Patents

Literature

48results about How to "No glitches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

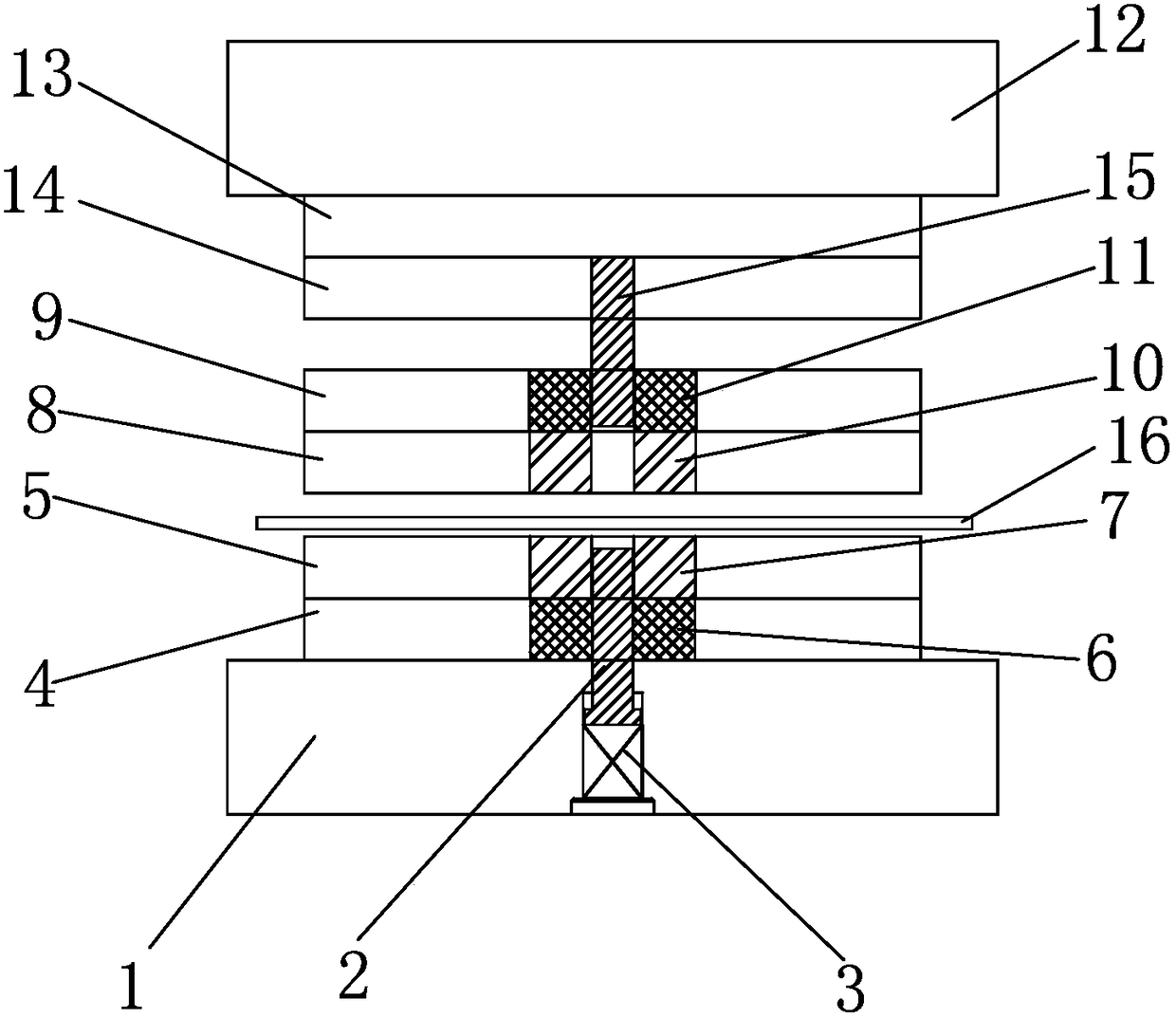

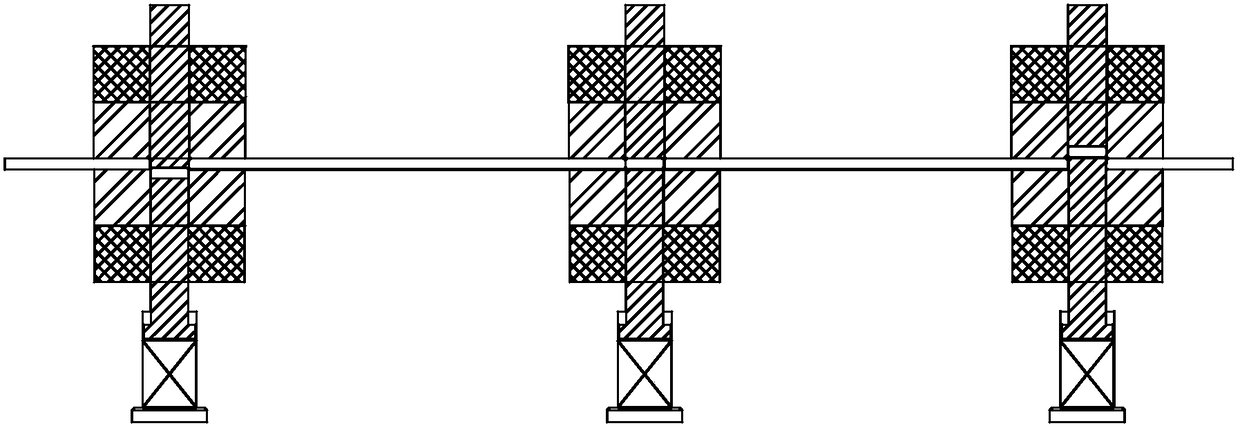

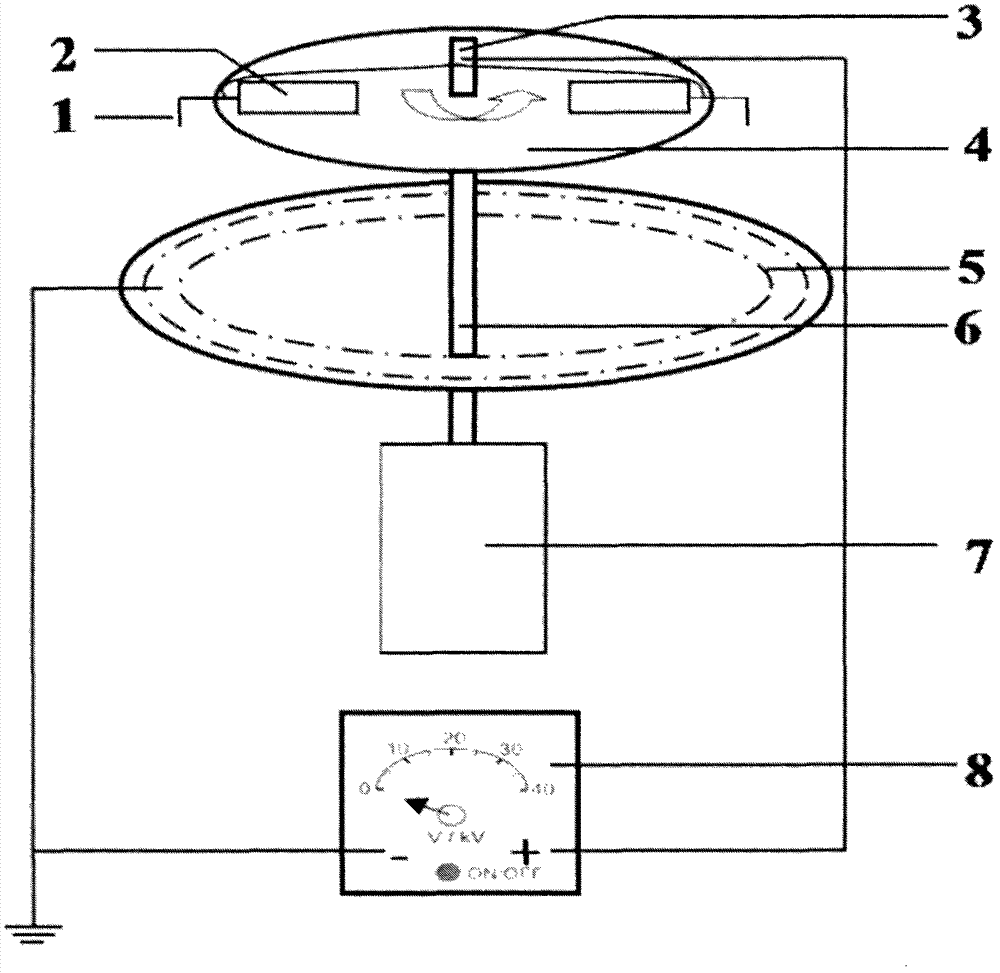

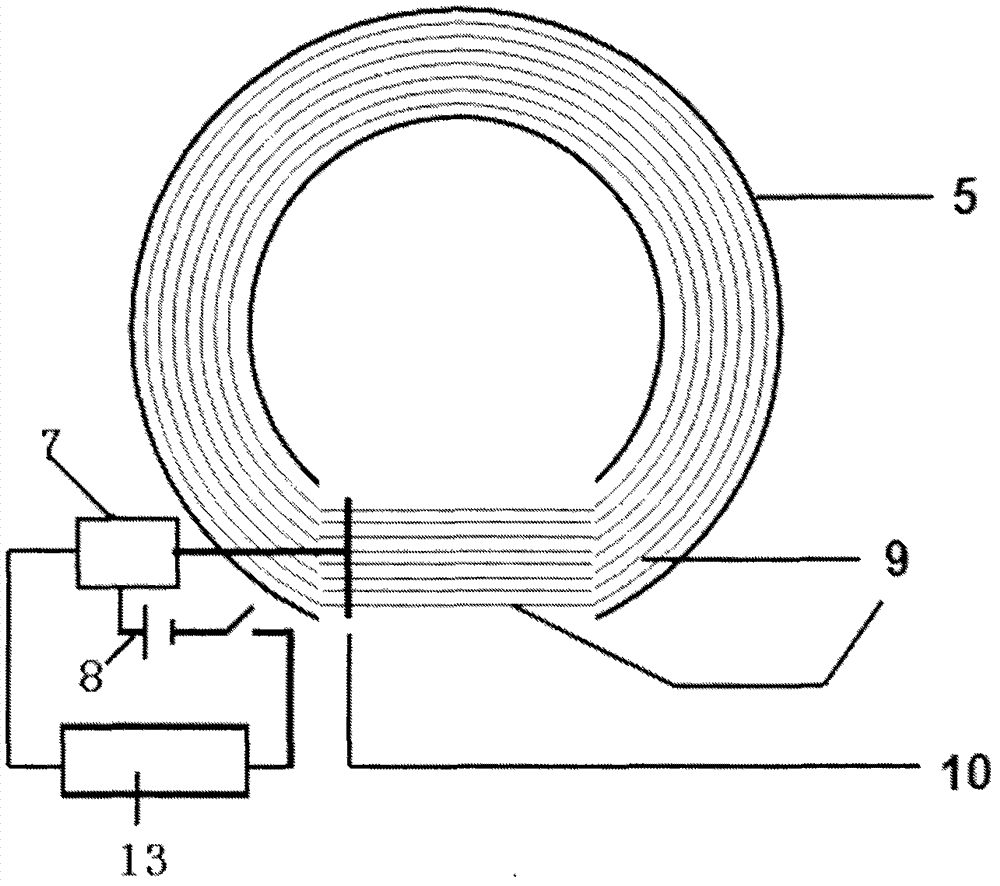

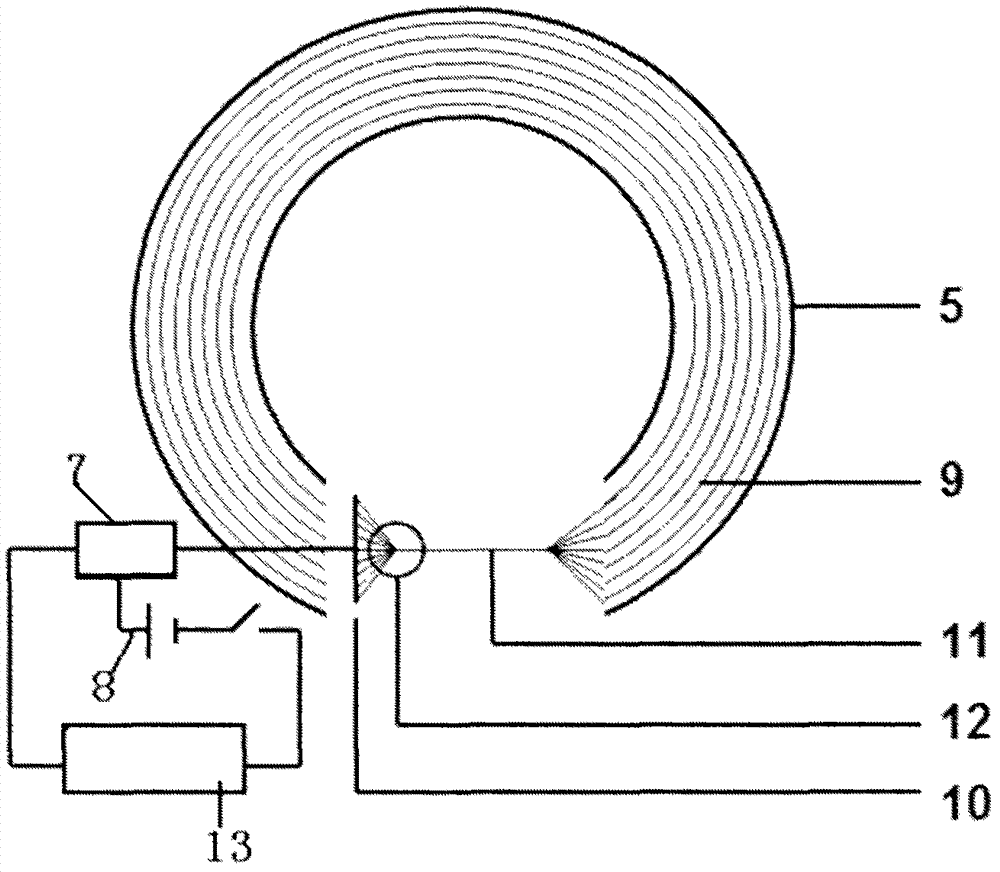

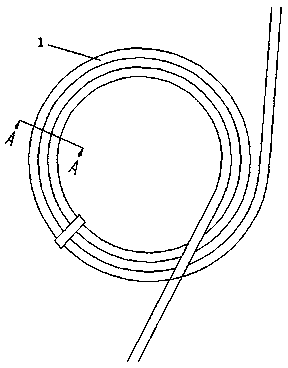

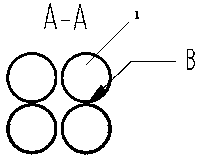

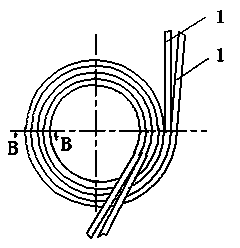

Device for preparing nano fiber twisted structure

InactiveCN102212893AThe number is accurate and controllableStranded wire structure and shapeArtificial thread manufacturing machinesFilament/thread formingMicro nanoVoltage

