Aluminum alloy building formwork and preparation method thereof

A technology for building formwork and aluminum alloy, applied in the field of aluminum alloy, can solve the problems of inability to meet processing and assembly requirements, insufficient mechanical properties due to hardenability, bending deformation of formwork materials, etc., to achieve excellent mechanical properties, improve hardenability, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

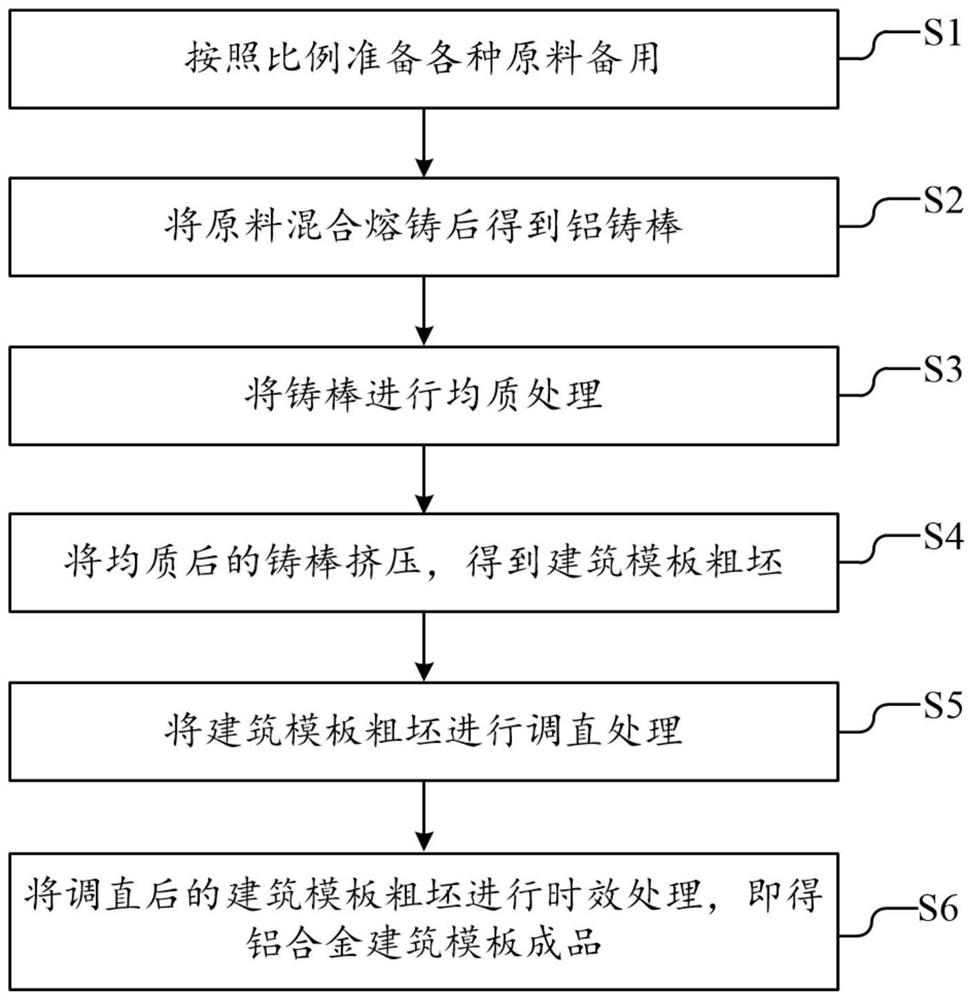

[0041] refer to figure 1 , the preparation method of aluminum alloy building formwork in the present invention comprises the following steps:

[0042] S1: Prepare various raw materials according to the proportion for later use;

[0043] Specifically, the raw materials in the present invention include but are not limited to: returned materials, pure aluminum ingots, Al-20%Mn master alloys, Al-20%Cr master alloys, Al-50%Cu master alloys, high-purity magnesium, high-purity silicon, Aluminum titanium boron wire (it is enough to control the content of Fe in each raw material, generally there is no need to specifically add Fe element, unless it is necessary to add Fe properly).

[0044] S2: Mix and cast the raw materials to obtain aluminum cast rods;

[0045] Specifically, S2 includes:

[0046] S21: mixing and melting the raw materials, and removing slag to obtain the first alloy liquid;

[0047] Specifically, the aluminum ingots are first added to the melting furnace, and the mel...

