Patents

Literature

69results about How to "Short aging time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

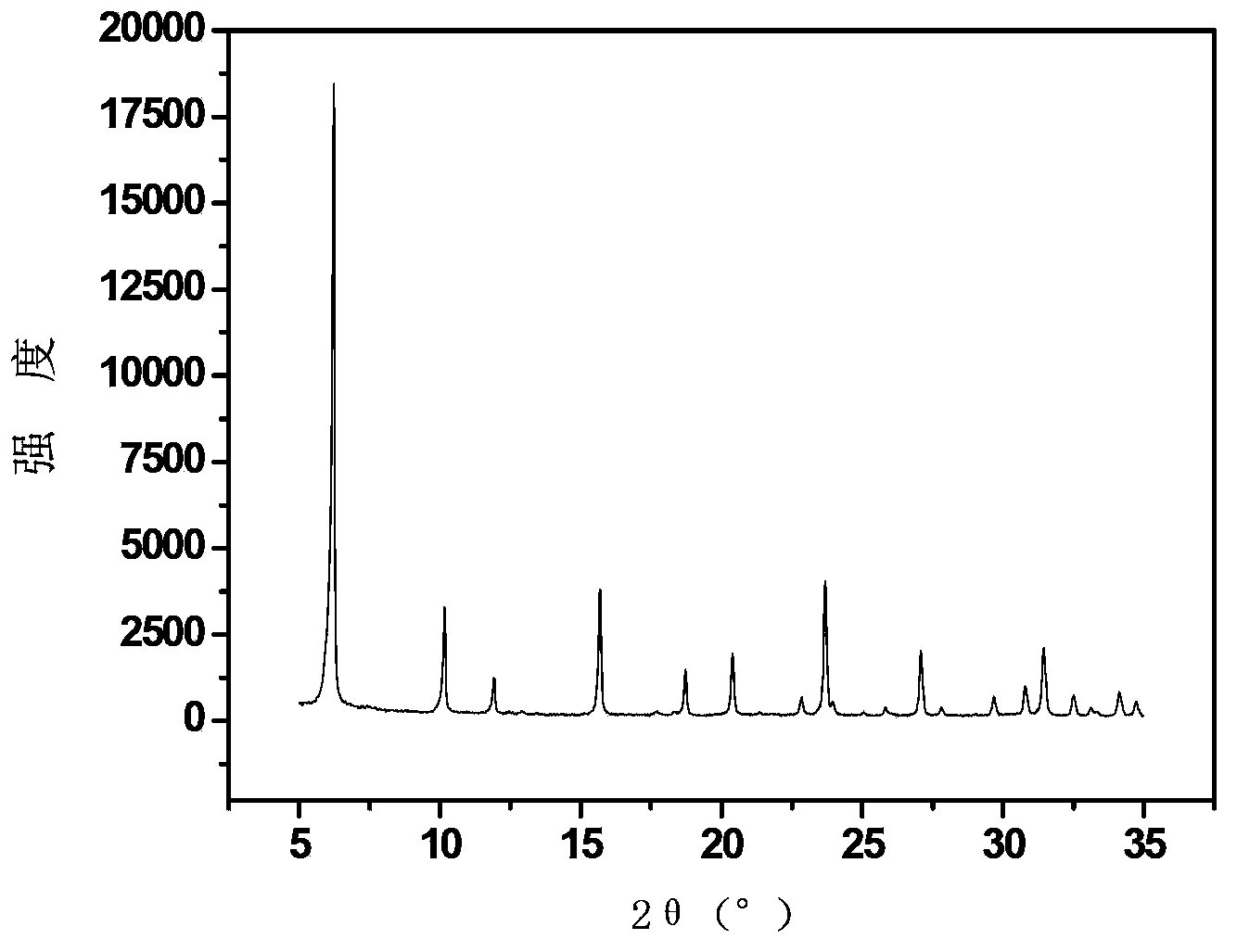

Synthetic method for NaY zeolite with high silica-alumina ratio

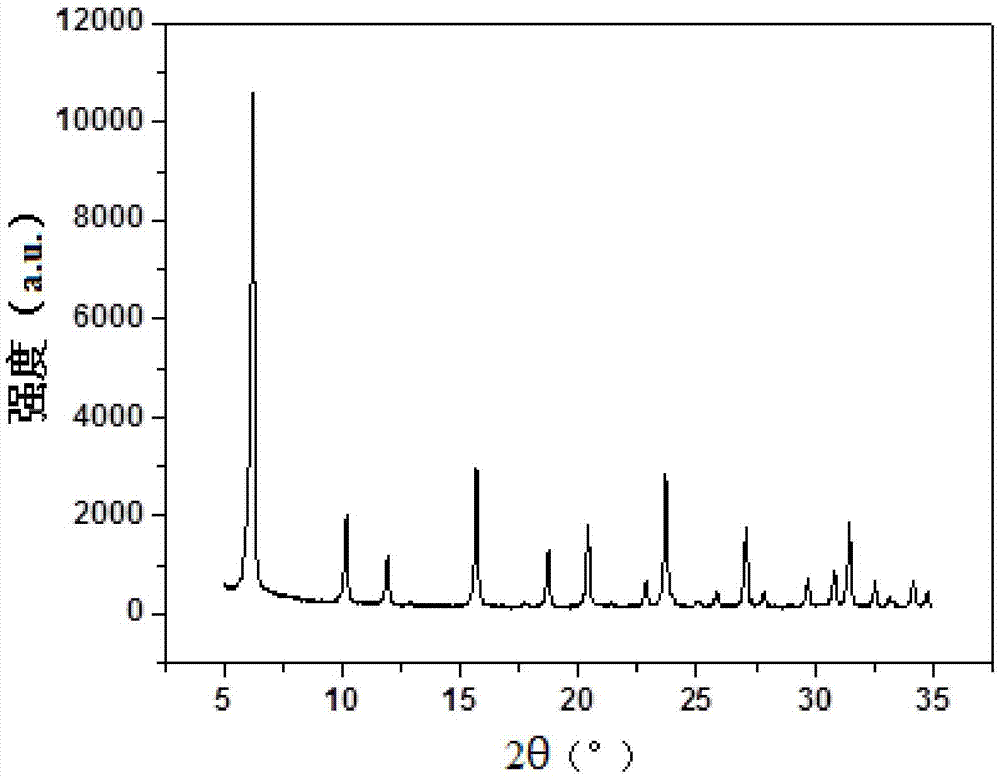

ActiveCN104118885AHigh crystallinityMild preparation temperatureFaujasite aluminosilicate zeoliteHigh silicaSilicon

The invention provides a synthetic method for NaY zeolite with a high silica-alumina ratio. The method comprises the main steps: according to the proportioning requirement of a directing agent to uniformly mix a silicon source, an aluminium source and water, and ageing at 15 DEG C-60 DEG C for 0.5-120 h, so as to prepare the directing agent; according to the proportioning requirement of a gel reaction mixture to adding the directing agent and an alkaline solution into a silicone source at 10 DEG C-90 DEG C, stirring for 1 h-80 h, and stirring uniformly to obtain the gel reaction mixture; performing crystallization on the gel reaction mixture at 80-120 DEG C for 10-50 h, and then filtering, washing and drying to prepare NaY zeolite. The method does not employ a template, the preparation of the directing agent is mild in temperature, NaY zeolite with high crystallization degree and the high silica-alumina ratio is synthesized at a relatively short crystallization time. Also the method is capable of replacing conventional production technology without changing current apparatuses for industrial production, and has great important meaning on improving performances of catalytic cracking catalysts.