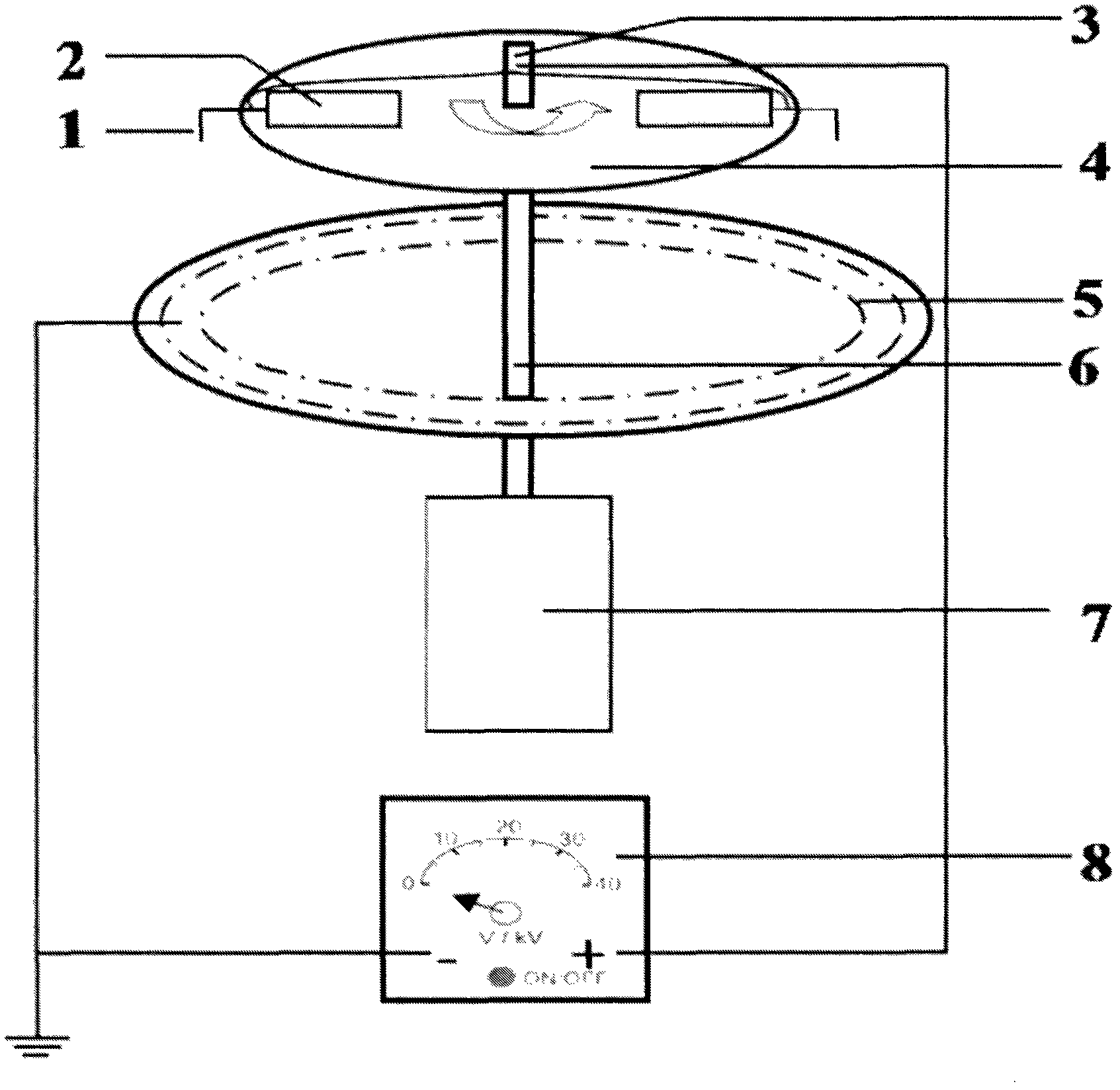

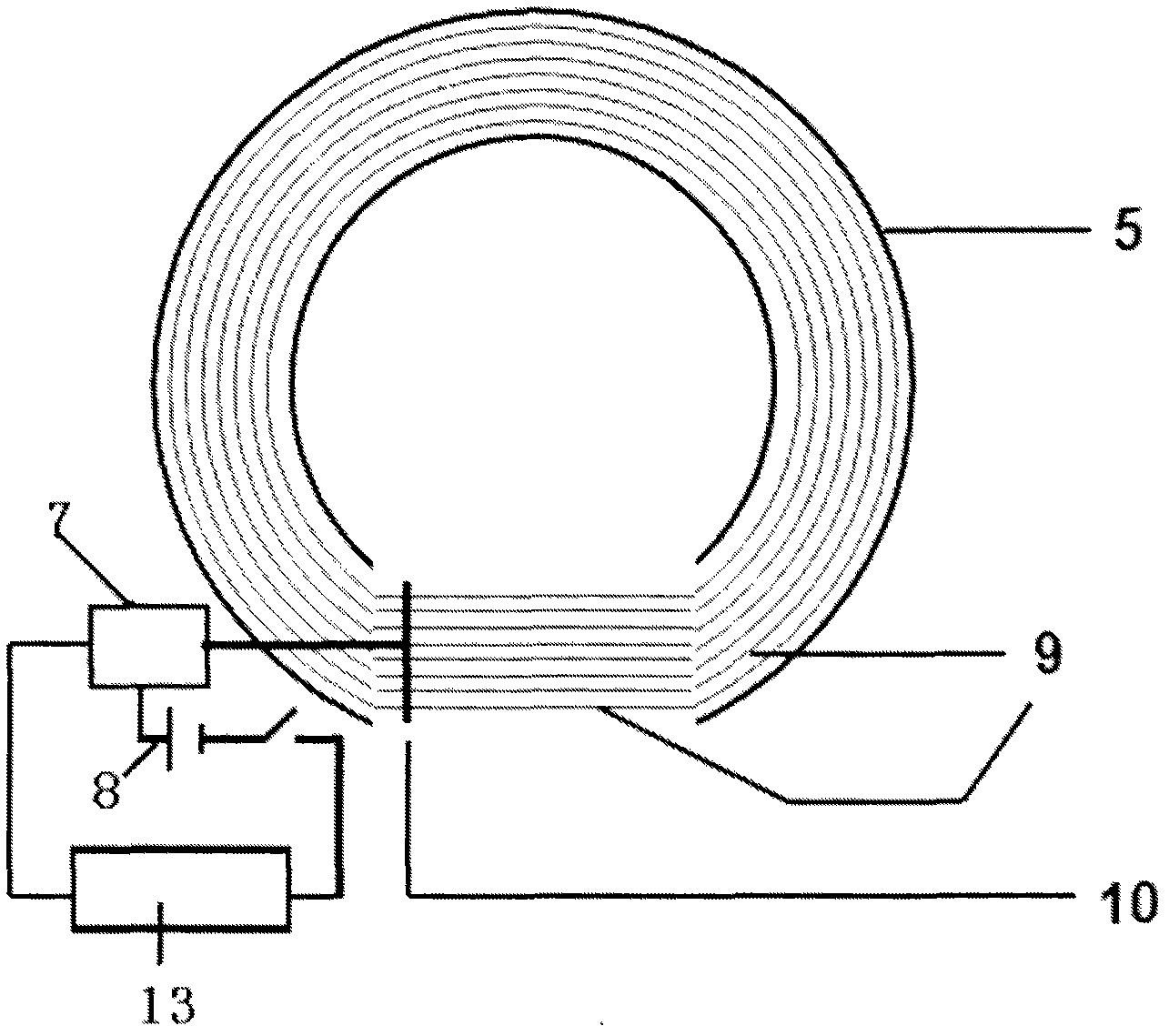

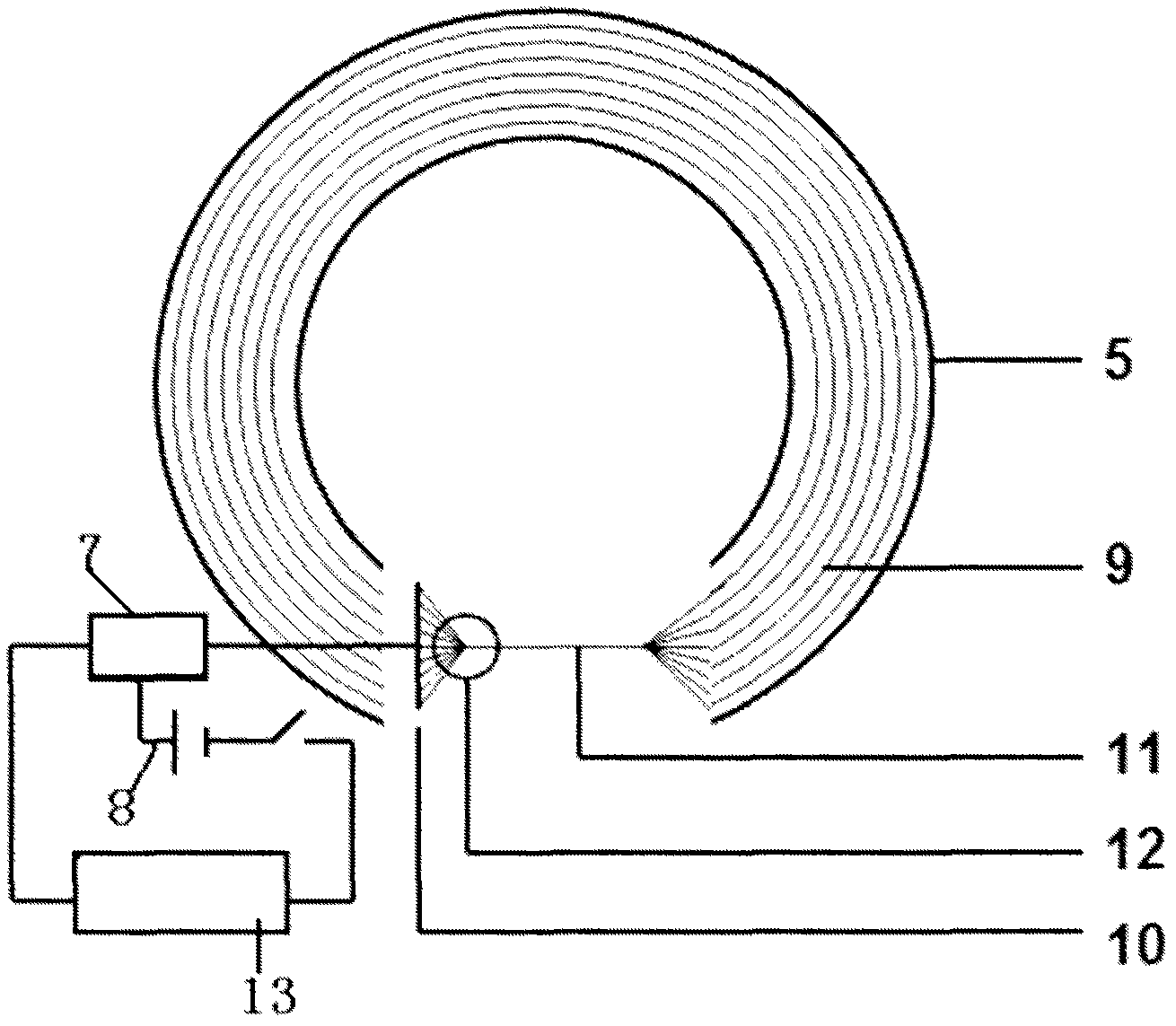

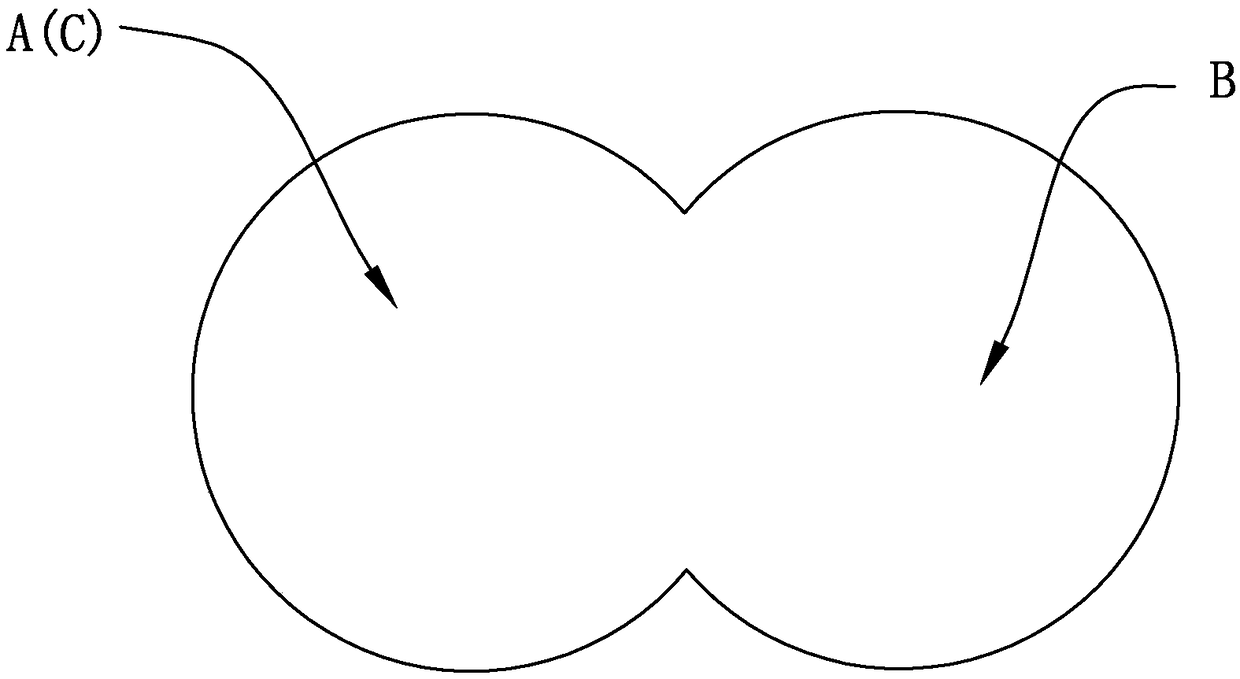

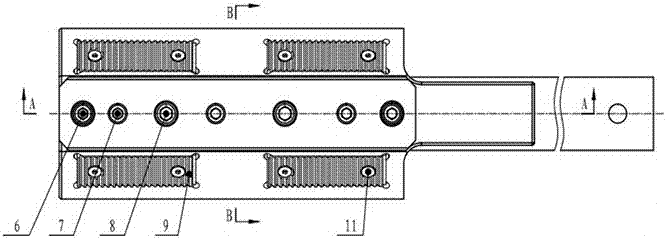

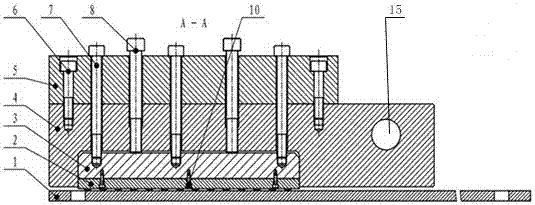

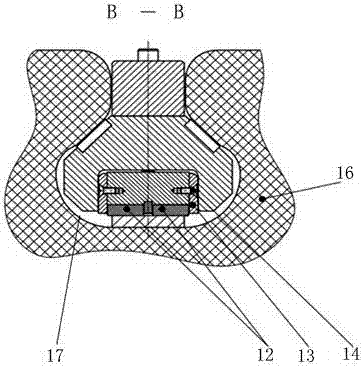

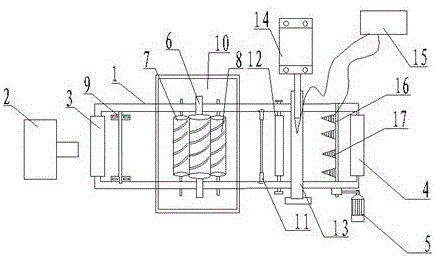

The invention belongs to the technical field of nano fiber twisted structure or micro-nano rope preparation, and particularly relates to a device for preparing a nano fiber twisted structure by using a centrifugal electrostatic spinning technology. A metal rod is placed in the vertical direction at the central line of an annular aluminum foil collector, a metal rod bracket passes through the center of the annular aluminum foil collector and is used for supporting and stabilizing the metal rod, and the bottom end of the metal rod is butted against and linked with the output shaft of a motor; and the upper part of the metal rod is provided with a circular insulated turntable vertical to the axis of the metal rod, two spinning solution containers are placed on the upper lateral surface of the insulated turntable and symmetrical to the central line of the metal rod, and the spinning solution containers are provided with communicated needle openings aligned with a spinning nozzle of the annular aluminum foil collector. The spun fiber number is accurate and controllable, the twisted structure is good, the lapping sequence is high, the voltage is low, burrs are not caused, and the deviceis convenient for measuring the mechanical property of single fibers.

