Thermal processing method improving impact resistance of 13Cr9Mo2Co1NiVNbNB forged piece

A heat treatment method and impact performance technology, applied in the field of heat treatment, can solve the problems of coarse grain size, low impact performance of forgings, instability, etc., and achieve the effect of increasing grain size, good plasticity and toughness, and improving shaping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0023] Implementation Li 1

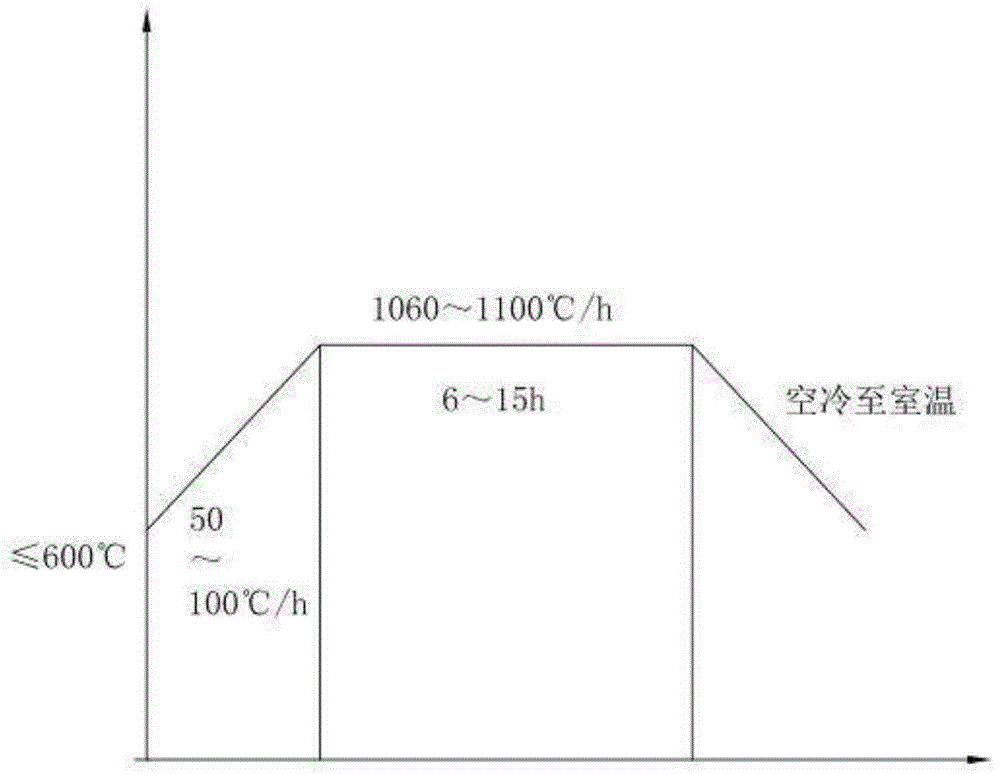

[0024] Such as figure 1 As shown, a heat treatment method for improving the impact performance of 13Cr9Mo2Co1NiVNbNB forgings comprises the following steps:

[0025] The first step: inspect the raw material composition and surface quality, the raw material composition table is shown in the following table:

[0026]

[0027] The above-mentioned materials are 13Cr9Mo2Co1NiVNbNB new materials for ultra-supercritical steam turbines. The new materials are electroslag ingots. The liquid feeding conditions of electroslag ingots are good, and the shrinkage cavity and porosity of the obtained ingots are small. The content of gas and inclusions improves the shaping of the material.

[0028] The second step: forging stage: the raw material is heated and forged to form a forging. The forging process includes steps su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com