Owner:PETROCHINA CO LTD +1

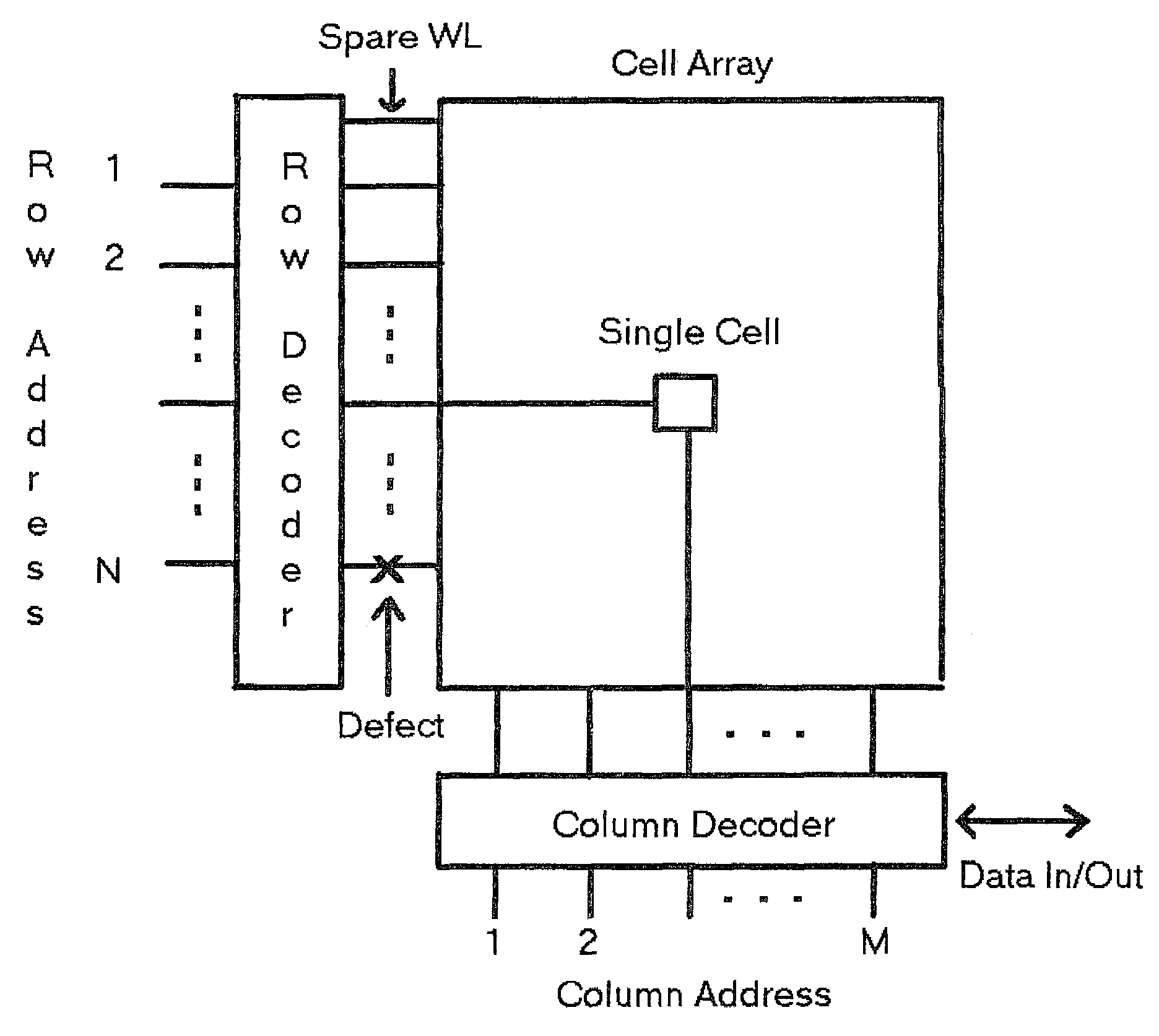

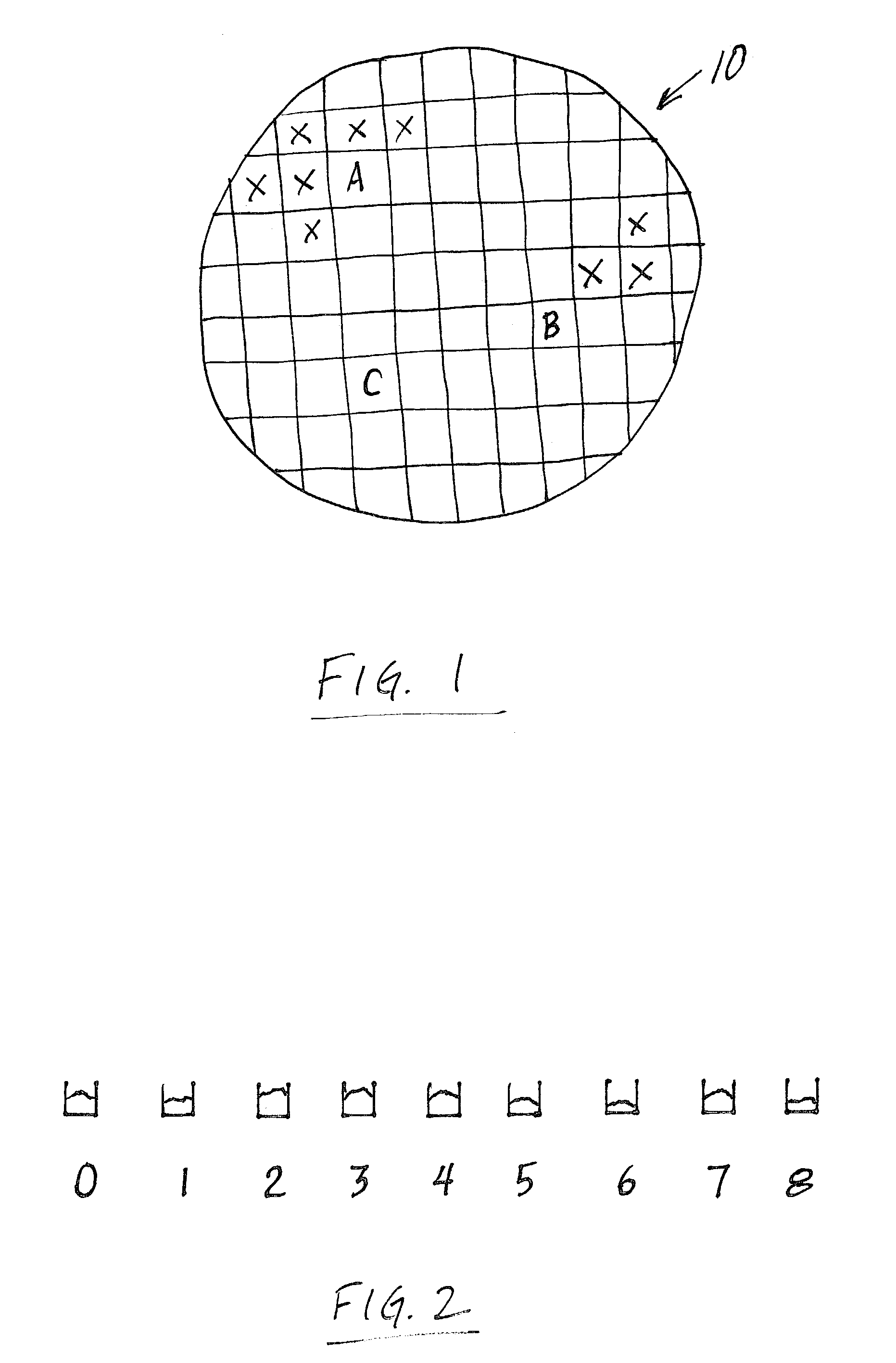

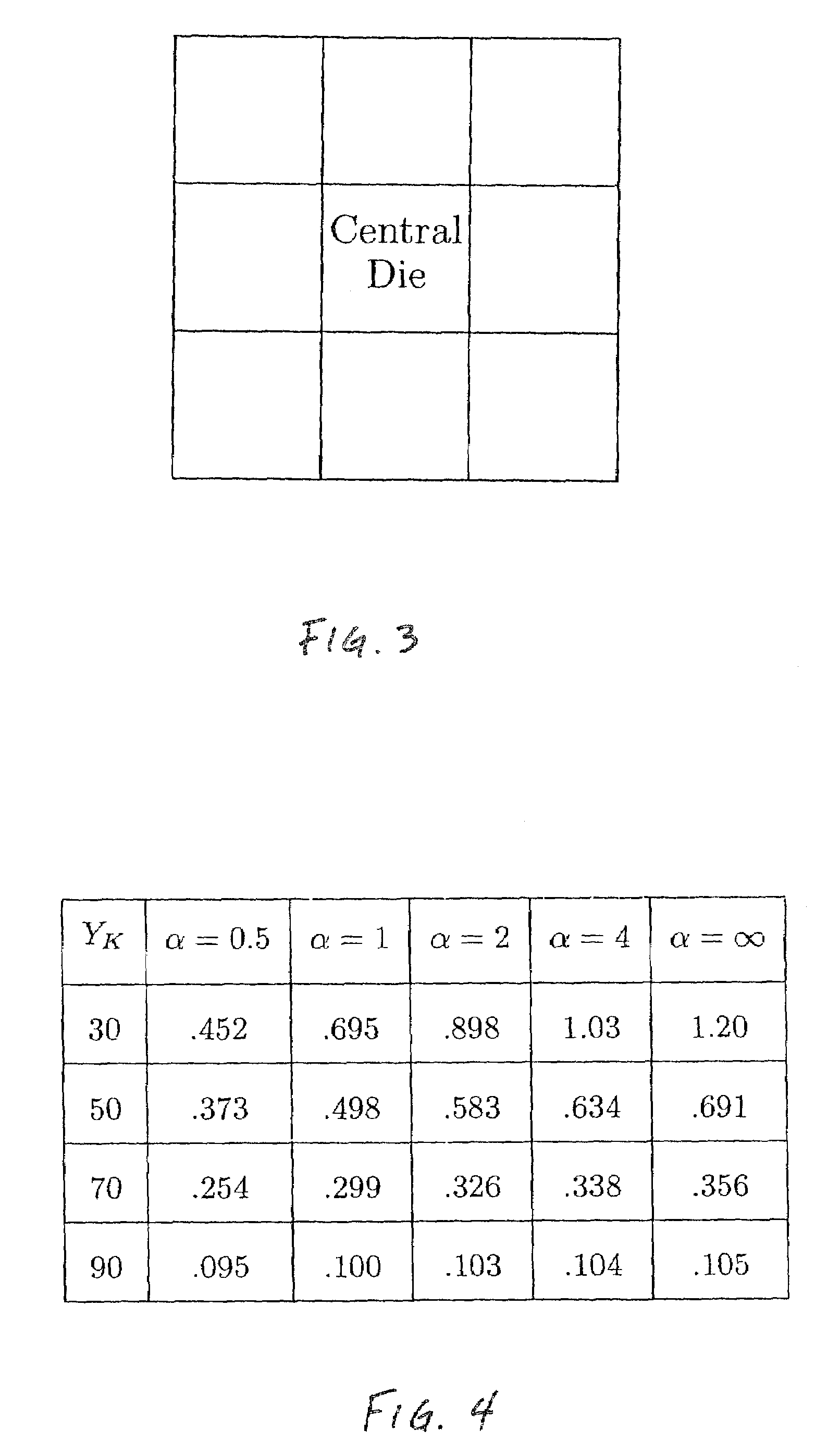

System and method for estimating reliability of components for testing and quality optimization

InactiveUS7194366B2Short aging timeEasy to optimizeSemiconductor/solid-state device testing/measurementDigital computer detailsQuality optimizationElectronic component

A system and method for determining the early life reliability of an electronic component, including classifying the electronic component based on an initial determination of a number of fatal defects, and estimating a probability of latent defects present in the electronic component based on that classification with the aim of optimizing test costs and product quality.

Owner:AUBURN UNIV

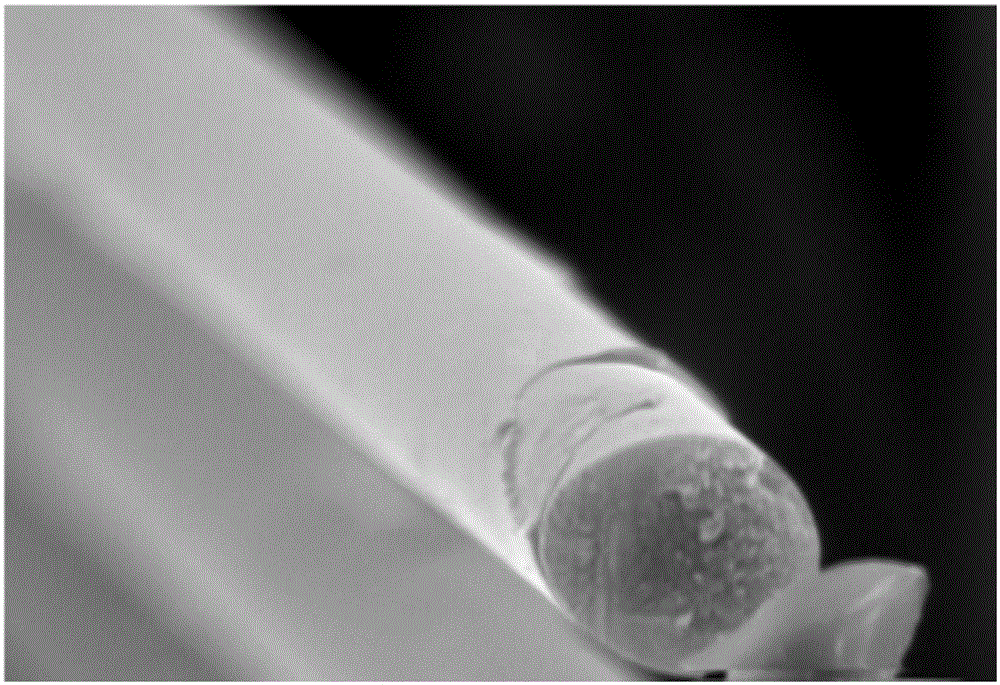

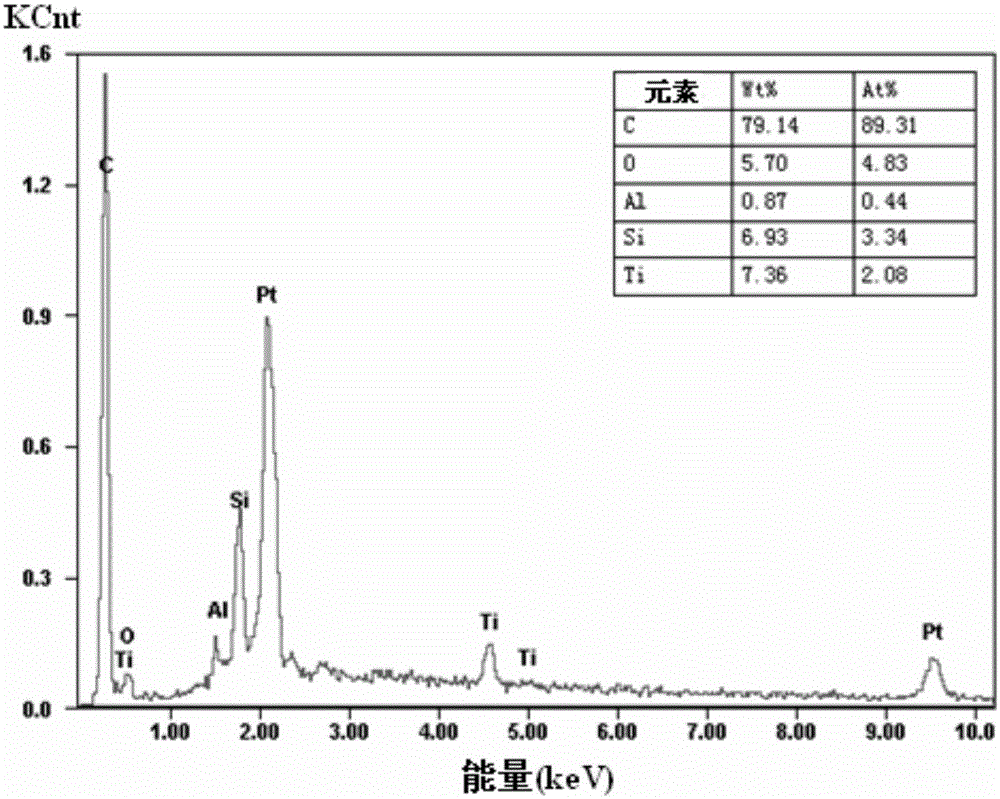

Method for preparation of antioxidant composite coating on carbon fiber surface

ActiveCN105113213ASimple preparation processReduced total preparation timeCarbon fibresFiberCarbon fibers

The invention relates to a method for preparation of an antioxidant composite coating on a carbon fiber surface. The antioxidant composite coating is an Al2O3-SiO2-TiO2 composite coating. The method is sol-gel method, which includes: composite sol preparation, carbon fiber surface activation treatment, coating, drying and heat treatment. The composite sol is prepared under room temperature, and the preparation process includes: firstly preparing a water-alcohol solution of tetraethyl orthosilicate and acetic acid into a mixed solution A, then pouring the mixed solution A into an alcohol solution of butyl titanate to prepare a mixed solution B, then under stirring, pouring an alcohol solution of aluminum nitrate nonahydrate into the mixed solution B to prepare a mixed solution C, finally adding an alcohol-water mixed solvent into the mixed solution C, and performing stirring to obtain the composite sol. With the ternary composite sol prepared by the method provided by the invention, a uniform and complete antioxidant coating with good adhesion and thickness within 3 micrometers can be prepared on the carbon fiber surface.

Owner:ZHEJIANG LIGHT TOUGH COMPOSITE MATERIALS

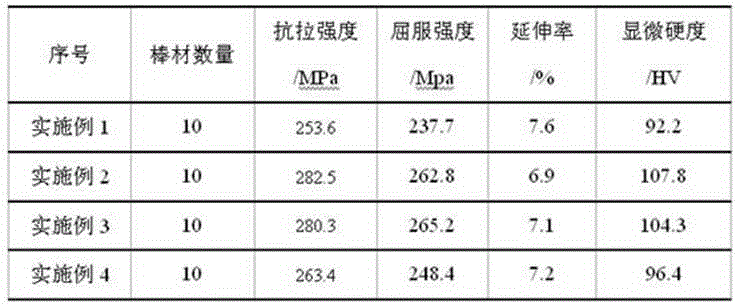

Al-Mg-Si as-cast aluminum alloy and aging treatment process thereof

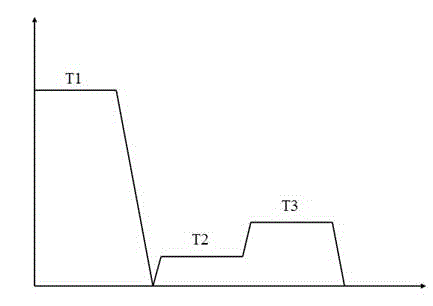

The invention discloses an Al-Mg-Si as-cast aluminum alloy and an aging treatment process thereof. The as-cast aluminum alloy is prepared from the following components in parts by weight in a mixing way: 6-8 parts of Mg, 4-6 parts of Si, 60-80 parts of Al, 2-3.5 parts of Fe, 0-1 part of Cu, 0-1 part of Zn, 0-1 part of Mn, 0-1 part of Ti and 0-1 part of Cr. The aging treatment process of the Al-Mg-Si as-cast aluminum alloy comprises the following steps: firstly performing solution treatment on the Al-Mg-Si as-cast aluminum alloy at 520-530 DEG C, performing low-temperature pre-aging treatment at 140-160 DEG C so that the aluminum alloy is in an under-aged state and the precipitated phases are mainly of solute atom aggregations, namely GP zones, and the precipitation density of the GP zones is increased a period of time after being under-aged state; and further increasing the aging temperature to 200 DEG C to perform high-temperature aging so that the number of the GP zones converted into beta' strengthening phases is increased, thereby effectively improving the mechanical property of the aluminum alloy.