Owner:QINGDAO UNIV

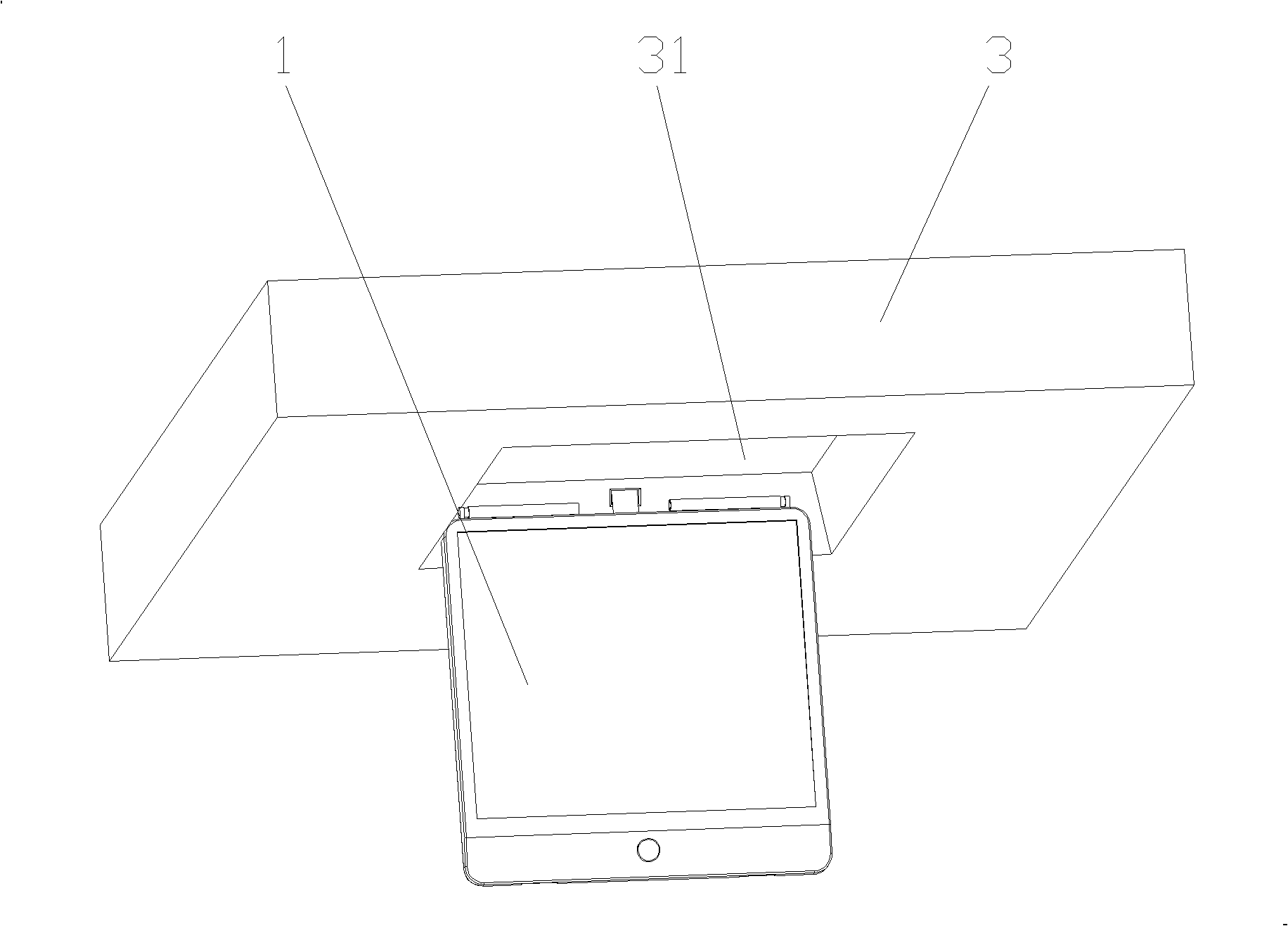

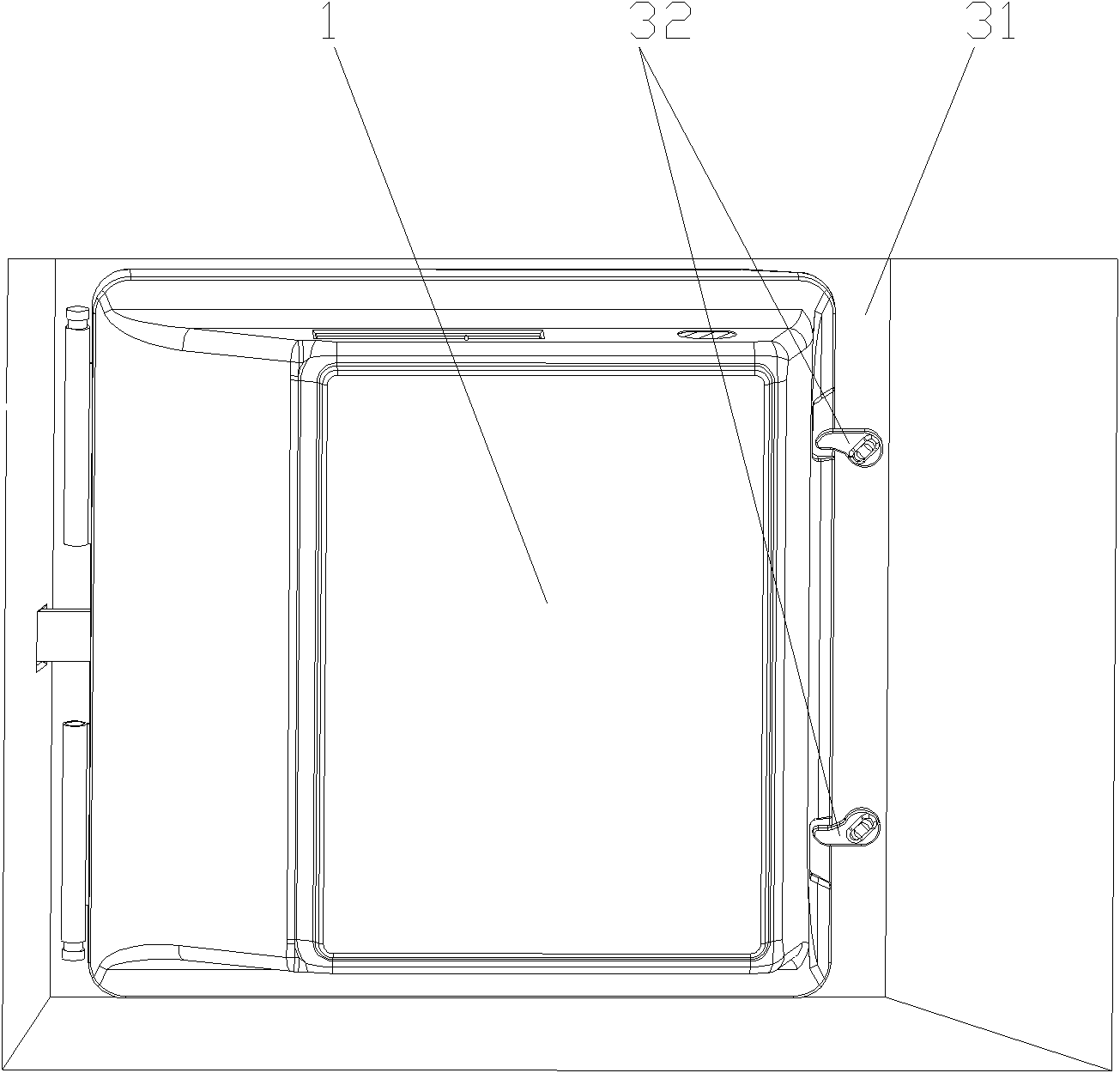

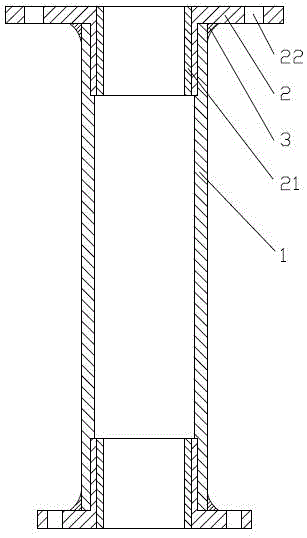

Vehicle-mounted computer adopting all-in-one computer

ActiveCN102445954BSmall footprintImprove reliabilityDigital data processing detailsVehicle componentsIn vehicleEngineering

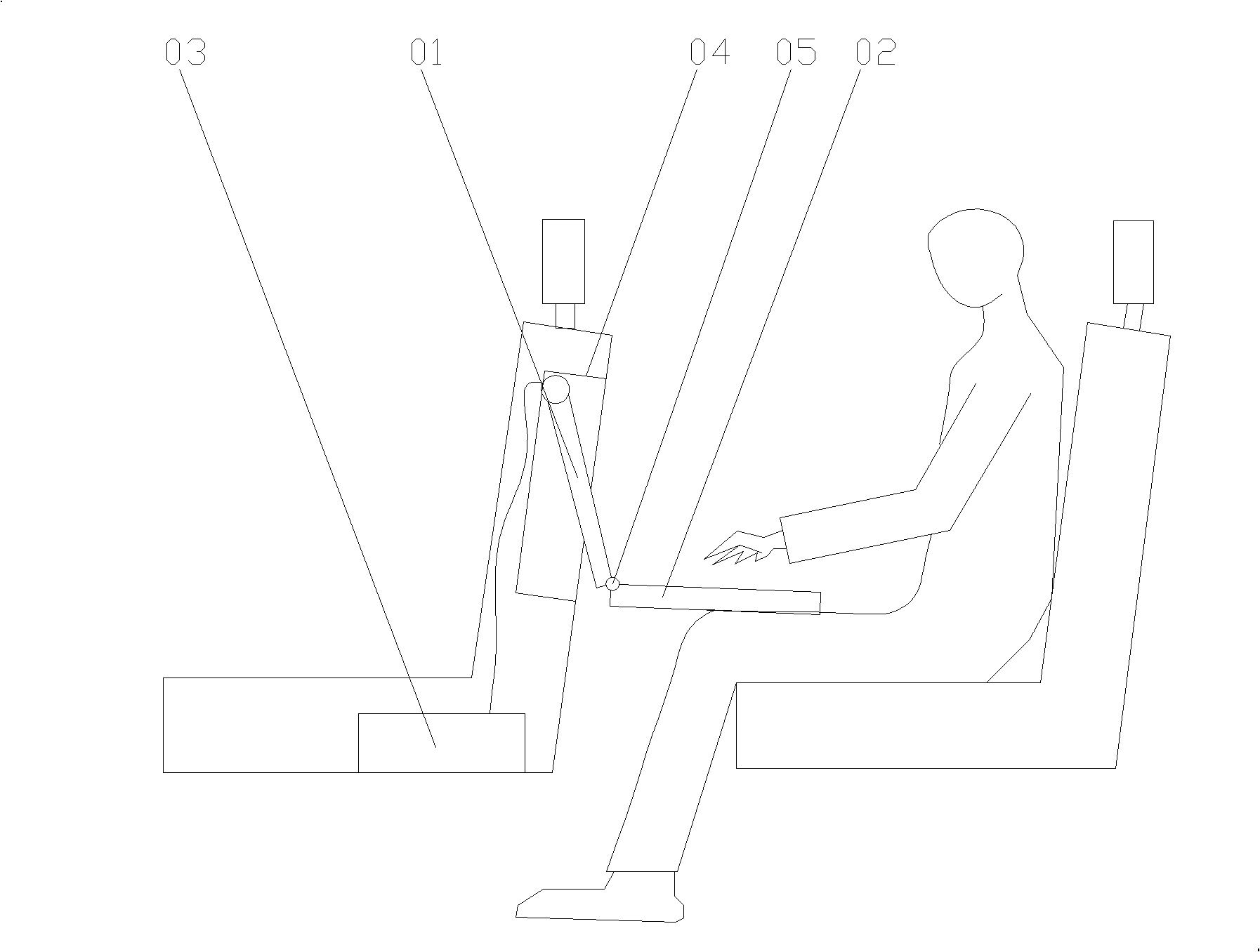

The invention discloses a vehicle-mounted computer adopting an all-in-one computer. The vehicle-mounted computer comprises the all-in-one computer and a keyboard. A sunken space matched with the all-in-one computer in size is arranged on a top plate in a vehicle body; one side of the all-in-one computer is connected to one inner side of the sunken space through a hinge; a fixing bolt is arranged at a position on the top plate, close to an edge of the sunken space; the sunken space matched with the keyboard in size is arranged on the rear side of a backrest of a seat; one side of the keyboard is connected to one inner side of the sunken space through a hinge; the position on the keyboard, close to the other side, is connected to the sunken space through a connecting rod; a sliding slot is formed on the connecting rod; one end of the connecting rod is hinged with the sunken space; a sliding block is arranged on the keyboard; the sliding block of the keyboard is buckled with the sliding slot of the connecting rod; and the keyboard is in wireless connection with the all-in-one computer. Compared with the prior art, the vehicle-mounted computer has the advantages that the keyboard and the all-in-one computer are in wireless connection and are respectively mounted in the reasonable positions in the vehicle, so that a user can more comfortably use the vehicle-mounted computer and the reliability of equipment is higher.

Owner:TPV ELECTRONICS (FUJIAN) CO LTD

Textile bobbin

The invention discloses a textile bobbin, and belongs to the field of textile machinery. The textile bobbin comprises a pipe body and side disks at the two ends of the pipe body, and an axial through hole is formed in the pipe body. The textile bobbin is characterized in that the side disks are stainless steel side disks and are in threaded connection with the wall of the axial through hole of the pipe body, central through holes are opened in the side disks, and rubber layers are arranged on the inner walls of the central through holes; arc-shaped transition rings are arranged at the contact sites on both sides of the pipe body and the side disks; a frosted layer is arranged on the outer circumferential surface of the pipe body. The wear resistance and strength at both ends of the bobbin are improved to avoid deformation or burr and prolong the service life.

Owner:李俊

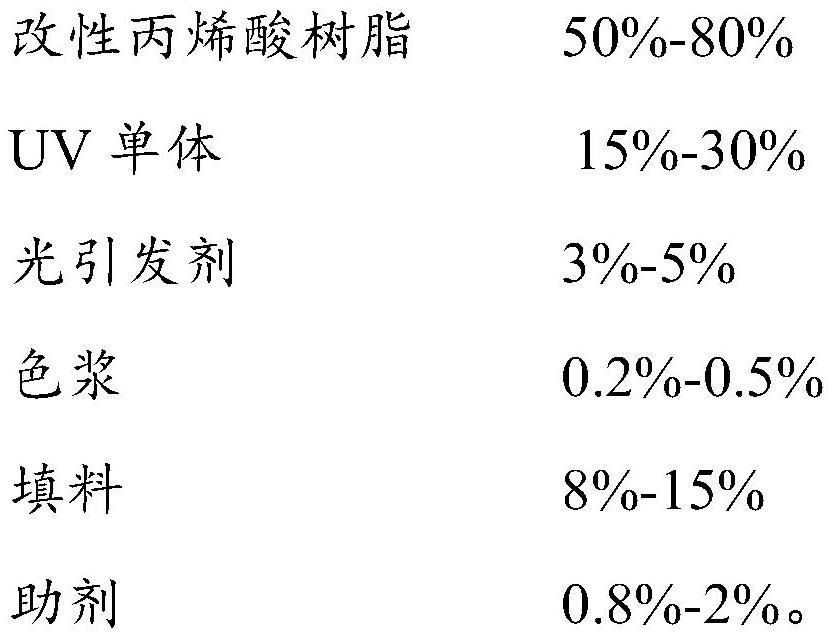

Drilling ink and application thereof

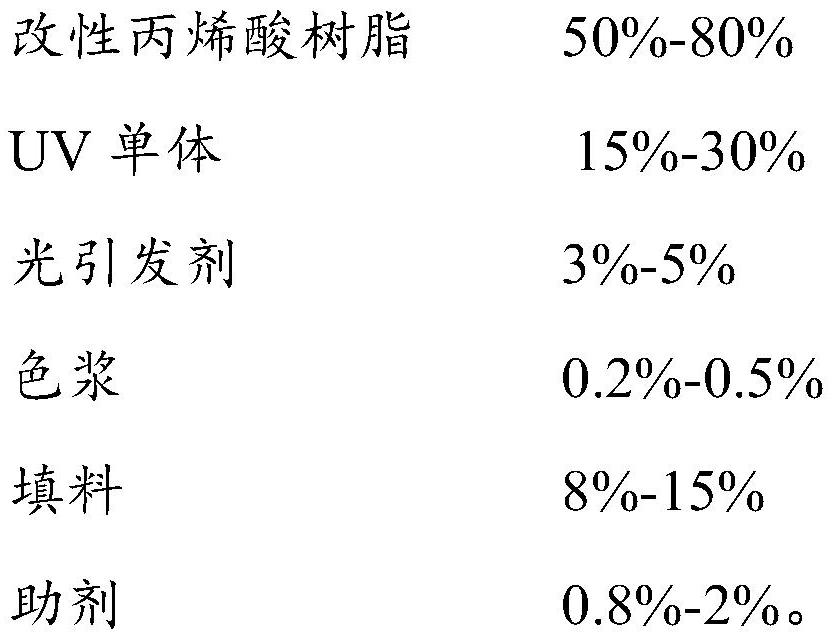

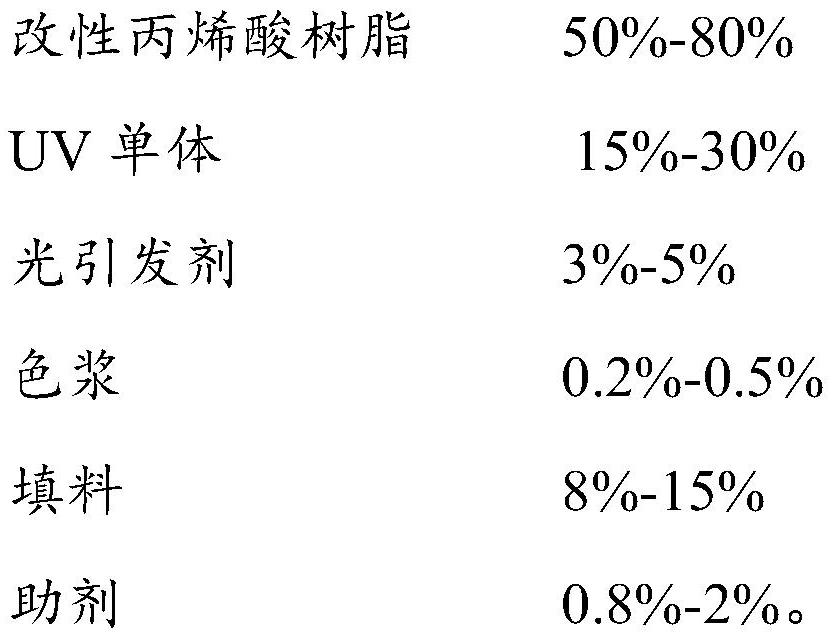

The invention belongs to the technical field of electronic materials, and particularly relates to drilling ink and application thereof. The drilling ink is prepared from the modified acrylic resin, a UV monomer, a photoinitiator, color paste, a filler and auxiliaries, an ink film formed after the drilling ink is cured has high hardness, the drilling ink can replace a traditional cover plate to be used for drilling in the drilling process of the printed circuit board, the ink film can be simply removed through laser and other methods after drilling is completed, and the drilling efficiency and the drilling precision can be remarkably improved. Meanwhile, due to the fact that traditional aluminum sheets, cold punching plates and the like are not used as cover plates, the production cost can be reduced, and the problems that chippings wind a cutter and the like can be solved.

