MC-MX containing precipitated phase high-speed train brake disc cast steel and preparation method

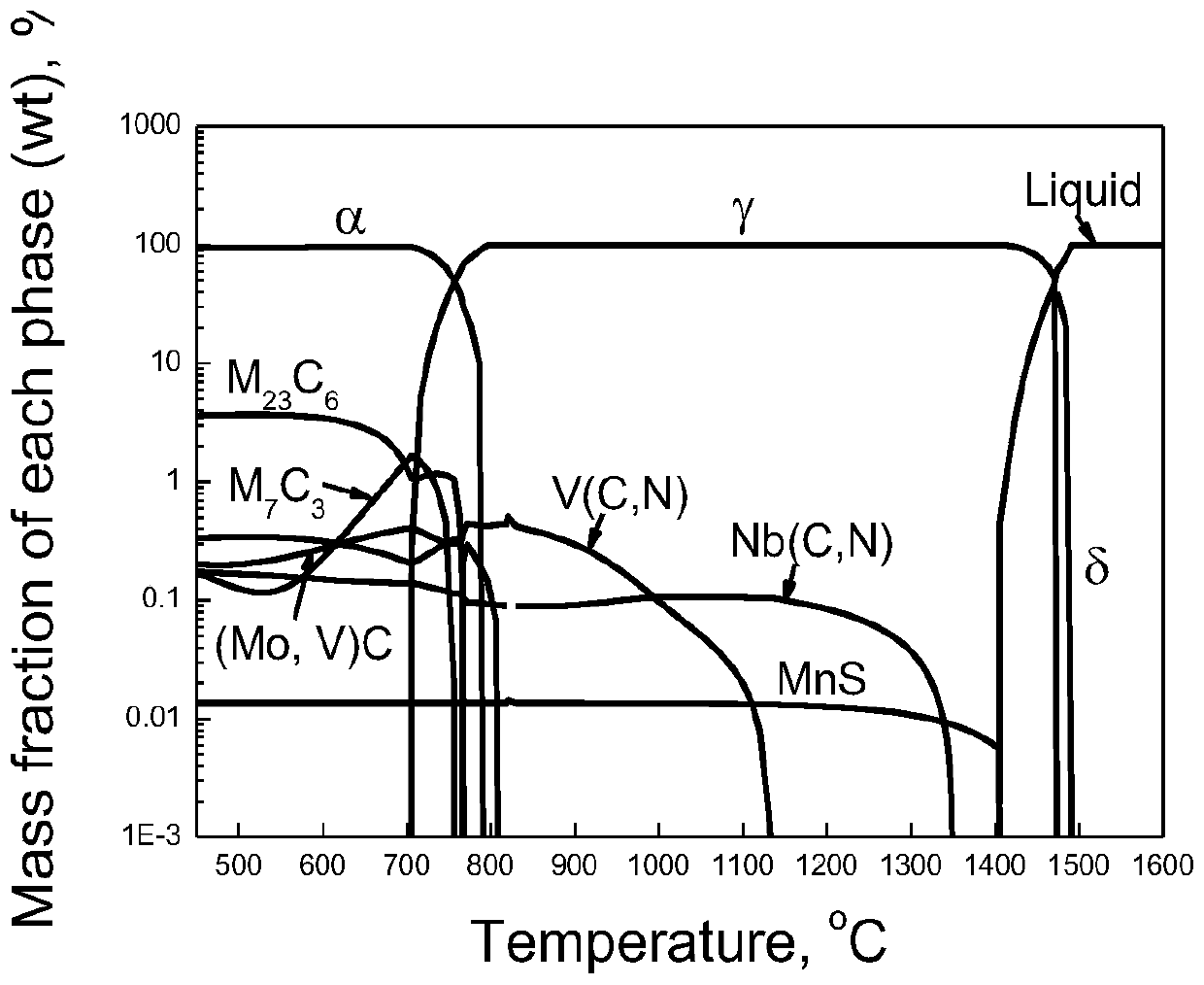

A technology for high-speed trains and precipitated phases, which is applied to the cast steel and preparation of MX-type precipitated phase high-speed train brake discs, including MC, can solve the problems of room temperature strength and toughness and high temperature mechanical properties matching, and achieve the control of room temperature strength and toughness, The effect of good anti-temper coarsening ability and good high-temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] On the other hand, the present invention provides a kind of preparation method that contains MC, MX type precipitation phase high-speed train brake disc cast steel, comprises the following steps:

[0041] Step 1: Prepare resin sand mold;

[0042] Use molding sand, resin, and curing agent, and use three-dimensional geometric entities or 3D printing equipment to prepare resin sand mold components. The part of the sand mold component that contacts the molten steel is painted with zircon powder coating for 1-10 times. After the sand mold is naturally dried and solidified, it is baked at 100-1000°C for 0.05-8h to remove the water in it, and the solid particles in the cavity are removed to form the mold.

[0043] The type of resin includes one or more of furan resin, phenolic resin and epoxy resin. The main purpose of brushing zircon powder is to improve the surface quality of castings and improve the demolding efficiency.

[0044] Step 2: Prepare smelting raw materials, an...

Embodiment 1

[0061] Example 1 of the present invention provides a cast steel for high-speed train brake discs containing MC and MX precipitates, the chemical composition of which is shown in Table 1 in mass percentage.

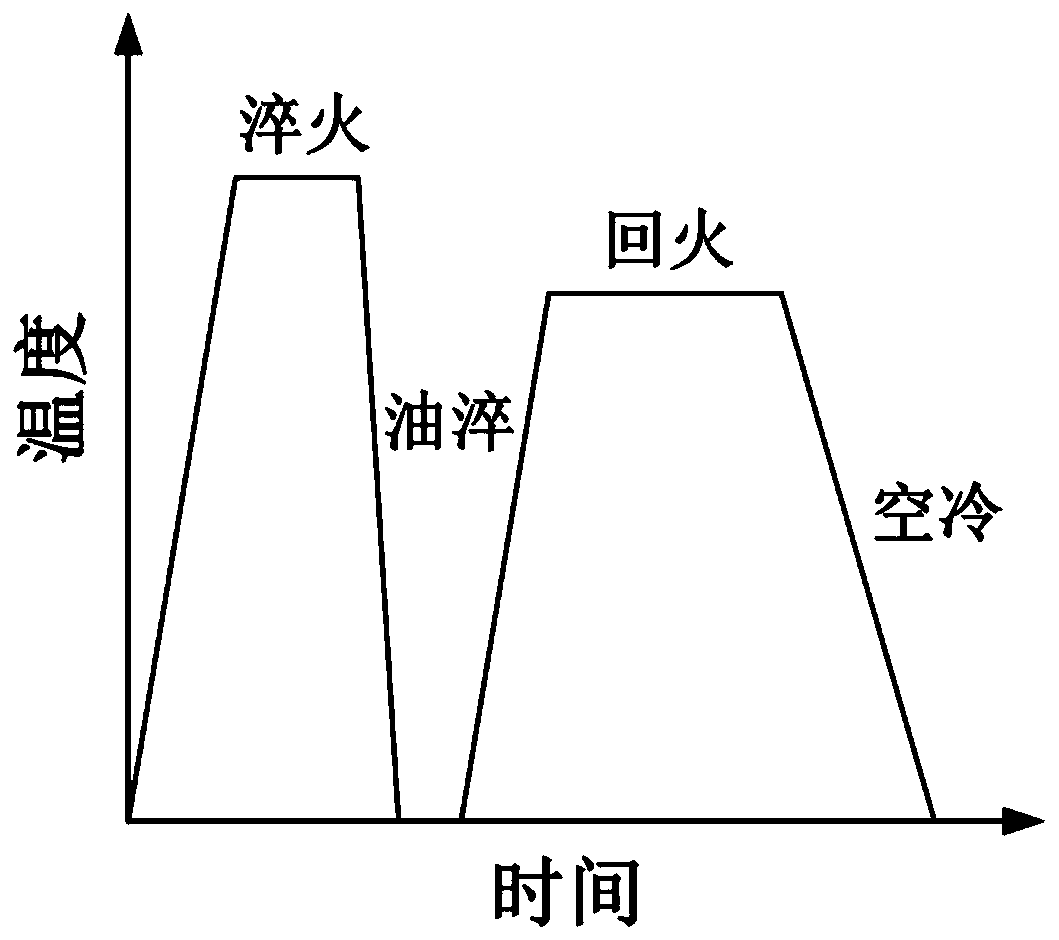

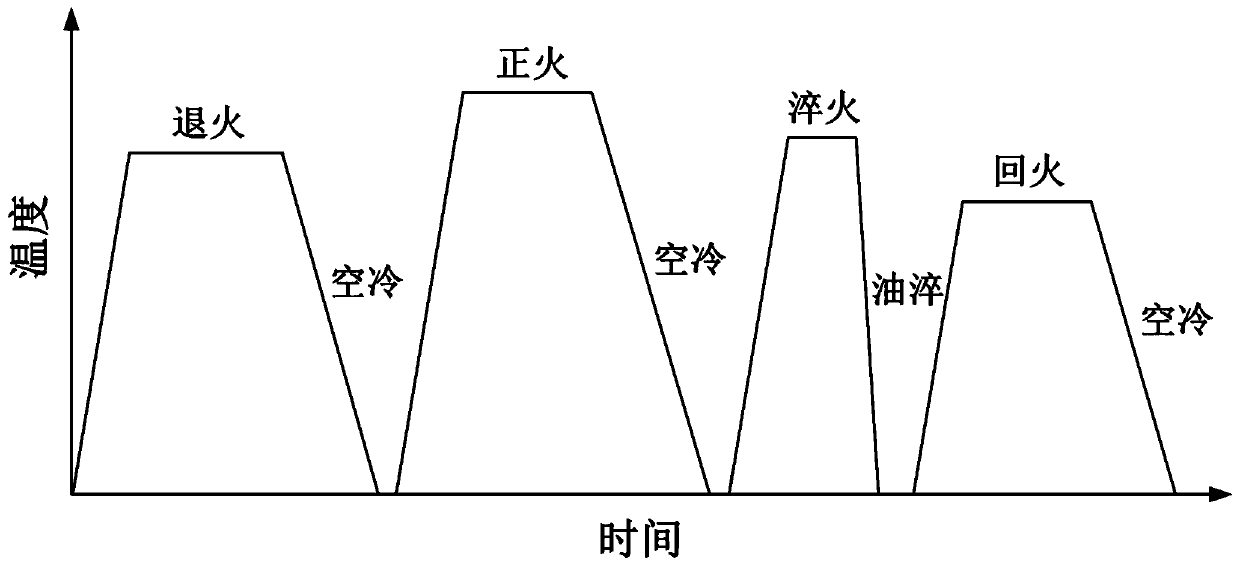

[0062] Embodiment 1 of the present invention provides a kind of cast steel for high-speed train brake disc containing MC and MX type precipitates, and the preparation includes the following steps:

[0063] Step 1: The phenolic resin sand mold is prepared by using a three-dimensional geometric entity, and the part of the sand mold component that contacts the molten steel is painted with zircon powder coating 3 times. After the sand mold is fully and naturally dried, it is baked at 600°C for 4 hours to fully remove moisture, and the solid particles are fully absorbed by negative pressure.

[0064] Step 2: Smelting the raw materials according to the mass percentage ratio of the cast steel chemical composition in Table 1. Vacuum smelting process is adopted, and the smelting r...

Embodiment 2

[0077] Embodiment 2 of the present invention provides a high-speed train cast steel brake disc containing MC and MX precipitates, and its chemical composition is shown in Table 3 in terms of mass percentage.

[0078] Embodiment 2 of the present invention provides a high-speed train cast steel brake disc containing MC and MX type precipitates, comprising the following steps:

[0079] Step 1: Use three-dimensional geometric entities and 3D printing equipment to prepare phenolic resin sand mold components, and paint the parts of the sand mold components in contact with molten steel with zircon powder paint three times. After the sand mold is naturally dried, it is baked at 600-900°C for 40 minutes to fully remove the water in it, and the solid particles are absorbed to form the mold.

[0080] Step 2: Smelting the raw materials according to the mass percentage ratio of the cast steel chemical composition in Table 3. The smelting process of the intermediate frequency furnace expos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com