Owner:GUIZHOU INST OF TECH

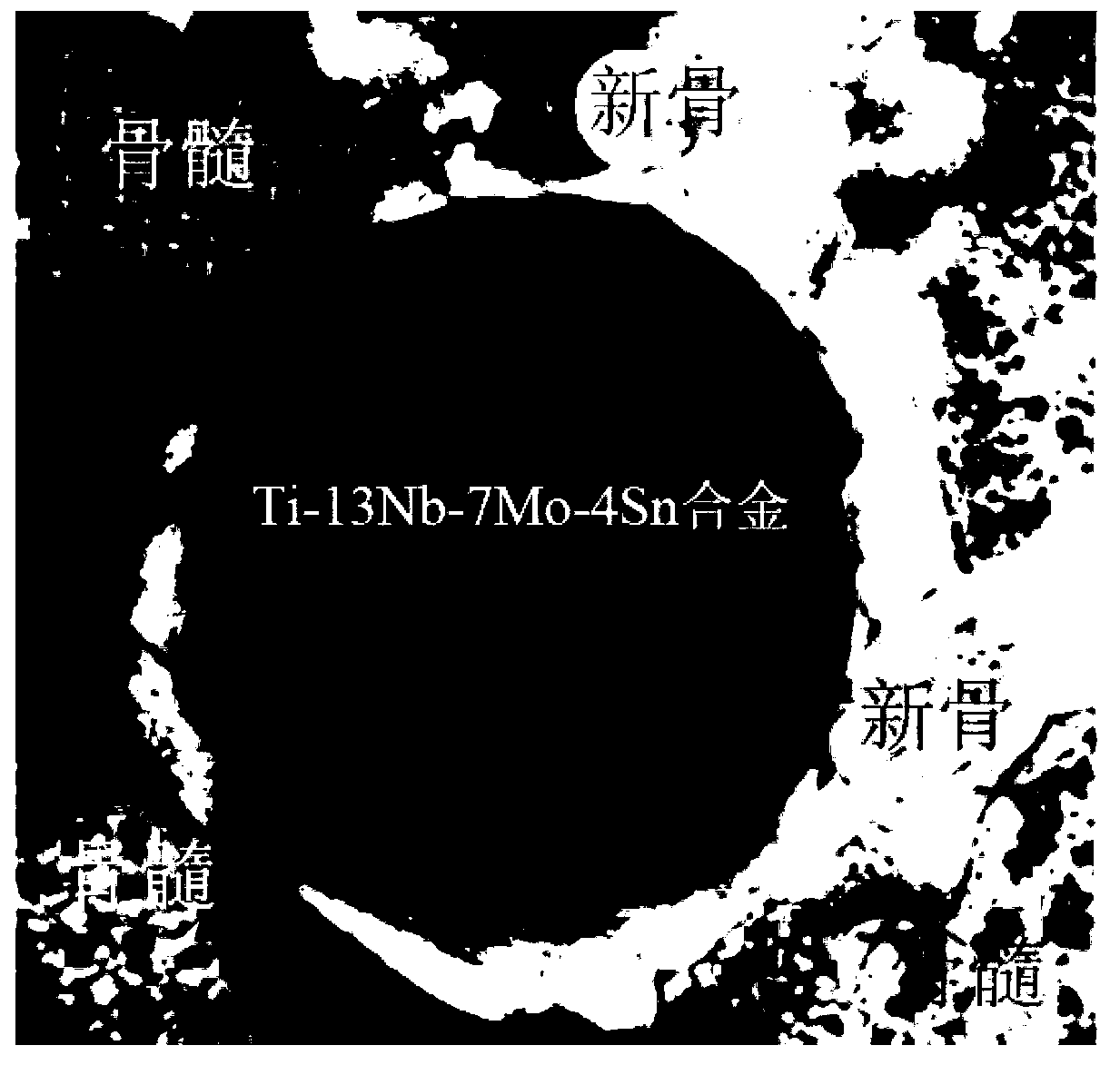

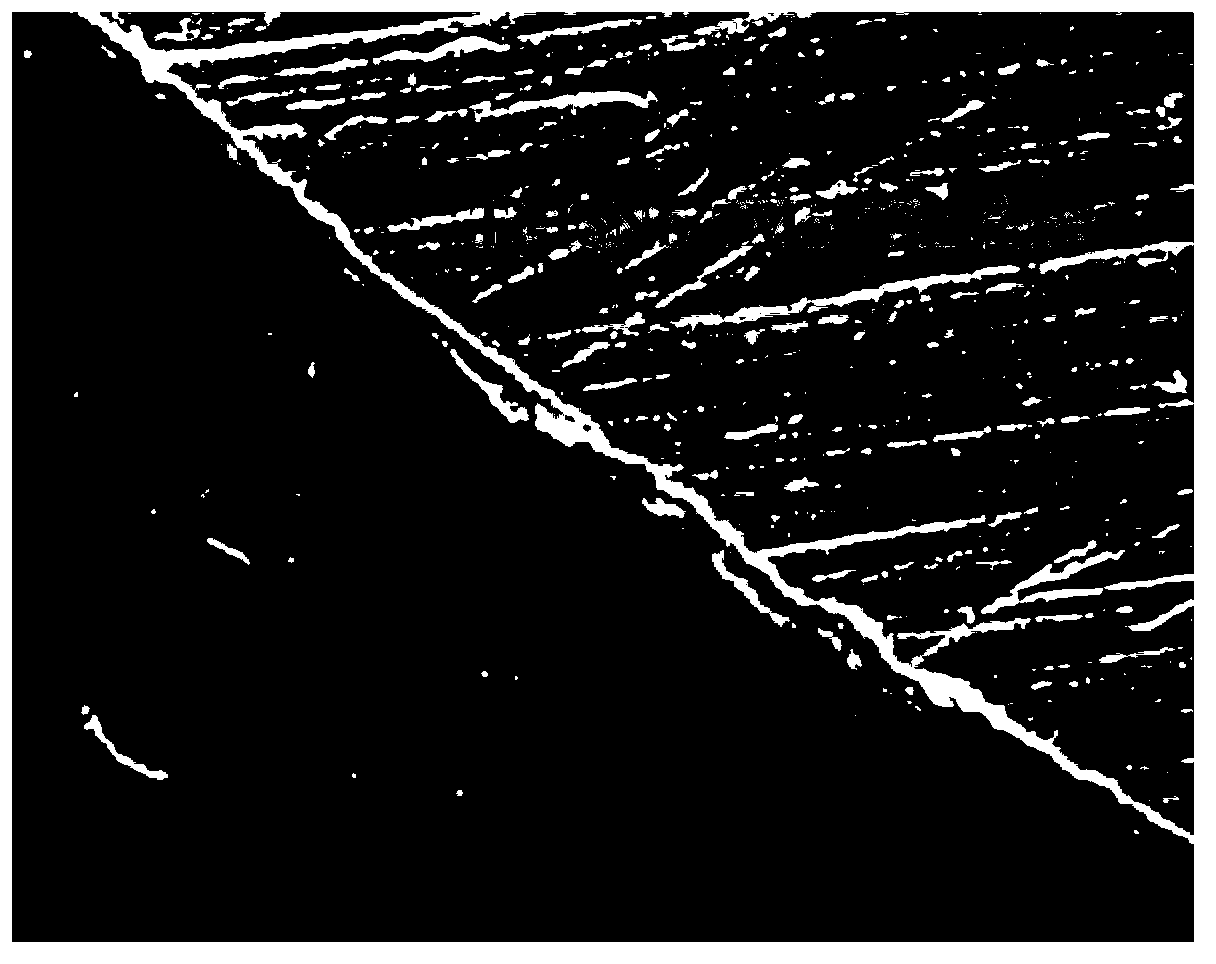

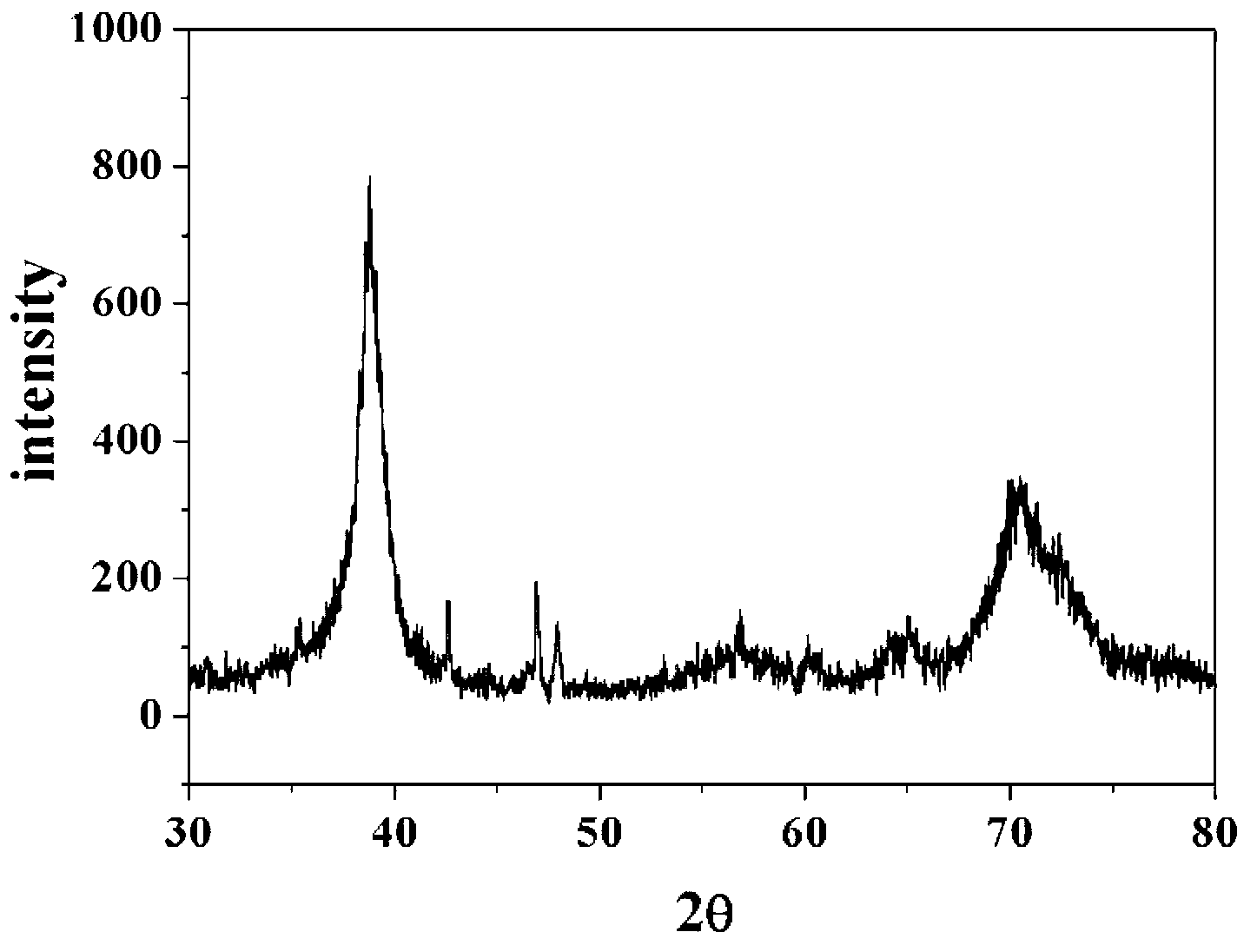

Preparation method of high-strength nanocrystalline type medical Beta titanium alloy for orthopaedic implanting

The invention discloses a preparation method of a high high-strength nanocrystalline type medical Beta titanium alloy for orthopaedic implanting. The titanium alloy is the Ti-Nb-Mo-Sn alloy prepared by the following steps in sequence: treating the alloy ingredients in a vacuum arc melting furnace, and sequentially carrying out the processes of quickly solidifying, rolling at a low temperature and instantaneously ageing at a high temperature, thus obtaining the large-dimension nanocrystalline type titanium alloy. The alloy has the average crystalline dimension less than 60 nanometers, and has strength of 1200 to 1600MPa, plasticity of 15 to 20%, elasticity modulus of 40 to 60 GPa, and super-elasticity recovery strain of 4 to 5%. According to the preparation method, the treatment processes of quick solidifying, low-temperature rolling and instantaneous ageing are creatively combined to treat the titanium alloy, thus, the purpose of unifying high strength, excellent processing performance, low elasticity modulus and excellent super-elasticity performance is realized, and high technological effect and huge potential economic value are brought.

Owner:XIANGTAN UNIV

Rapid ageing method of tangerine peel

InactiveCN103932086AAchieve the purpose of agingEfficient removalFood dryingFood preparationAge methodAtmospheric pressure

The invention discloses a rapid ageing method of tangerine peel. The rapid ageing method is characterized by comprising the steps of putting fresh citrus peels in a drying cabinet, drying at the temperature of 100-120 DEG C until the water content of the citrus peels is 20-30 percent, cooling, putting the dried and cooled citrus peels in a sealed vessel, and continuously introducing oxygen or pure air from one end of the vessel while discharging gas from the other end of the vessel till the air pressure in the vessel is 0.2-0.3 MPa higher than barometric pressure, gas in the vessel is completely replaced once after 30-60 minutes, and the citrus peels are processed in the vessel for 10-12 months, thereby obtaining the tangerine peel with good ageing quality. Compared with the prior art, the rapid ageing method has the advantages of non necessity in frequency movement, short ageing time and high ageing quality.

Owner:叶贤忠

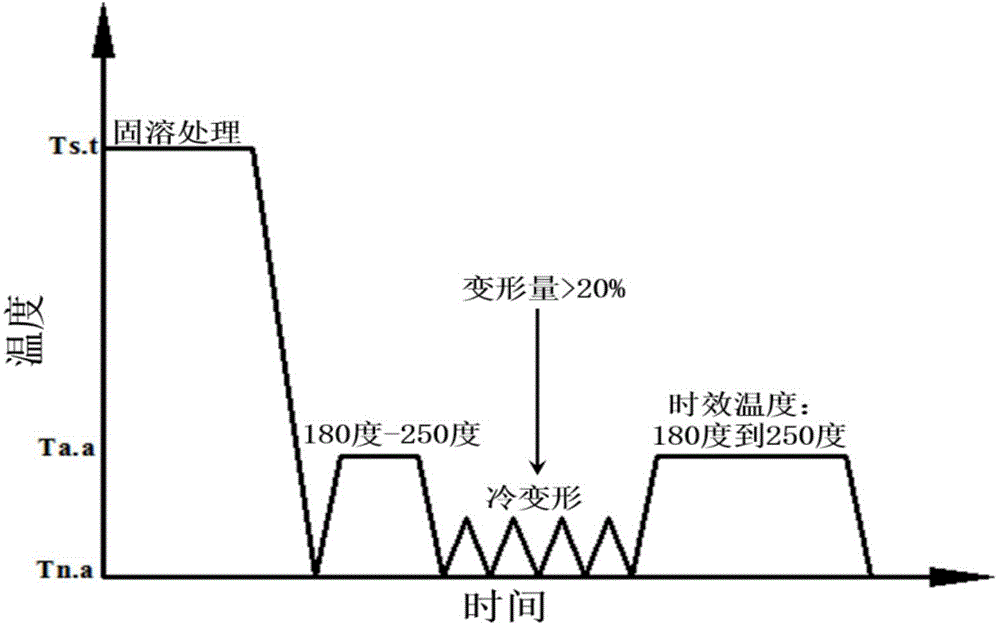

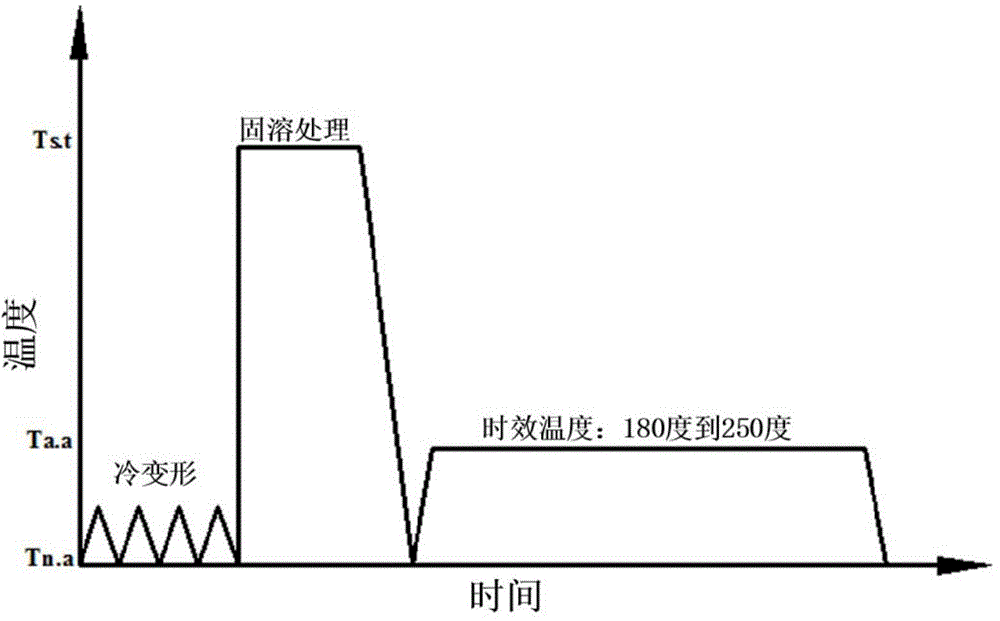

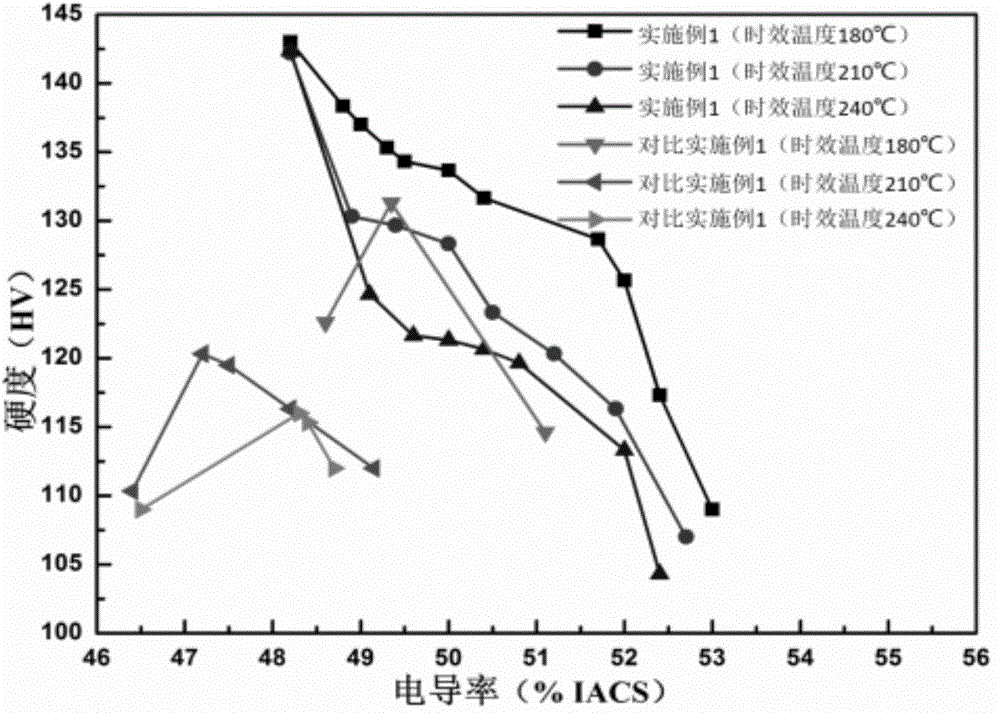

Hot working method capable of simultaneously improving electrical conductivity and strength of aluminum alloy

The invention belongs to the technical fields of preparation and heat treatment of metals and alloys, and discloses a hot working method capable of simultaneously improving the electrical conductivity and the strength of an aluminum alloy. The method comprises the following steps: firstly, casting the aluminum alloy to form a cast ingot, carrying out homogenizing treatment and thermal deformation treatment on the cast ingot, thus forming a plate; and sequentially carrying out solid solution and quenching treatment, first artificial ageing treatment, cold deformation treatment and second artificial ageing treatment on the plate which is subjected to thermal deformation treatment. According to the method, only the process order is adjusted; equipment and procedure do not need to be added, but the electrical conductivity and the strength of the prepared aluminum alloy are greatly improved by reasonably controlling the temperatures and the time of twice artificial ageing treatment; the hot working method can be implemented on existing hot working equipment; and extra manufacturing cost is not increased.