Owner:SHENZHEN BAROY NEW MATERIAL TECH CO LTD

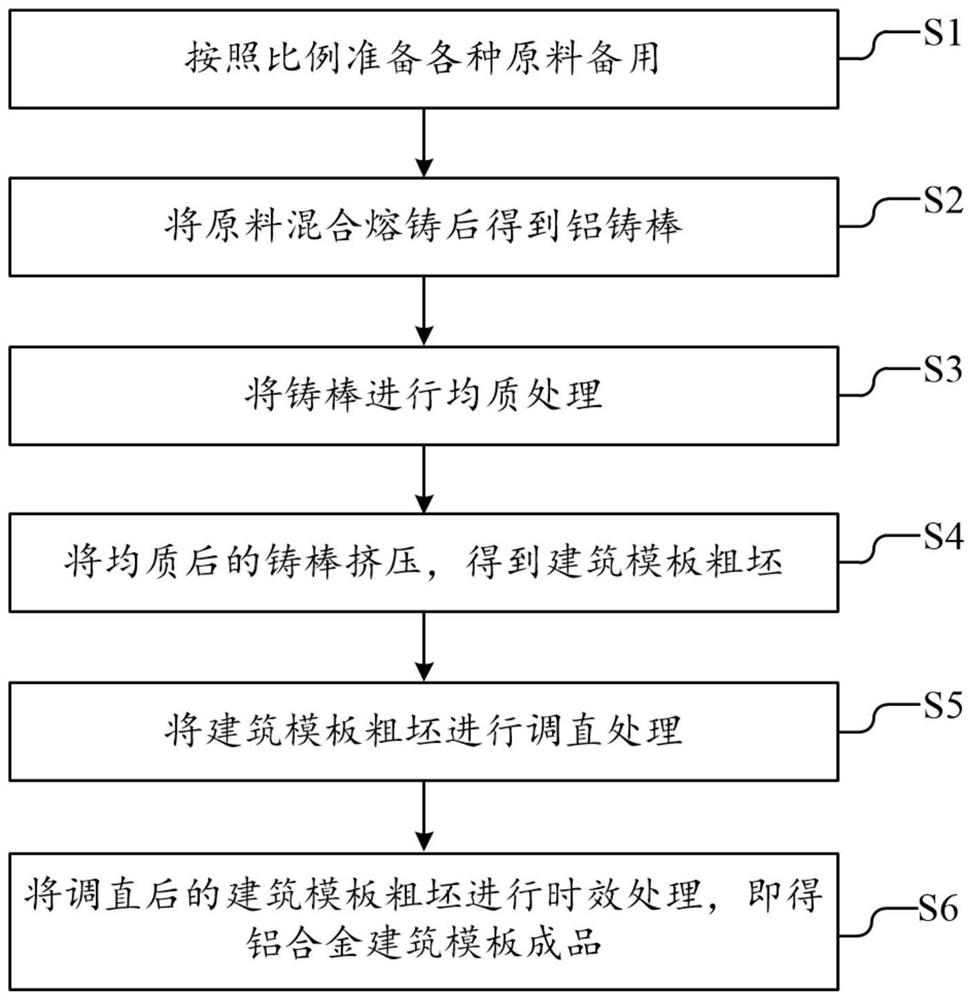

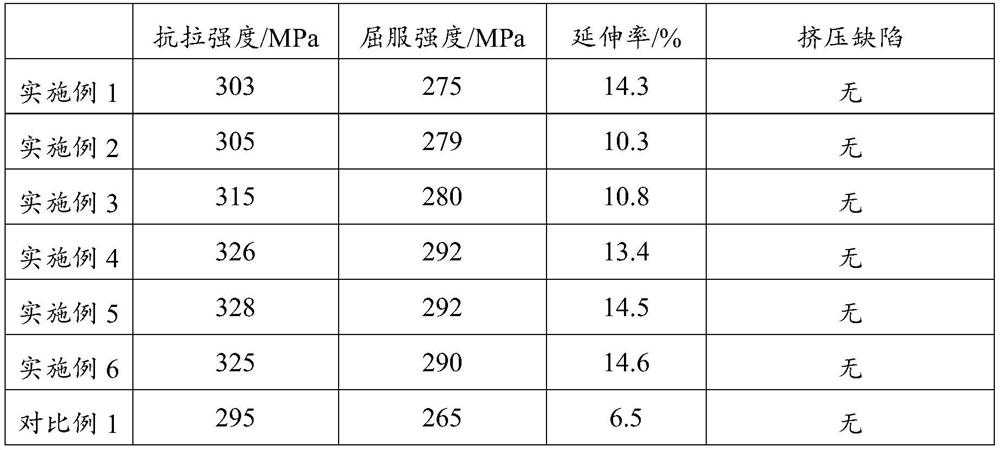

Aluminum alloy building formwork and preparation method thereof

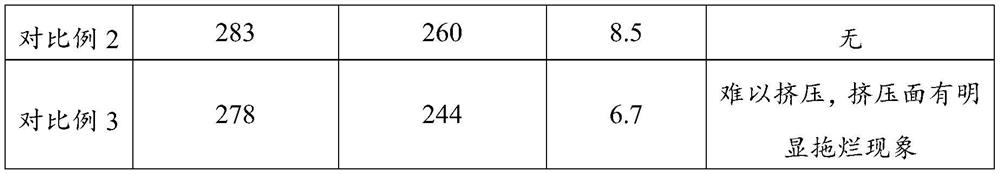

PendingCN113234972AReduced Quench SensitivityImprove solid solubilityFurnace typesHeat treatment furnacesAluminium alloyMechanical properties of carbon nanotubes

The invention discloses an aluminum alloy building formwork mainly comprising, by mass, 0.4%-1.0% of Si, 0.8%-1.3% of Mg, 0.05%-0.2% of Cu, 0.001%-0.15% of Mn, 0.2%-0.7% of Fe, less than or equal to 0.25% of Zn, 0.001%-0.1% of Cr, 0.03%-0.15% of Ti and the balance Al and inevitable impurities. The content of the inevitable impurities is less than or equal to 0.15%. Correspondingly, the invention further discloses a preparation method of the aluminum alloy building formwork. The aluminum alloy building formwork is excellent in mechanical property, the extrusion speed can reach 8-10 m / min, and the production efficiency is high.

Owner:GUANGDONG JMA ALUMINUM PROFILE FACTORY GRP +1

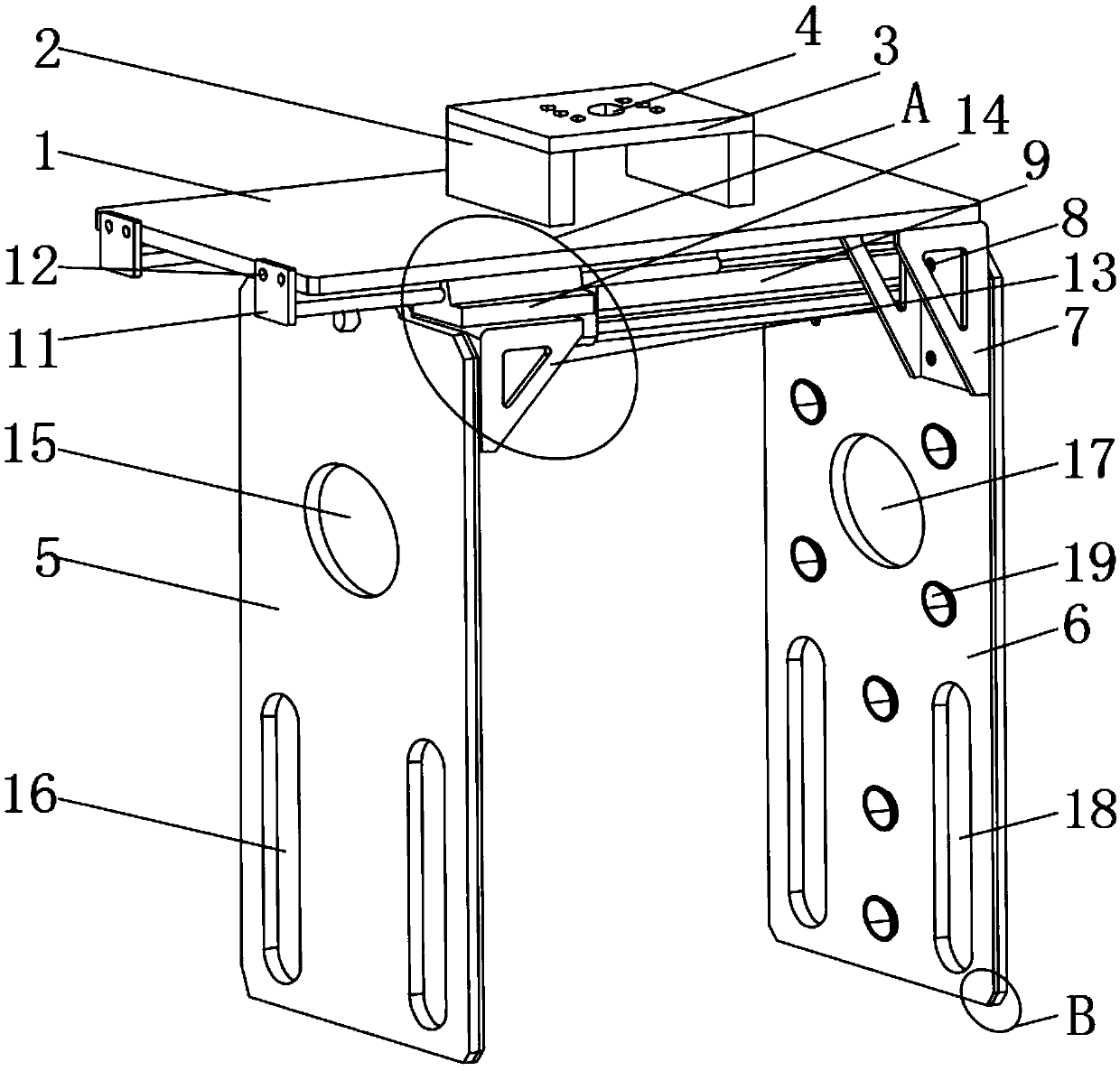

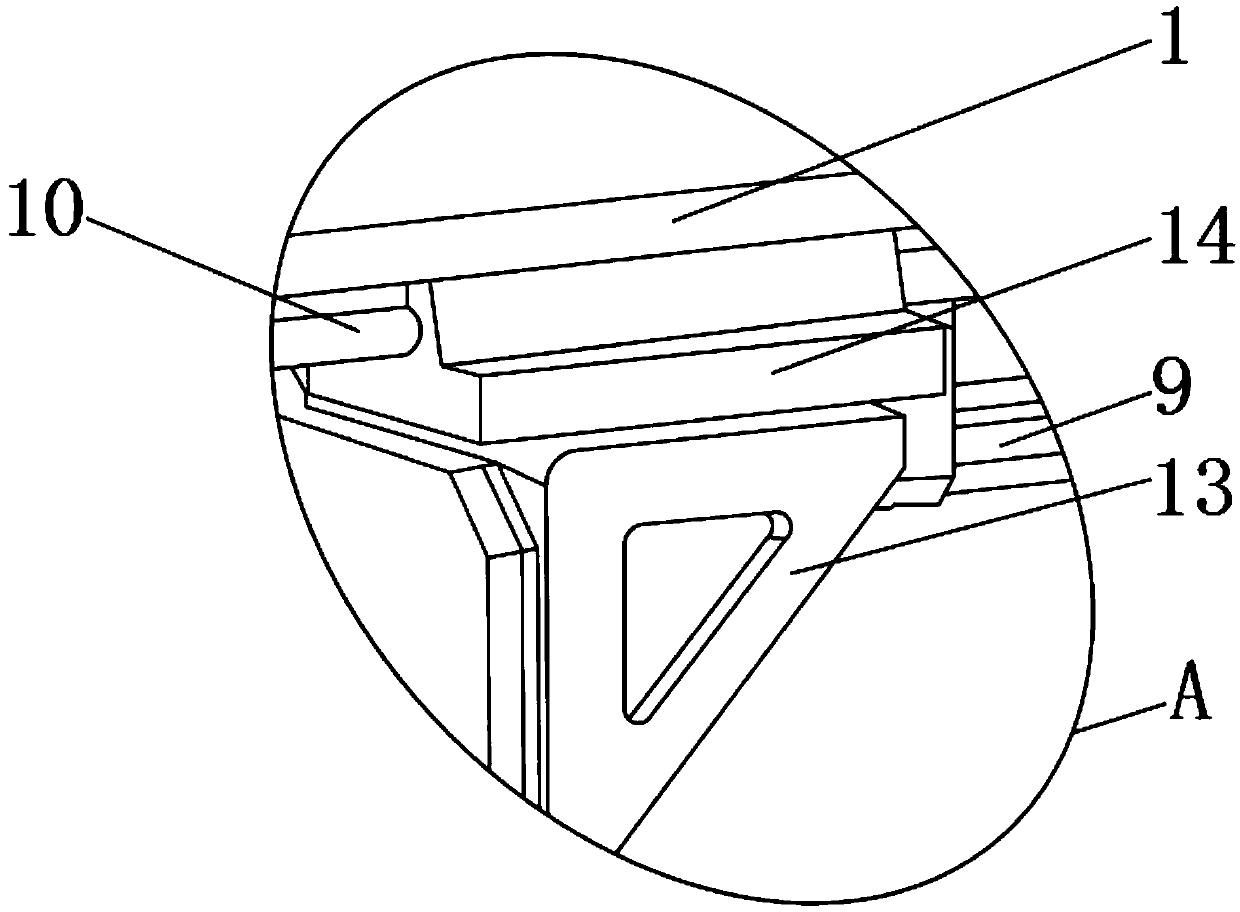

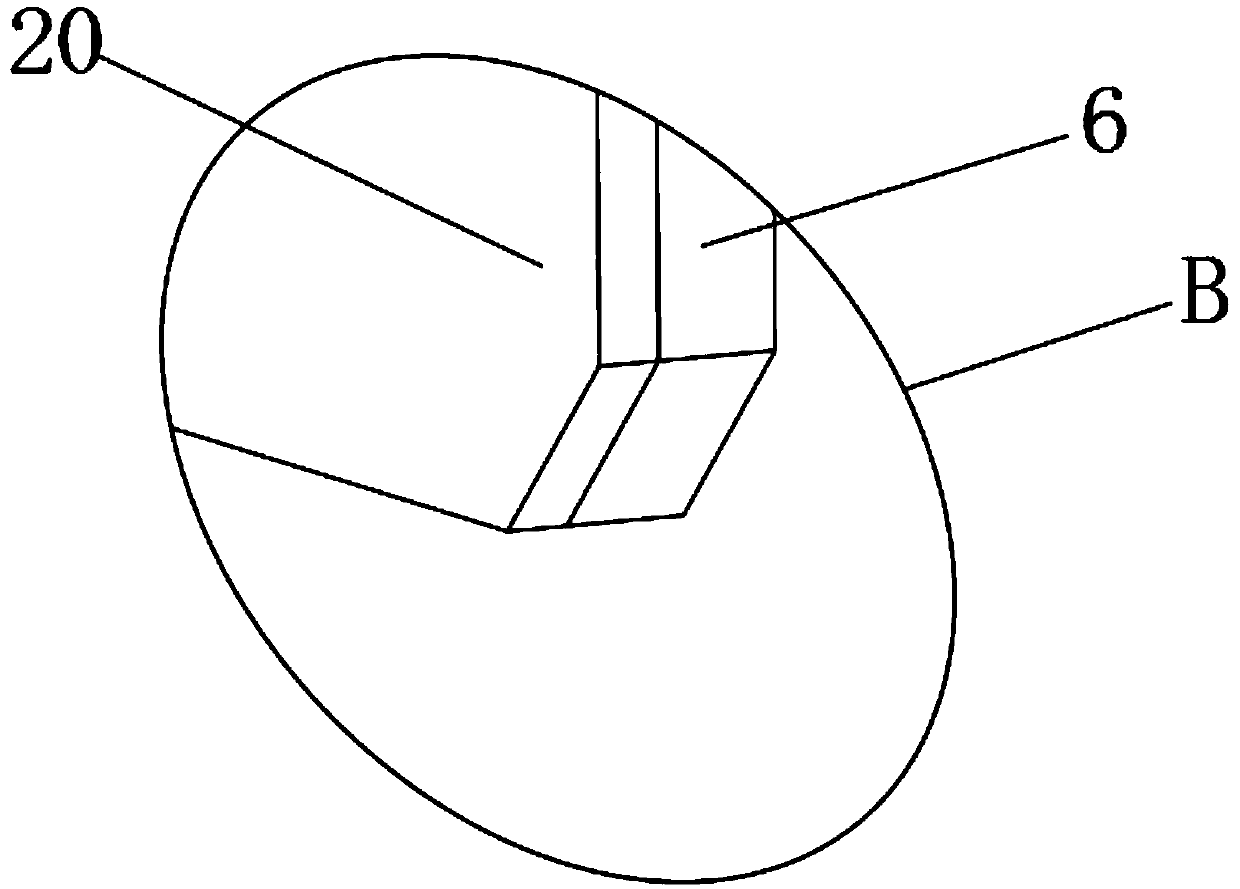

Robot gripper convenient to operate and applied to logistics transportation

PendingCN109573610AReduce weightReduce production materialsConveyor partsLogistics managementEngineering

The invention discloses a robot gripper convenient to operate and applied to logistics transportation. The robot gripper comprises a top plate, wherein two support blocks are fixedly mounted at a center position of the top plate; a connection block is fixedly mounted at the tops of the two support blocks; a mounting hole is formed in the upper surface of the connection block; a movable clamping plate is arranged at a position of one side of the lower part of the top plate. According to the robot gripper convenient to operate and applied to logistics transportation, a first through hole, firstthrough grooves, suction cups and rubber mats are arranged; firstly, the self weight of the robot gripper can be reduced, the production materials can also be reduced, the robot gripper has higher practicability, the stability can be improved, and the phenomenon that the robot gripper falls can be avoided; secondly, the protection performance is improved, and the damage to the clamped articles canbe avoided; in addition, according to the whole robot gripper, a single cylinder is just used for driving the movable clamping plate to move on a fixed rail by means of a movable rail, so that the capability of gripping cargos can be achieved; the robot gripper is simple in structure and convenient to operate, and can bring a better application prospect.

Owner:UNIV OF SCI & TECH LIAONING

Backward blanking die and blanking machining method thereof

The invention discloses a backward blanking die and a blanking machining method thereof. The backward blanking die comprises a forward blanking punch, a backward blanking punch, a forward blanking female die plate and a backward blanking female die plate; the backward blanking female die plate is located above the forward blanking female die plate, a forward blanking female die is arranged on theforward blanking female die plate, a backward blanking female die is arranged on the backward blanking female die plate, the forward blanking punch penetrates through the backward blanking female dieand points to the forward blanking female die, and the front end of the backward blanking punch penetrates through the forward blanking female die and points to the backward blanking female die; and aspring is installed at the tail end of the backward blanking punch, the spring is arranged in the length direction of the backward blanking punch, and the outer contour of the forward blanking punchis larger than the inner diameter of a blanking groove in the forward blanking female die. According to the backward blanking die, the structure is simple and reasonable, the manufacturing cost is low, the blanking quality is good, burrs cannot be generated along an edge after blanking, and the use effect is good; and meanwhile, the machining method does not require for manual judgment, the die and the method can be applied to the production process of a mechanical assembly line, the machining cost is low, and the machining efficiency is high.

Owner:SUZHOU JUPITER ELECTRONICS CO LTD

Secondary sand-shooting molding technique for casting sand core

The invention discloses a two-time sand shooting forming process for casting a sand core. Firstly a mould is provided with a small sand core mould cavity, in which a mould joint is different from a mould joint of the whole sand core, and a whole sand core mould cavity inside, and a sand inlet is arranged on each mould cavity; the small mould cavity is subjected to sand shooting to produce a small sand core; the small sand core is taken out, placed on a position corresponding to the whole sand core mould cavity, and subjected to mold spotting, and the sand is shot in the whole sand core mould cavity to produce the whole sand core. The process has the advantages of one-time forming and simple and quick operation; and for the formed sand core, no connector is existed, and no phenomenon of core breaking, burr and flap edge occurs, thereby effectively ensuring the quality of the sand core.

