Preparation method of high-strength nanocrystalline type medical Beta titanium alloy for orthopaedic implanting

A β-titanium alloy and nanocrystalline technology, which is applied in the field of preparation of high-strength nanocrystalline medical β-titanium alloy, can solve the problems of low plasticity of non-toxic medical titanium alloy nanomaterials, cancer-induced senile dementia, elastic modulus mismatch, etc. , to achieve the effects of increasing phase transition induced stress, short aging time and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

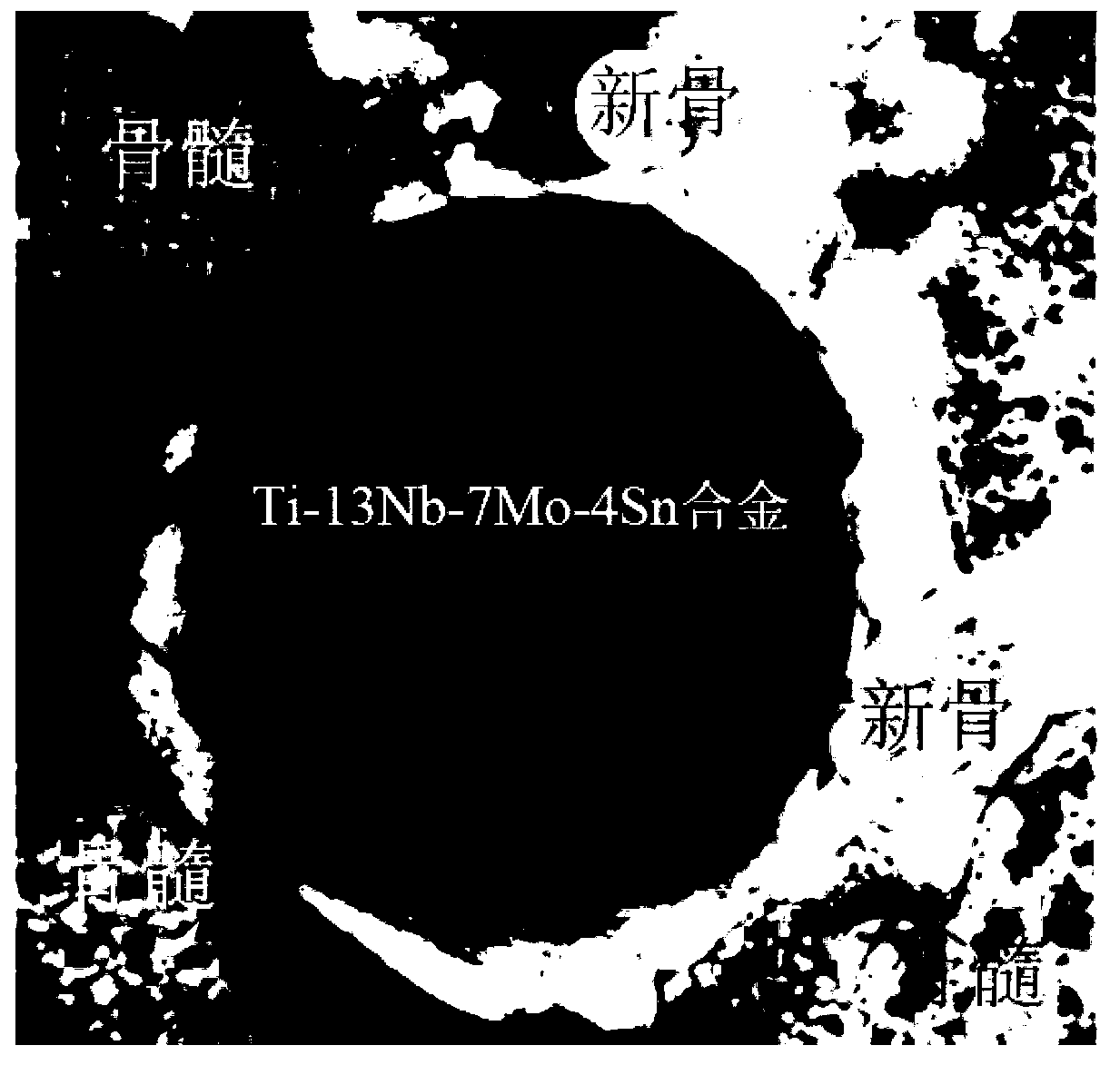

[0049] The preparation process of this example is as follows: according to the weight percentage, Nb13; Mo7; Sn4; Ti balance is weighed, and the Ti is divided into three parts and respectively mixed with Nb element, Mo element and Sn element in a vacuum melting furnace to obtain a Ti-Nb alloy , Ti-Mo alloy and Ti-Sn alloy; then put the obtained Ti-Nb alloy, Ti-Mo alloy and Ti-Sn alloy together to evacuate and then fill with argon protection, and repeat the melting five times in the vacuum melting furnace , in a water-cooled copper mold for instant suction casting, to obtain an alloy sheet with an average grain size of less than 10 μm and a thickness of 5 mm; the cooling rate of the rapid solidification treatment of the mold cooling method is 10 6 K / s; Then, the alloy sheet obtained by the rapid solidification treatment is rolled at a low temperature of -140°C in a twin-roll mill under liquid nitrogen cooling, and the rolling strain rate is 5s-1, and it is directly rolled to the...

