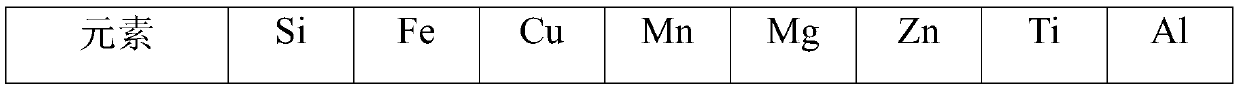

Patents

Literature

57results about How to "Reduced Quench Sensitivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

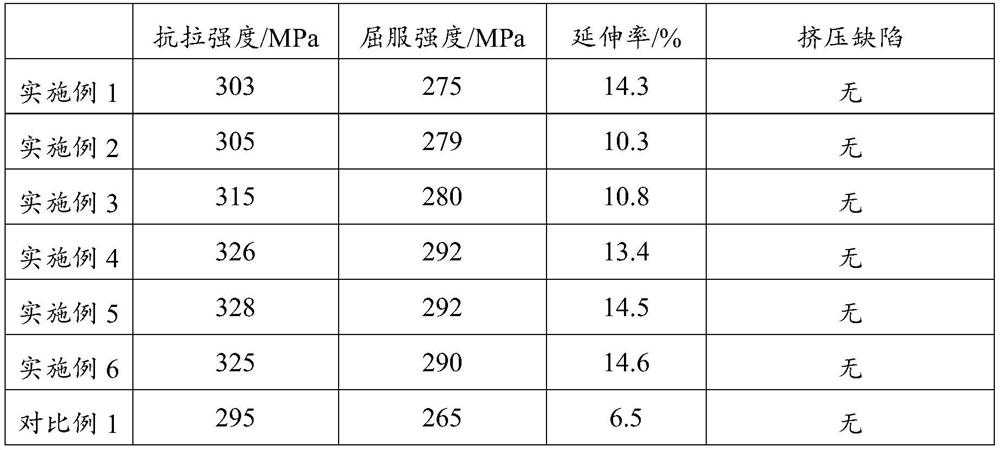

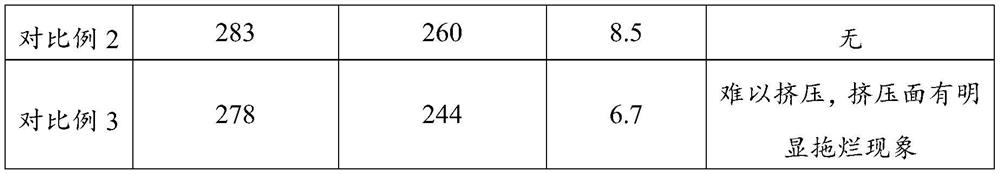

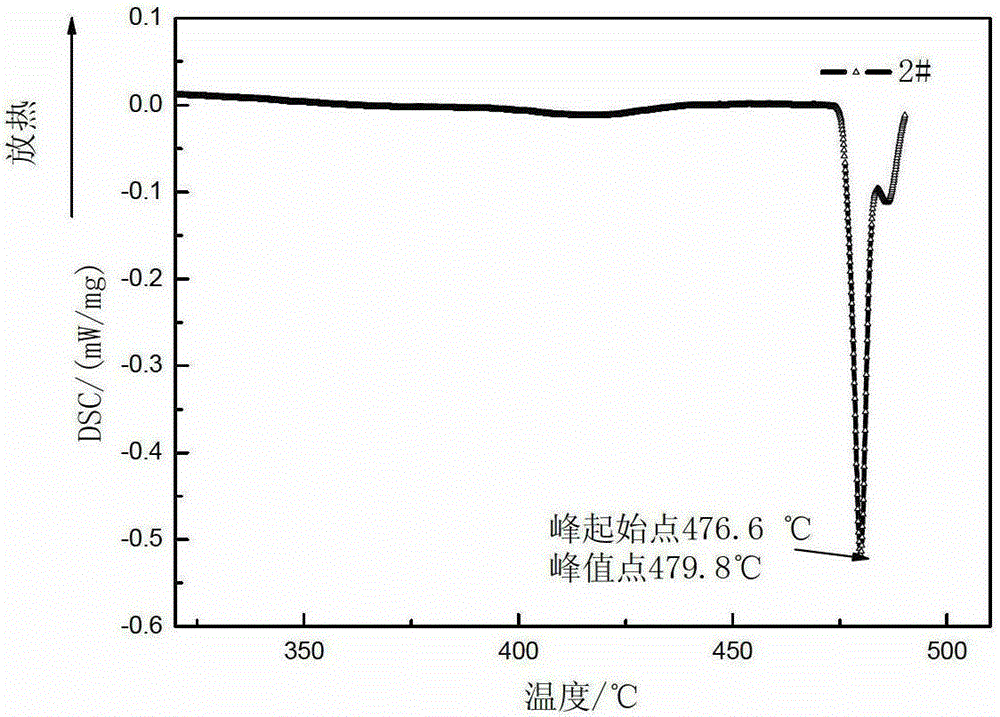

Aluminium alloy profile for building template, and preparation method thereof

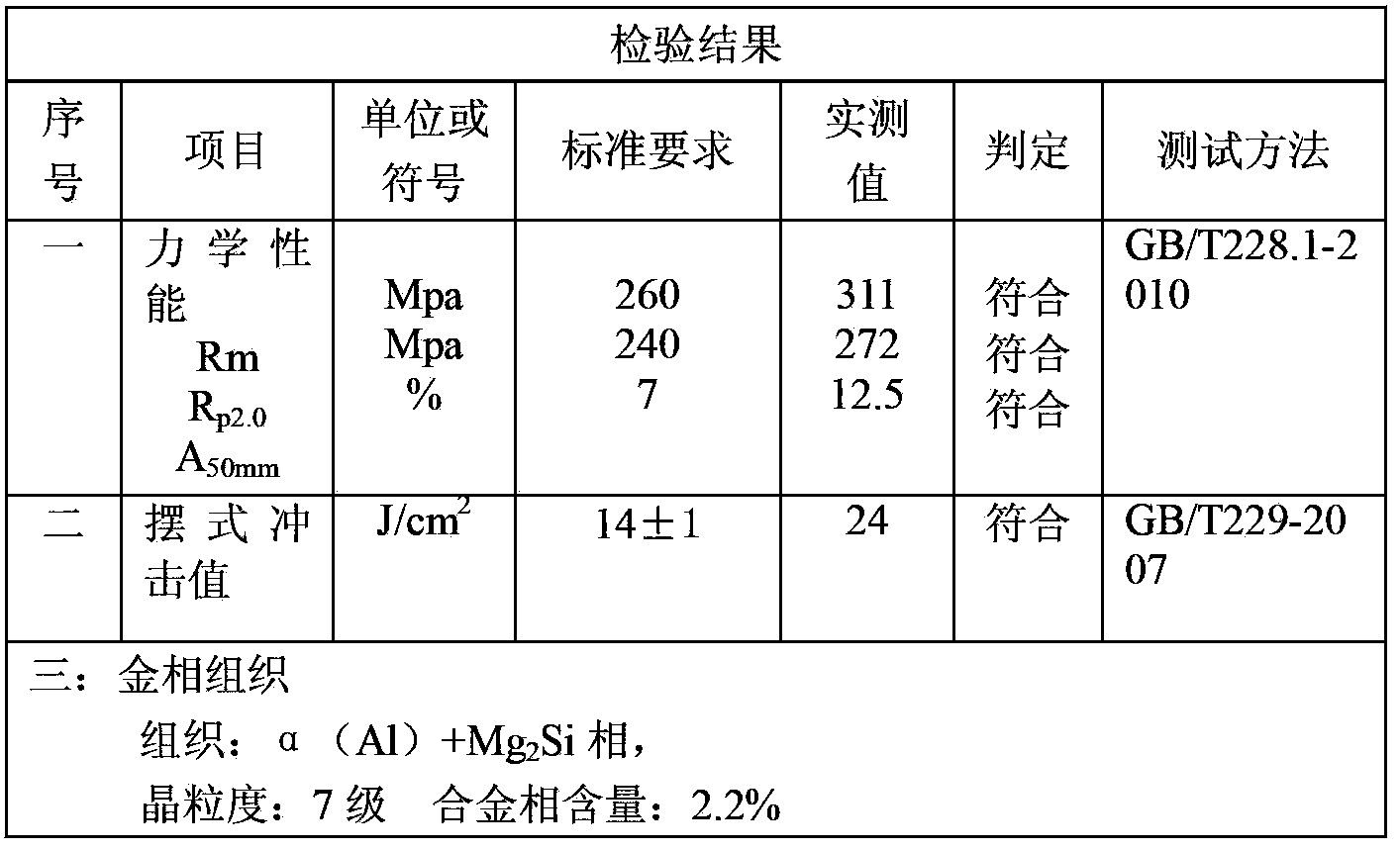

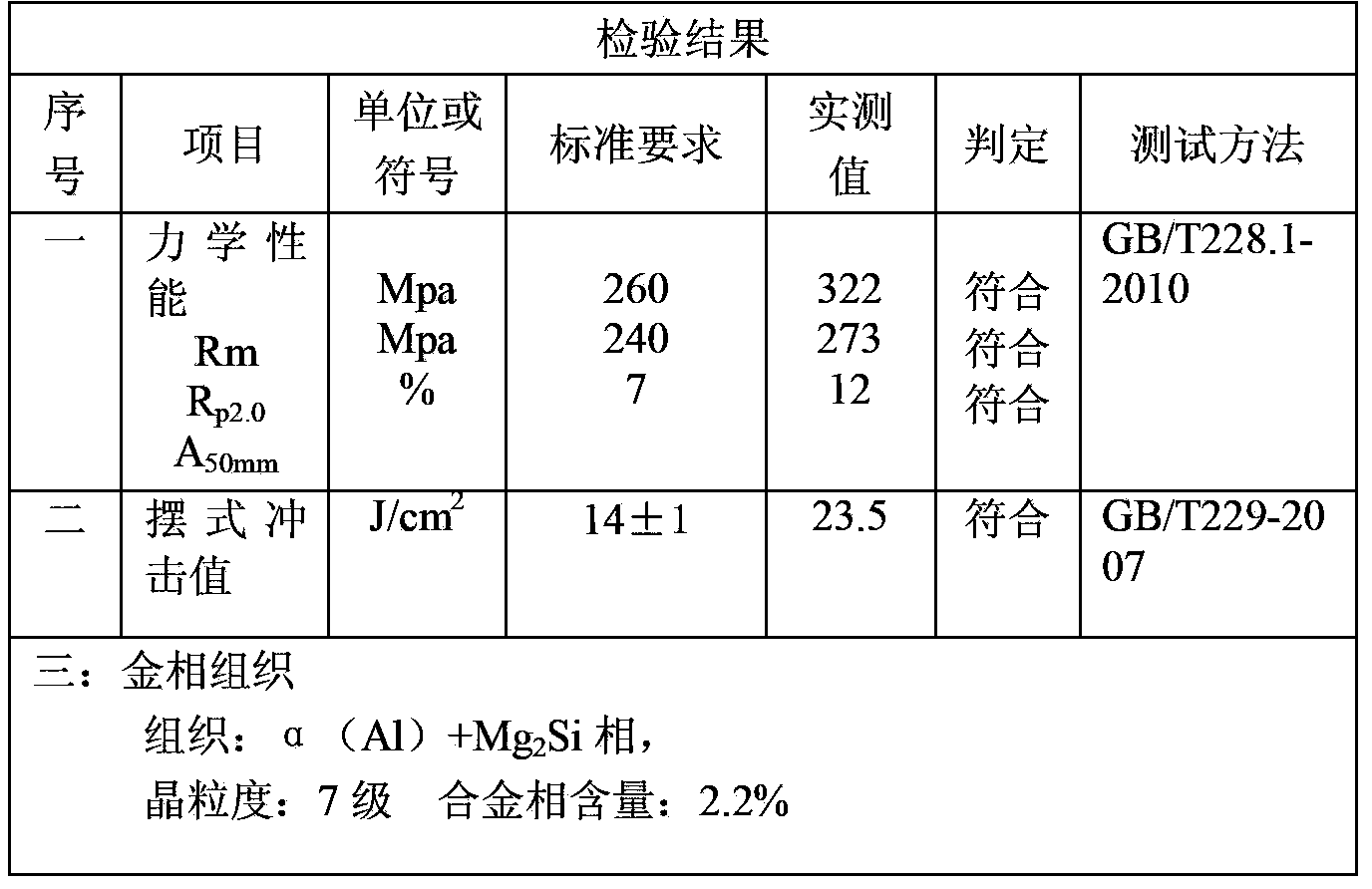

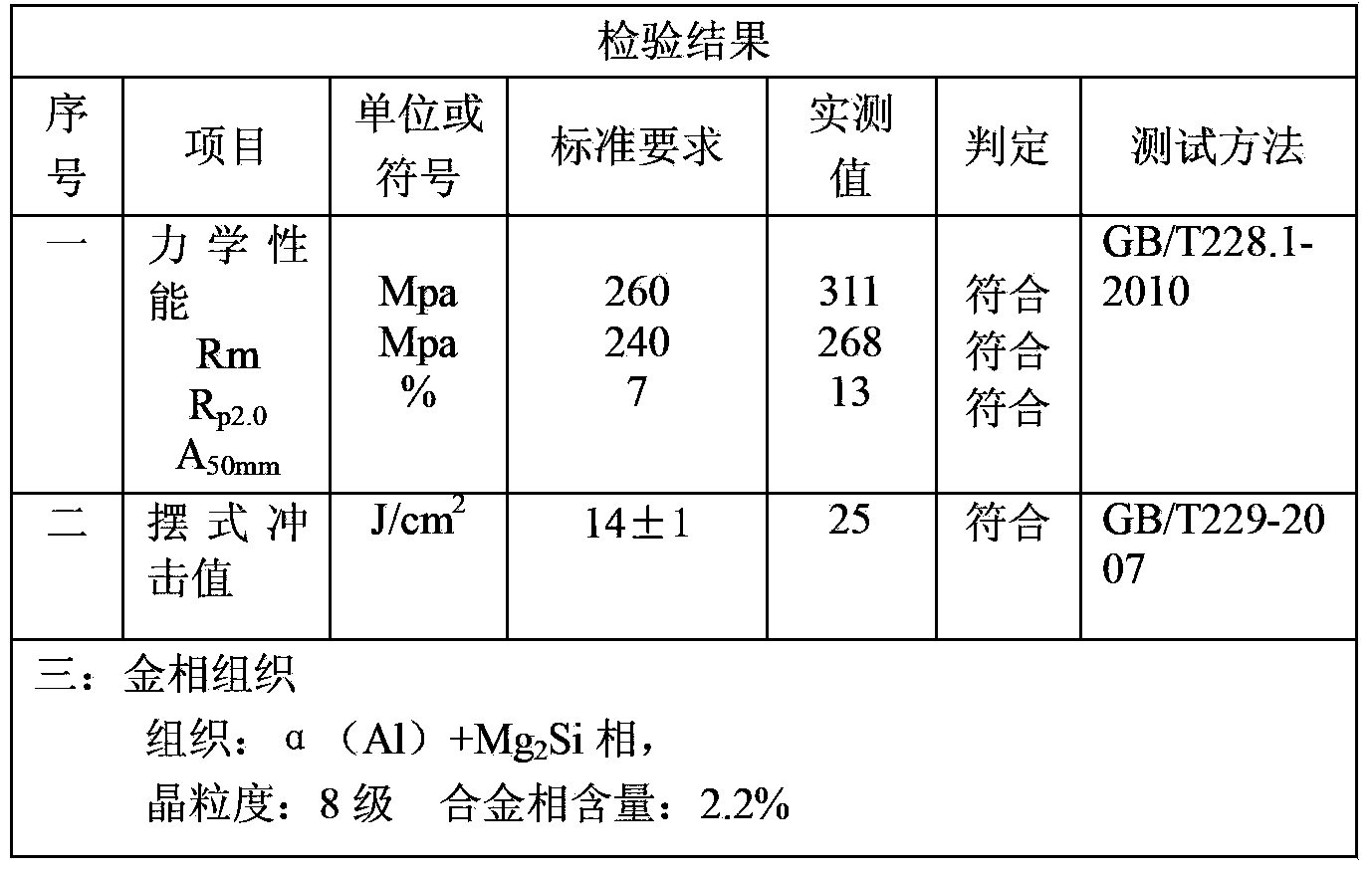

The invention discloses an aluminium alloy profile for a building template, and a preparation method thereof. The aluminium alloy profile comprises the following components in percentage by weight: 0.85-0.95 percent of magnesium, 0.06-0.65 percent of silicone, 0.15-0.20 percent of copper, 0.05-0.08 percent of manganese, 0.03-0.05 percent of zirconium, 0.04-0.06 percent of chromium, 0.008-0.012 percent of titanium, 0-0.2 percent of iron, 0-0.10 percent of zinc and the balance of aluminium. The aluminium alloy profile provided by the invention has the advantages that the tensile strength is more than 300 MPa, the yield strength is more than 260 MPa, the breakage elongation percentage is more than 12 percent, the tenacity, the weldability and the corrosion resistance are obviously improved compared with that of an original 6061 alloy, the pendulum impact value is more than 20 J / cm<2>, the welding coefficient is not less than 0.6, smaller quench sensitivity is provided, and critical quenching speed is dropped from 10 DEG C / S of the original alloy to 7 DEG C / S; during the processing of the aluminium alloy profile, air cooling is adopted to process an extrusion outlet with the temperature of 450 DEG C in a high-temperature segment as well as an extrusion outlet with the temperature of being smaller than or equal to 25 DEG C in a low-temperature segment, while a moderate-temperature segment, namely a quench sensitive area with the temperature of 450-250 DEG C utilizes water mist to replace direct water-cooling, so that the difficulty for controlling cross section deformation of the profile in the production field is greatly reduced.

Owner:GUANGDONG WEIYE ALUMINUM FACTORY GRP