Owner:南通华东液压铸业有限公司

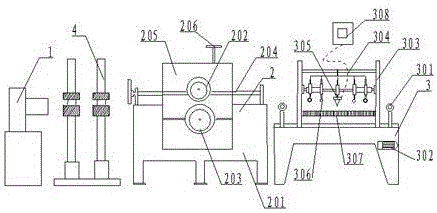

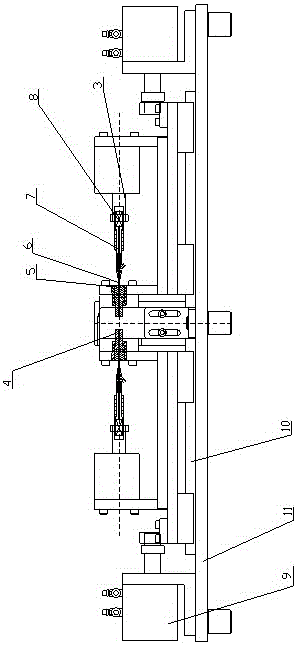

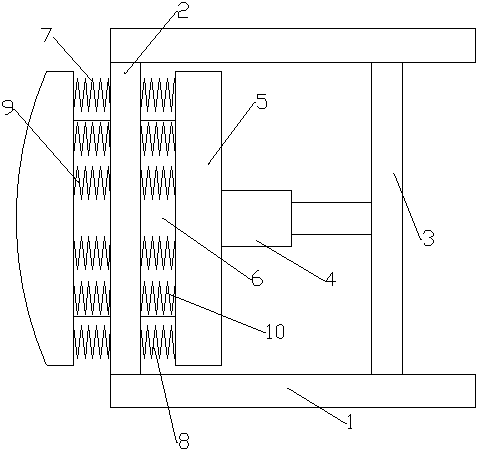

Calendering and cutting system for polytetrafluoroethylene plastic products

InactiveCN106079212AImprove cut qualityProcessing levelFlat articlesMetal working apparatusMechanical engineeringQuality standard

The invention discloses a calendering and cutting system for polytetrafluoroethylene plastic products. The calendering and cutting system for the polytetrafluoroethylene plastic products comprises a pushing oil cylinder, fluoroplastic supporting rods, a calender and a cutting machine, wherein a left line of oil injection holes and a right line of oil injection holes are formed in the pushing oil cylinder, a supporting base is arranged at the lower ends of the fluoroplastic supporting rods, and two vertical stand columns are arranged on the fluoroplastic supporting base. According to the calendering and cutting system for the polytetrafluoroethylene plastic products, system equipment is compact in design, height adjustment is easy and convenient, and workpieces are processed smoothly; and in addition, the cutting quality of the polytetrafluoroethylene plastic products is high, burrs are avoided, and the polytetrafluoroethylene plastic products meet the processing requirements of the industrial quality standard.

Owner:SUZHOU CHONGEN MOLDING

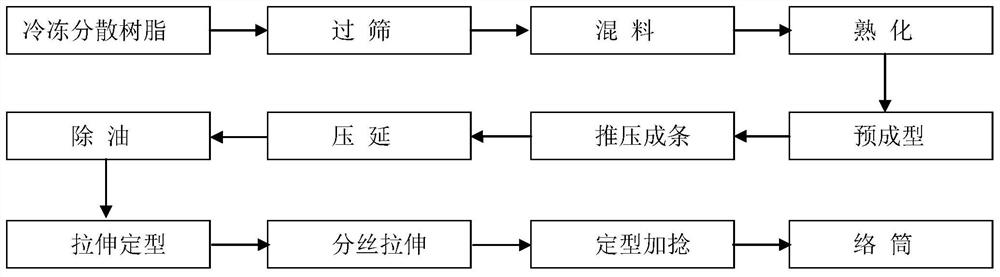

Preparation method of polytetrafluoroethylene ultra-thin filament

ActiveCN113005545AHigh tensile strengthTwist evenlyFilament/thread formingMonocomponent halogenated hydrocarbon artificial filamentCompression moldingPolymer science

The invention belongs to the technical field of polytetrafluoroethylene fiber preparation, and particularly relates to a preparation method of a polytetrafluoroethylene ultra-thin filament. The preparation method comprises the steps of carrying out low-temperature treatment on polytetrafluoroethylene dispersed granules, mixing the treated polytetrafluoroethylene dispersed granules with auxiliary oil, curing, and carrying out compression molding; putting the polytetrafluoroethylene mixture into a pushing and pressing die cavity with the compression ratio of 260, pushing and pressing, and continuously extruding strips to obtain polytetrafluoroethylene material strips; pressing the polytetrafluoroethylene material strips into a film, and performing heat treatment to remove oil; stretching the de-oiled film for multiple times to obtain a polytetrafluoroethylene film; longitudinally cutting the polytetrafluoroethylene film into a plurality of flat filaments, heating and stretching, preparing the obtained filaments into round filaments in a secondary twisting manner, performing twisting and setting while quickly cooling, and finally winding the filaments on a shaft through a winding drum to prepare the polytetrafluoroethylene ultra-thin filament. The polytetrafluoroethylene ultra-thin filament prepared by the preparation method disclosed by the invention is high in strength, uniform in linear density, free of burrs and low in shrinkage rate.

Owner:SHANDONG SENRONG PLASTIC IND TECH

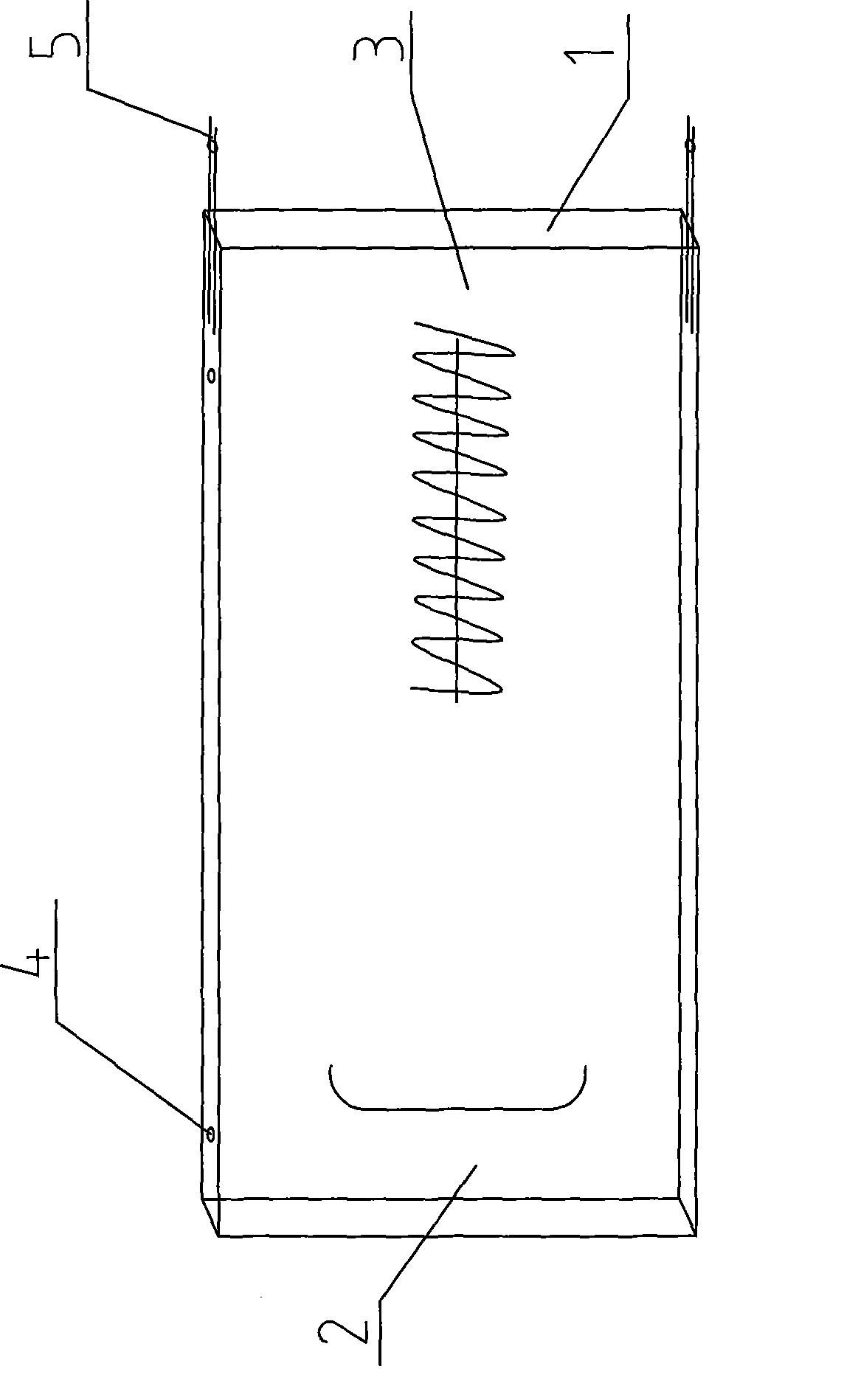

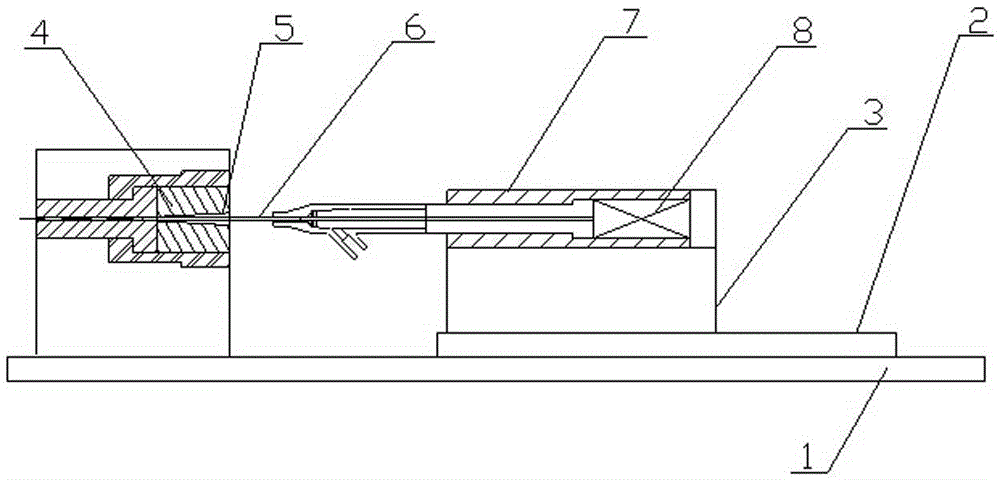

Catheter head melting equipment and catheter head melting technique based on same

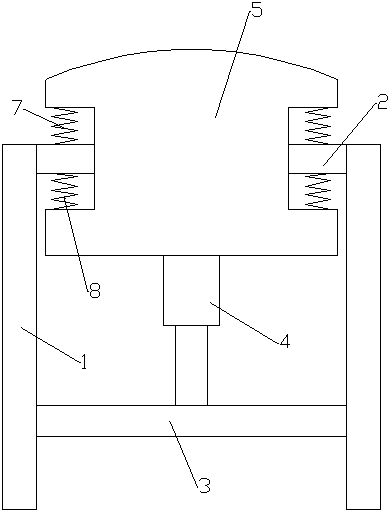

The invention discloses catheter head melting equipment. The catheter head melting equipment comprises a base, a guide rail arranged on the base, a needle core assembling and fixing base and a forming mould component, wherein the forming mould component and the needle core assembling and fixing base are located on two sides of the base; the needle core assembling and fixing base can move on the guide rail; a catheter sleeves a needle core; one end of the catheter is pushed forwards into the forming mould component; the tail end of the needle core is fixed in a needle core assembly component; a spring is arranged behind the needle core assembly component; and the needle core assembly component and the spring are both fixed in the needle core assembling and fixing base. The invention further discloses a catheter head melting technique which is characterized in that the catheter is fixed by using the needle core, and the catheter is melted and moulded. The medical catheter is pushed forwards into the forming mould component for head melting; after head melting is finished, the needle core and the catheter retreat simultaneously; the moulded tail end angle of the catheter can be adjusted more easily; phenomena including burs, damage and the like in a traditional catheter cutting process cannot occur; the head melting effect is good; and product quality is high.

Owner:汪洋

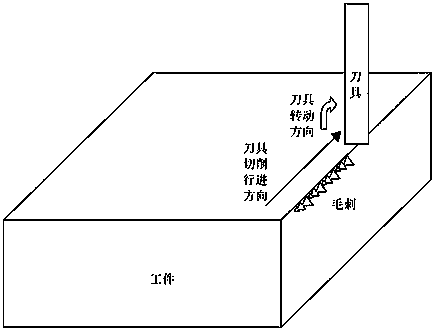

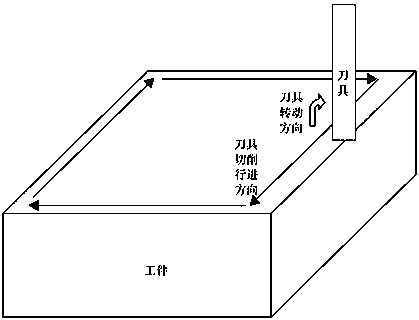

Machining method for reducing workpiece burrs for numerical control machine tool

The invention discloses and aims at providing a machining method for reducing workpiece burrs for a numerical control machine tool. According to the machining method, machining efficiency is improved,the burrs are reduced, and the workpiece quality is improved. The machining method comprises the following steps that A, a tool is controlled through the numerical control machine tool to rotate clockwise; and B, before normal machining, the tool carries out cutting in the peripheral reverse cutting direction of a workpiece. The machining method is applied to the technical field of numerical control machine tools.

Owner:珠海艾诚精密模具有限公司

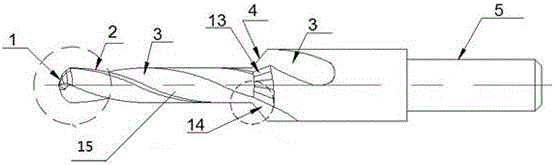

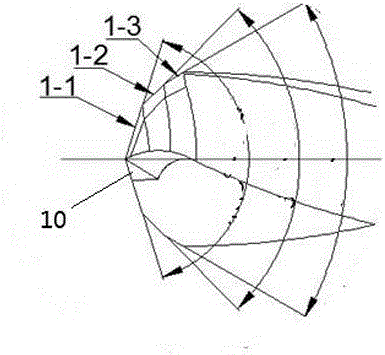

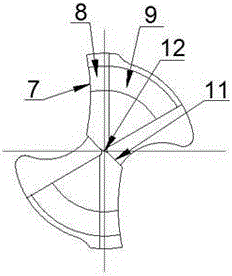

Drilling and countersinking integrated dagger drill

InactiveCN107520487AImprove the finishNo cleavageTransportation and packagingWorkpiecesChiselMachining process

The invention discloses a drilling and countersinking integrated dagger drill comprising a drill body. A drill tip part is arranged at the front end of the drill body, a spiral cutting edge part and a chip removal groove are formed along the surface of the drill body, and a counter sinking part is arranged at the low end of the drill body and connected with a handle part. The drilling and countersinking integrated dagger drill is characterized in that the drill tip part is in a three-vertex-angle shape and comprises a front blade face, a first rear blade face, a second rear blade face, a tooth gap chip containing groove, a tooth gap cut-in angle and a chisel edge angle; the chip removal groove spirally extends from the drill tip part to the handle part; and the counter sinking part comprises a counter sinking step angle and a cutter back chipping part. According to the drilling and countersinking integrated dagger drill, the problems of material layering, burring and edge-cracking in the machining process in the prior art are solved, and machining which needs to be conducted through the multiple process steps in the prior art can be conducted at a time. Through the cutter, the surface quality and the production efficiency of a machined material are improved, and the production cost is reduced.

Owner:JIANGSU TIANGONG TOOLS CO LTD +1

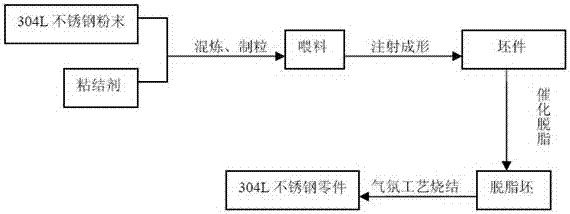

A kind of 304l stainless steel metal powder injection molding method

The invention discloses a method for injection molding of 304L stainless steel metal powder, which comprises mixing and granulating 304L stainless steel powder and binder to make feed material, preparing blanks by injection molding, catalytic degreasing and negative pressure degreasing, vacuum internal firing and forced Cooling three-stage atmosphere process sintering and other steps. The 304L stainless steel part obtained by the invention has high dimensional precision, high surface precision and no burr phenomenon, and the invention avoids complicated processes of solvent degreasing and thermal degreasing, and has high production efficiency and low production cost.

Owner:重庆地恩科技开发有限责任公司

Device for preparing nano fiber twisted structure

InactiveCN102212893BThe number is accurate and controllableThere will be no broken wiresArtificial thread manufacturing machinesFilament/thread formingMicro nanoNanofiber

The invention belongs to the technical field of nano fiber twisted structure or micro-nano rope preparation, and particularly relates to a device for preparing a nano fiber twisted structure by using a centrifugal electrostatic spinning technology. A metal rod is placed in the vertical direction at the central line of an annular aluminum foil collector, a metal rod bracket passes through the center of the annular aluminum foil collector and is used for supporting and stabilizing the metal rod, and the bottom end of the metal rod is butted against and linked with the output shaft of a motor; and the upper part of the metal rod is provided with a circular insulated turntable vertical to the axis of the metal rod, two spinning solution containers are placed on the upper lateral surface of the insulated turntable and symmetrical to the central line of the metal rod, and the spinning solution containers are provided with communicated needle openings aligned with a spinning nozzle of the annular aluminum foil collector. The spun fiber number is accurate and controllable, the twisted structure is good, the lapping sequence is high, the voltage is low, burrs are not caused, and the deviceis convenient for measuring the mechanical property of single fibers.