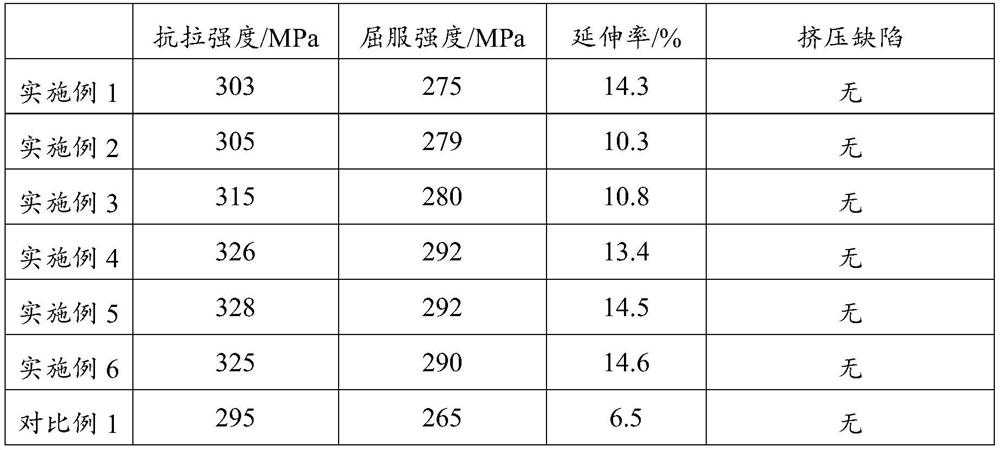

Embodiment 1

[0066] This embodiment provides a kind of aluminum alloy building formwork, and its formula is:

[0067] Si 0.9%, Mg 0.8%, Cu 0.15%, Mn 0.005%, Fe 0.6%, Zn 0.2%, Cr 0.04%, Ti0.13%, unavoidable impurities 0.1%, and the balance is Al.

[0068] Its preparation method is:

[0069] (1) Prepare various raw materials according to the ratio for subsequent use;

[0070] (2) mixing and casting the raw materials to obtain cast rods;

[0071] (3) Homogenize the cast rod; wherein, the homogenization temperature is 570° C., and the time is 6 hours; after homogenization, it is cooled by strong wind;

[0072] (4) Extrude the homogenized casting rod to obtain the building template rough billet; wherein, the extrusion speed is 9.5m / min, the temperature of the extrusion die is 450°C, and the temperature of the extrusion cylinder is 420°C. The temperature of the cast rod is 500°C, the temperature of the building formwork rough billet after extrusion is 540°C, and it is cooled by strong wind on...

Embodiment 2

[0077] This embodiment provides a kind of aluminum alloy building formwork, and its formula is:

[0078] Si 0.8%, Mg 1.1%, Cu 0.2%, Mn 0.1%, Fe 0.4%, Zn 0.05%, Cr 0.1%, Ti 0.05%, unavoidable impurities 0.15%, and the balance is Al.

[0079] Its preparation method is:

[0080] (1) Prepare various raw materials according to the ratio for subsequent use;

[0081] (2) mixing and casting the raw materials to obtain cast rods;

[0082] (3) Homogenize the cast rod; wherein, the homogenization temperature is 575° C., and the time is 6 hours; after homogenization, strong wind cooling + water mist cooling;

[0083] (4) Extrude the homogenized casting rod to obtain the building formwork rough billet; wherein, the extrusion speed is 8m / min, the temperature of the extrusion die is 460°C, the temperature of the extrusion cylinder is 430°C, and the casting before extrusion The temperature of the rod is 480°C, the temperature of the building formwork rough billet after extrusion is 550°C, ...

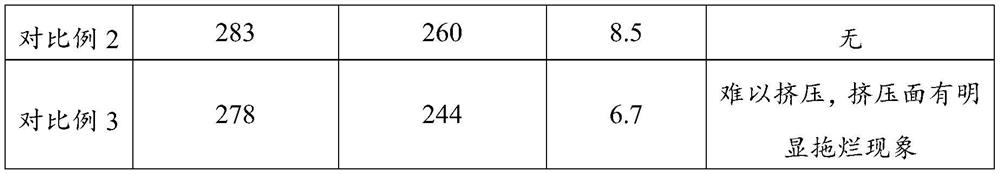

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com