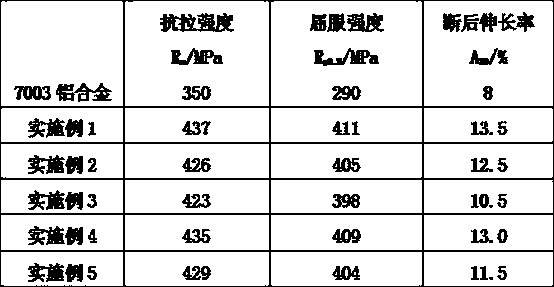

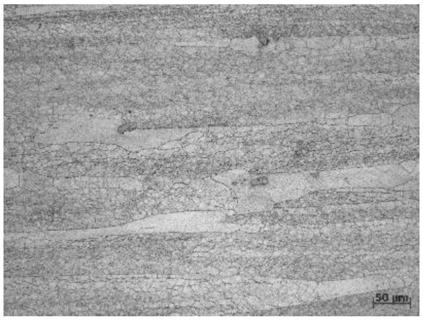

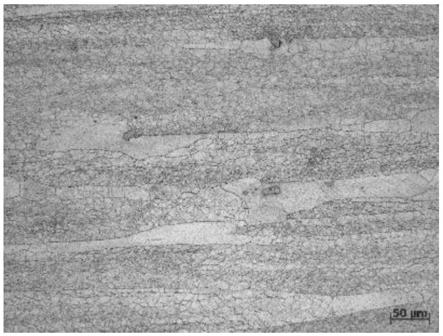

Aluminium alloy used for automobile anti-collision beam, and manufacturing method for product thereof

The invention relates to an aluminum alloy used for an automobile anti-collision beam, and a manufacturing method for a product thereof. The aluminum alloy comprises, by mass, 6.50%-6.80% of Zn, 0.90%-1.10% of Mg, 0.2-0.30% of Cu, 0.15%-0.20% of Zr, 0.10%-0.15% of Mn, 0.01-0.02% of Ti, less than or equal to 0.05% of Cr, less than or equal to 0.25% of Fe, less than or equal to 0.20% of Si, and the balance being Al. The tensile strength of the automobile anti-collision beam obtained by the aluminum alloy can reach over 420 MPa; yield strength can be stably controlled between 390 MPa and 420 MPa; percentage elongation after fracture is larger than 10%; and weldability and corrosion resistance are increased to different degrees than an automobile anti-collision beam obtained by adopting an original alloy system. The aluminum alloy can meet anti-collision and energy absorption requirements of the automobile, and retains the low quenching sensitivity of 7003 alloy, and can be used for producing high performance automobile anti-collision beams.

Owner:GUANGDONG HAOMEI ALUMINUM

Al-Mg-Si-Cu alloy and preparation method thereof

The invention discloses Al-Mg-Si-Cu alloy and a preparation method thereof. The alloy consists of the following components in percentage by mass: 0.4 to 0.6 percent of Mg, 0.45 to 0.6 percent of Si, 0.3 to 0.8 percent of Cu, 0.1 to 0.2 percent of Mn, 0.1 to 0.7 percent of Zn, 0 to 0.1 percent of Cr, 0.01 to 0.02 percent of Ti, not more than 0.3 percent of Fe, not more than 0.1 percent of other impurities (total content), and the balance of Al. The alloy has the characteristics of the reduction of deformation resistance, improves extrusion speed and production efficiency, and can improve the yield under the condition of constant productivity. In addition, the alloy does not need an extra water quenching process, and can reduce investment cost of equipment by on-line air quenching after hot extrusion.