Owner:QINGDAO UNIV

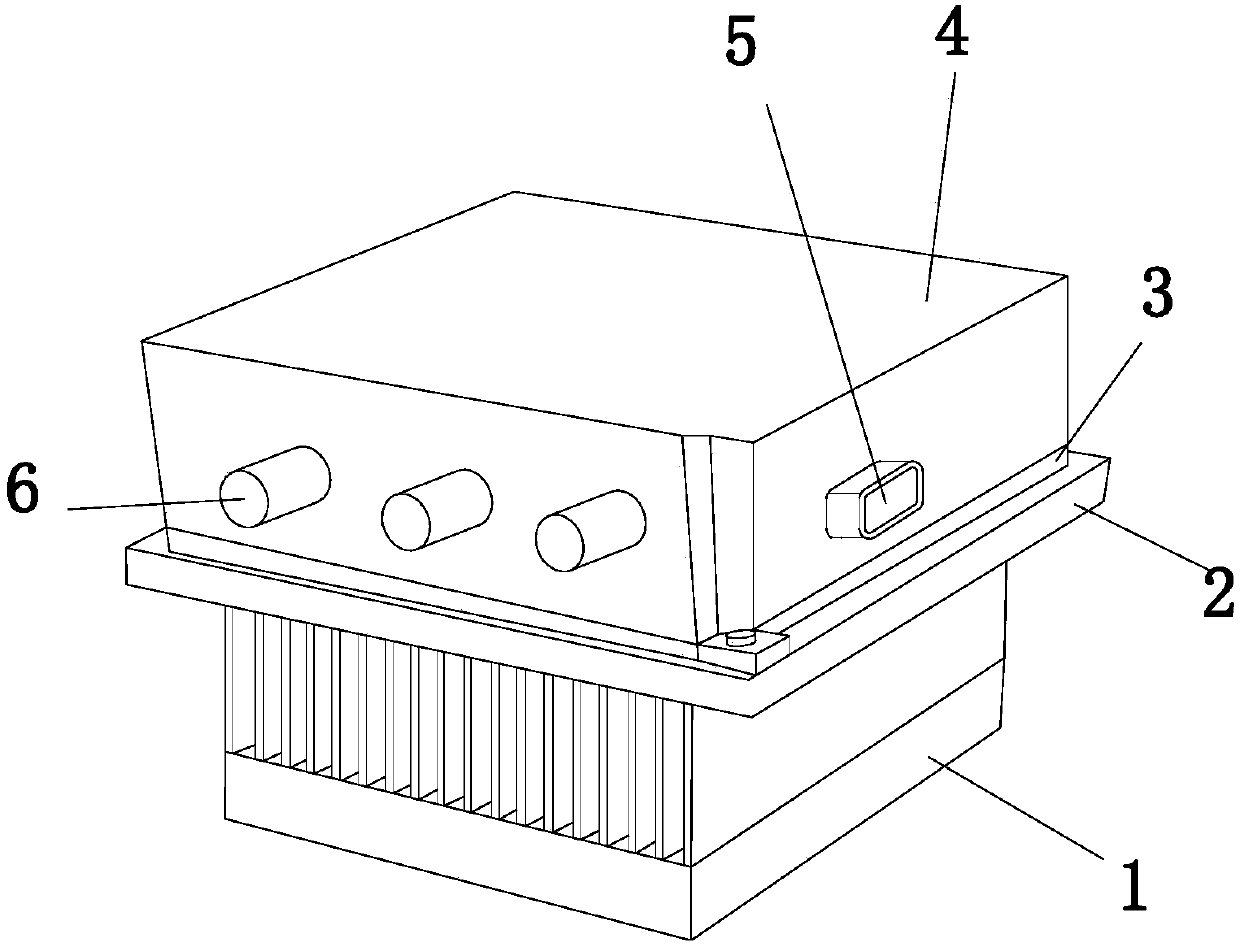

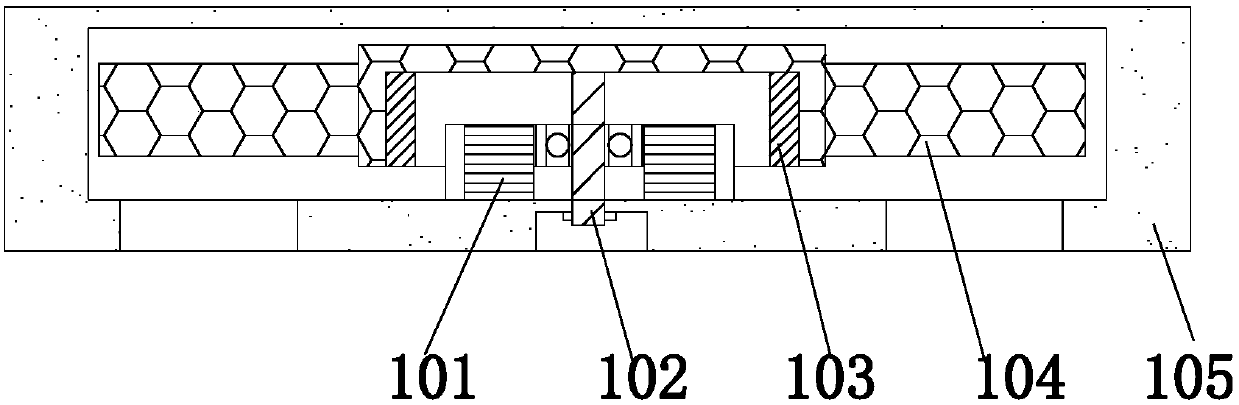

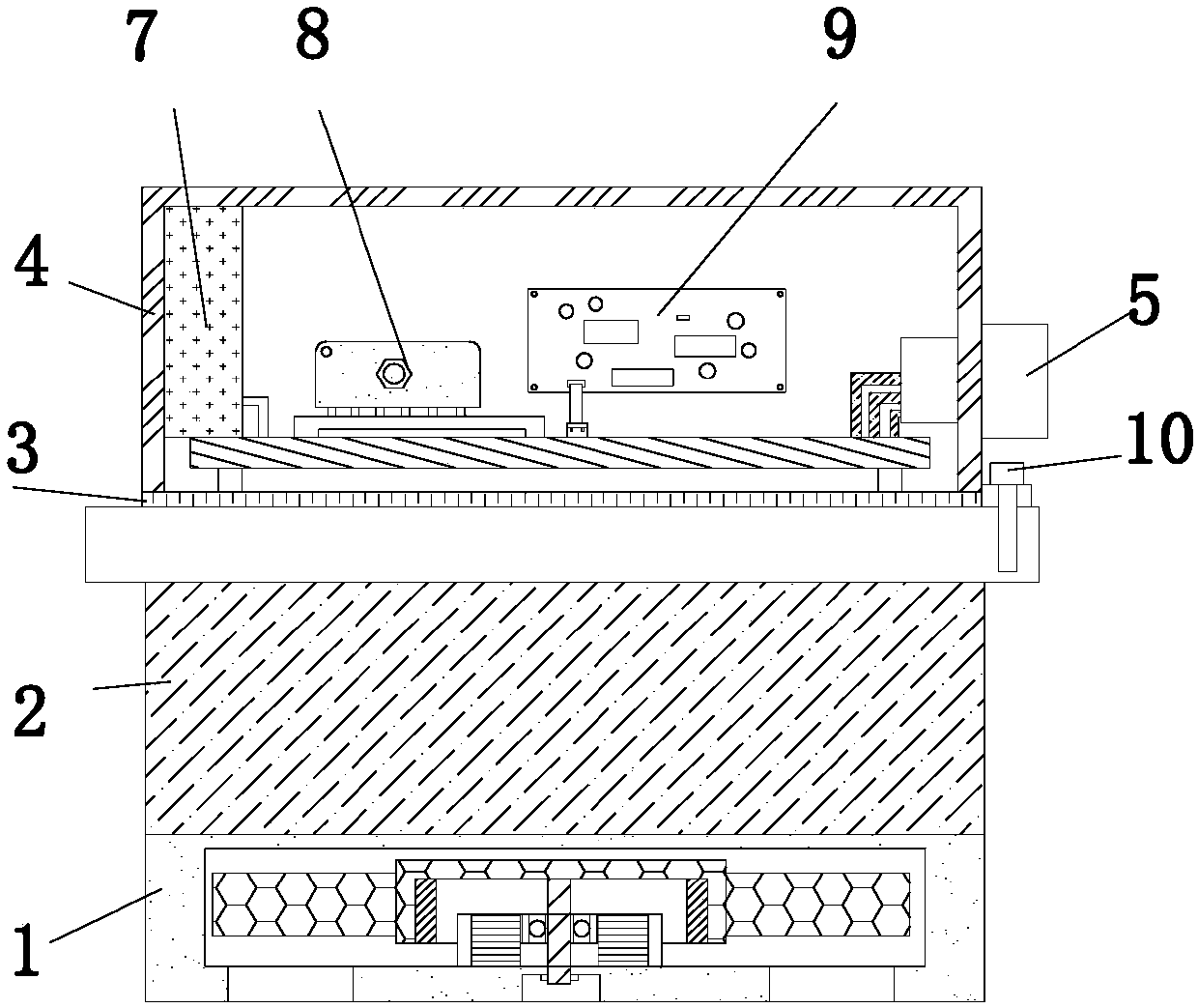

Low-voltage control box for new energy automobile

InactiveCN107592779AReduce the temperatureNo glitchesCooling/ventilation/heating modificationsInterference fitLow voltage

The invention discloses a low-voltage control box for a new energy automobile. The low-voltage control box structurally comprises a radiator, a radiating plate, a base, a shell, a data interface, a sensor interface, a laminated capacitor, a control power panel, a driving module and a fastening bolt, wherein the radiator is fixedly arranged below the radiating plate, and interference fit is adopted; the base is mounted above the radiating plate, and bolted connection is adopted; the base is mounted below the shell, and buckled connection is adopted; the data interface is mounted on the right side of the sensor interface, and signal connection is adopted between pins of the data interface and pins of the sensor interface. The radiator is provided with a coil, a rotating shaft, a permanent magnet, fan blades and a frame body, the radiator of the improved low-voltage control box for the new energy automobile in the prior art is additionally arranged outside, the temperature of the controller is reduced through the cooperation with radiating fins, and the problem of electric appliance fault caused by condensed water vapor when the temperature of main board components is reduced once theautomobile is turned off cannot appear.

Owner:HUBEI HAILIAN TECH CONSULTATION CO LTD

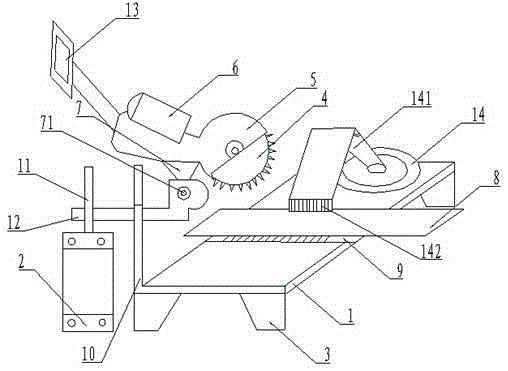

Furniture strip board sawing device

The invention discloses a furniture strip board sawing device. The furniture strip board sawing device comprises a base; a horizontal rail is arranged in a middle position of an upper end of the base; a workpiece is arranged on the horizontal rail; a supporting upright is arranged on the base; a hoist cylinder is arranged near one end of the supporting upright; a movable spindle is connected to the hoist cylinder; a supporting cross beam is arranged between the movable spindle of the hoist cylinder and the supporting upright; a fixture is placed on the supporting cross beam; a motor is arranged on an upper end of the fixture and connected with a cutting saw web. The furniture strip board sawing device is convenient for processing furniture strip boards, high in speed, and meanwhile, good in cutting quality and long in service life.

Owner:SUZHOU DONGBANG FURNITURE

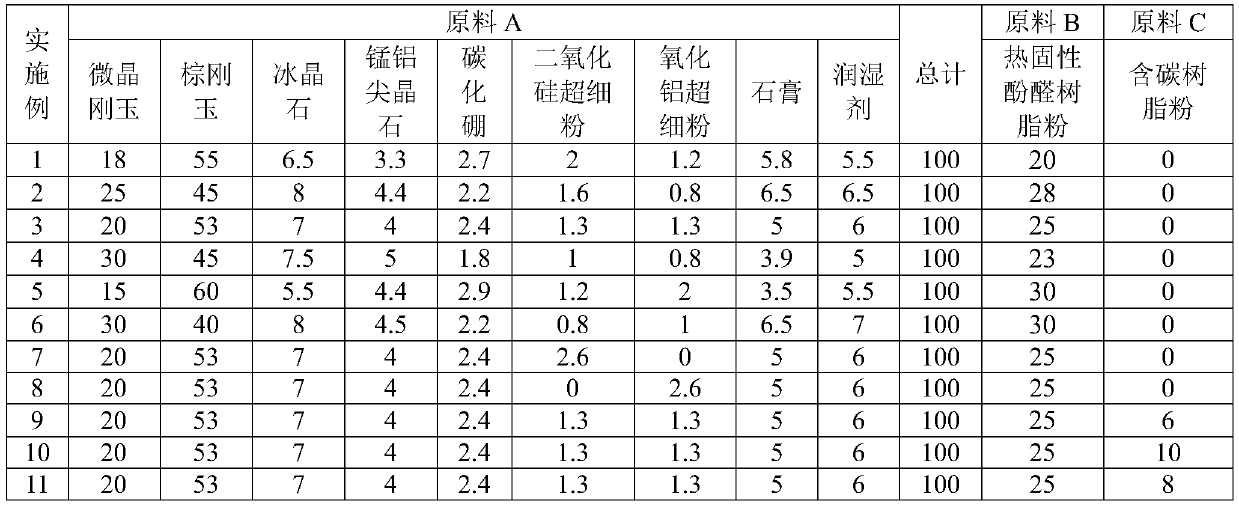

Thermosetting phenolic resin abrasive cutting wheel and preparation method thereof

ActiveCN110977795AImprove sharpnessImprove grinding efficiencyBonded abrasive wheelsGrinding devicesManganeseGrinding wheel

The invention relates to a thermosetting phenolic resin abrasive cutting wheel and a preparation method thereof, and belongs to the technical field of abrasive cutting wheel production. The abrasive cutting wheel comprises a grinding body and a reinforcing mesh embedded in the grinding body, and the grinding body is prepared from, by weight, a raw material A and a raw material B; the raw materialA comprises microcrystalline corundum, brown fused alumina, cryolite, manganese alumina spinel, boron carbide, ultrafine powder, gypsum and a wetting agent; the raw material B is thermosetting phenolic resin powder, and the addition amount of the thermosetting phenolic resin powder is 20-30% of the total weight of the raw material A. According to the abrasive cutting wheel, through cooperation ofthe raw materials, the abrasive cutting wheel has high sharpness, high grinding efficiency and high rotation strength, and the service life of the abrasive cutting wheel is prolonged. According to thepreparation method of the abrasive cutting wheel, abrasive cutting wheel preparation is stable, the bonding strength between the raw materials is improved, and the use effect of the abrasive cuttingwheel is improved.

Owner:郑州九天工贸有限公司

Low-smoke halogen-free flame-retardant non-ferrous alloy material for extrusion and stamping and processing method thereof

The invention discloses a low-smoke halogen-free flame-retardant non-ferrous alloy material for extrusion and stamping and a processing method thereof. The alloy material mainly comprises the following raw materials in parts by weight: 55-60 parts of PC, 15-20 parts of ABS, 10-15 parts of a halogen-free organic phosphorus flame retardant, 0.3-0.8 part of an impact-resistant filler, 0.4-0.9 part of a lubricating agent and 0.1-0.3 part of a toner. The processing method comprises the following steps: drying PC and ABS to be added into a high-speed mixer to be preheated for 5 minutes, adding the halogen-free organic phosphorus flame retardant, the impact-resistant filler, the lubricating agent and the toner into the high-speed mixer, and mixing for 10 minutes at a temperature of 65-70 DEG C. The modified material is not required to be added with a color masterbatch carrier and is good in flame-retardant effect, free of halogen, low in smoke, easy to extrude, stable to form, smooth in punching surface and free of burr phenomena. The processing qualification rate of products is ensured by means of the excellent performance of the material; the low-smoke halogen-free flame-retardant non-ferrous alloy material disclosed by the invention can be widely applied to high-speed rails, nuclear power, new energy and other electrical fields.