Owner:HUNAN UNIV

Method for alcoholizing cigar leaf

The invention discloses a cigar leaves alcoholizing method, which is characterized in that the method sequentially steps that: an additive which contains wintergreen glue is dissolved in the water and evenly sprayed on the cigar leaves; the cigar leaves are positioned in a cellar where the temperature is below 42 DEG C and the humidity is smaller than 30 percent for the ferment of 60 to 90 days; the additive is added with the wintergreen glue with the amount ranging from 2 to 5 per mill, herbal medicament with the amount ranging from 1 to 8 per mill and biological active enzyme with the amount ranging from 0.5 to 8 per mill. By the method of the invention, the cigar leaf taste is increased, the alcoholizing time is short, the alcoholizing result is good, the alcoholizing quality is stable and the alcoholizing cost is low.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

High-strength non-evaporating brick and preparation method thereof

InactiveCN101654941ASolve the problemSolve transportation difficultiesCeramic shaping apparatusBuilding componentsFrostBrick

The invention discloses a high-strength non-evaporating brick and a preparation method thereof, belonging to the technical field of building materials. The non-evaporating brick comprises the following components in percentage by weight: 30-45 unground grain slag, 30-45 heavy slag, 10-20 fly ash, 2-5 industrial by-product gypsum, 1-5 activity excitant and 5-14 water. The preparation method of thehigh-strength non-evaporating brick is simple, has low production cost and produces non-evaporating bricks with strong frost-resistant performance, low drying shrinkage value and high strength over MU15.

Owner:武汉钢铁有限公司

Aging method of cylindrical lithium ion batteries

InactiveCN102035025APromote regenerationEasy to chooseFinal product manufactureElectrolyte accumulators manufactureRegenerative processLithium electrode

The invention relates to an aging method of cylindrical lithium ion batteries, which comprises the following steps: charging a battery cell to increase the voltage to that of an initial battery cell; and placing the battery cell in an environment with the preset aging temperature. By adopting the high temperature aging method, the regenerative process of forming a solid electrolyte interface (SEI) is promoted more effectively to form a more even and stable SEI film, and a battery cell the interior microcircuit of which has low voltage can be better picked out. Compared with the existing methods, the aging time is shorter, the temperature is higher, and compared with the normal battery cells, the voltage of the battery cell with interior micro short circuit is more obvious, so that the battery cell with low voltage can be picked out more easily, thereby shortening the period, saving the energy source and increasing the economic benefits.

Owner:BALEAF XIAMEN NEW ENERGY TECH

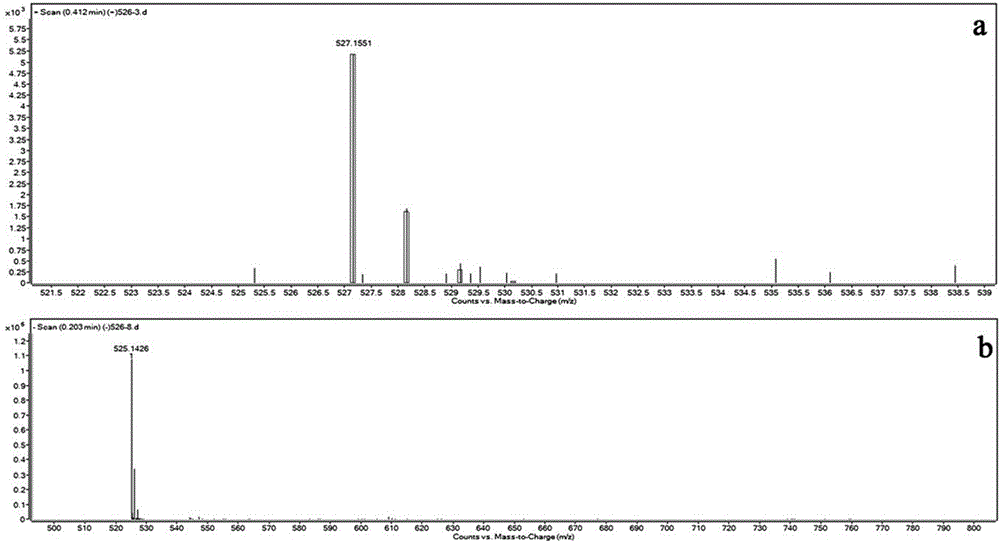

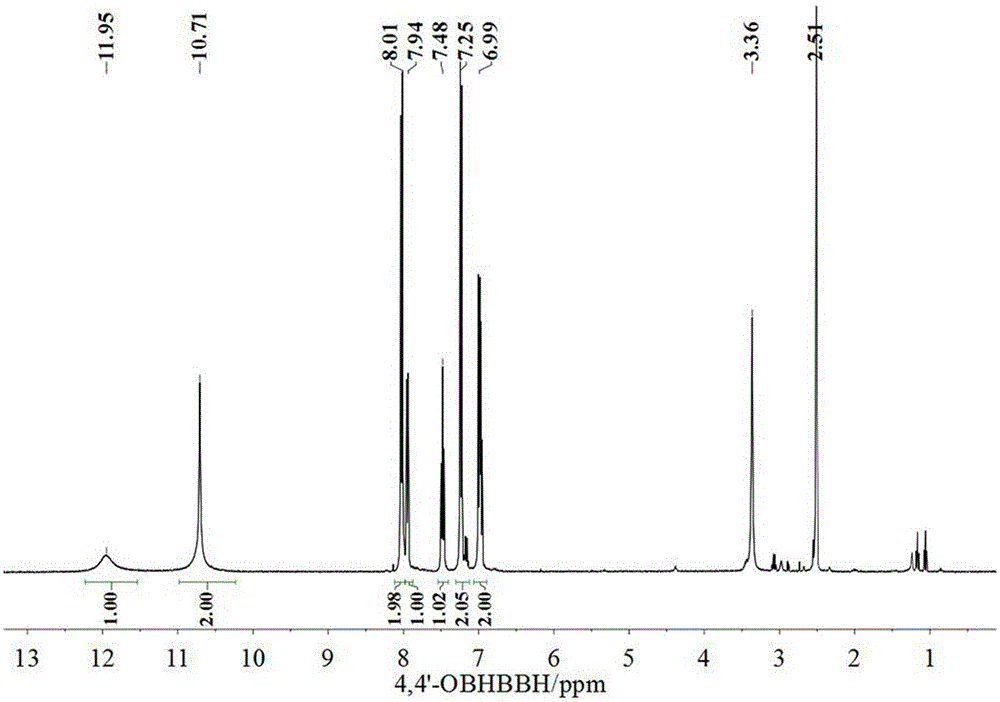

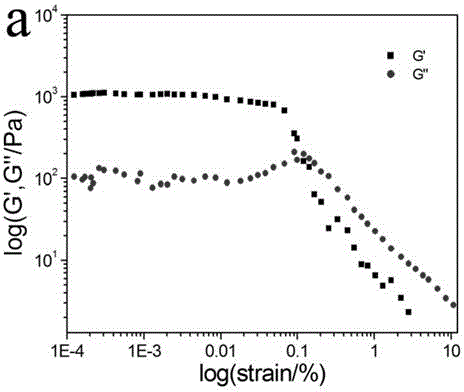

Aggregation luminescence enhancement ammonia sensitive metal-organic gel compound soft material and preparation thereof

InactiveCN104829487AImprove stabilityReduce manufacturing difficultyOther chemical processesHydrazide preparationPhenacylOrganic solvent

The present invention discloses an aggregation luminescence enhancement ammonia sensitive metal-organic gel compound soft material and a preparation method thereof. According to the invention, the gel compound soft material is prepared from newly-synthesized 4, 4 '-oxybis-N '-(2-hydroxy benzoyl) benzoyl hydrazine as a ligand and zinc acetate hydrate in the presence of a polar organic solvent at room temperature, and the gel mass fraction is about 1.3 wt % (solute / solvent* 100%). The gel material has a significant aggregation luminescence enhancement effect and ammonia gas sensitive luminescence response function, also has the functions of selective adsorption of dyes and in-situ preparation of nano gold particles and the like. The preparation method is simple and easy to operate, the raw material price is moderate, and the production cost is low.

Owner:FUZHOU UNIV

Processing method of blackberry fruit wine

InactiveCN103642622AIncrease the juice yieldPure tasteAlcoholic beverage preparationCold treatmentFruit wine

The invention discloses a processing method of a blackberry fruit wine. The processing method takes blackberry and honeysuckle flower as the main raw materials, and then subjects the raw materials to processes of pre-treating, mixing, clarifying, inoculating, fermenting, ultra-filtering, brewing, examining, packing, and sterilizing so as to obtain the blackberry fruit wine. During the process of blackberry pulping, wheat bran is added and mixed with the blackberries, and thus the blackberry juice yield is increased. In the enzymolysis process, a plurality of enzymes is mixed, so the nutrients in blackberries can be comprehensively decomposed. In the fermentation process, microzyme, which is selected and subjected to an enlarged cultivation, is adopted in order to guarantee the pure taste of fermentation liquid. In the brewing process, a microwave assisted cold treatment method is adopted, so that the brewing time is short, the microzyme is pure, and the enzymolysis effect is good. The blackberry fruit wine has the advantages of rich nutrients, rich taste, and fruity and pure fragrance.

Owner:张俊辉

Vermicelli and production method thereof

The invention relates to vermicelli which comprises the following components in parts by weight: 55-65 parts of sweet potato starch,10-14 parts of potato starch, 7-9 parts of corn starch, 1.4-1.8 parts of vermicelli opening agent and proper amount of water, wherein the vermicelli opening agent is the vermicelli opening agent containing no alum in another patent application of the applicant. The invention further discloses a production method of the vermicelli. The production method comprises the following steps of: ingredient mixing, stirring, powder processing, powder cutting, natural aging, soaking, vermicelli bulking, cleaning, dehydrating and drying, powder selecting and weight, drying, natural moisture absorbing and regaining and the like, and finally a finished product is prepared. With the production method for producing, the process flow is smooth, the aging time is short, the vermicelli bulking is easy, the production effect is improved, the labor productivity is improved, the product performance is improved, the prepared vermicelli can not stick together, can not break, can not make soup muddy, has no odor, and is glittering and translucent, the color of the vermicelli can be adjusted randomly from taupe to white according to requirements, all the minor ingredients an be purchased from the market, the vermicelli has no toxic and side effects, has production cost, and is suitable for industrialized production or small-scale production.

Owner:许兆宏

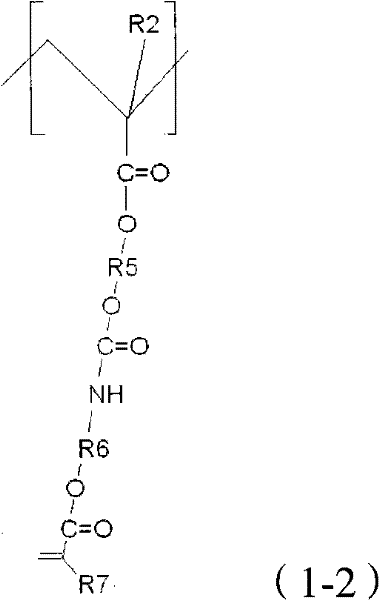

Adhesive binder, adhesive composition including the same, optical member, and a method for preparing adhesive binder layer

InactiveCN102181244APrevents common phenomenon light leakageShorten aging timeFilm/foil adhesivesPolyureas/polyurethane adhesivesHigh humidityAdhesive

An adhesive binder, an adhesive composition including the same, a method for preparing the adhesive, an optical member including the optical film, and a method for forming an adhesive binder layer, the adhesive binder including a (meth)acrylic copolymer having urethane, hydroxyl, aromatic, and vinyl groups in side chains thereof. The adhesive composition is endurable in the high-temperature and high-humidity condition. Additionally, the adhesive composition is used for reducing the time of solidifying and preventing the frequent light leakage in the polarization film.

Owner:CHEIL IND INC

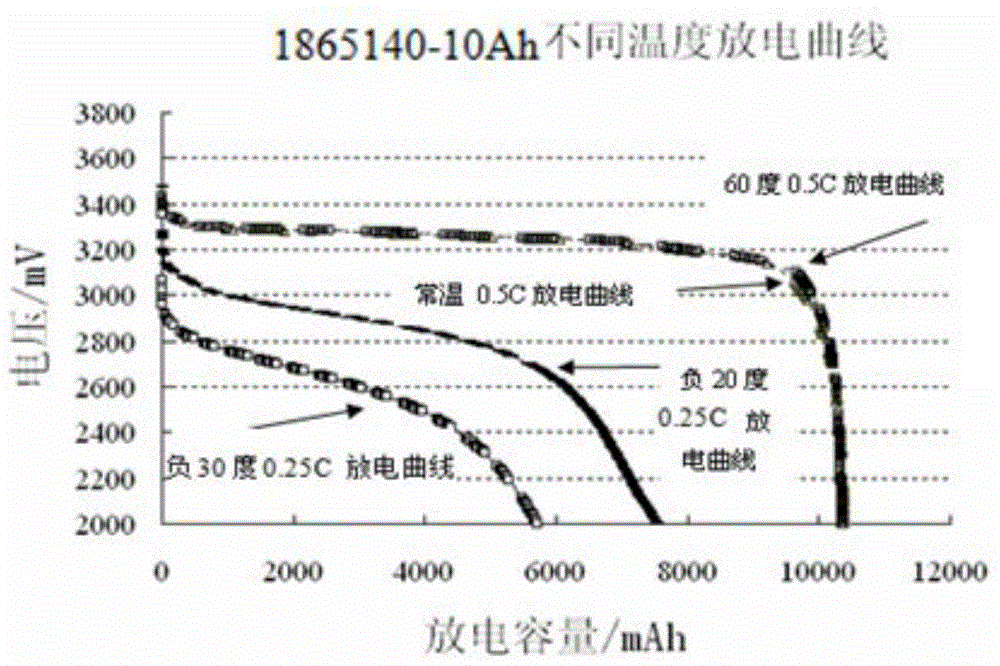

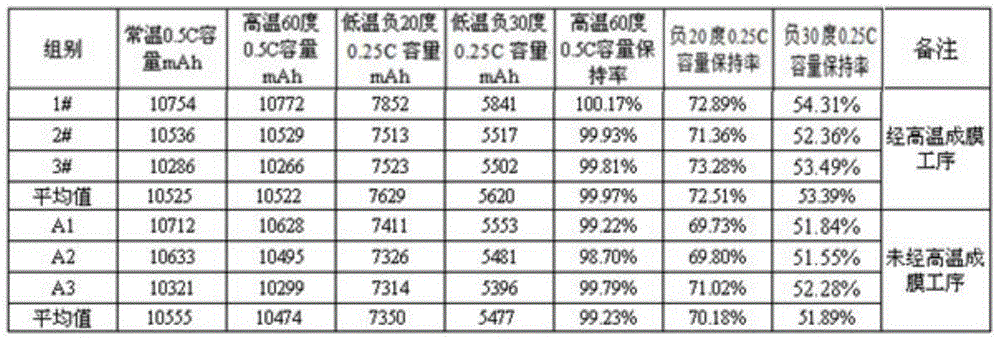

Lithium iron phosphate power battery and preparation method thereof

InactiveCN104393331ABoth high and low temperatureImprove high temperature performanceFinal product manufactureCell electrodesCooking & bakingMethyl carbonate

The invention discloses a lithium iron phosphate power battery and a preparation method thereof. Secondary particle lithium iron phosphate, which is agglomerated by primary nano particles and has the D50 value of 1-3 mu m, is taken as a positive active material; a negative electrode utilizes high-interlayer-spacing synthetic graphite with an amorphous carbon coating structure; a diaphragm utilizes a high-air-permeability diaphragm with PP, PE and PP as a base material, and the air permeability is not greater than 300 s / 100 ml; an electrolyte liquid comprises the following ingredients: 25-35% ethylene carbonate (EC), 5-10% propylene carbonate (PC), 25-35% ethyl methyl carbonate (EMC) and 10-15% diethyl carbonate (DEC); lithium salt is a composite conductive salt of lithium hexafluorophosphate and lithium difluoroborate, and the concentration of the lithium salt is 10-15%; and the additive comprises butanedinitrile, ethylene sulfite and fluorinated hydrocarbon. Square aluminum shell lithium-ion battery positive and negative electrode plates are subjected to treatment of winding, core-winding, cover plate welding, shelling, baking, laser welding, secondary baking, injecting, forming, air exhausting, steel ball pressing, volume dividing and 45-75 DEG C high-temperature aging for 120-24 hours at a high temperature to form the film.

