High-hardness and high-toughness metal ceramic and preparation method and application thereof

A cermet, high toughness technology, applied in the field of ceramic materials, can solve the problems of high sintering cost and long sintering time, and achieve the effects of improving mechanical properties, inhibiting grain growth, improving red hardness and thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. According to 55wt% TiC 0.7 N 0.3 , 17wt% WC, 7wt% Ni, 7wt% Co, 8wt% Mo 2 C, 6wt% NbC is used for powder mixing, WC-C cemented carbide balls (YG8) with a diameter of 10mm, and an appropriate amount of absolute ethanol are added, and the mixed powder is ball milled on the ball mill for 24 hours by using a planetary ball mill, and the mixed powder ;

[0029] 2. Put the mixed powder in an electric drying oven with a temperature of 100°C for 16 hours to make the powder fully dry.

[0030] 3. Add polyvinyl alcohol as a molding agent to the dried mixed powder for granulation, and improve the fluidity, formability and reduce friction of the powder during the pressing process through granulation.

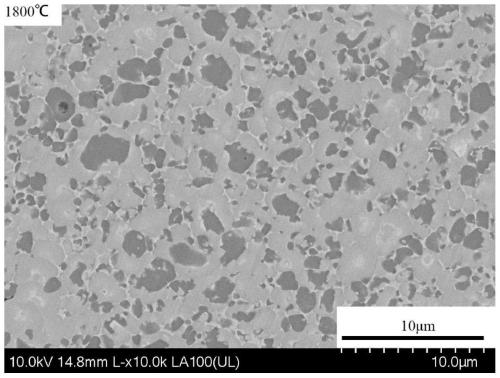

[0031] 4. Put the pressed blank into an SPS mold, sinter at a temperature of 1800° C. and hold it for 3 minutes to obtain a cermet.

[0032] Performance test: The bending strength of the obtained cermet is 2285MPa, the Vickers hardness is 1880HV, and the density is 6.77g / cm 3 ...

Embodiment 2

[0034] 1. According to 60wt% TiC 0.7 N 0.3 , 15wt% WC, 7wt% Ni, 7wt% Co, 7wt% Mo 2 C, 4wt% NbC is used for powder mixing, WC-C cemented carbide balls (YG8) with a diameter of 10mm, and then add an appropriate amount of absolute ethanol, and use a planetary ball mill to mill the mixed powder on the ball mill.

[0035] 2. After mixing for 30 hours, place the mixed powder in an electric drying oven at a temperature of 100°C for 12 hours to dry the powder sufficiently to obtain a mixed powder.

[0036] 3. Add polyvinyl alcohol powder molding agent to the dried mixed powder for granulation. Through granulation to improve the fluidity, formability and reduce the friction of the powder during the pressing process.

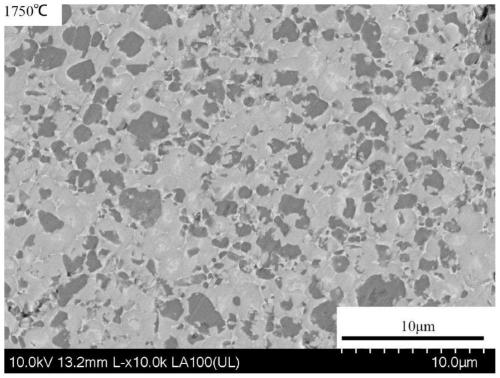

[0037] 4. Put the pressed blank into an SPS mold, sinter at a temperature of 1750° C. and keep it warm for 4 minutes to make a cermet.

[0038] Performance test: The bending strength of the obtained cermet is 2218MPa, the Vickers hardness is 1850HV, and the density is...

Embodiment 3

[0040] 1. According to 60wt% TiC 0.7 N 0.3 , 15wt% WC, 7wt% Ni, 7wt% Co, 7wt% Mo 2 C, 4wt% NbC is used for powder mixing. WC-C cemented carbide balls (YG8) with a diameter of 10mm are added with an appropriate amount of absolute ethanol, and the mixed powder is ball milled and mixed on the ball mill for 30 hours using a planetary ball mill.

[0041] 2. Put the mixed powder in an electric drying oven at a temperature of 100° C. for 12 hours to dry the powder sufficiently to obtain the mixed powder.

[0042] 3. Add polyvinyl alcohol powder molding agent to the dried mixed powder for granulation, and improve the fluidity, formability and reduce the friction of the powder during the pressing process through granulation.

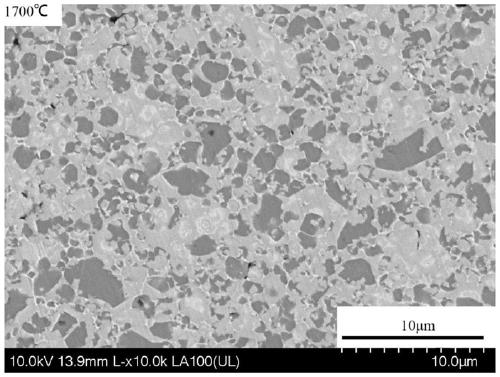

[0043] 4. Put the pressed blank into the SPS mold, sinter at a temperature of 1700°C and keep it warm for 5 minutes to make a cermet.

[0044]Performance test: The bending strength of the obtained cermet is 2182MPa, the Vickers hardness is 1900HV, and the dens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com