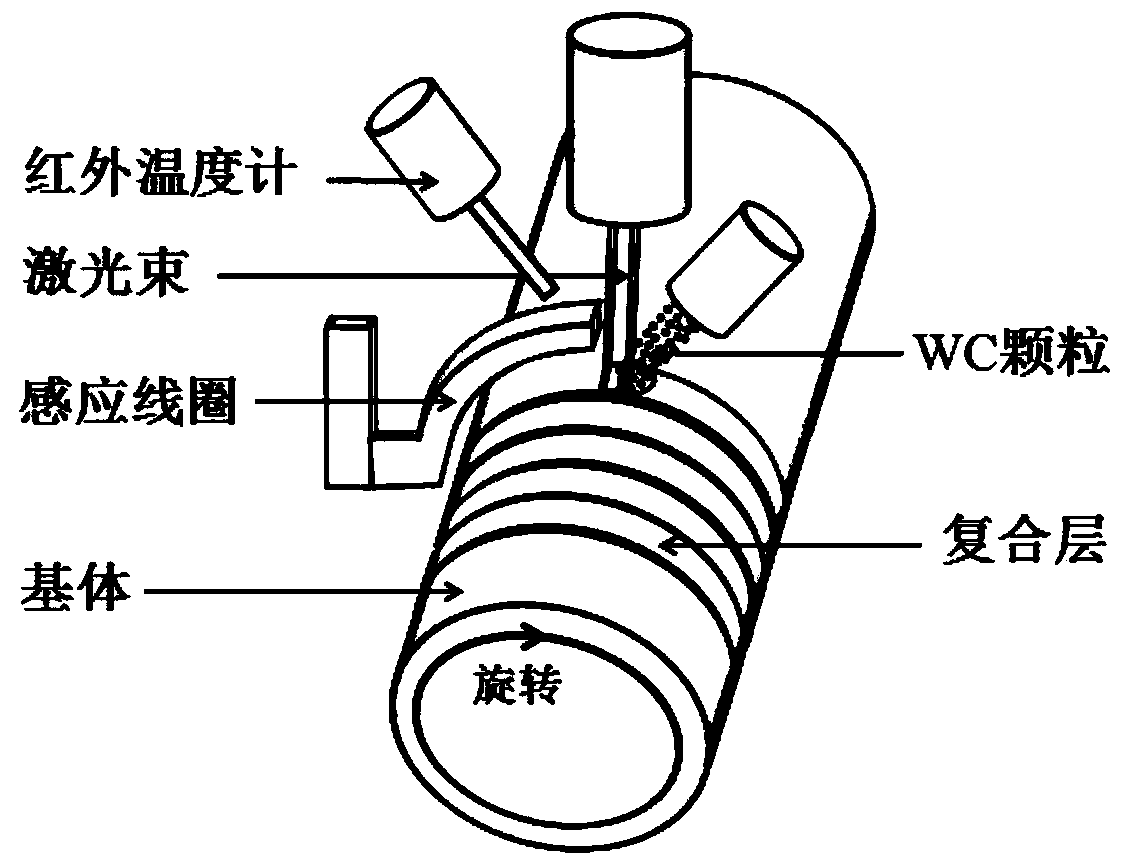

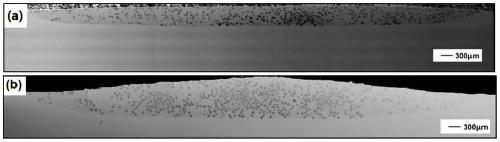

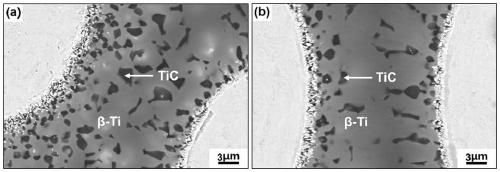

[0025] Using the laser-induction composite melt injection method in the present invention, and using the conventional laser melt injection in the prior art as a comparison, the WC particle reinforced Ti-6Al-4V based composite layer is prepared.

[0026] The implementation process of this example is:

[0027] Step a: selection of reinforcing particles: due to the high temperature reaction stability of WC and titanium alloy Ti-6Al-4V, the linear expansion coefficient is similar; the reinforcing particles are spherical cast WC particles with an average particle size of 45-75 μm, composed of WC and W 2 C two-phase composition, and then put the reinforced particles into the hopper of the automatic powder feeder;

[0028] Step b: Preparation of the base material: the base material is a titanium alloy Ti-6Al-4V bar with a diameter of 110 mm, and its chemical composition is (mass percentage) 5.5-6.8% Al, 3.5-4.5% V, 0.3% Fe, 0.2 %O, 0.15% Si, 0.1% C, 0.05% N, 0.01% H, 0.5% others, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com