Owner:YUNNAN TIN GROUP HLDG

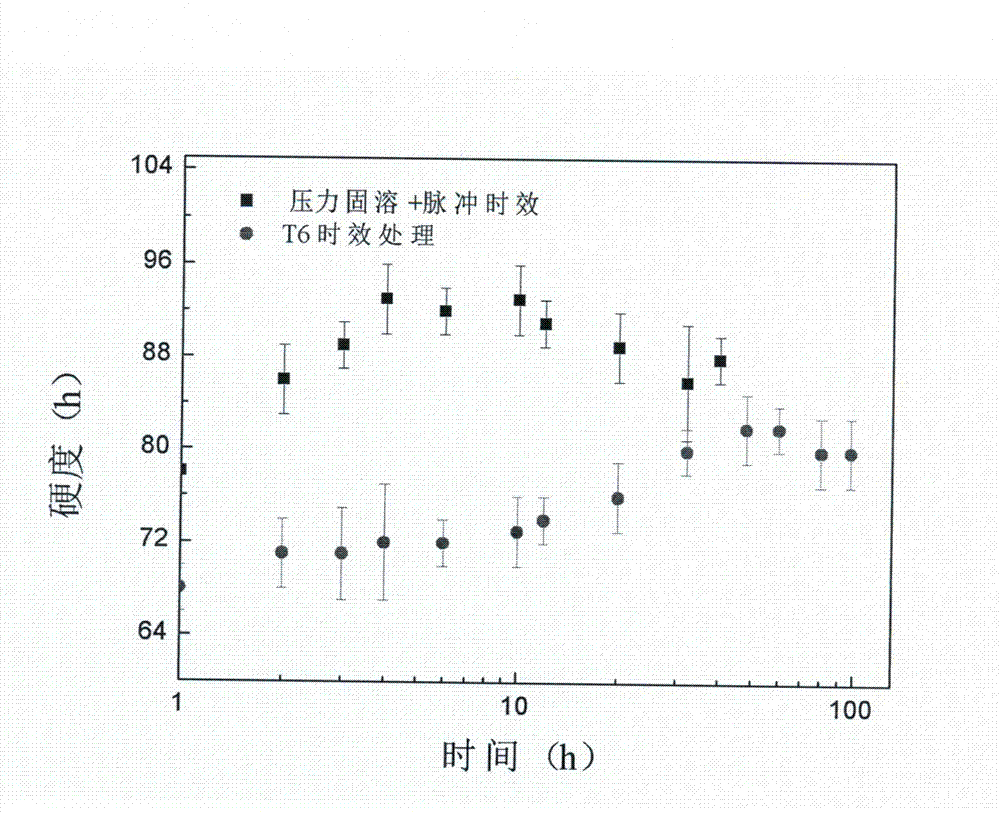

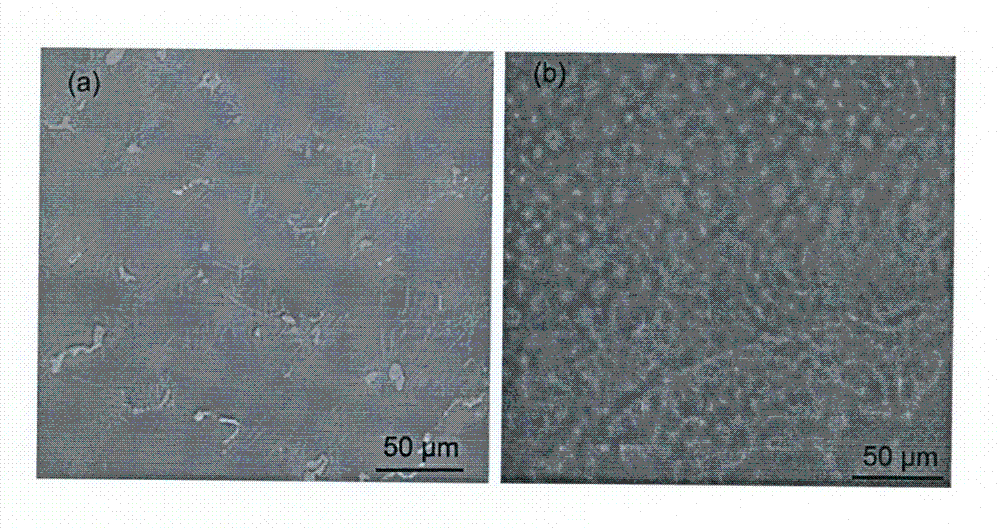

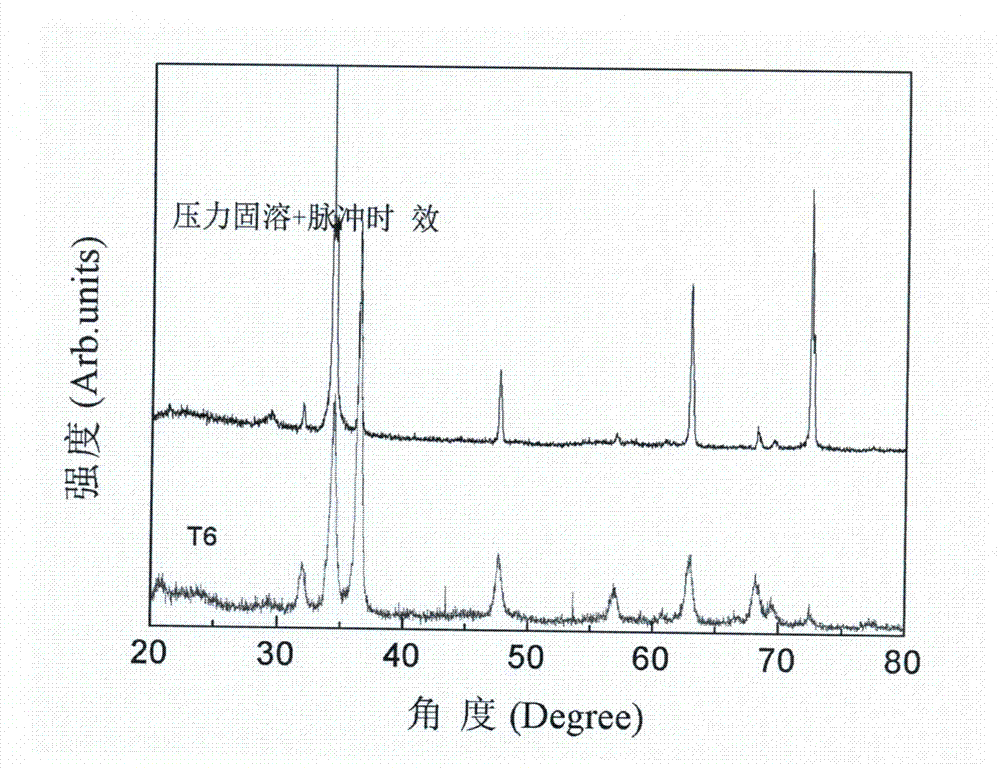

Thermal treatment method suitable for magnetism alloy with age-hardening property

The invention discloses a thermal treatment method suitable for magnetism alloy with an age-hardening property. The magnetism alloy with the age-hardening property is Mg-xM-0.6Zr-0.2Mn based alloy, M contains Sn, Pb, Zn and rare earth, and x ranges from 5 to 20 wt%. When multiple kinds of rare earth elements are included, the contents of all rare earth elements are same. Solid solution is carried out on the magnetism alloy under an isobaric outer field of 0.5 to 1GPa and 0.7 to 0.85 Tm (Tm: the melting point of the alloy), and the time of solid solution ranges from 2 to 4 hours. Pressure is removed after the treatment; the hot water ranges from 60 to 80 DEG C is directly used for cooling; under the external stress of 30 to 50 MPa and the pulse electric field of 1 to 10 Kv / cm, room temperature aging is carried out for 10 to 50 thousands of pulses per hour, and the pulse interval is 1 second; and the peak hardness can be acquired. The thermal treatment method suitable for the magnetism alloy with the age-hardening property has the advantages of simplicity in operation technology, short aging time, low aging temperature, low energy consumption and the like.