Owner:CENT SOUTH UNIV

Aluminium alloy section bar for structural engineering, and preparation method thereof

The invention discloses an aluminium alloy section bar for structural engineering, and a preparation method thereof. The aluminium alloy section bar comprises the following compositions by weight percent: 0.50-0.60% of magnesium, 0.65-0.75% of silicon, 0-0.25% of manganese, 0-0.10% of chromium, 0.005-0.009% of titanium, 0-0.30% of iron, 0-0.10% of zinc, 0-0.10% of copper, and the balance aluminium. Compared with 6063 alloy and 6063A alloy, the aluminium alloy section bar of the invention has tensile strength of 290 MPa or more, yield strength of 240 MPa or more, and elongation at break of 8% or more. 6061 alloy is high in quench sensitivity, and quenching and water cooling must be employed for guarantee of obtaining demanded mechanical properties during production, and therefore the extruded aluminium section bar is serious in deformation; compared with 6061 alloy, the alloy material of the invention is smaller in quench sensitivity, and by using strong wind cooling or mist cooling, the demanded properties are obtained when the section bar is processed; and the aluminium alloy section bar of the invention is good in toughness, and has a pendulum impact value of 20 J / cm<2> or more.

Owner:GUANGDONG WEIYE ALUMINUM FACTORY GRP

Machining method for 7-series aluminum alloy thick plates

The invention belongs to the technical field of aluminum alloy production, and relates to a machining method for 7-series aluminum alloy thick plates. Aluminum alloy ingots comprise the following components in percentage by mass: Si not more than 0.20%, Fe not more than 0.25%, 1.2-2.1% of Cu, 1.2-2.2% of Mg, 5.0-7.0% of Zn, 0.02-0.15% of Ti, 0.02-0.15% of Zr, Ti+Zr not more than 0.15%, single impurity not more than 0.05%, total impurity not more than 0.15%, and the balance of Al. The machining method for the aluminum alloy thick plates adopts a mode of multi-pass hot rolling, and adopts double-stage solid solution and double-stage aging to enable the finally prepared 7-series aluminum alloy thick plates to achieve excellent strength and rupture toughness.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

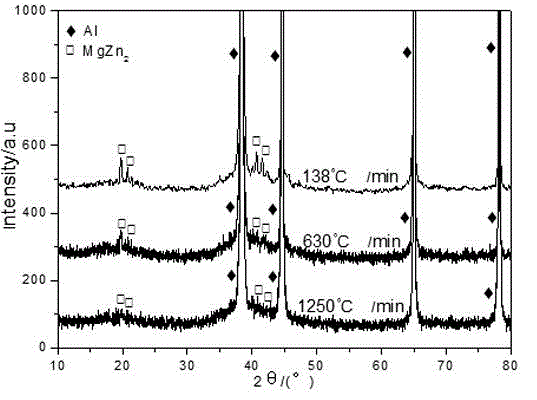

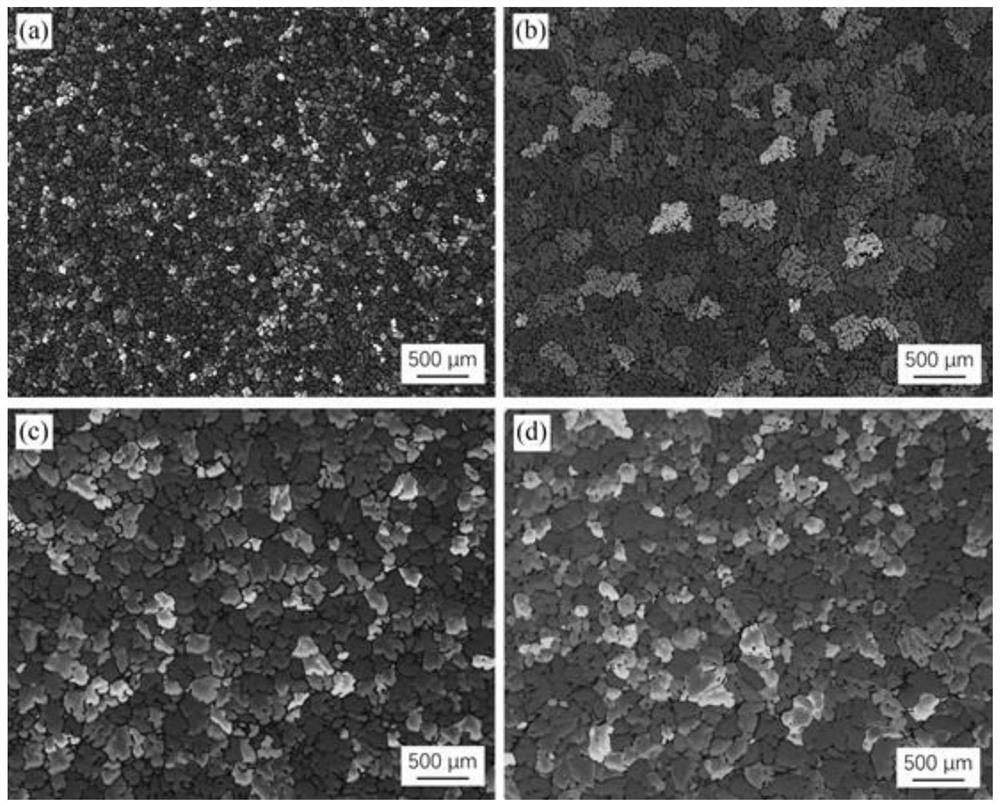

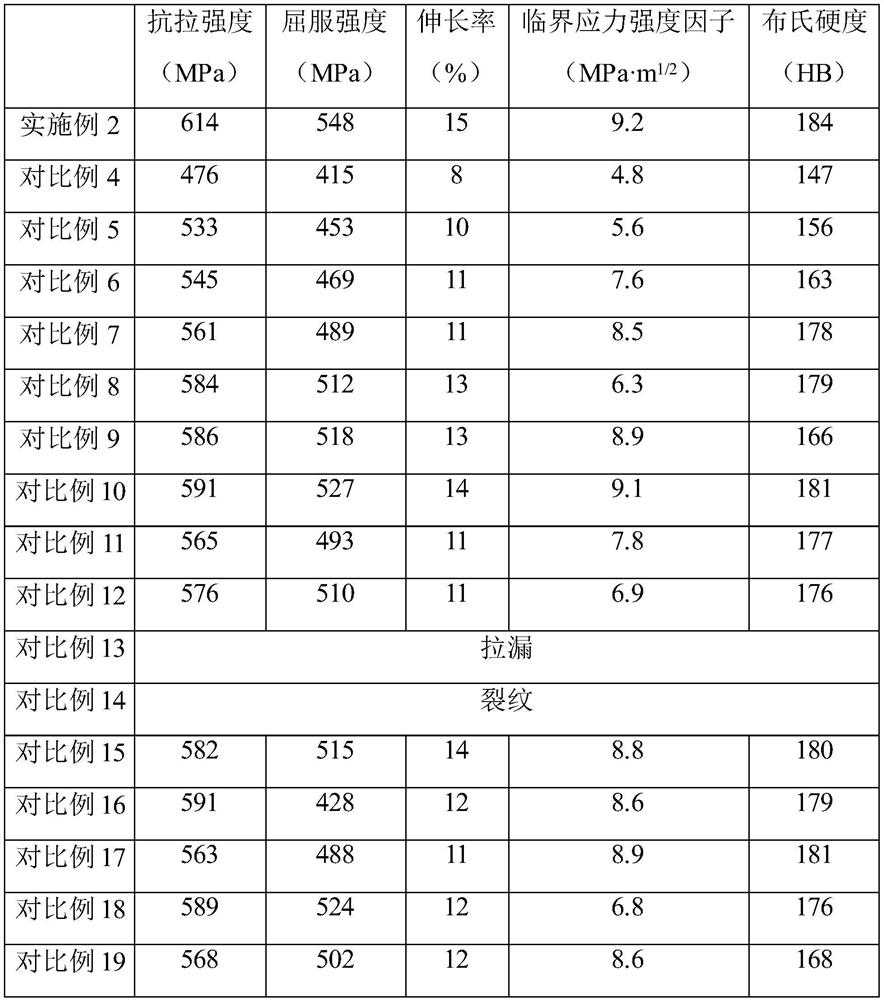

600 MPa level low-quenching-sensitivity ultrahigh strength aluminum alloy and preparing method thereof

The invention discloses a 600 MPa level low-quenching-sensitivity ultrahigh strength aluminum alloy and a preparing method thereof. The content and weight percent of Zn, Mg, Cu, Zr, Mn, Cr and Ti in the aluminum alloy are adjusted, and the three-level homogenizing treatment technology and the peak value aging or double-level aging treatment technology is adopted in the preparing technology. By adoption of the novel aluminum alloy prepared through the method, the comprehensive performance of the novel aluminum alloy is superior to AA7085.

Owner:FOSHAN UNIVERSITY

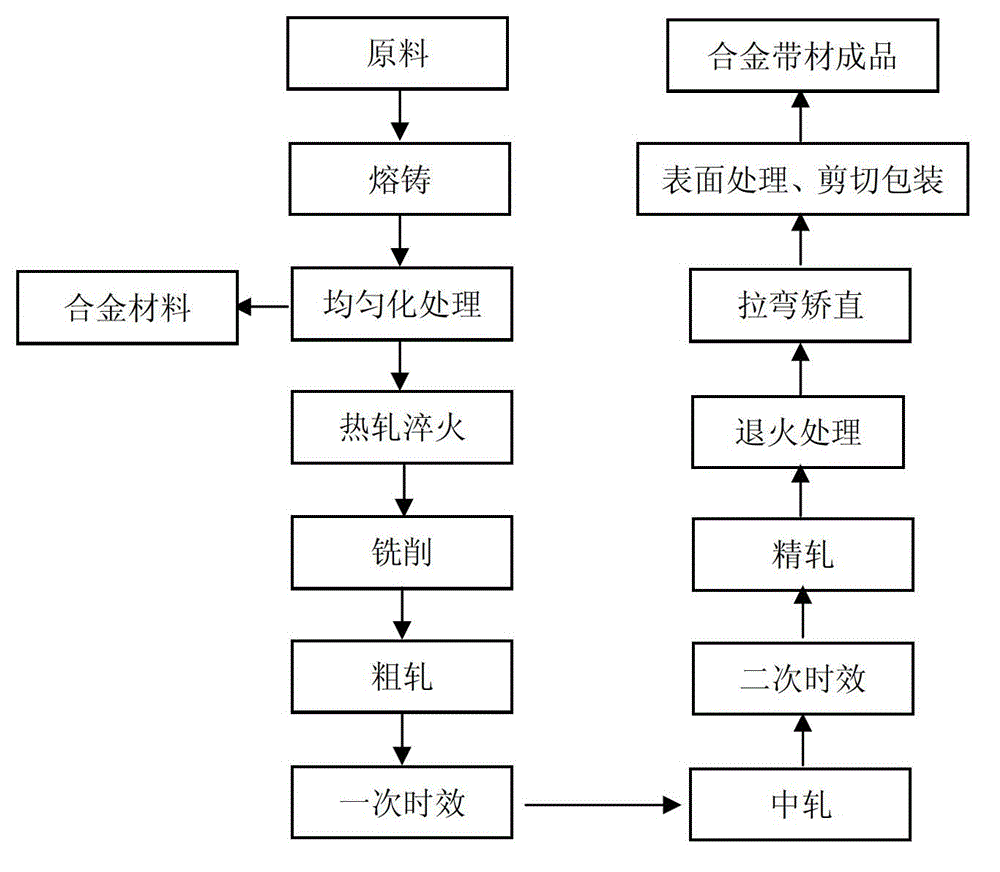

CuNiSiMg alloy material and preparation method thereof as well as method for preparing strip using alloy material