Owner:SHANGHAI YIFENG PLASTIC PROD CO LTD

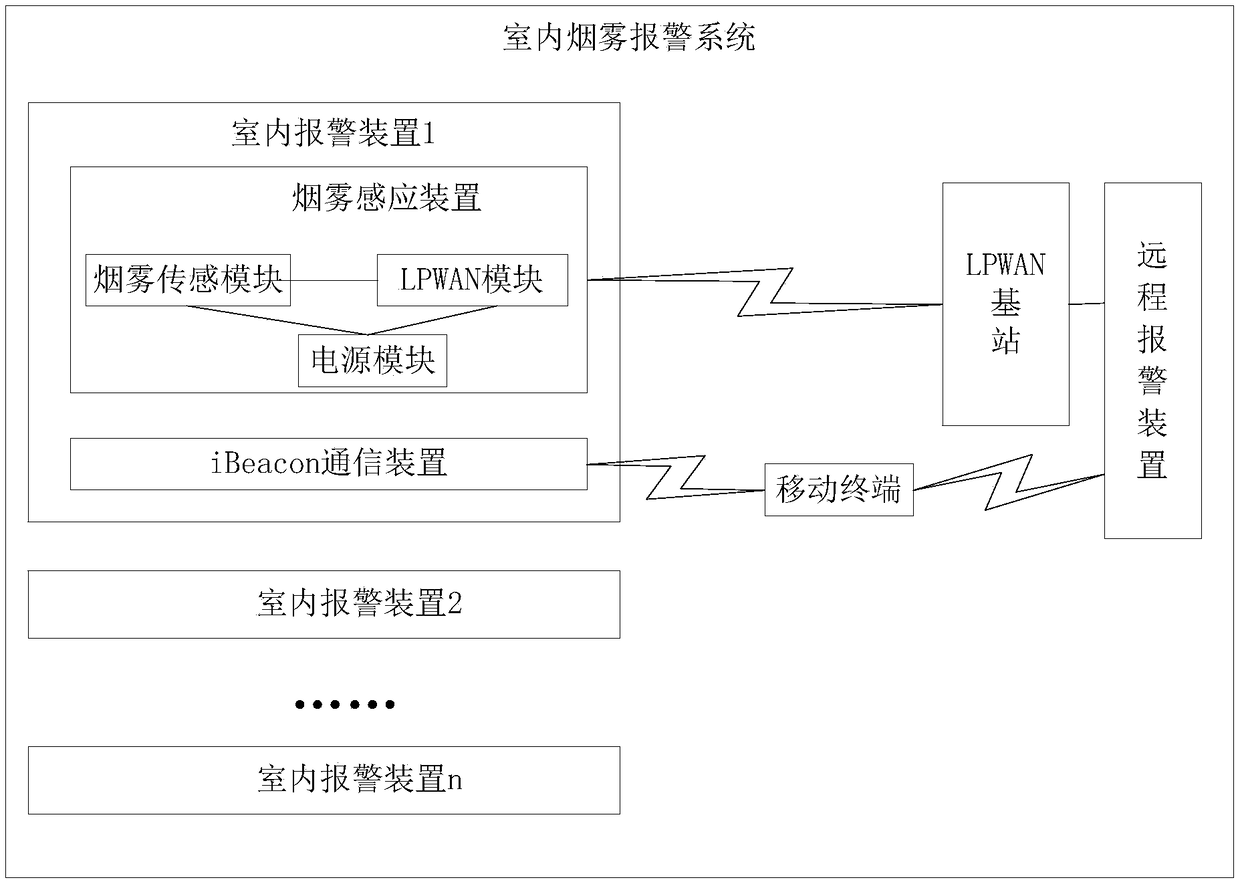

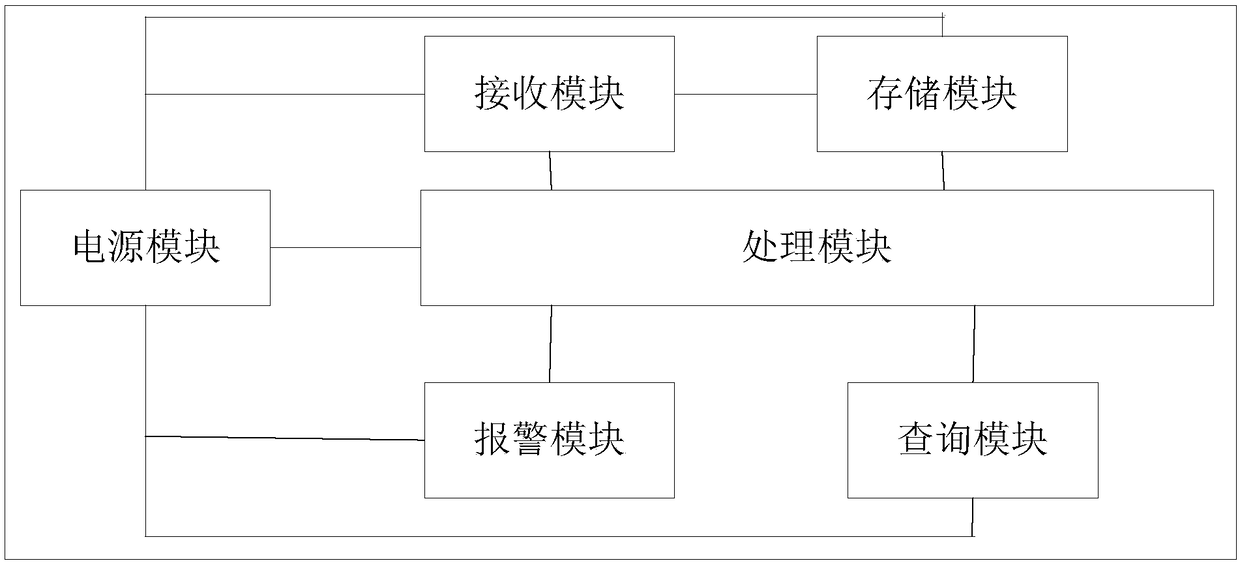

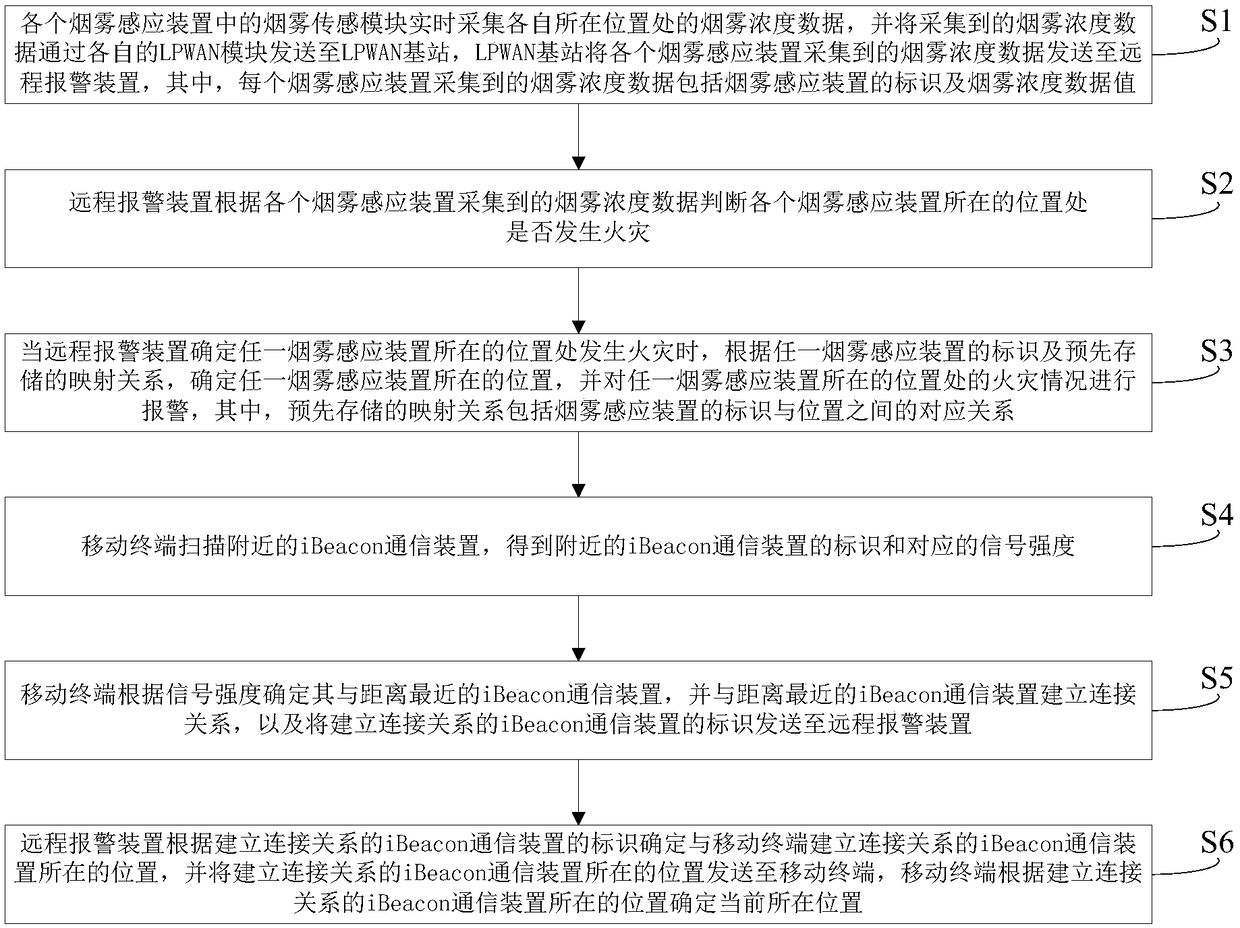

Indoor smoke alarm system and alarm control method thereof

InactiveCN108765855AImprove reliabilityHigh degree of intelligenceFire alarm smoke/gas actuationEngineeringAlarm device

The present invention relates to an indoor smoke alarm system and an alarm control method thereof, belonging to the technical field of smoke alarm. The system comprises a plurality of indoor alarm devices, a LPWAN station and a remote alarm device, the indoor alarm devices are distributed in a floor or a room, the LPWAN station and the remote alarm device are distributed at the control center, each indoor alarm device comprises one smoke induction device, each smoke induction device comprises one smoke sensing module, one power module and one LPWAN module; the power module in each smoke induction device is connected with the smoke sensing module and the LPWAN module thereof, and the smoke sensing module is connected with the LPWAN module; and the LPWAN module in each smoke induction deviceis connected with the LPWAN station. A mode of transmission of smoke concentration data through a cable in a traditional indoor smoke alarm system is improved to a mode of transmission of the smoke concentration data through the LPWAN modules so as to improve the intelligent degree, the network degree and the module connection mode reliability, and it is avoid that the burnout of the cable causessystem faults to improve the reliability of the system.

Owner:谢馨慧

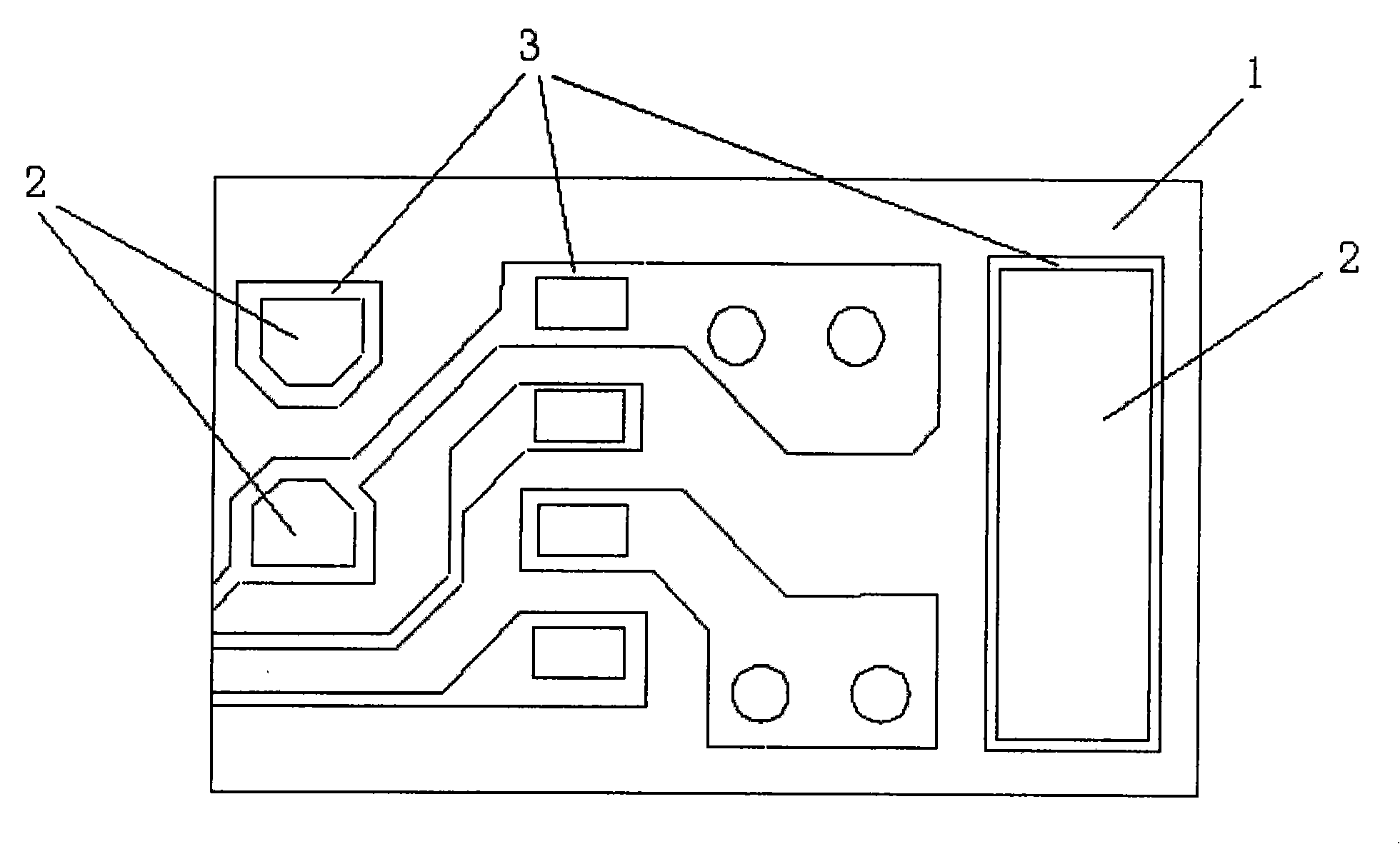

Method for preparing solder pad of printed circuit board

InactiveCN101325844BSmall size errorStrong pullNon-metallic protective coating applicationSurface mountingHigh surface