Owner:YANSHAN UNIV

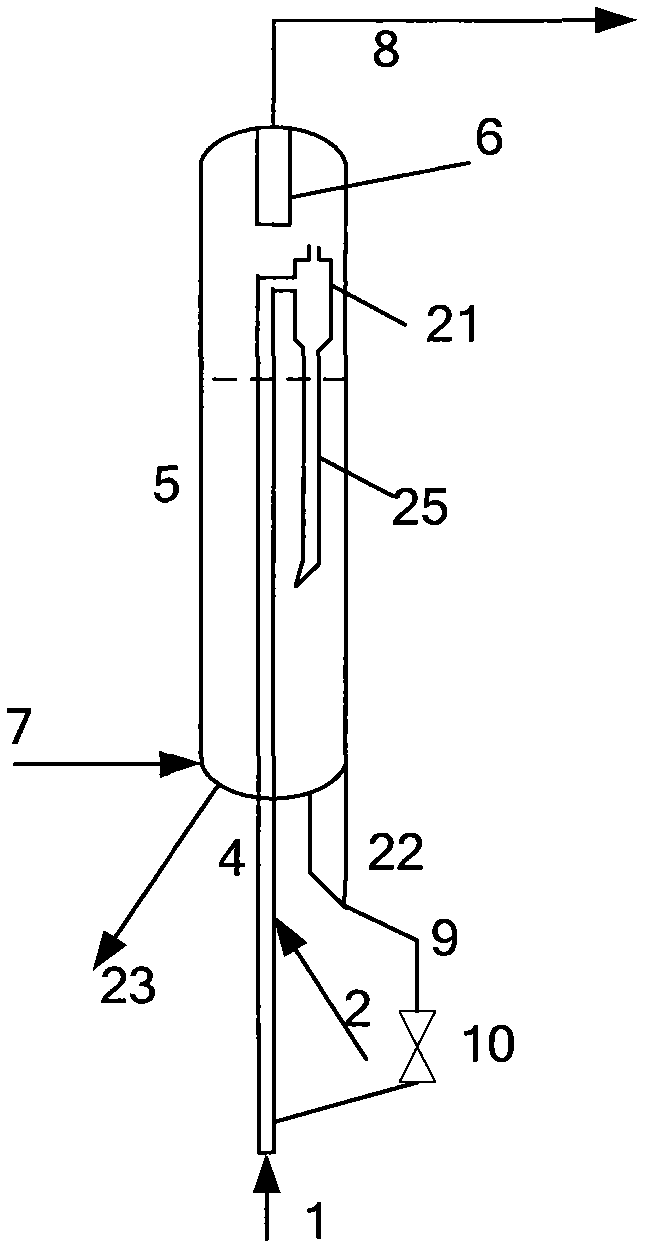

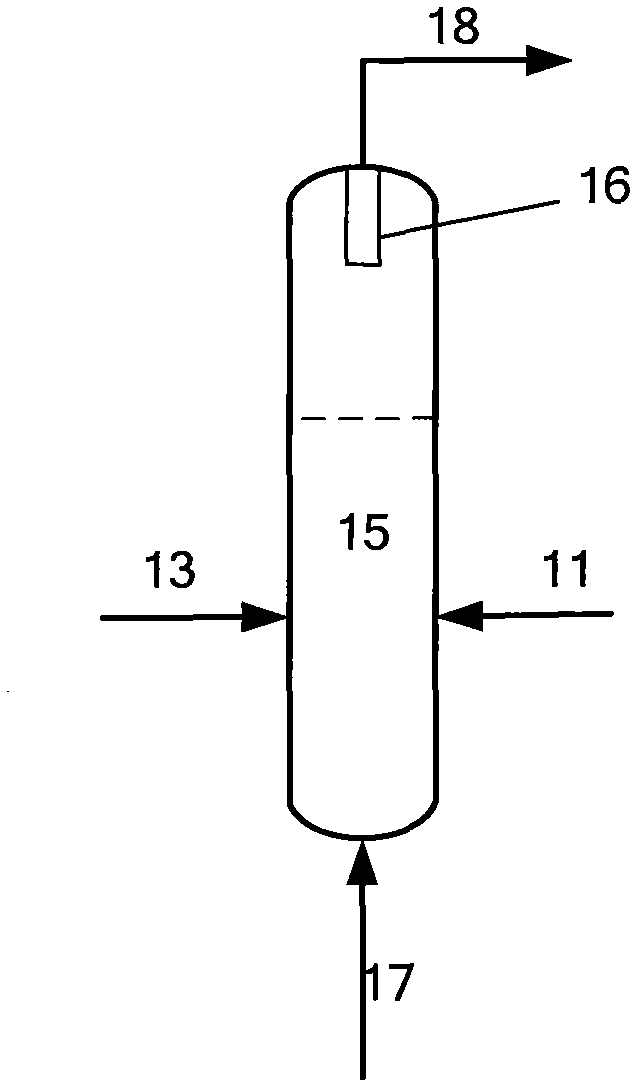

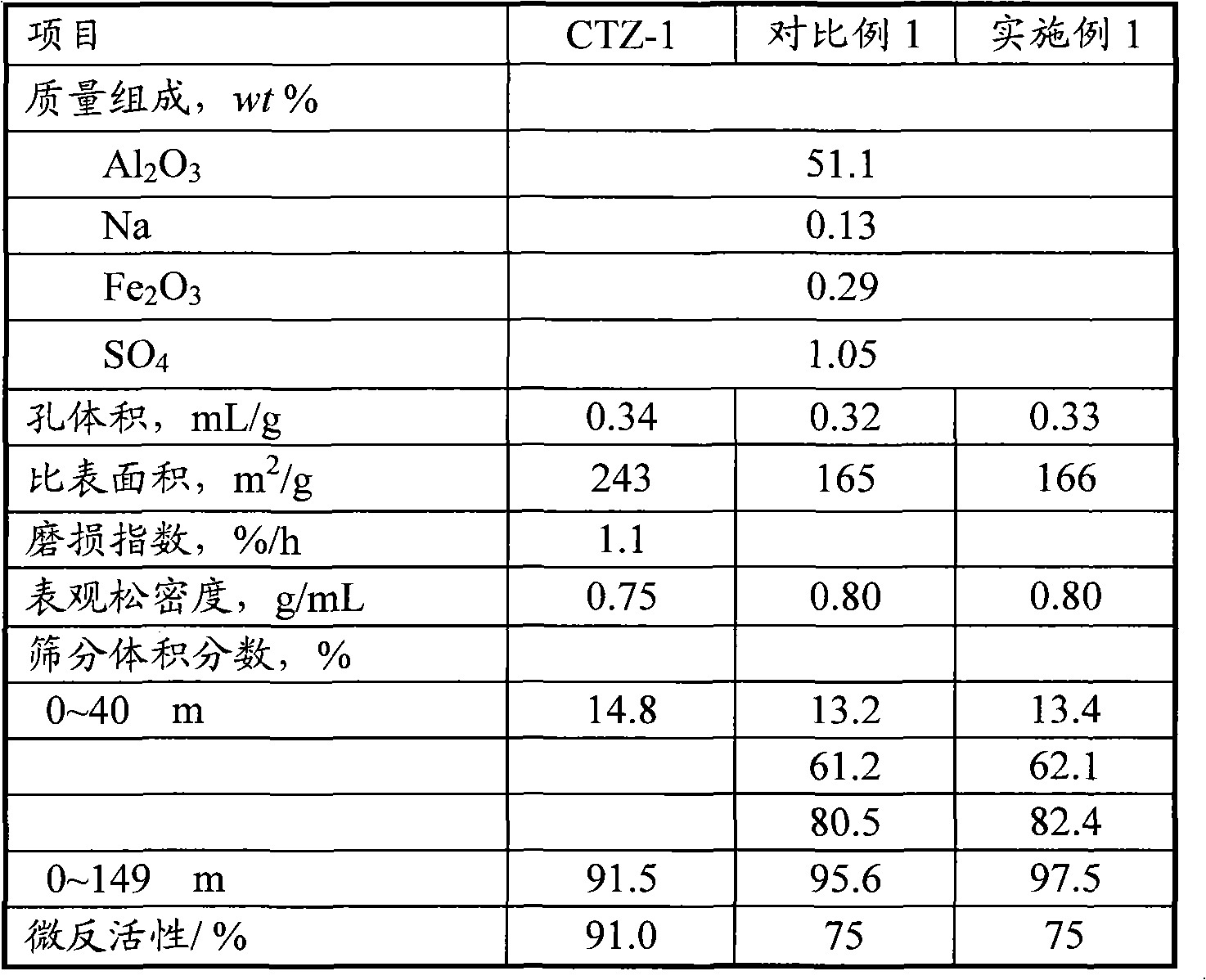

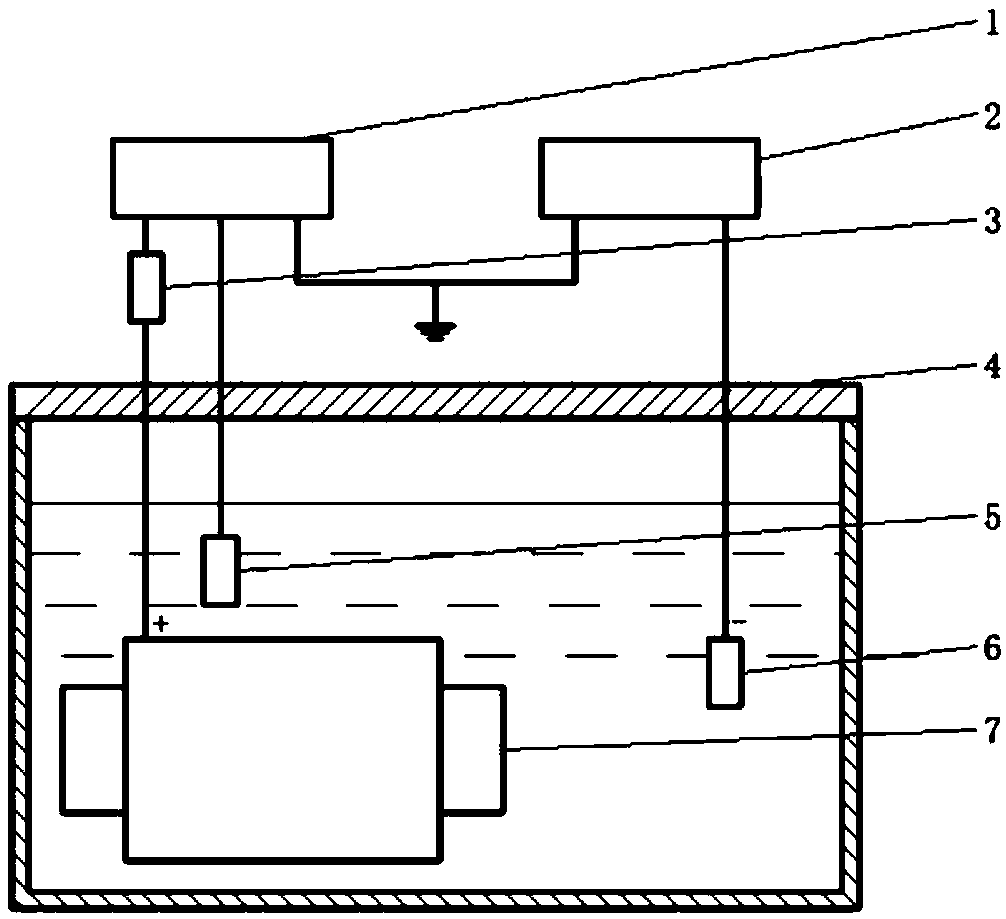

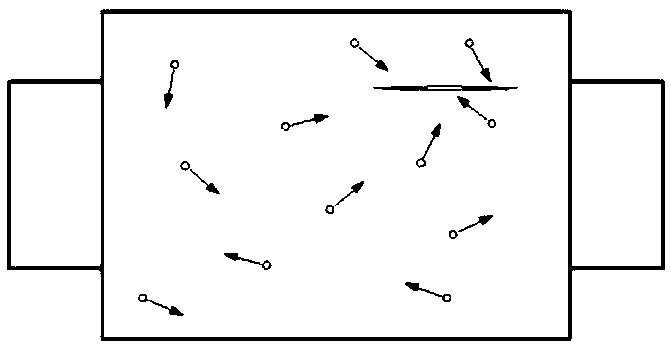

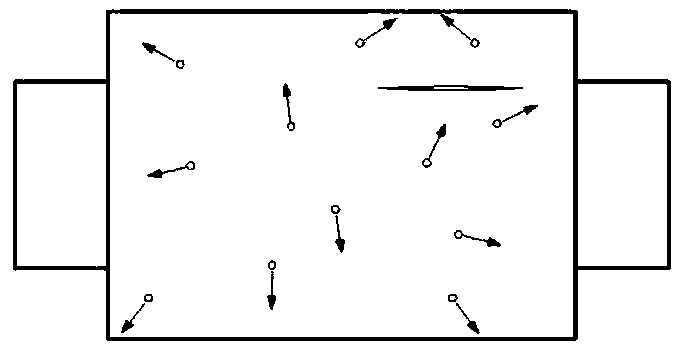

Catalytic cracking catalyst continuous aging method and device

The invention relates to a catalytic cracking catalyst continuous aging method and a catalytic cracking catalyst continuous aging device. The method comprises the steps that: a catalyst enters a bottom of a dilute-phase combustion tube, and then mixed with oxygen-containing gas and a fuel; the mixture is combusted and flows upward; gas-solid separation is carried out at the port of the dilute-phase combustion tube; catalyst obtained by separation enters a fluidized-bed reactor; the catalyst is subjected to a reaction with steam, such that activity is reduced; gas-solid separation is carried out at the top of the fluidized-bed reactor, and gas is discharged out of the device; the catalyst enters a catalyst buffering tank from the bottom of fluidized-bed reactor, and is circulated back to the bottom of the dilute-phase combustion tube through a control valve; when aging is finished, the catalyst is unloaded; material level in the catalyst buffering tank is maintained, and the catalyst continues to participate in circulation reaction in the dilute-phase combustion tube and the fluidized-bed reactor. The invention also relates to a device used for realizing the aging method. With the aging method and device provided by the invention, combustion reaction and hydro-thermal reaction operation conditions can be respectively controlled; and activity of aged catalyst is uniformly distributed. When the catalyst is used in hydrocarbon oil catalytic cracking reactions, product distribution can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nickel-cobalt-manganese-lithium power battery and manufacturing method thereof

InactiveCN104393332AIncrease energy densityImprove high temperature storage performanceCell electrodesSecondary cellsAlkaline earth metalCobalt

The invention discloses a nickel-cobalt-manganese-lithium power battery and a manufacturing method thereof. A positive electrode active substance with the diameter 50 being 8-10 microns adopts nickel-cobalt-manganese-lithium, and a negative electrode adopts one or two of a middle-phase carbon microsphere, artificial graphite and composite graphite; a diaphragm adopts a three-layer composite diaphragm of which the surface is coated with Al<2-x>BxO3 (x=0.02-0.1), namely an Al<2-x>BxO3 / PP / PE / PP high-security ceramic diaphragm, wherein B is one or several of alkaline-earth metal ions, rare earth metal ions and transitional metal ions; electrolyte consists of 25-30 percent of acid-containing vinyl ester, 5-10 percent of propylene carbonate (PC), 25-30 percent of fluorobenzene (FB) and 10-15 percent of diethyl carbonate (DEC); lithium salt is lithium hexafluorophate (LiPF6) with the concentration being 10-12 percent; an additive is vinylethylene carbonate (VEC), sulfuric acid and vinyl resin, fluorinated hydrocarbon, biphenyl, maleate and maleimide and accounts for 10 percent of the total amount of the electrolyte; positive and negative plates of a profile aluminum shell lithium ion battery are subjected to winding, core lapping, cover plate welding, feeding into a shell, baking, laser welding, secondary baking, liquid injection, formation, gas extraction, steel ball pressing, partial containing, high-temperature aging under 45-75 DEG C and high-temperature heating for 120 hours to 24 hours for film forming.