The invention discloses a CuNiSiMg alloy material which comprises the following components in percentage by weight: 1.40-1.80% of nickel, 0.33-0.43% of silicon, 0.05-0.10% of magnesium, 0.02-0.05% of phosphorus, 0.10-0.50% of zinc, and the balance of copper and inevitable impurities. The CuNiSiMg alloy material disclosed by the invention and the strip formed by the alloy material have the strength not less than 650 MPa, conductivity not less than 55%IACS, and softening temperature not less than 400 DEG C, and have the performances of high strength, high conductivity and high temperature resistance.

Owner:TONGLING JINVI COPPER CORP +1

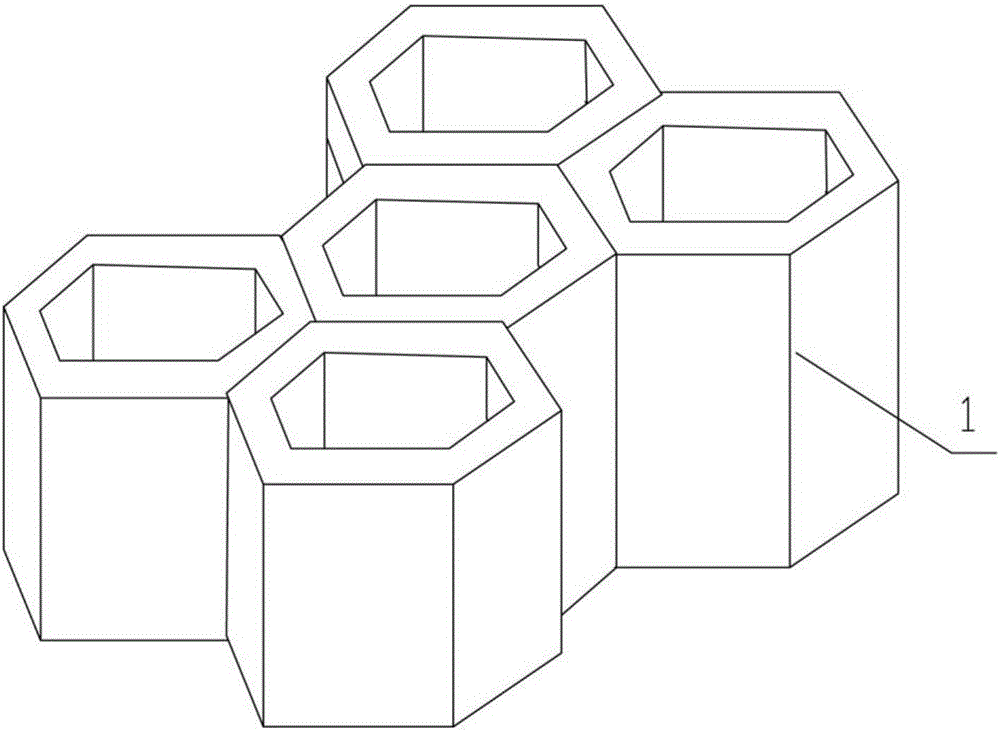

Energy absorption aluminum profile for railway vehicle body and manufacturing method thereof

InactiveCN104988366ATo achieve the effect of densificationHigh strengthRailway wheel guards/bumpersEnergy absorptionCrystal structure

The invention relates to an energy absorption aluminum profile for a railway vehicle body and a manufacturing method thereof. The energy absorption aluminum profile comprises, by mass, 0.5%-0.7% of Si, 0-0.15% of Fe, 0.4%-0.6% of Mg, 0.2%-0.3% of Mn, 0-0.01% of Cu, 0.1%-0.2% of Cr, 0-0.01% of Zn, 0.04%-0.06% of Ti, 0.04%-0.1% of V, and the balance of Al. By adding the 0.04%-0.1% of V into the energy absorption aluminum profile, the columnar crystal structure of a cast ingot can be reduced, the cast structure can be refined, the effects of restraining recrystallization of deformed grains and growth of recrystallized grains can be achieved in the heat treatment and heat deformation processes of the alloy, the purpose of refining the profile structure is achieved, the strength, toughness, ductility and corrosion resistance of the profile are improved, and the energy absorption property of the profile is significantly improved.

Owner:龙口市丛林铝材有限公司

Al-Mg-Zn alloy

The invention discloses Al-Mg-Zn aluminum alloy. The Al-Mg-Zn aluminum alloy comprises 6.0-10.0% of Mg, 3.0-5.0% of Zn, 2.0% of Cu and lt, 0.5% of Mn and lt, 0.3% of Fe and lt, 0.3% of Si and lt, less than or equal to 0.5% of each of Zn, S and c or less than or equal to 0.8% of the compound of the Zn, S and c, less than or equal to 0.05% of each of the other impurity elements, and rest of Al, wherein the total weight of the impurities is less than or equal to 0.2%, and the weight ratio of Zn to Mg is 0.48-0.62. The Al-Mg-Zn alloy has high intensity, good plasticity, low density and low quenching sensitivity. The intensity of the material (component) prepared by the alloy is larger than or equal to 500 Mpa under T6, the room temperature elongation percentage of the material is larger than or equal to 10%, and the density is lower than or equal to 2.7 g / cm3.

Owner:CENT SOUTH UNIV

Aluminum alloy extrusion material for subway rigid suspension bus bar

The invention belongs to the field of metal materials, and particularly relates to a formula and processing technique of an aluminum alloy rigid suspension bus bar extrusion material for urban rail transportation. The aluminum alloy comprises the following elements in percentage by weight: 0.45-0.50% of magnesium, 0.50-0.55% of silicon, 0.10-0.25% of iron, at most 0.05% of copper, at most 0.01% of manganese, at most 0.01% of chrome, at most 0.01% of titanium, at most 0.01% of vanadium, at most 0.10% of zinc, at most 0.10% of other impurities (at most 0.03% for each impurity) and the balance of aluminum, totaling 100%. The preparation method comprises the following steps: melting, stirring, component regulation, hot top casting, heat treatment, ingot blank sawing, extrusion molding, cooling and the like. The aluminum alloy provided by the invention has the advantages of high strength, favorable toughness, favorable conductivity, low quench sensitivity, low production cost and the like, and can be used for large-scale production.

Owner:GUANGDONG XINGFA ALUMINUM HENAN

Super-strength aluminum alloy section

The invention discloses a super-strength aluminum alloy section. The super-strength aluminum alloy section comprises, by mass, 6%-10% of zinc, 0.1%-3% of copper, 1%-3% of magnesium, 0.5%-1% of silicon, 0.3%-0.6% of manganese, 0.03%-0.05% of scandium, 0.02%-0.04% of zirconium, 0.02%-0.04% of erbium, 0.03%-0.05% of lanthanum, 0.01%-0.03% of yttrium, 0.01%-0.03% of cerium, 0.03%-0.06% of titanium, 0.08%-0.1% of boron and the balance aluminum. By means of the super-strength aluminum alloy section, the comprehensive mechanical property of the aluminum alloy section is improved while it is guaranteed that an aluminum alloy has the super strength.

Owner:ANHUI LANT ALUMINUM

Ultrahigh-strength high-hardenability Al, Zn, Mg and Cu alloy

Ultrahigh-strength high-hardenability Al, Zn, Mg and Cu alloy belongs to the technical field of metal alloy. The ultrahigh-strength high-hardenability Al, Zn, Mg and Cu alloy comprises 10.0% of Al, 1.6% of Zn, 1.4% of Mg, 0.12% of Cu and Zr. Hardening depth of the alloy is increased by 32%, while hardening degree is lowered by 3.3%. Improvement action of alloy microelements on hardenability is not obvious. Therefore, quenching sensitivity of the alloy is lowered by increasing Zn-to-Mg ratio and controlling copper content, while cost is not evidently increased.

Owner:BEIJING UNIV OF TECH

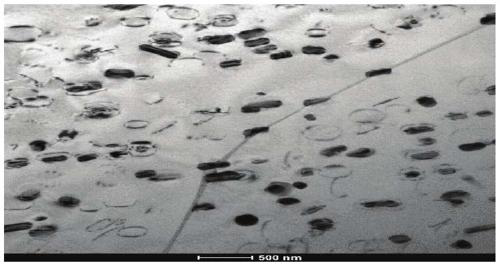

Method for improving intergranular corrosion performance of Al-Cu-Mg aluminium alloy

ActiveCN109825748AEliminate the disadvantages of dispersed phase precipitationEliminate the disadvantages of precipitation5005 aluminium alloyIngot

The invention provides a method for improving the intergranular corrosion performance of an Al-Cu-Mg aluminium alloy. The method includes the steps that (1) an Al-Cu-Mg aluminium alloy ingot is cast;and (2) homogenizing treatment is conducted on the cast ingot. According to the technical scheme, the problem of dispersed phase precipitation is overcome by homogenizing heat treatment, and a fine, uniform and dispersed AlCuMn phase can be precipitated in a matrix within short homogenizing time; and by low temperature short-time treatment, the dendritic structure in the microstructure is eliminated, meanwhile a small amount of coarse phases remaining in the microstructure are controlled, the aluminum matrix is in the state of undersaturation in solid solution, the quenching sensitivity of materials is reduced, the precipitation of nanoscale second phases at the material grain boundary is inhibited after solid solution, and the effects of improving the production efficiency and improving the intergranular corrosion resistance of a product are obtained. The method is suitable for industrial production of large cast ingots, has good operability, can shorten the time of homogenizing heattreatment and saves energy consumption of heat treatment.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD +1

Modified 6063T6 aluminum alloy and processing method thereof

The invention discloses a modified 6063T6 aluminum alloy and a processing method thereof. The total weight of the aluminum alloy is improved, and the modified aluminum alloy is prepared from the following chemical components: 0.45-0.50% of Si, 0.65-0.70% of Mg, 0.02-0.10% of Cu, less than or equal to 0.23% of Fe, less than 0.10% of Mn, less than 0.10% of Cr, less than 0.01% of Zn, less than 0.1% of Ti, and the balance Al. The modified 6063T6 aluminum alloy has high strength, high hardness and high elongation, has the mechanical property reaching 6061T6 standard, and can replace 6061T6 aluminumalloy, thereby reducing the production cost.

