Machining method for 7-series aluminum alloy thick plates

A processing method and technology for aluminum alloy plates, applied in the processing of 7-series aluminum alloy thick plates, and the processing field of 7-series aluminum alloy thick plates, can solve problems such as sharp increase in production costs, achieve excellent strength and fracture toughness, and improve alloy strength , Improve the effect of thermoplasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

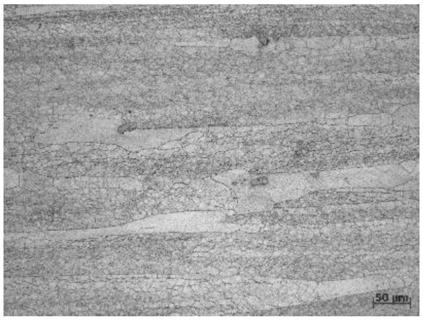

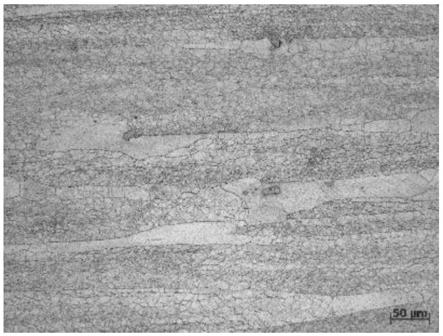

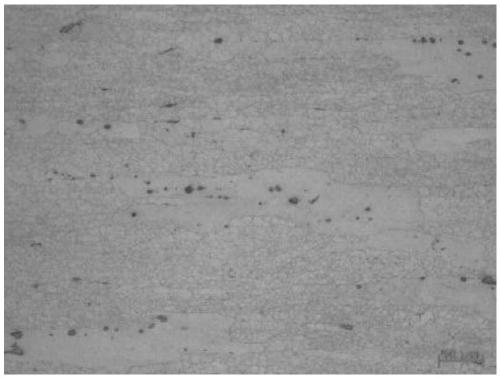

Image

Examples

Embodiment 1

[0033] A processing method for a 7-series aluminum alloy thick plate, comprising the steps of:

[0034] A. Ingredients: aluminum alloy ingots are made according to the following mass percentages:

[0035] element

Si

Fe

Cu

Mg

Zn

Ti

Zr

Al

content

0.2

0.25

1.2

1.2

5.5

0.02

0.13

margin

[0036] Single impurity ≤ 0.05%, total impurity ≤ 0.15%;

[0037] B. Melting: Put the prepared aluminum alloy raw materials in a melting furnace to melt into liquid aluminum alloy, and melt and cast the liquid aluminum alloy into aluminum alloy ingot. The melting temperature of the liquid aluminum alloy is 700°C. When the aluminum alloy raw material is 30% melted into molten aluminum, the electromagnetic stirring is turned on. Composition, converter to holding furnace for in-furnace refining. After the composition is qualified, the melt is left to stand for 30 minutes, and then the gas and slag in the melt are removed at ...

Embodiment 2

[0045] A processing method for a 7-series aluminum alloy thick plate, comprising the steps of:

[0046] A. Ingredients: aluminum alloy ingots are made according to the following mass percentages:

[0047] element

Si

Fe

Cu

Mg

Zn

Ti

Zr

Al

content

0.12

0.20

2.0

1.7

6.2

0.08

0.07

margin

[0048] Single impurity ≤ 0.05%, total impurity ≤ 0.15%;

[0049] B. Melting: Put the prepared aluminum alloy raw materials in a melting furnace to melt into liquid aluminum alloy, and melt and cast the liquid aluminum alloy into aluminum alloy ingot. The melting temperature of the liquid aluminum alloy is 760°C. When the aluminum alloy raw material is 30% melted into molten aluminum, the electromagnetic stirring is turned on. Composition, converter to holding furnace for in-furnace refining. After the composition is qualified, the melt is left to stand for 30 minutes, and then the gas and slag in the melt are removed at...

Embodiment 3

[0057] A processing method for a 7-series aluminum alloy thick plate, comprising the steps of:

[0058] A. Ingredients: aluminum alloy ingots are made according to the following mass percentages:

[0059] element

Si

Fe

Cu

Mg

Zn

Ti

Zr

Al

content

0.2

0.25

1.7

1.5

6.0

0.12

0.03

margin

[0060] Single impurity ≤ 0.05%, total impurity ≤ 0.15%;

[0061] B. Melting: Put the prepared aluminum alloy raw materials in a melting furnace to melt into liquid aluminum alloy, and melt and cast the liquid aluminum alloy into aluminum alloy ingot. The smelting temperature of the liquid aluminum alloy is 760°C. When 40% of the aluminum alloy raw material is melted into molten aluminum, the electromagnetic stirring is turned on. Composition, converter to holding furnace for in-furnace refining. After the composition is qualified, the melt is left to stand for 80 minutes, and then the gas and slag in the melt are removed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com