Owner:YUNNAN TIN GROUP HLDG

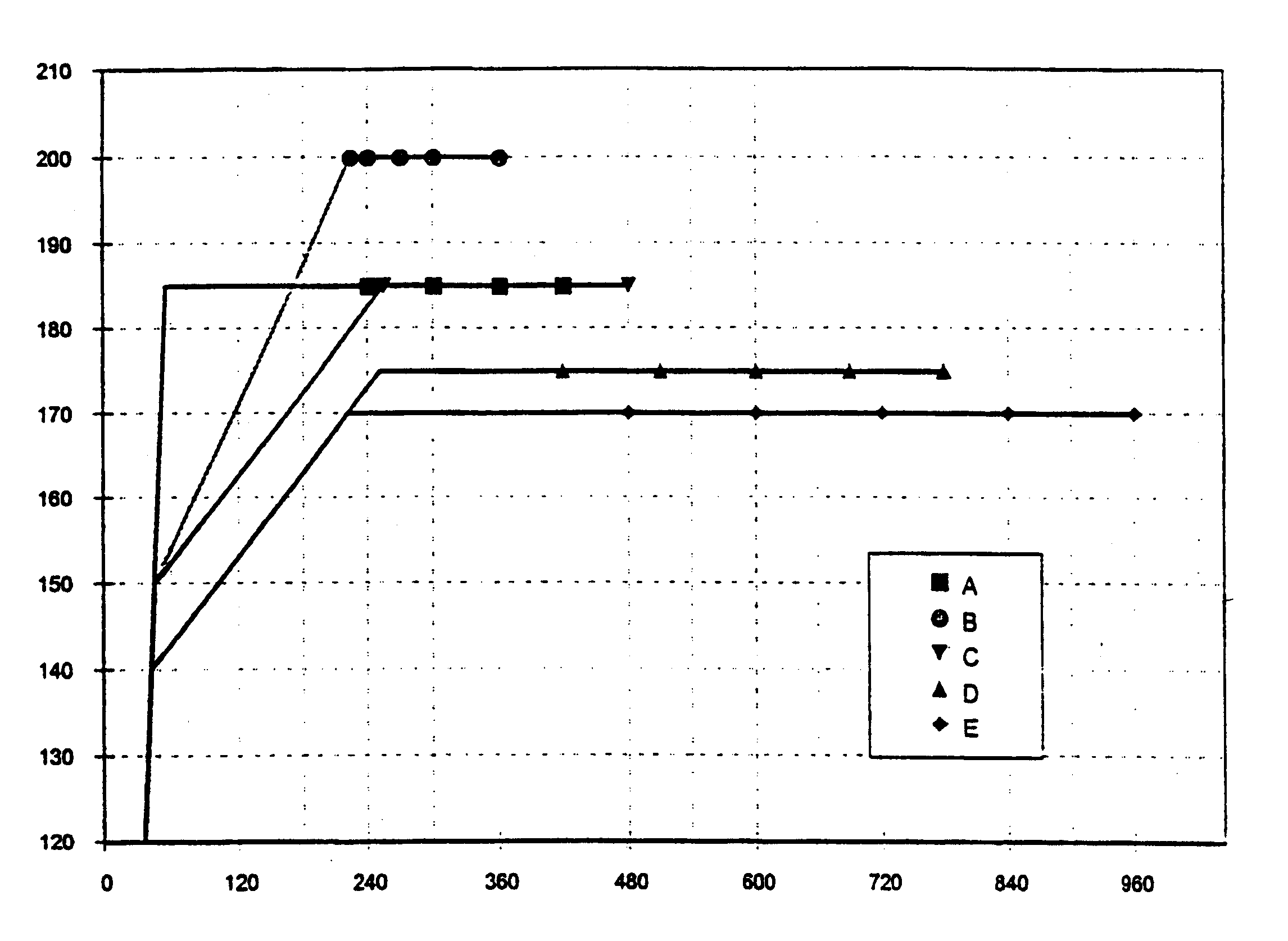

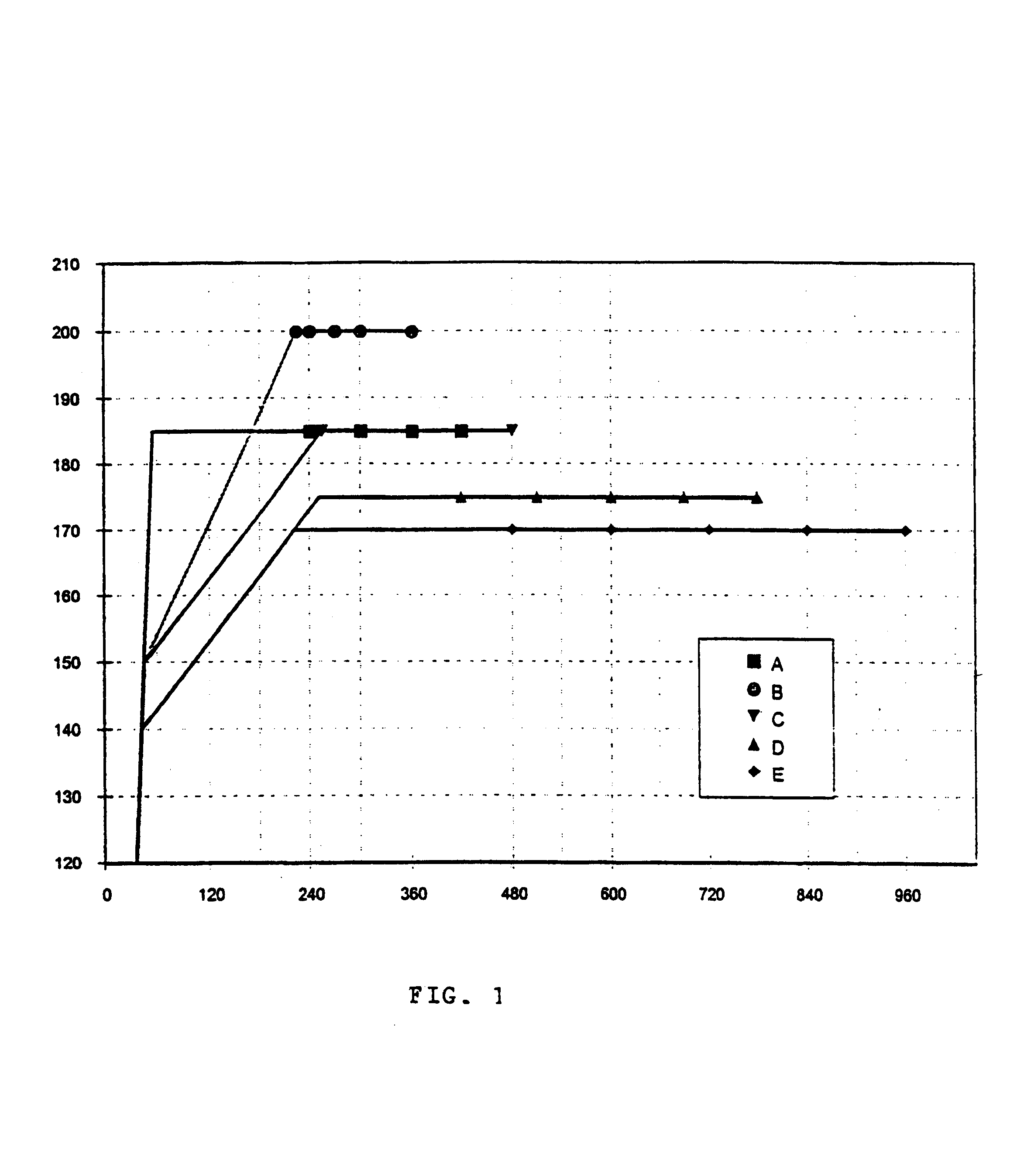

Process of aging an aluminum alloy containing magnesium and silicon

An ageing process capable of producing an aluminum alloy with better mechanical properties than possible with traditional ageing procedures. The ageing process employs a dual rate heating technique that comprises a first stage in which the aluminum alloy is heated at a first heating rate to a temperature between 100 and 170° C. and a second stage in which the aluminum alloy is heated at a second heating rate to a hold temperature of 160 to 220° C. The first heating rate is at least 100° C. / hour and the second heating rate is 5 to 50° C. / hour. The entire ageing process is performed in a time of 3 to 24 hours.

Owner:NORSK HYDRO ASA

High-activity nitro humic acid compound fertilizer and preparation method thereof

PendingCN108059577AIncreased activationPromote growthAlkali orthophosphate fertiliserExcrement fertilisersPhosphateBiological activation

The invention belongs to the field of fertilizer, and particularly relates to high-activity nitro humic acid compound fertilizer and a preparation method thereof. The method comprises the preparationsteps that 5 to 7 parts of lignite are put into a reaction kettle; 0.001 part of rhamnolipid is added; then, dilute nitric acid is added for performing oxidizing reaction; then, ammonium bicarbonate is added; the pH is regulated to be 6 to 7; next, aging is performed for 4 to 6h to obtain nitro humic acid; meanwhile, bacillus amyloliquefaciens is diluted by water into a bacterium suspension with the effective bacterium content being 1*10<7>cfu / ml; the bacterium suspension is inoculated to the organic fertilizer; a fermentation filling material is prepared; the nitro humic acid, the fermentation filling material, ammonium nitrate, monoammonium phosphate and potassium sulphate are uniformly mixed, and are put into a pelletizer; steam is introduced, and sulfuric acid and ammonia gas are introduced; pelleting is performed to obtain the nitro humic acid compound fertilizer. The preparation method is simple; the lignite activation degree is high; the prepared compound fertilizer can effectively improve the crop yield; the hardening degree of the soil is effectively improved; the utilization rate of the fertilizer is improved.

Owner:CHONGQING HUAQIANG ECOLOGICAL FERTILIZER IND CO LTD

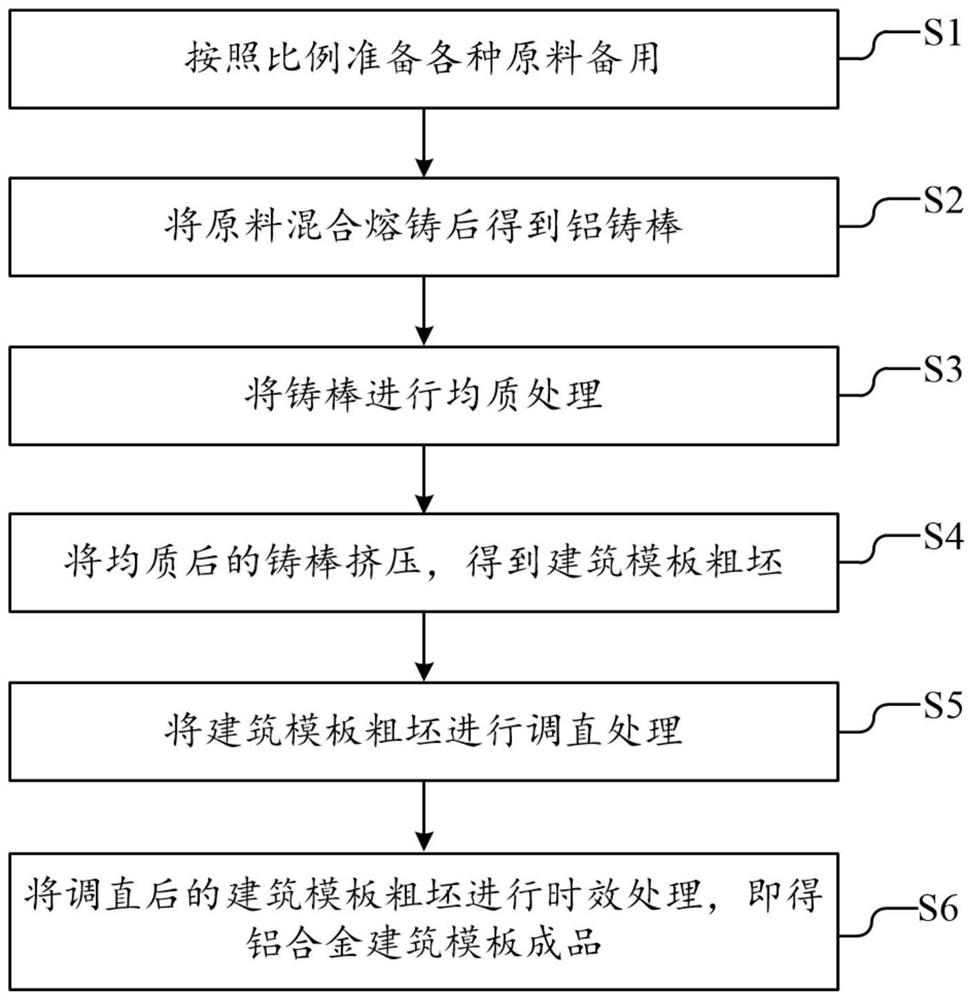

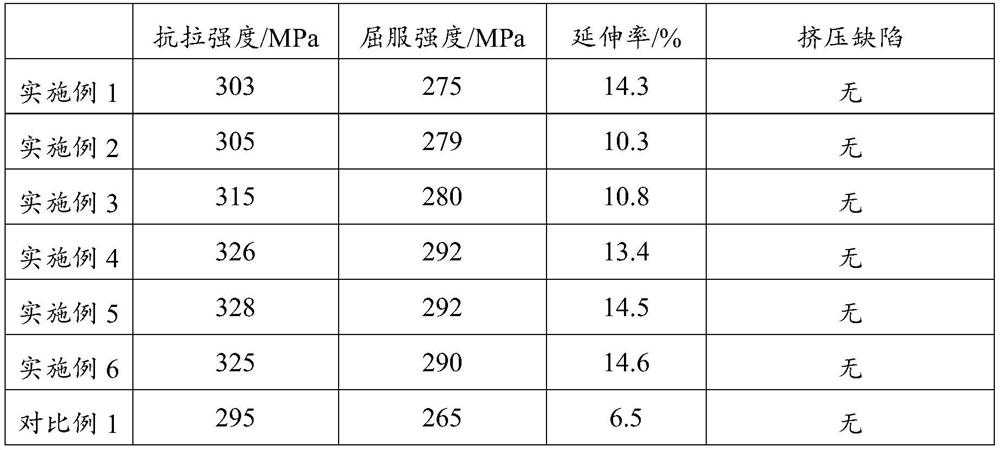

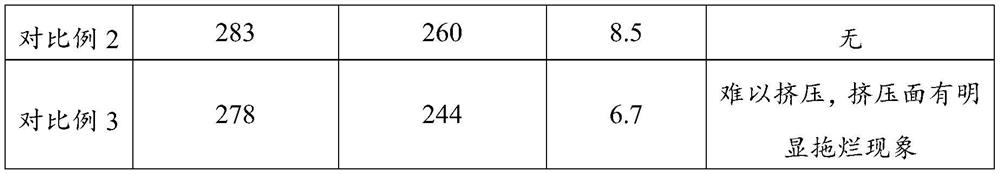

Aluminum alloy building formwork and preparation method thereof

PendingCN113234972AReduced Quench SensitivityImprove solid solubilityFurnace typesHeat treatment furnacesAluminium alloyMechanical properties of carbon nanotubes

The invention discloses an aluminum alloy building formwork mainly comprising, by mass, 0.4%-1.0% of Si, 0.8%-1.3% of Mg, 0.05%-0.2% of Cu, 0.001%-0.15% of Mn, 0.2%-0.7% of Fe, less than or equal to 0.25% of Zn, 0.001%-0.1% of Cr, 0.03%-0.15% of Ti and the balance Al and inevitable impurities. The content of the inevitable impurities is less than or equal to 0.15%. Correspondingly, the invention further discloses a preparation method of the aluminum alloy building formwork. The aluminum alloy building formwork is excellent in mechanical property, the extrusion speed can reach 8-10 m / min, and the production efficiency is high.

Owner:GUANGDONG JMA ALUMINUM PROFILE FACTORY GRP +1

Quick ageing processing method for white tea

The invention discloses a quick ageing processing method for white tea. According to the method, white tea dried in the sun is damp and hot alternatively converted for three times in an ageing room, so as to obtain the aged white tea. The method is short in ageing time and simple in operation. The acquired aged white tea is characterized by orange red bright tea soup, mellow flavor, arabian jasmine flower fragrance and sweat aftertaste with drug fragrance.

Owner:横县南方茶厂

Casting process of aluminum alloy ingots for ships and warships

The invention discloses a casting process of aluminum alloy ingots for ships and warships. The process comprises the following steps that A, alloys are smelted to obtain aluminum alloy melts; B, the aluminum alloy melts are subjected to counter gravity casting, and the aluminum alloy ingots are obtained; and C, the obtained aluminum alloy ingots are sequentially subjected to homogenization, solidsolution treatment and aging treatment, and the aluminum alloy ingots for the ships and warships are obtained. The process can obtain the aluminum alloys with the excellent comprehensive properties like tensile strength, yield strength, ductility and exfoliating corrosion resistance, solves the problems that when existing aluminum alloys are applied on ships, the aluminum alloys are poor in corrosion resistance and low in intensity, and accordingly prolonging the service life of the ships in complex and atrocious environments of the ocean.

Owner:CENT SOUTH UNIV

Wine processing technology

The invention discloses a wine processing technology. The wine processing technology comprises 1, selecting grapes with sugar content greater than or equal to 12%, removing decayed, diseased and broken grapes and foreign materials and adding potassium metabisulfite into the grapes according to a weight ratio of 1: 25000-1: 6000, 2, breaking the grapes, putting the grapes into a tank, carrying out natural fermentation at the room temperature of 20-22 DEG C, when the fermentation residual sugar ratio is 0.2% or less, discharging the grape paste out of the tank and carrying out distillation,3, treating oak chips through 0.06-0.07 mol of alkali lye at a temperature of 10-15 DEG C for 2 days, putting the oak chips into the fermented wine, storing the wine at a temperature of 20-25 DEG C for 6-8 months, carrying out bottling, adjusting alcoholic strength to 40 and cane sugar content to 0.5%, adding essence into the wine, carrying out refrigeration, standing and filtration and then carrying out bottling. The wine processing technology has simple processes and short aging time and realizes a thick wine fragrance.

Owner:QINGDAO SHOUTAI AGRI SCI & TECH CO LTD

Ambergris perfume formula

InactiveCN103599042AReasonable formulaOptimized formulaCosmetic preparationsToilet preparationsSandalwood oilMusk ketone

The invention discloses an ambergris perfume formula. The perfume is composed of raw materials of ambergris tincture, a rose absolute oil, musk ketone, a myrcia oil, a sandalwood oil, a jasmine essence and ethanol. The ambergris perfume formula is reasonable and simple, can be used immediately after being prepared, has short alcoholization time, pure and refreshing fragrance and lasting fragrance, has efficacies of raising spirit, refreshing consciousness, eliminating body odor and beautifying the environment, and is widely loved by the people.