Owner:湖南海铝汽车工业有限公司

CuZnNiSi alloy, preparation method thereof and method for preparing strips using the same

The invention discloses CuZnNiSi alloy, a preparation method thereof and a method for preparing strips using the same. The method comprises the following steps: weighting 10-20% of zinc, 0.462-1.89% of nickel, wherein silicon accounts for 0.11-0.42% of the total amount of copper silicon alloy and the balance is copper; placing copper and nickel into an intermediate frequency induction melting furnace, heating to 1250-1300 DEG C and melting; after melting, adding zinc, copper silicon alloy, uniformly stirring up and casting; obtaining CuZnNiSi alloy using homogenization processing. The CuZnNiSi alloy strips can be obtained by hot rolling, quenching, rolling, annealing and tension-leveling. The CuZnNiSi alloy is high in strength and conductivity.

Owner:CHANGSHA ZHONGGONG NEW MATERIAL

Ultra-thick high-strength aluminum alloy plate and preparation method thereof

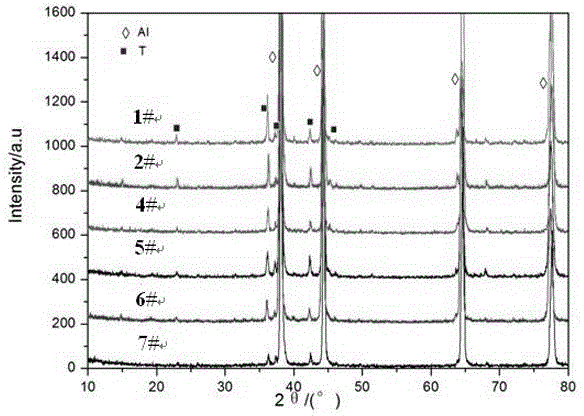

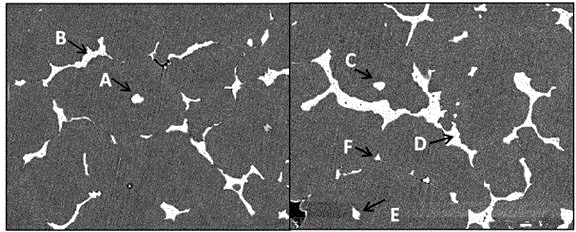

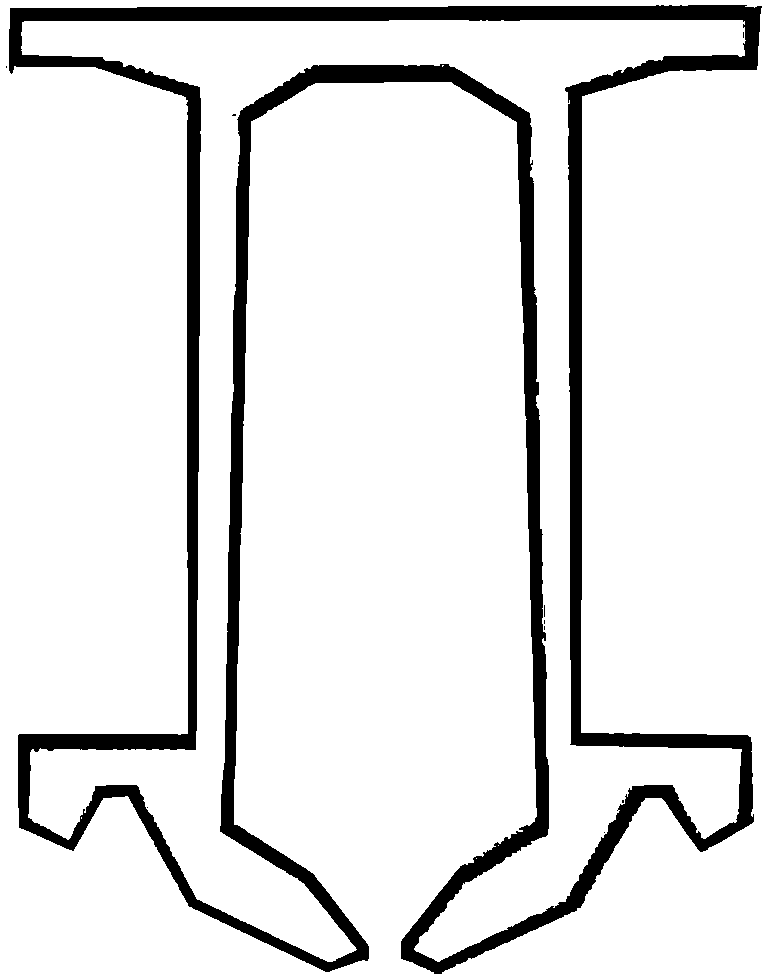

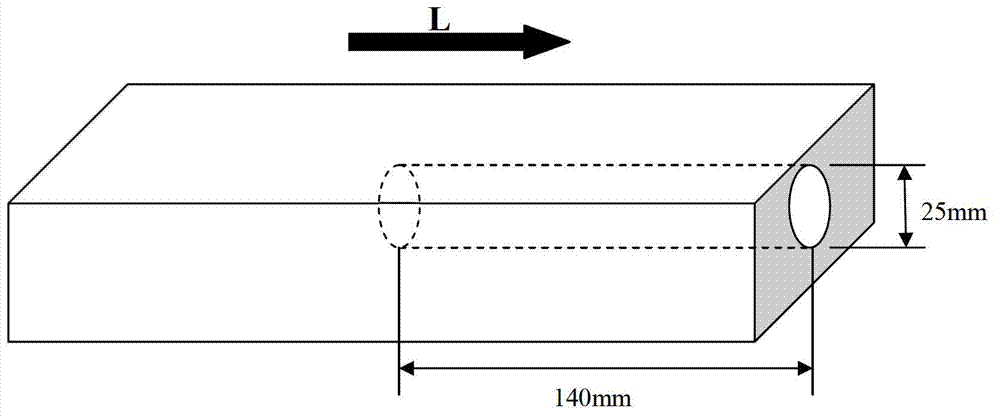

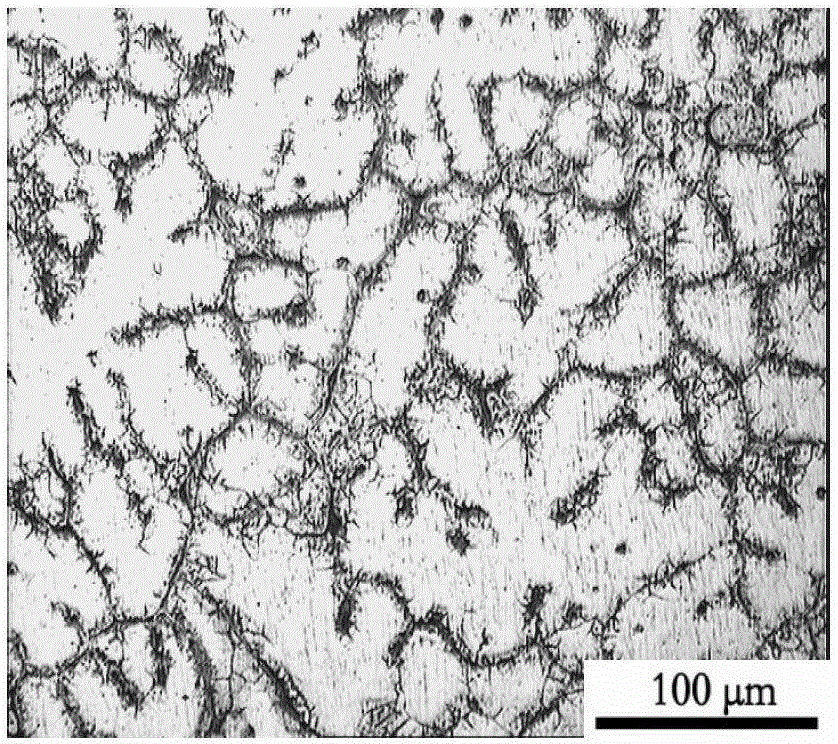

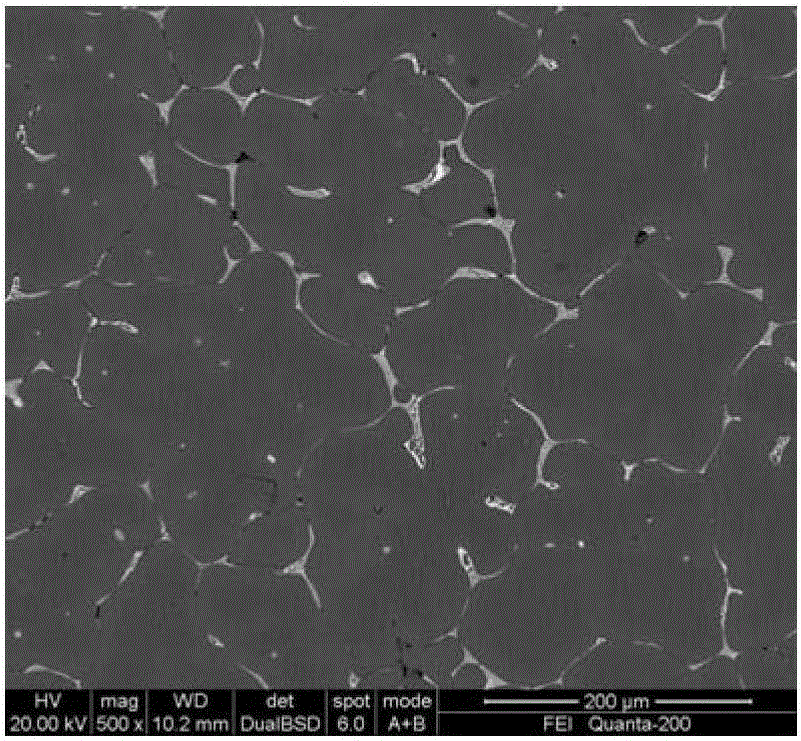

ActiveCN109022965AReduced Quench SensitivityReduced mechanical properties Corrosion resistanceSolution treatmentUltimate tensile strength

The invention belongs to the field of production of aluminum alloy sections, and relates to an ultra-thick high-strength aluminum alloy plate and a preparation method thereof. The ultra-thick high-strength aluminum alloy plate comprises, by mass, 7.85-8.3% of Zn, 2.07-2.10% of Mg, 1.66-1.69% of Cu, 0.035-0.04% of Si, 0.05-0.065% of Fe, 0.025% of Ti, no more than 0.15% of impurities and the balanceAl, wherein the content of each impurity is no more than 0.05%. Casting, homogenizing, extruding, solution treatment, stretcher straightening and multi-stage low-temperature aging treatment are sequentially conducted on high-strength aluminum alloy, and the Mg content, the Cu content and the process parameters in the preparation process are accurately controlled, so that the quenching sensitivityof the prepared aluminum alloy plate is greatly reduced, the mechanical strength and corrosion resistance of the aluminum alloy plate are improved, sections prepared from the aluminum alloy plate canreach the industrial standard, and the product forming rate is greatly increased.