Embodiment 2

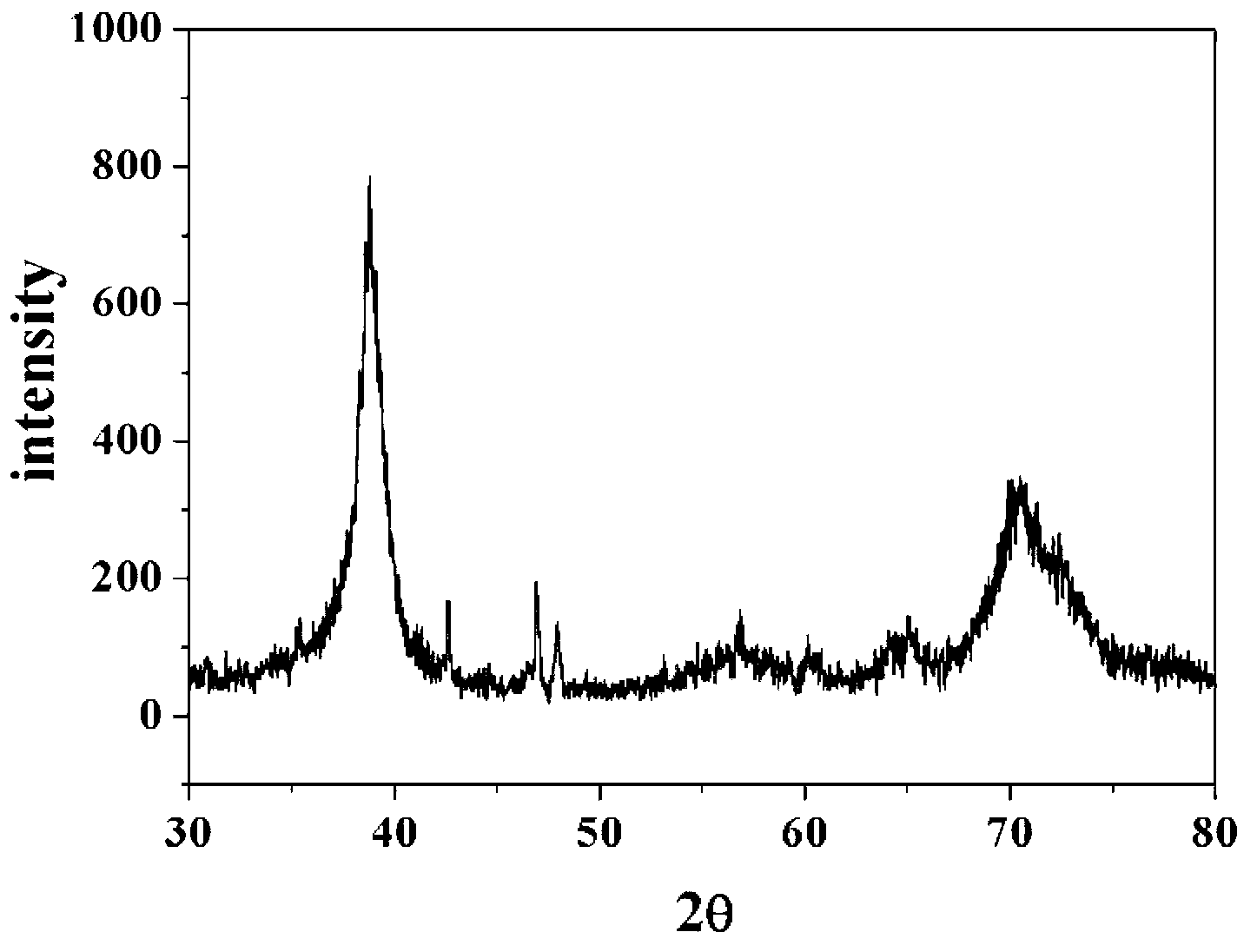

[0051] The preparation process of this example is as follows: Different from Example 1, the alloy sheet obtained by the rapid solidification treatment is rolled at a low temperature by a twin-roll mill under liquid nitrogen cooling, and is directly rolled to a thickness of 0.5mm sheet (deformation is 90%), the grain size is about 40 nanometers; the alloy after low-temperature cold treatment is aged at 823K for 200s, and the average grain size of the final nanocrystalline titanium alloy is about 45 nanometers ( Figure 6 , Figure 7 ), the strength is 1450MPa, and the plasticity is 17% ( Figure 8 ), the elastic modulus is 47GPa, and the hyperelastic recovery strain is 4.4% ( Figure 9 ).

