Warm mix polymer modified asphalt and its preparation method

A technology for modifying asphalt and polymers, which is applied in building construction, building insulation materials, production of bulk chemicals, etc., can solve the problems of high service temperature, poor thermal stability and anti-aging performance of asphalt, and environmental pollution. Achieve the effect of low production and use temperature, improve anti-aging performance and shorten reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

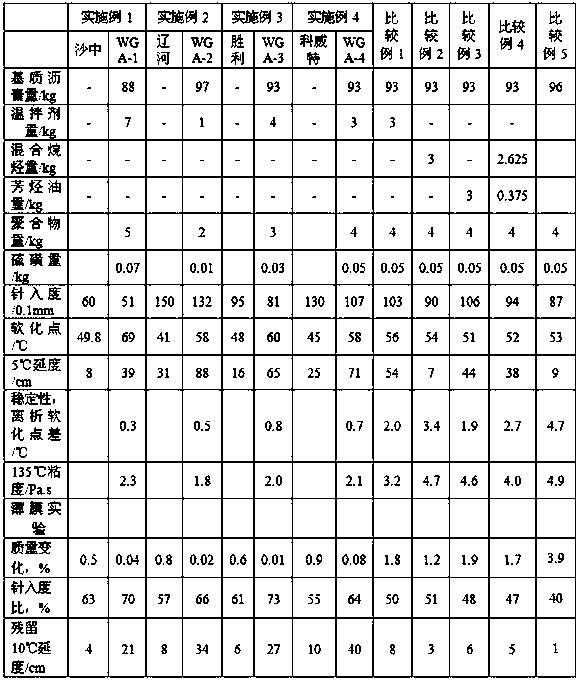

Embodiment 1

[0055] (1) Preparation of warm mixing agent

[0056] Using Ni metal as a catalyst, the CO obtained after coal gasification is combined with H 2 The synthesis reaction is carried out to obtain a mixed alkane with a carbon number of 30-60 alkane accounting for 90%.

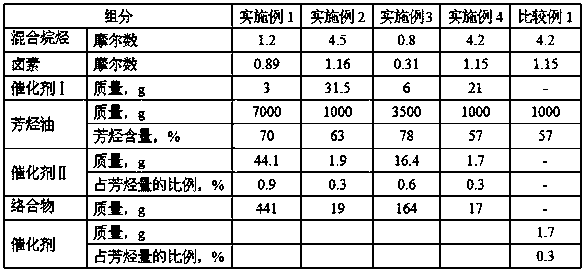

[0057] ① Weigh 1000g of the above mixed alkanes, about 1.2mol, put it in a closed container, heat to 480℃, add 3g of catalyst anhydrous CuCl 2 , Keep this temperature and introduce 0.89 mol of chlorine, and pass nitrogen to keep the pressure of the reaction vessel at 3MPa, react for 30min to obtain the intermediate;

[0058] ②Weigh 7000g minus four-line extraction oil with 70% aromatic content, and add 441g complex [Cu(NH 3 ) 4 〕SO 4 And 44.1g of catalyst Cu, packed in another airtight container and heated to 350°C, reacted at this temperature for 180min at a constant temperature to obtain the aromatic complex component;

[0059] ③Introduce the aromatic complex component into the above intermediate, keep the temperature at 4...

Embodiment 2

[0064] (1) Preparation of warm mixing agent

[0065] Using Co metal as a catalyst, the CO obtained after coal gasification is combined with H 2 The synthesis reaction is carried out to obtain mixed alkanes with 90% carbon number of alkanes from 30 to 130.

[0066] ① Weigh 3500g of the above mixed alkanes, about 4.5mol, put them in a closed container, heat to 400℃, add 31.5g of catalyst anhydrous MnCl 2 , Keep this temperature and introduce 1.16mol of chlorine, and pass nitrogen to keep the pressure of the reaction vessel at 5MPa, react for 60min to obtain the intermediate;

[0067] ②Weigh 1000g of FCC oil slurry with 63% aromatic content, and add 19g of complex K to it 4 〔Fe(CN) 6 ] And 1.9g of catalyst Fe, packed in another airtight container and heated to 270°C, reacted at this temperature for 120 minutes at a constant temperature to obtain the aromatic hydrocarbon complex component;

[0068] ③Introduce the aromatic complex component into the above intermediate, keep the temperature ...

Embodiment 3

[0073] (1) Preparation of warm mixing agent

[0074] Using Fe metal as a catalyst, the CO obtained after coal gasification, and H 2 The synthesis reaction is carried out to obtain mixed alkanes with a carbon number of 70-90 alkanes accounting for 90%.

[0075] ① Weigh 1000g of the above mixed alkanes, about 0.8mol, put it in a closed container, heat it to 440℃, add 6g catalyst anhydrous NiCl 2 , Keep this temperature and introduce 0.31 mol of fluorine, and blow in nitrogen to keep the pressure of the reaction vessel at 4MPa, react for 45 minutes to obtain the intermediate;

[0076] ②Weigh 3500g of phenol refined extract oil with 78% aromatic content, and add 164g of complex [Ni(CO) 4 ] And 16.4g of catalyst Ni, packed in another airtight container and heated to 310°C, reacted at this temperature for 160min at a constant temperature, to obtain aromatic hydrocarbon complex components;

[0077] ③Introduce the aromatic complex component into the above intermediate, keep the temperature at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com