Owner:YINGKOU ZHONGWANG ALUMINUM CO LTD

Al-Mg-Si alloy having a high ductility and method of its manufacture

An AlMgSi-alloy suitable for manufacturing components having a high ductility, characterized in that the alloy comprising, in wt. %: <table-cwu id="TABLE-US-00001"> <number>1< / number> <tgroup align="left" colsep="0" rowsep="0" cols="4"> <colspec colname="OFFSET" colwidth="56PT" align="left" / > <colspec colname="1" colwidth="63PT" align="left" / > <colspec colname="2" colwidth="28PT" align="right" / > <colspec colname="3" colwidth="70PT" align="left" / > <row> <entry>< / entry> <entry>< / entry> < / row> <row> <entry>< / entry> <entry namest="OFFSET" nameend="3" align="center" rowsep="1">< / entry> < / row> <row> <entry>< / entry> <entry>Mg< / entry> <entry>0.3 to< / entry> <entry>1.0< / entry> < / row> <row> <entry>< / entry> <entry>Si< / entry> <entry>0.3 to< / entry> <entry>1.2< / entry> < / row> <row> <entry>< / entry> <entry>Fe< / entry> <entry>max.< / entry> <entry>0.35< / entry> < / row> <row> <entry>< / entry> <entry>Mn< / entry> <entry>>0.15 to< / entry> <entry>0.4< / entry> < / row> <row> <entry>< / entry> <entry>V< / entry> <entry>0.05 to< / entry> <entry>0.20< / entry> < / row> <row> <entry>< / entry> <entry>Cu< / entry> <entry>max.< / entry> <entry>0.3< / entry> < / row> <row> <entry>< / entry> <entry>Cr< / entry> <entry>max.< / entry> <entry>0.2< / entry> < / row> <row> <entry>< / entry> <entry>Zn< / entry> <entry>max.< / entry> <entry>0.2< / entry> < / row> <row> <entry>< / entry> <entry>Ti< / entry> <entry>max.< / entry> <entry>0.1< / entry> < / row> <row> <entry>< / entry> <entry namest="OFFSET" nameend="3" align="center" rowsep="1">< / entry> < / row> < / tgroup> < / table-cwu> impurities max. 0.05% each, total max. 0.15%, balance aluminium

Owner:BORST GERHARD +1

High-strength aluminum alloy and preparation method thereof

The invention relates to aluminum alloy and provides high-strength aluminum alloy with the tensile strength of more than 700MPa and a preparation method thereof. The high-strength aluminum alloy comprises the following raw materials in percentage by weight: 0.10%-0.14% of Fe, 0.03%-0.04% of Mn, 0.02%-0.04% of Si, 0.01%-0.06% of Ti, 0.03%-0.09% of B, 2.2%-2.9% of Zn, 0.9%-1.0% of Mg, 1.1%-1.3% of Cu, 0.5%-1.0% of Ce, 0.1%-0.4% of Sc and the balance of Al.

Owner:FUJIAN MINFA ALUMINUM

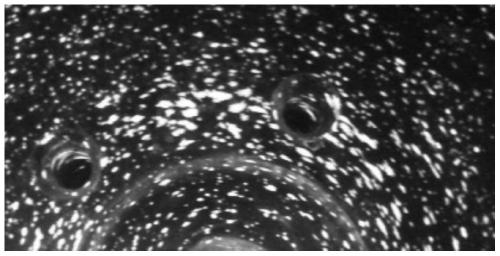

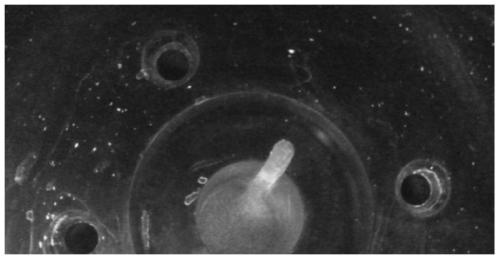

Hot isostatic pressing treatment process method for casting forming ZL101A aluminum alloy

The invention relates to a hot isostatic pressing treatment process method for a casting forming ZL101A aluminum alloy, belongs to the technical field of aluminum alloy casting and heat treatment, andsolves the problems that defects exist in a casting forming ZL101A aluminum alloy material, the fatigue performance of the material is affected, the heat treatment is carried out separately after hotisostatic pressing, many production processes are needed, and the period is long in the prior art. The hot isostatic pressing treatment process method for the casting forming ZL101A aluminum alloy comprises the following steps of step 1, casting ZL101A aluminum alloy castings; and step 2, carrying out hot isostatic pressing treatment on the ZL101A aluminum alloy castings in hot isostatic pressingequipment, wherein the step of carrying out hot isostatic pressing treatment comprises the steps of sequentially carrying out heating and boosting, high-temperature-segment heat preservation and pressure maintaining, pressure maintaining and quick cooling, low-temperature-segment heat preservation and pressure maintaining and cooling and depressurization. According to the method, the improvementof the strength and the anti-fatigue mechanical property of the ZL101A aluminum alloy material is realized, the production cycle of the conventional hot isostatic pressing treatment casting aluminum alloy is shortened, and the production cost is saved.

Owner:钢研昊普科技有限公司 +1

6XXX series aluminum alloy round cast ingot and preparation method thereof

The invention belongs to the technical field of formulas and preparation of aluminum alloy materials, and discloses a 6XXX series aluminum alloy round cast ingot. The 6XXX series aluminum alloy roundcast ingot is prepared from the following components in parts by weight: 0.60-0.65% of Si, less than or equal to 0.25% of Fe, less than or equal to 0.05% of Cu, less than or equal to 0.05% of Mn, 0.50-0.55% of Mg, less than or equal to 0.05% of Cr, less than or equal to 0.05% of Zn, less than or equal to 0.05% of Ti and the balance of Al. The invention further discloses a production method of the6XXX series aluminum alloy round cast ingot. The production method comprises the steps of material supplementing, smelting, casting and homogenizing. Compared with the prior art, the production methodhas the advantages that by optimizing the alloy composition and adding a small amount of Mg and Si auxiliary materials in the production process, an aluminum alloy has low quenching sensitivity, thecontrol difficulty of section deformation of a section on a production site is reduced, the quality of the section is improved, and the comprehensive performance requirement of an aluminum template for construction is met.

Owner:SNTO TECH GRP

Aluminum alloy and preparation method thereof

The invention is suitable for the field of material processing, and provides an aluminum alloy and a preparation method thereof. The aluminum alloy comprises the following components in percentage bymass: 0.62-0.78% of silicon, 0.56-0.70% of magnesium, 0.15-0.20% of copper, 0.25-0.38% of manganese, 0.10-0.18% of chromium, 0.03-0.08% of vanadium, iron not more than 0.20% and more than 0, titaniumnot more than 0.03% and more than 0, and the balance of aluminum. In the aluminum alloy, through limiting of the contents of silicon, magnesium and copper fed elements, the product strength is improved when the extrusion performance of the aluminum alloy is not reduced; and meanwhile, through feeding of such elements as manganese, chromium and vanadium and cooperation with subsequent process treatment, dispersion separation mass points can be generated to achieve an effect of inhibiting recrystallization in the extrusion process, that is, the product strength and ductility are further improved, and prepared products achieve higher strength, ductility, stress corrosion resistance and extrusion performance.

Owner:广东和胜新能源科技有限公司

7000-series aluminum alloy for automobile stand column and manufacturing method of plate by 7000-series aluminum alloy

PendingCN111876639AImproved Quenching SensitivityImprove stamping effectHot stampingUltimate tensile strength

The invention discloses a 7000-series aluminum alloy for an automobile stand column and a manufacturing method of a plate by the 7000-series aluminum alloy, and belongs to the technical field of alloymaterials. The 7000-series aluminum alloy for the automobile stand column is composed of, by weight percent, less than or equal to 0.05% of Si, less than or equal to 0.1% of Fe, 1.2%-1.8% of Cu, lessthan or equal to 0.1% of Mn, 2.2%-2.6% of Mg, less than or equal to 0.1% of Cr, 5.5%-6.0% of Zn, less than or equal to 0.1% of Ti, 0.04%-0.1% of Zr and the balance Al and inevitable impurities, wherein the total amount of the inevitable impurities is less than or equal to 0.1%. The plate prepared according to the formula and the method has higher mechanical properties (the tensile strength is 540MPa or above, the yield strength is 460 MPa or above, and the ductility is larger than 14%), and the hot stamping forming percent of pass is high (the hot stamping forming percent of pass is 95% or above).