Embodiment 3

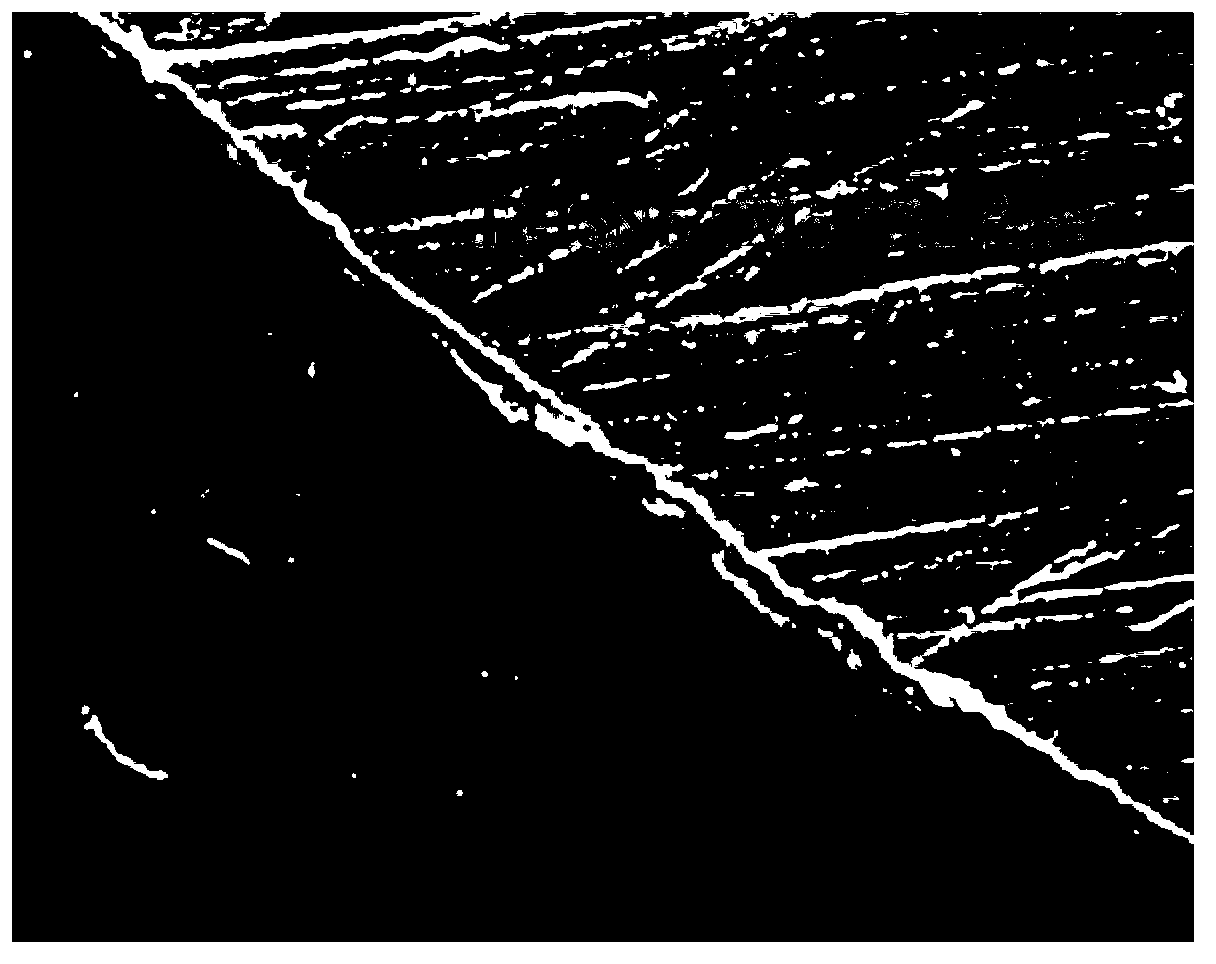

[0053] The preparation process of this example is as follows: Different from Example 1, the alloy sheet obtained by the rapid solidification treatment is rolled at a low temperature by a twin-roll mill under liquid nitrogen cooling, and is directly rolled to a thickness of 0.65mm sheet (87% deformation), the grain size is about 20-50 nanometers; the alloy after low-temperature cold treatment is aged at 923 for 250s, and finally the nanocrystalline titanium alloy is prepared with an average grain size of about 45 nanometers and high strength. It is 1340MPa, and the plasticity is 20% ( Figure 10 ), the elastic modulus is 41GPa, and the hyperelastic recovery strain is 4.1% ( Figure 11 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com