Owner:SUZHOU CITY WUZHONG DISTRICT TAIHU LIGHT TEXTILE

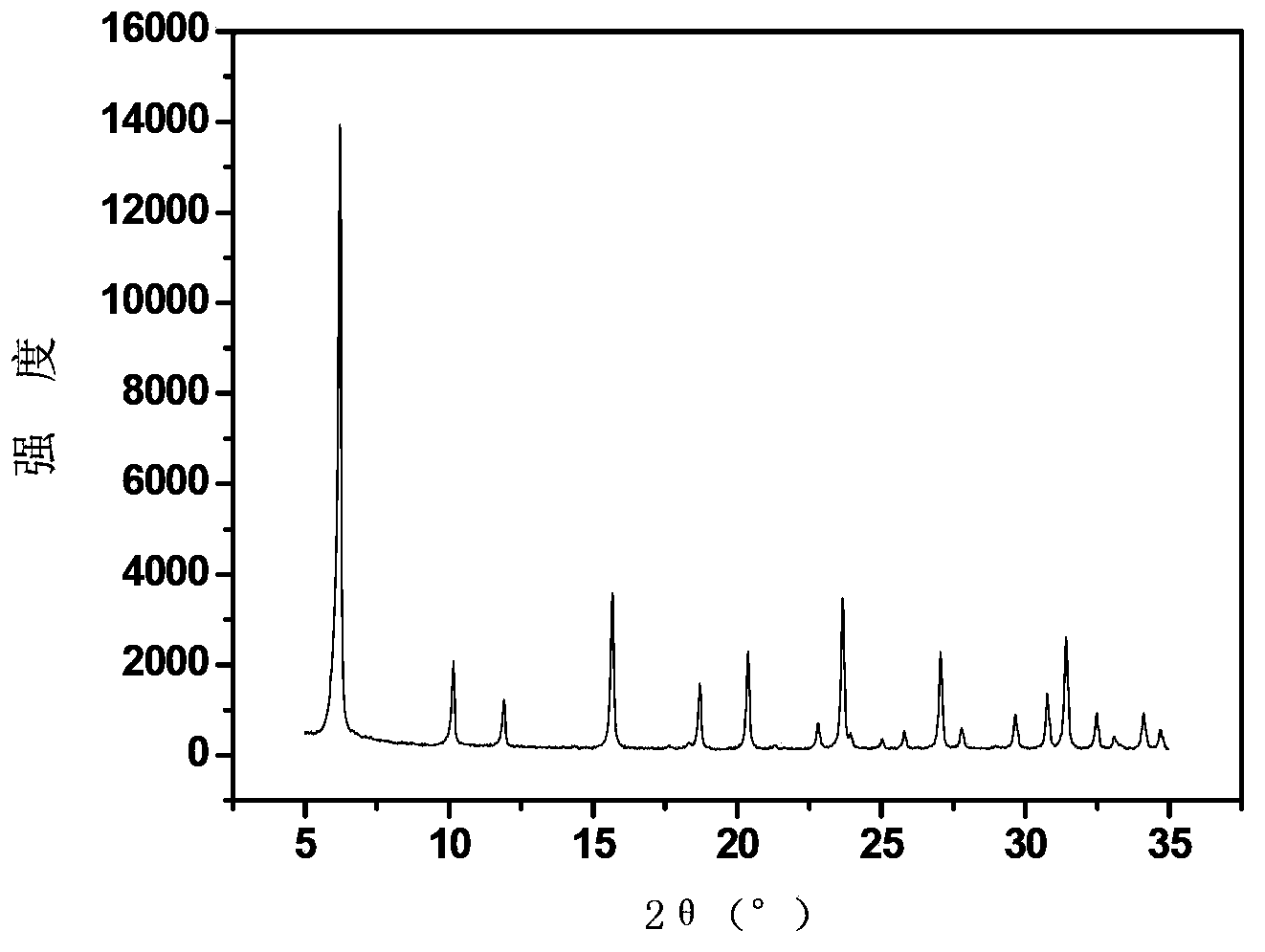

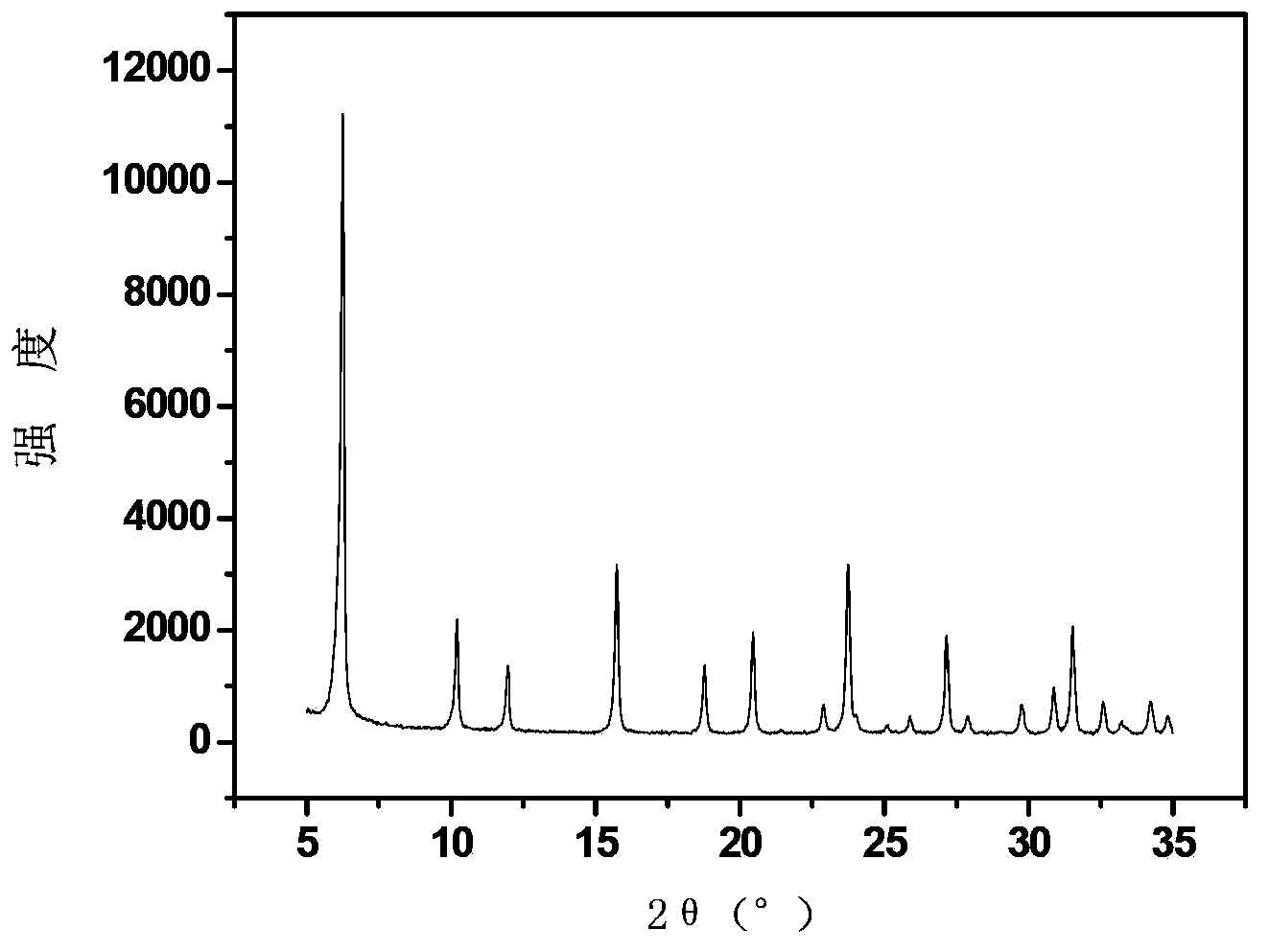

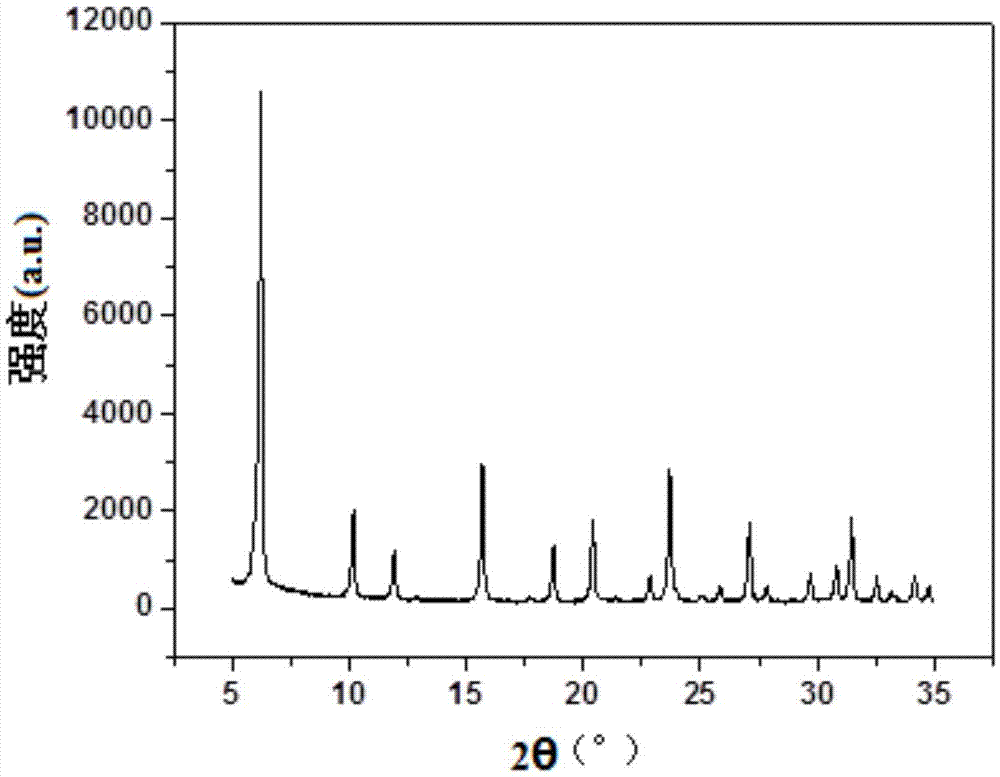

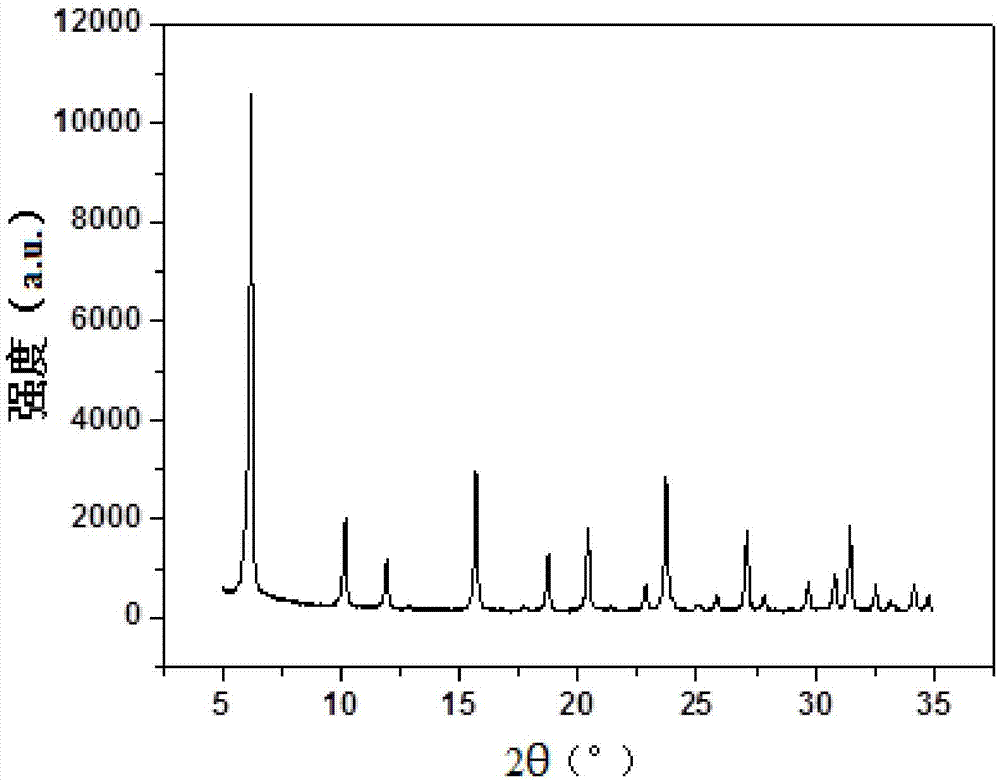

Y molecular sieve and preparation method thereof

InactiveCN106927484AImprove production efficiencyHigh activityFaujasite aluminosilicate zeoliteMolecular sieveMicrowave

The invention relates to a preparation method of a Y molecular sieve. The preparation method includes mixing a silicon source with an aluminum source, adding oxygen-containing organic matter and water into the mixture, and ageing the mixture at the temperature of 15-60 DEG C for 1-60 hours to obtain a guiding agent; adding the guiding agent, an alkaline solution and the water into the silicon source at the temperature of 10-90 DEG C, stirring for 1-80 hours, adding the aluminum source, and stirring evenly to obtain a gel reaction mixture; subjecting the gel reaction mixture to microwave heating, increasing the temperature to 80-120 DEG C, performing crystallization for 10-60 minutes, and performing filtering, washing and drying to obtain a Y molecular sieve product. By the preparation method, the Y molecular sieve with relative crystallinity of 80-85% and SiO2 / Al2O3 mole ratio of 4.8-5.2 can be synthesized in 10-60 minutes.

Owner:PETROCHINA CO LTD

Propolis odor type perfume formula

InactiveCN103599040AReasonable formulaOptimized formulaAntibacterial agentsCosmetic preparationsWound healingPropolis

The invention discloses a propolis odor type perfume formula. The perfume is composed of raw materials of a propolis extraction liquid, an essence, deionized water, a coloring matter and ethanol, and is prepared by the steps of mixing ethanol and deionized water for dissolving, adding deionized water into ethanol and stirring, after mixing evenly, adding the coloring matter for color modulation, after standing for a week, filtering, and then subpackaging. The propolis odor type perfume formula is reasonable and simple, can be used immediately after being prepared, has short alcoholization time, pure and refreshing fragrance and lasting fragrance, has efficacies of inhibiting bacteria, killing bacteria, relieving itching, deodorizing, promoting granulation growth and accelerating wound healing, and is widely loved by the people.

Owner:SUZHOU CITY WUZHONG DISTRICT TAIHU LIGHT TEXTILE

Refreshing perfume formula

InactiveCN103599016AReasonable formulaOptimized formulaCosmetic preparationsToilet preparationsLavender oilItching

The invention discloses a refreshing perfume formula. The perfume is composed of raw materials of a lavender oil, a mint oil, camphor, an essence, an evening primrose absolute oil and ethanol. The refreshing perfume formula is reasonable and simple, can be used immediately after being prepared, has short alcoholization time, pure and refreshing fragrance and lasting fragrance, has efficacies of diminishing inflammation, relieving itching, raising spirit and refreshing consciousness, and is widely loved by the people.

Owner:SUZHOU CITY WUZHONG DISTRICT TAIHU LIGHT TEXTILE

Electrochemical rapid hydrogen diffusion method for large forgings

The invention discloses an electrochemical rapid hydrogen diffusion method for large forgings. A forging as an anode is arranged in an electrolytic cell of an electrochemical hydrogen expansion device, an electrolyte is stored in the electrolytic cell and submerges the forging, the electrolyte is a sodium hydroxide solution having a concentration of 0.05 to 0.4 mol / L, the electrolyte has a temperature of 0-100 DEG C, a power supply is started and applies polarization constant potential of 0.1-5V / dm<2> to the forging so that the forging is polarized, in the experiment, a reference electrode isused as a zero potential point, the voltage is the potential difference relative to the zero potential point, the current change of the anode is observed and recorded and when the current density is less than a certain value of 0.5 micro-A / cm<2>, the reaction is finished. The method has the advantages of simple processes, convenient operation, easy control, energy saving, short aging time, low temperature and low energy consumption.

Owner:YANSHAN UNIV

Rapid aging and perfuming method for threaded dried tangerine or orange peel

The invention relates to a rapid aging and perfuming method for threaded dried tangerine or orange peel. The water content of dried threaded dried tangerine or orange peel is controlled within 13%, the dried and cooled threaded dried tangerine or orange peel is put into a sealed container B, Yunnan Puer tea of a same mass weight is put into a container A, oxygen or pure air is continuously introduced from one end of the container A, gases are discharged from the other end of the container A, discharged gases of t he container A are introduced from one end of the container and are discharged from the other end of the container B, then the air pressure in the container A and the container B is 0.15-0.25MPa higher than the atmospheric pressure, the time for completely exchanging the gases inthe container A with the container B is 60-90 minutes, the treatment time of the threaded dried tangerine or orange peel in the container B is 4-6 months, and thus threaded dried tangerine or orange peel which is good in aging quality and has the perfume with adsorbed fragrance of the Yunnan Puer tea is obtained. Compared with the prior art, the method has the advantages that frequent movement isnot needed, the aging time is short, the aging quality is ensured, and the perfume adsorbs the fragrance of the Yunnan Puer tea.

Owner:江门市新会区金康宝陈皮食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com