Owner:BEIBU GULF UNIV

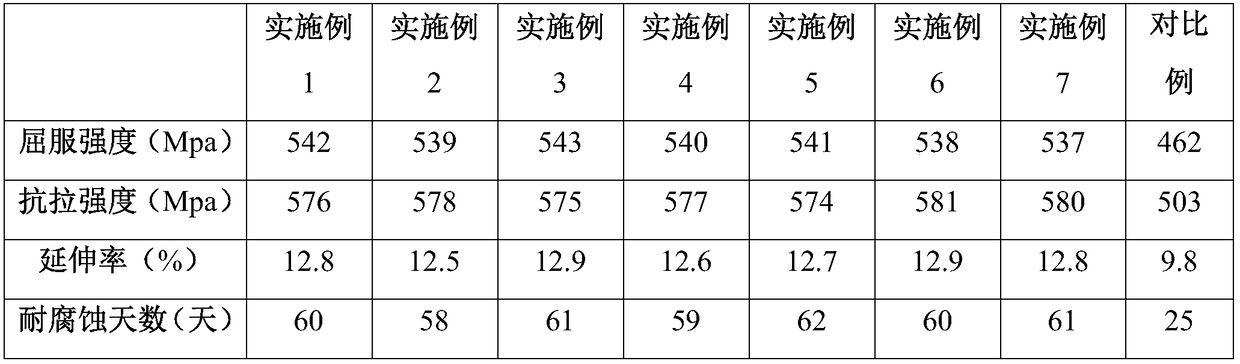

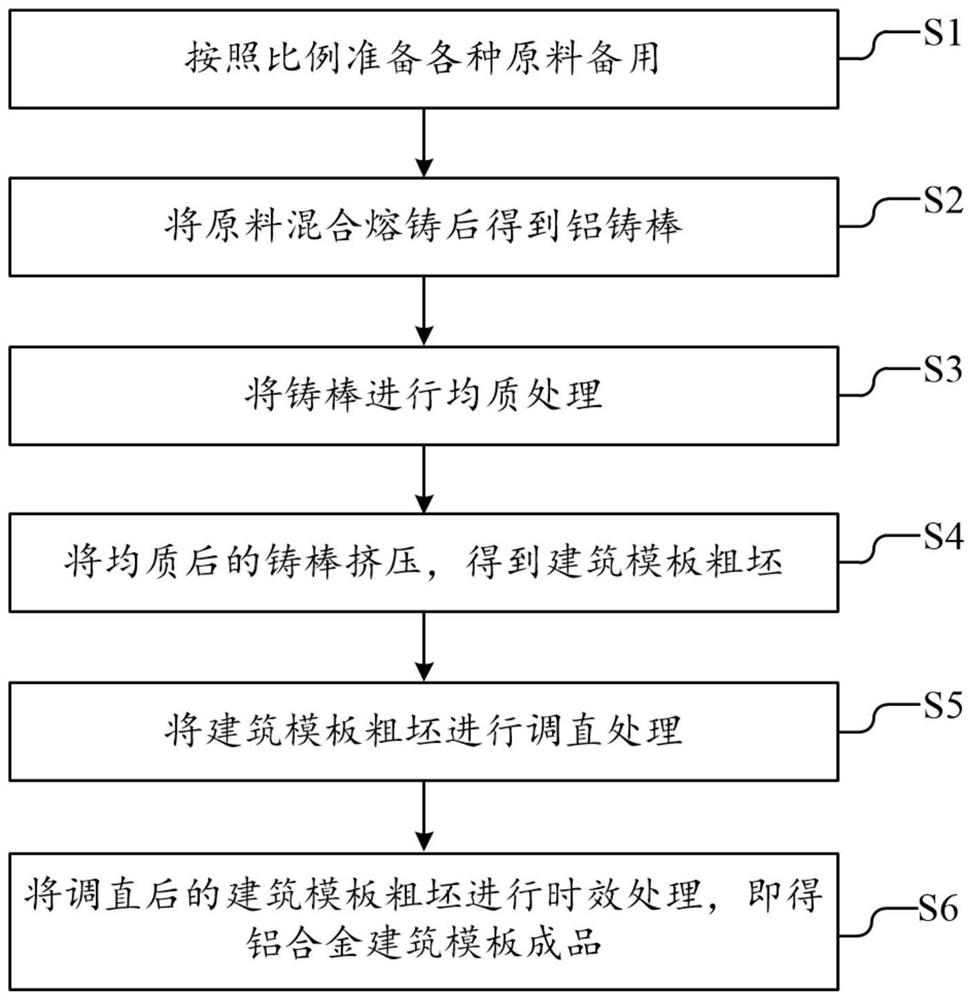

Aluminum alloy building formwork and preparation method thereof

PendingCN113234972AReduced Quench SensitivityImprove solid solubilityFurnace typesHeat treatment furnacesAluminium alloyMechanical properties of carbon nanotubes

The invention discloses an aluminum alloy building formwork mainly comprising, by mass, 0.4%-1.0% of Si, 0.8%-1.3% of Mg, 0.05%-0.2% of Cu, 0.001%-0.15% of Mn, 0.2%-0.7% of Fe, less than or equal to 0.25% of Zn, 0.001%-0.1% of Cr, 0.03%-0.15% of Ti and the balance Al and inevitable impurities. The content of the inevitable impurities is less than or equal to 0.15%. Correspondingly, the invention further discloses a preparation method of the aluminum alloy building formwork. The aluminum alloy building formwork is excellent in mechanical property, the extrusion speed can reach 8-10 m / min, and the production efficiency is high.

Owner:GUANGDONG JMA ALUMINUM PROFILE FACTORY GRP +1

Aluminum alloy material for triangular valves and preparation method thereof

The invention relates to an aluminum alloy material for triangular valves, which contains the following chemical components in percentage by mass: 0.7-0.9% of copper, 2.2-22.5% of silicon, 1.8-2.1% of manganese, 4.0-4.2% of magnesium, 0.01-0.03% of titanium, 0.3-0.5% of chromium, 0.005-0.008% of molybdenum and the balance of aluminum. The aluminum alloy has the advantages of light weight, favorable wear resistance, low expansion coefficient, excellent corrosion resistance, favorable plasticity, low quenching sensitivity, long service time and lower cost than brass triangular valves, and is suitable for making triangular valves. Part of scrap iron is used as the raw material, and the raw materials are fed in batches, so that the alloy quality is more stable and uniform, thereby enhancing the comprehensive mechanical properties. When the refining agent is used for casting production, the porosity in the casting can be lowered by 1-2 degrees, the oxide inclusion content is Grade 2 or so, the air tightness of the casting is high, and the yield is high.

Owner:ANHUI KING AUTO ELECTRONICS TECH CO LTD

A Al-zn-mg-cu Series Aluminum Alloy with Low Quenching Sensitivity

Owner:CENT SOUTH UNIV

7075 aluminum alloy and preparation method and application thereof

The invention discloses a 7075 aluminum alloy and a preparation method and application thereof, and belongs to the technical field of aluminum alloys. The aluminum alloy comprises the following elements: greater than or equal to 5.7% and less than or equal to 6.1% of Zn, greater than or equal to 2.1% and less than or equal to 2.4% of Mg, greater than or equal to 1.2% and less than or equal to 1.5% of Cu, greater than or equal to 0.18% and less than or equal to 0.22% of Cr, greater than or equal to of 0.05% and less than or equal to 0.35% of Er, greater than or equal to 0.05% and less than or equal to 0.25% of Gd, greater than or equal to 0.02% of less than or equal to 0.2% of Ge, greater than or equal to 0.12% and less than or equal to 0.5% of Er+Gd, greater than or equal to 0.15% and less than or equal to 0.6% of Er+Gd+Ge, less than or equal to 0.2% of Mn, less than or equal to 0.3% of Si, less than or equal to 0.3% of Fe, less than or equal to 0.2% of Ti, less than or equal to 0.05% of single content of other impurity elements, less than or equal to 0.12% of the total amount of other impurity elements, and the balance of Al. The aluminum alloy has the characteristics of low stress corrosion sensitivity, low quenching sensitivity and high strength and toughness, and can be used as a worked material of aviation equipment.

Owner:GUANGDONG INST OF NEW MATERIALS

Preparation method of high-strength and corrosion-resistant Al-Y-Sc alloy and Al-Y-Sc alloy

InactiveCN112301242AImprove grain boundary strength and creep resistanceReduced tendency to thermal cracksCorrosion resistantChloroethane

The invention discloses a preparation method of a high-strength and corrosion-resistant Al-Y-Sc alloy and the Al-Y-Sc alloy. The preparation method includes the following steps that S1, an alloy castingot is prepared, specifically, intermediate alloys are prepared from Cu, Sc, Zr, Y, Fe, Cr, Ti Mn and Al, Mg is divided into two parts, the intermediate alloys Al-Cu, Al-Sc, Al-Zr, Al-Y, Al-Fe, Al-Cr, Al-Ti and Al-Mn, pure Zn and high-purity Al are smelted, and then a first part of Mg, an Al-Ti-B grain refiner, hexachloroethane and a second part of Mg are sequentially added; casting is performedto obtain the alloy cast ingot; and S2, the alloy cast ingot is sequentially subjected to homogenization treatment, solid solution treatment, quenching, pre-aging, regression and re-aging treatment,and the high-strength and corrosion-resistant aluminum alloy is obtained. The prepared aluminum alloy is high in strength, good in toughness, excellent in heat stability and fatigue resistance and long in service life.

Owner:GUANGXI UNIV

A kind of high-strength aluminum alloy and preparation method thereof

ActiveCN104195391BLow fracture toughnessReduced Quench SensitivityUltimate tensile strengthAluminium alloy

The invention relates to aluminum alloy and provides high-strength aluminum alloy with the tensile strength of more than 700MPa and a preparation method thereof. The high-strength aluminum alloy comprises the following raw materials in percentage by weight: 0.10%-0.14% of Fe, 0.03%-0.04% of Mn, 0.02%-0.04% of Si, 0.01%-0.06% of Ti, 0.03%-0.09% of B, 2.2%-2.9% of Zn, 0.9%-1.0% of Mg, 1.1%-1.3% of Cu, 0.5%-1.0% of Ce, 0.1%-0.4% of Sc and the balance of Al.

