Lithium iron phosphate power battery and preparation method thereof

A technology of lithium iron phosphate and power battery, which is applied in the field of lithium iron phosphate energy storage power battery, which can solve the problems of process influence, high temperature performance, and large specific surface area of nano-materials, so as to improve high and low temperature performance and high safety Performance, improvement of high temperature performance and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

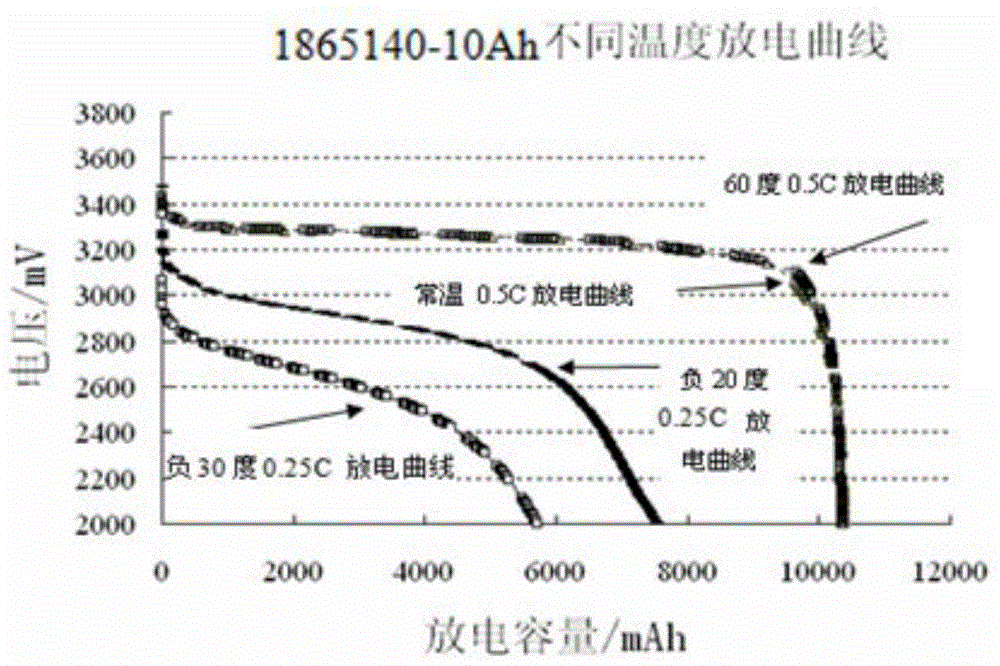

example 1865140-10

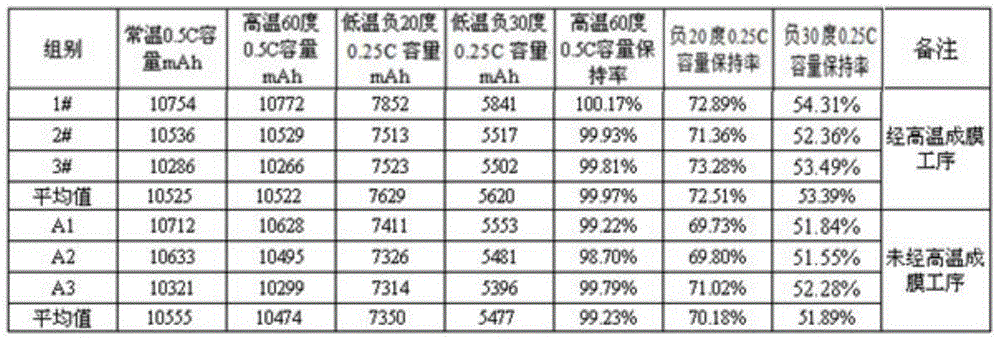

[0018] Example of the present invention 1865140-10Ah lithium iron phosphate lithium ion battery

Embodiment 1

[0020] 1. Secondary particles formed by agglomeration of primary nanoparticles of positive active material D50 (1-3um). The negative electrode adopts high-layer spacing artificial graphite with amorphous carbon coating structure. It is beneficial to improve the high and low temperature performance of the battery.

[0021] 2. The diaphragm is made of PP, PE, PP with a high air permeability diaphragm, and the air permeability is ≤300s / 100ml.

[0022] 3. The electrolyte adopts high and low temperature solvent formula, containing EC25%-35%, PC5%-10%, EMC25%-35%, DEC 10%-15%, lithium salt is LiPF6, lithium difluorooxalate borate composite conductive Salt, concentration 10%-15%. The additives are succinonitrile, vinylene sulfate, and fluorinated hydrocarbons.

[0023] 4. The positive and negative plates of the aluminum shell power lithium-ion battery are wound, wound cores, welded cover plates, shelled, baked, laser welded, secondary baked, liquid injected, formed, pumped, presse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com