Owner:HUIZHOU BLUEWAY ELECTRONICS

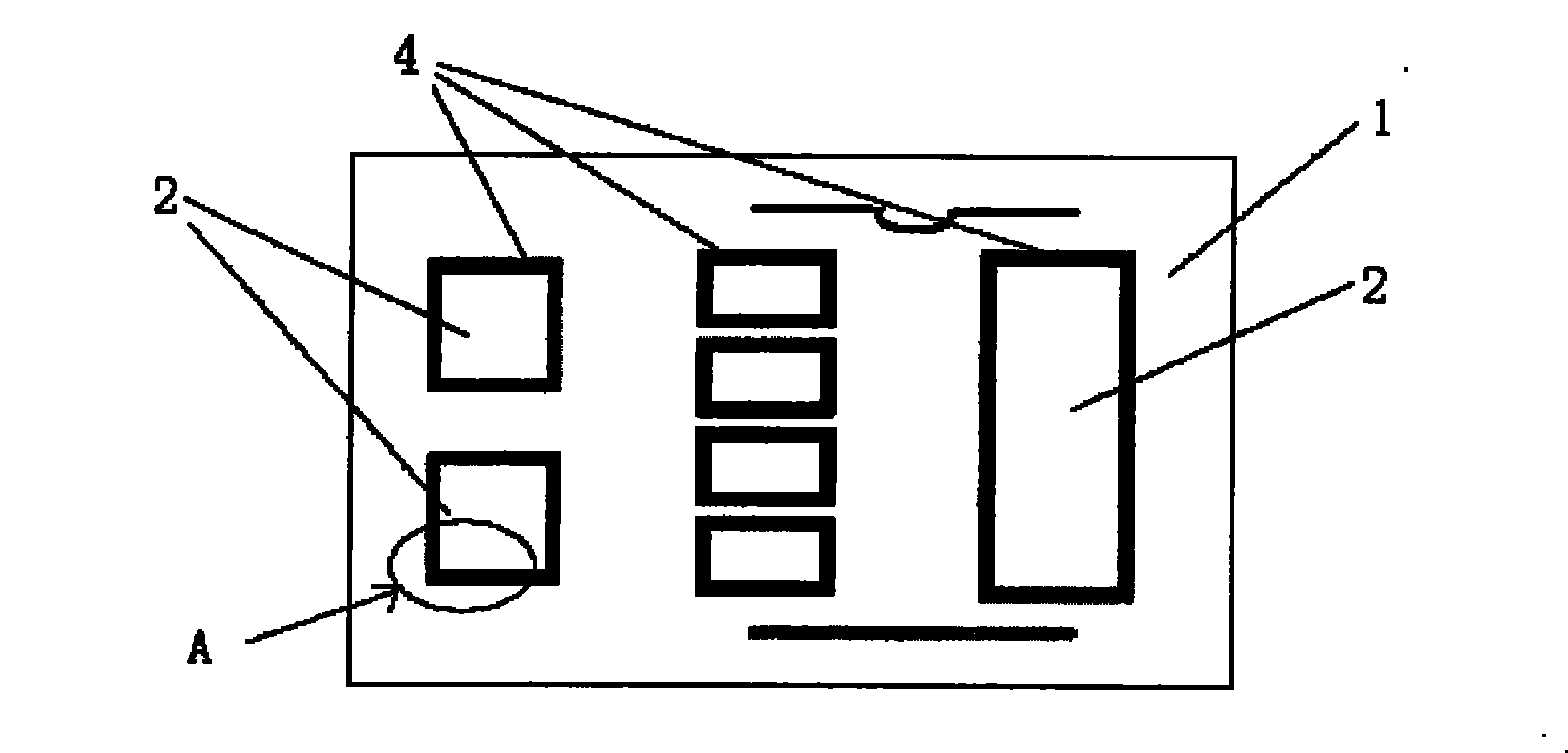

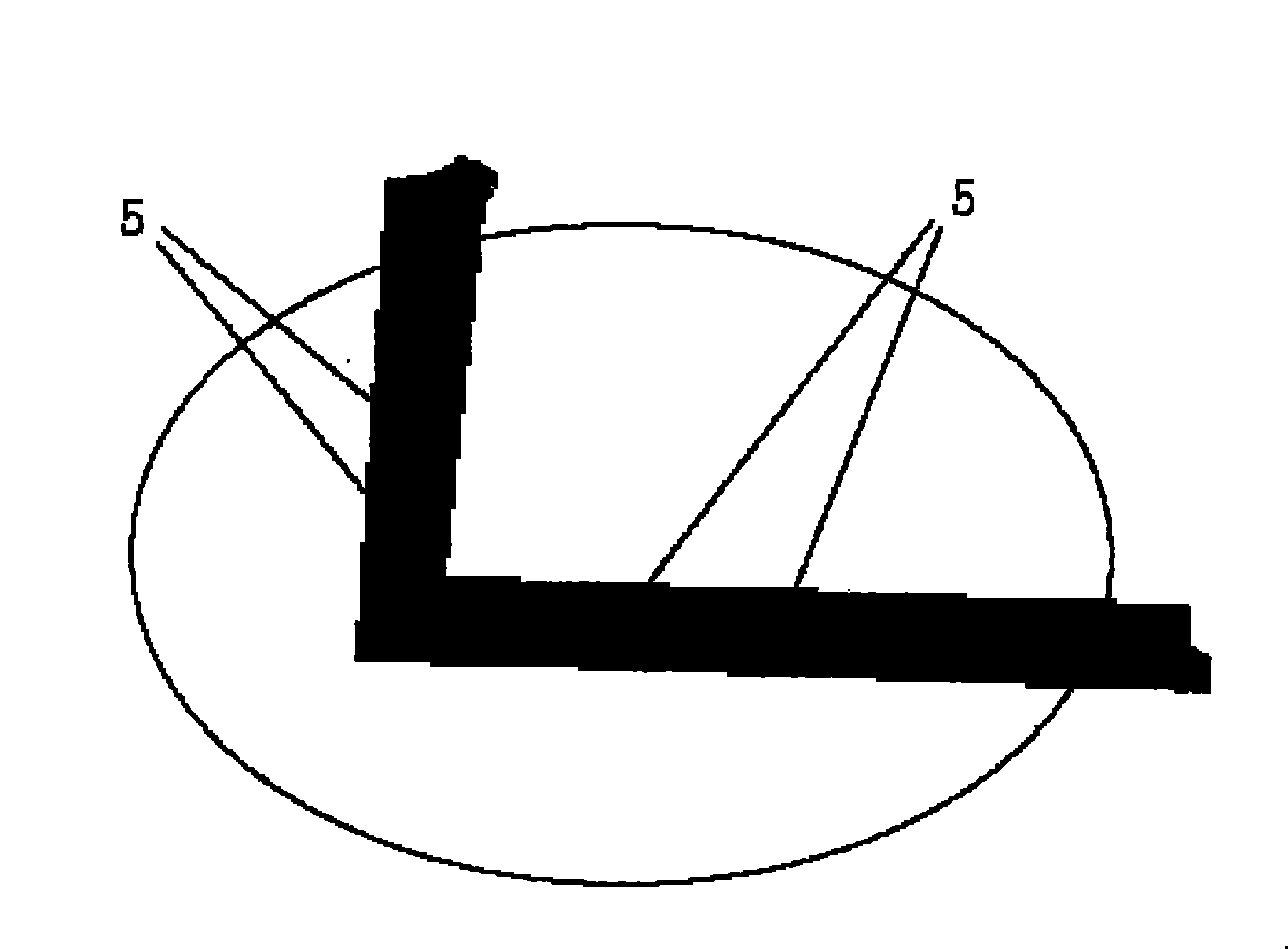

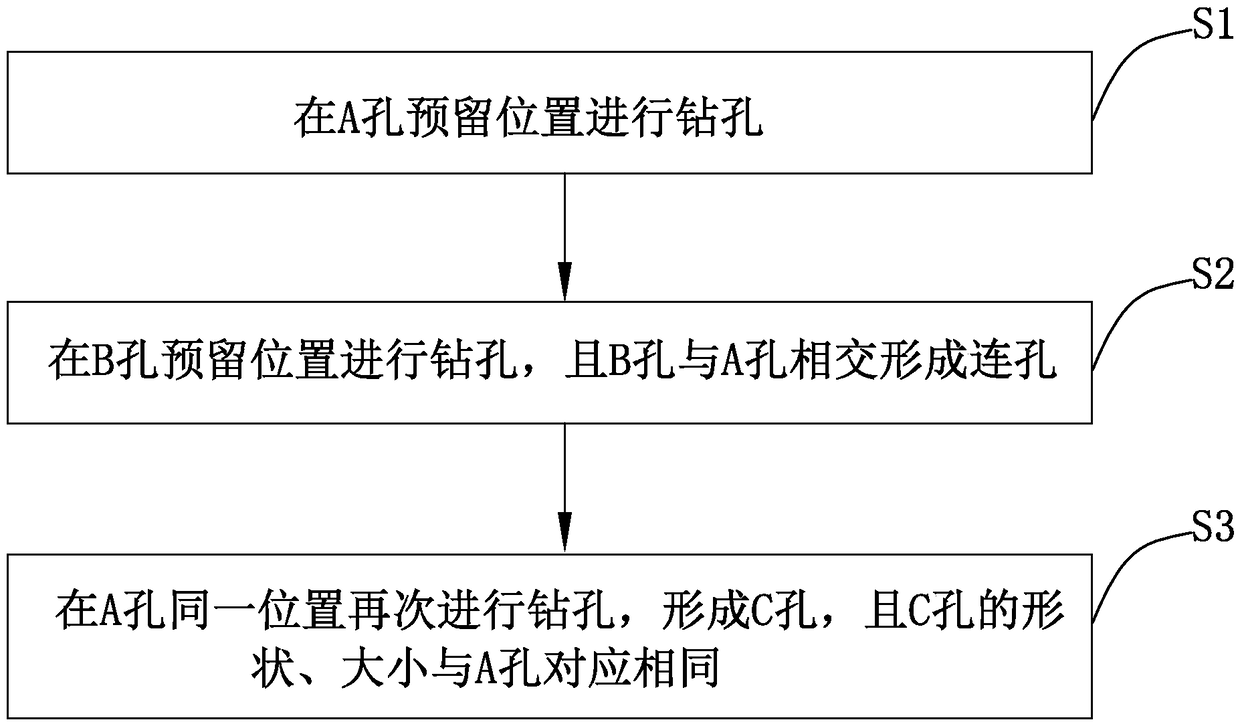

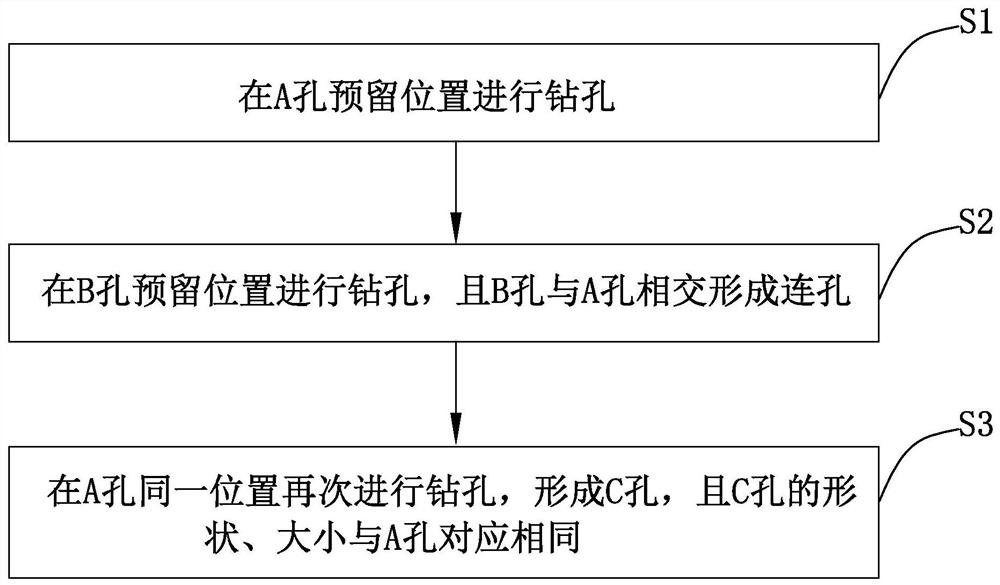

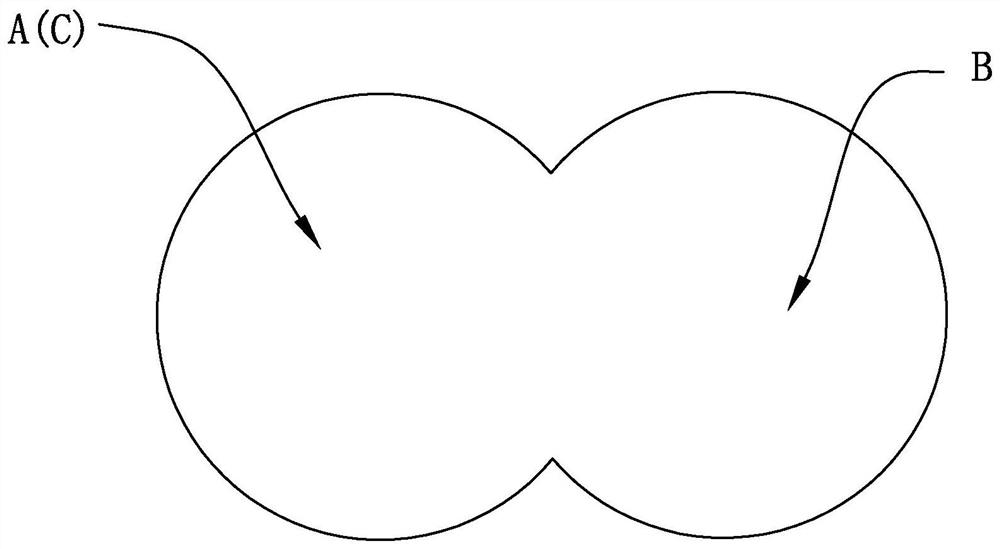

Treatment method for PTH communication hole burr

ActiveCN108770207AEasy to operateReduce the number of stacksInsulating layers/substrates workingPetroleum engineering

The invention discloses a treatment method for a PTH communication hole burr. The treatment method for a PTH communication hole burr comprises the following steps: drilling at a reserved position of an A hole; drilling at a reserved position of a B hole, wherein the B hole and the A hole are intersected to form a communication hole; step S3: drilling again at the same position of the A hole to form a C hole, wherein the shape and size of the C hole are the same as those of the A hole. The treatment method for a PTH communication hole burr provided by the invention has the advantages of simpleprocess, and the product has no burr after the washing, scouring and electroplating processes.

Owner:江西旭昇电子有限公司

Magnet yoke dovetail-shaped broach

The invention discloses a magnet yoke dovetail-shaped broach comprising a long guide rail, a dovetail-shaped broach body, a height cushion block and broach blades. The dovetail-shaped broach body is slidably mounted on the long guide rail through a rolling core pressing strip. A rolling core pressing plate is arranged on the rolling core pressing strip and located on an inner groove part in the lower surface of the dovetail-shaped broach body. Multiple layers of broach blades are mounted on the left and right sides of the upper surface of the dovetail-shaped broach body correspondingly. The broach blades on the left side and the broach blades on the right side are symmetrically arranged. The broach blades on the left side include front parts and rear parts which are mounted in a front end broach blade groove and a rear end broach blade groove correspondingly, and the front end broach blade groove is deeper than the rear end broach blade groove. The height cushion block is mounted in the middle area of the upper surface of the dovetail-shaped broach body and connected with the dovetail-shaped broach body through hexagon socket cap screws A. The magnet yoke dovetail-shaped broach has the beneficial effects that using is convenient, cutting is stable, the quality of the machining surface is good, and working efficiency is high.

Owner:四川天虎工具有限责任公司

Fluoroplastic plate calendering and cutting all-in-one machine

The invention discloses a fluoroplastic plate calendering and cutting all-in-one machine which comprises a base. A supporting column structure is arranged on the base. Two parallel horizontal supporting frames are connected to a supporting column and provided with guide rail structures. A driving roller A, an electric furnace shell, a flattening roller, a transverse cutting tool rest, a longitudinal cutting tool rest and a driving roller B are sequentially arranged on the horizontal supporting frames. A driving motor is arranged on the driving roller B in a connected manner. A fluoroplastic plate is driven by power of the driving motor to move. The fluoroplastic plate calendering and cutting all-in-one machine is compact in structural design and high in finished product machining efficiency, a fluoroplastic product is calendered evenly, the cutting forming effect is good, and no burr or wrinkle appears.

Owner:SUZHOU CHONGEN MOLDING

A kind of thermosetting phenolic resin cutting wheel and preparation method thereof

ActiveCN110977795BImprove sharpnessImprove grinding efficiencyBonded abrasive wheelsGrinding devicesManganeseGrinding wheel

Owner:郑州九天工贸有限公司

Automobile crash buffer system and method

ActiveCN107499265BImprove driving safety factorSimple structureBumpersTransport engineeringShock absorber

The invention relates to an automobile collision buffer system and a method, wherein a limiting blocking beam is disposed on the rear end of a main beam; a horizontal viscous damper is installed on the inner side of the limiting blocking beam; a collision buffer device is disposed on the front end of the horizontal viscous damper; collision force is blocked by an anti-collision block; when the anti-collision block is stricken, collision is buffered by a buffer spring on the outer front end, a buffer spring on the outer rear end, a buffer spring on the inner front end and a buffer spring on the inner rear end; the horizontal viscous damper and the limiting blocking beam are used for limiting and further buffering; under fixation of the main beam and the horizontal beam, the collision is buffered and reduced; sensitivity is high; real-time defense is achieved; failure does not take place after installation; the buffering is achieved based on pure mechanical principles; overall cost is low; overall cost is low, but a safety coefficient is high; overall installation is completed with an automobile; the service life is long; buffer failures or other faults caused by electronic equipment failures do not take place; a safe driving coefficient of the automobile is increased; and harm generated from accident occurrence is reduced.

Owner:HUNAN UNIV OF ARTS & SCI

Double tubes for double-connected double-bag peritoneal dialysis

The invention discloses a twin tube connected with a twin bag for peritoneal dialysis. The twin tube includes two catheters which are of separated structures. The catheters are in paralleling coil state, the bottom surfaces of the catheters are attached to the same plane, and the coined catheters are connected to a plurality of contact points between the adjacent catheters by plastic welding or gluing. With the twin tube connected with the twin bag for the peritoneal dialysis, the problems of burrs appearing on the contact points between the catheters and a peritoneum and tearing of the catheters in use are avoided; success rate of surgeries are improved, and sequela of the surgeries are prevented.

Owner:JIANGSU KANGJIN MEDICAL INSTR

An annealing control method of an automatic control spring washer

ActiveCN109371226BGood hardness uniformityImprove tissue uniformityFurnace typesHeat treatment process controlEngineeringNitrogen gas

The invention relates to an automatically controlled annealing control method of spring washers. According to the method, an annealing atmosphere of first methanol and following nitrogen and a two-section annealing process are adopted at the same time, so that the hardness and the structure uniformity of the spring washers can be good, the surfaces are flat, the edges are smooth, and no burr phenomenon exists.

Owner:杭州弹簧垫圈有限公司

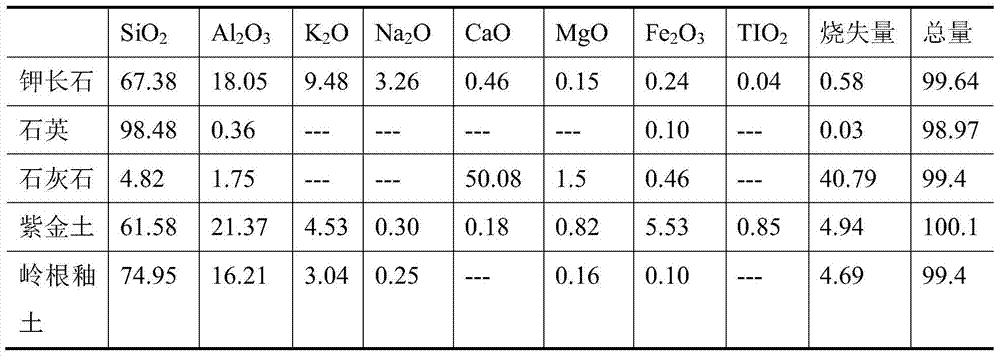

A kind of Longquan celadon tireless glaze wall and its production method and application

The invention discloses a Longquan celadon tireless glazed wall and its production method and application. The tireless glazed wall includes glaze, and the raw material composition of the glaze includes: 40-60% of potassium feldspar, 10-20% of quartz, limestone 10 to 20%, 5 to 15% of purple gold soil and 5 to 15% of lingen glaze soil; the method of making tireless glazed wall includes at least the step of drying and crushing the glaze material, and making glaze pillars, and combining the glaze pillars with the prepared Cake bonding and biscuit firing to obtain biscuit; at least one glaze firing is included, that is, the biscuit is put into a high-temperature shuttle kiln atmosphere furnace and fired for 9-11 hours, so that the kiln temperature gradually rises from normal temperature to 1250-1280 ℃, keep warm for 30-60 minutes, turn off the flame and cool naturally to obtain a tireless glaze wall with a thin base layer at the bottom, and finally polish the thin base layer to obtain a finished product. The tireless glazed wall of the present invention does not contain a carcass, and the finished product is crystal clear and moist, which fills the blank of seldom research on tireless thick-glazed celadon in the prior art, and can meet people's demand for high-grade celadon.

Owner:LISHUI UNIV

How to deal with the burr in the pth connecting hole

ActiveCN108770207BGood removal effectNo glitchesInsulating layers/substrates workingMechanical engineeringPhysics

The invention discloses a method for processing PTH connecting hole burrs. The method for processing the burr in the PTH connecting hole includes the following steps: drilling at the reserved position of hole A; drilling at the reserved position of hole B, and the intersection of hole B and hole A forms a connecting hole; step S3: Drill again at the same position to form hole C, and the shape and size of hole C are the same as hole A. The method for treating the burr of the PTH connecting hole provided by the invention has a simple process, and the product has no burr phenomenon after being washed with water and electroplating.

Owner:江西旭昇电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com