Owner:FUJIAN MINFA ALUMINUM

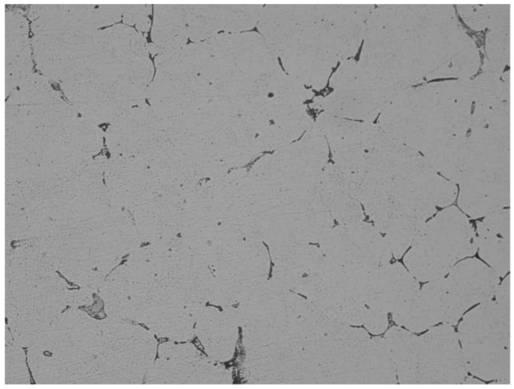

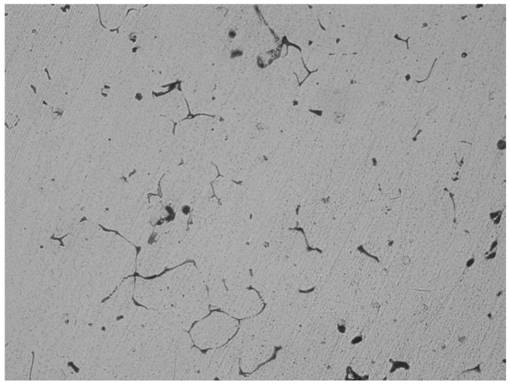

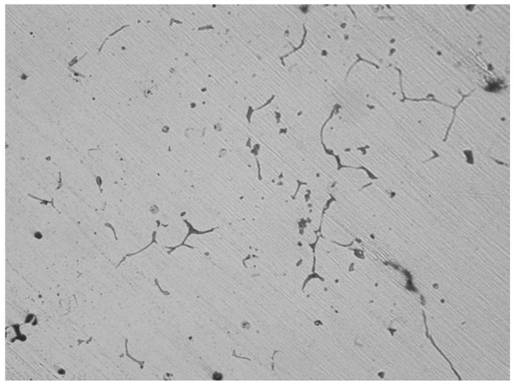

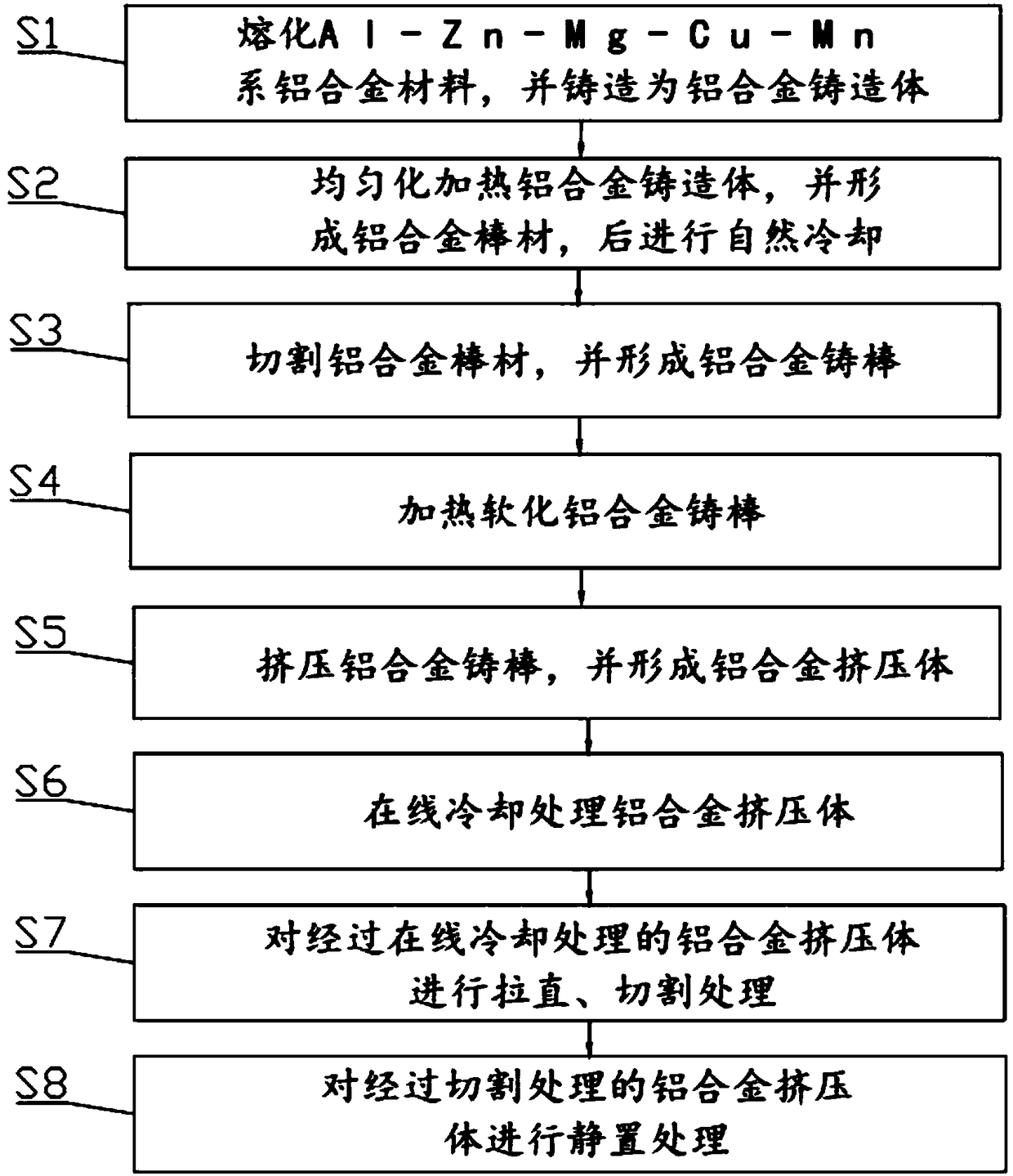

Al-Zn-Mg-Cu-Mn aluminum alloy and preparation process thereof

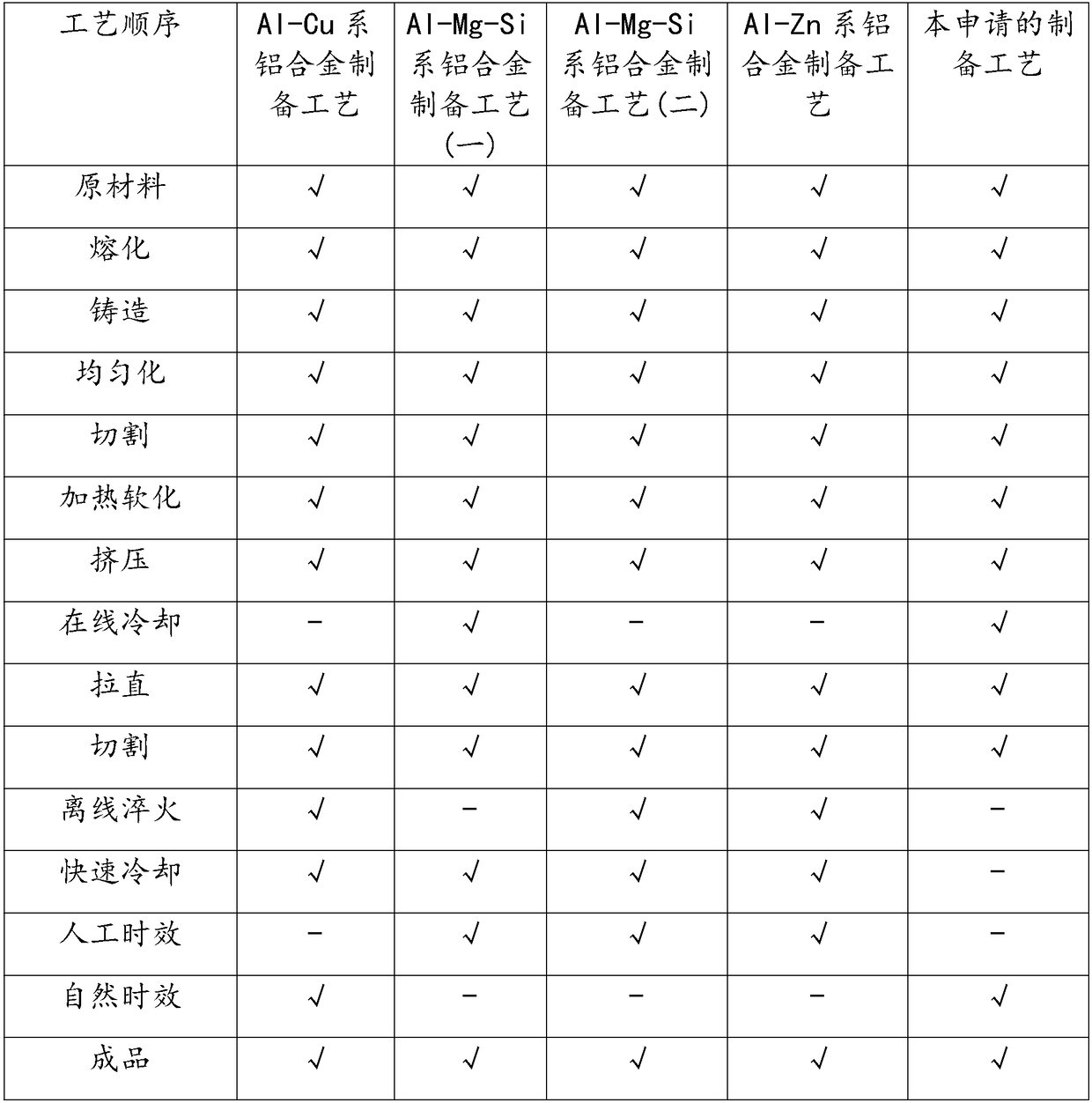

The invention discloses Al-Zn-Mg-Cu-Mn aluminum alloy and a preparation process thereof. The Al-Zn-Mg-Cu-Mn aluminum alloy is prepared from the following components according to weight percent: 5.5 wt% to 6.6 wt% of Zn, 0.35 wt% to 0.55 wt% of Mg, 0.15 wt% to 0.25 wt% of Cu, 0.1 wt% to 0.19 wt% of Mn, 0.1 wt% to 0.2 wt% of Zr, 0.05 wt% to 0.2 wt% of Cr, less than 0.05 wt% of Ti, less than 0.15 wt%of Si, less than 0.25 wt% of Fe and the balance of Al. The preparation process of the Al-Zn-Mg-Cu-Mn aluminum alloy comprises the steps of melting the components of the Al-Zn-Mg-Cu-Mn aluminum alloyand casting into an aluminum alloy casting first, then uniformly heating the aluminum alloy casting so as to form an aluminum alloy rod, cutting the aluminum alloy rod into aluminum alloy casting rods, heating again so as to soften the aluminum alloy casting rods, extruding the softened aluminum alloy casting rods so as to form aluminum alloy extruded bodies, and finally, performing online coolingstraightening and cutting and standing treatment on the aluminum alloy extruded bodies in sequence, so that the Al-Zn-Mg-Cu-Mn aluminum alloy is obtained.

Owner:ASIA PACIFIC LIGHT ALLOY NANTONG TECH

High-performance photovoltaic aluminum alloy frame and production process thereof

InactiveCN113684400ALow costReduce the cost of electricity productionAnodisationPhotovoltaicsPhotovoltaic solar energyPhotovoltaic industry

The invention discloses a processing process of a high-performance photovoltaic aluminum alloy frame, and belongs to the technical field of preparation of aluminum alloy materials. The processing process comprises the following steps of proportioning the following elements in percentage by mass: 0.60-0.65% of Si, less than or equal to 0.15% of Fe, less than or equal to 0.05% of Cu, less than or equal to 0.05% of Mn, 0.50-0.55% of Mg, less than or equal to 0.05% of Cr, less than or equal to 0.1% of Zn, less than or equal to 0.1% of Ti and the balance of Al, then carrying out casting, extrusion, sand blasting and oxidation procedures, and achieving processing and forming of the aluminum alloy frame. The Vickers hardness is 15 Hw or above, the mechanical property is high, compared with 6063 aluminum alloy, under the same strength requirement, the wall thickness of the photovoltaic solar frame can be reduced by 50% or above, the cost of aluminum for the photovoltaic frame is reduced by 50%, and the power generation cost of the photovoltaic industry is greatly reduced.

Owner:山东华建铝业科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com