Al-Mg-Si as-cast aluminum alloy and aging treatment process thereof

A technology of aging treatment and pre-aging treatment, which is applied in the field of aluminum alloy heat treatment, can solve the problems of alloy performance degradation, aging treatment process is not specific and perfect, and achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

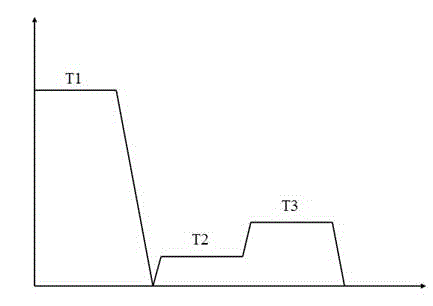

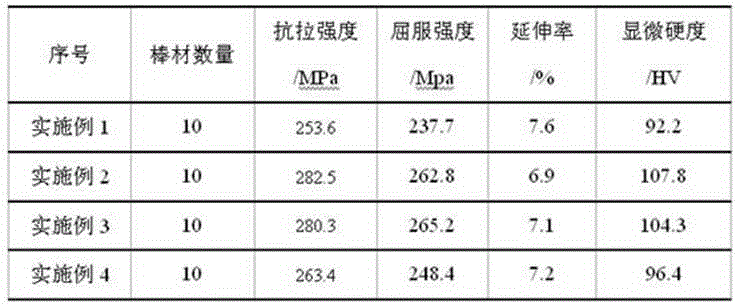

[0015] Example 1), calculated in parts by weight, the cast aluminum alloy consists of 6-8 parts of magnesium, 4-6 parts of silicon, 60-80 parts of aluminum, 2-3.5 parts of iron, 0-1 part of copper, and 0-1 part of zinc. 1 part, 0~1 part of manganese, 0~1 part of titanium, 0~1 part of chromium are mixed, and the Al-Mg-Si series cast aluminum alloy is subjected to solid solution treatment at a temperature of 520 ° C to 530 ° C and kept for 3 hours ~4 hours, and then aged at 200°C for 4 hours to 5 hours to peak T6 state.

Embodiment 2)

[0016] Example 2), calculated in parts by weight, the cast aluminum alloy consists of 6-8 parts of magnesium, 4-6 parts of silicon, 60-80 parts of aluminum, 2-3.5 parts of iron, 0-1 part of copper, and 0-1 part of zinc. 1 part, 0~1 part of manganese, 0~1 part of titanium, 0~1 part of chromium, and solid solution treatment of Al-Mg-Si cast aluminum alloy, temperature 520℃~530℃, heat preservation for 3 hours~ 4 hours, then the first stage is aged at 140°C for 3 hours to 4 hours, and the second stage is aged at 200°C for 3 hours to 4 hours.

Embodiment 3)

[0017] Example 3), calculated in parts by weight, the cast aluminum alloy consists of 6-8 parts of magnesium, 4-6 parts of silicon, 60-80 parts of aluminum, 2-3.5 parts of iron, 0-1 part of copper, and 0-1 part of zinc. 1 part, 0~1 part of manganese, 0~1 part of titanium, 0~1 part of chromium, and solid solution treatment of Al-Mg-Si cast aluminum alloy, temperature 520℃~530℃, heat preservation for 3 hours~ 4 hours, then the first stage is aged at 150°C for 2 hours to 3 hours, and the second stage is aged at 200°C for 2 hours to 3 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com