Patents

Literature

43results about How to "Reduce production materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

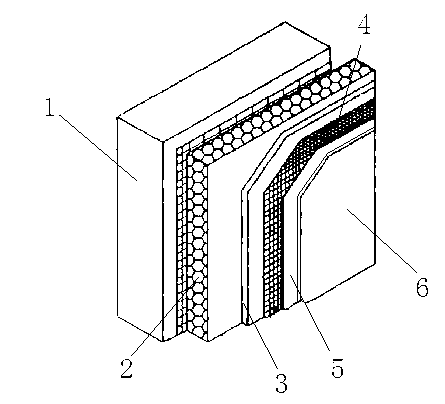

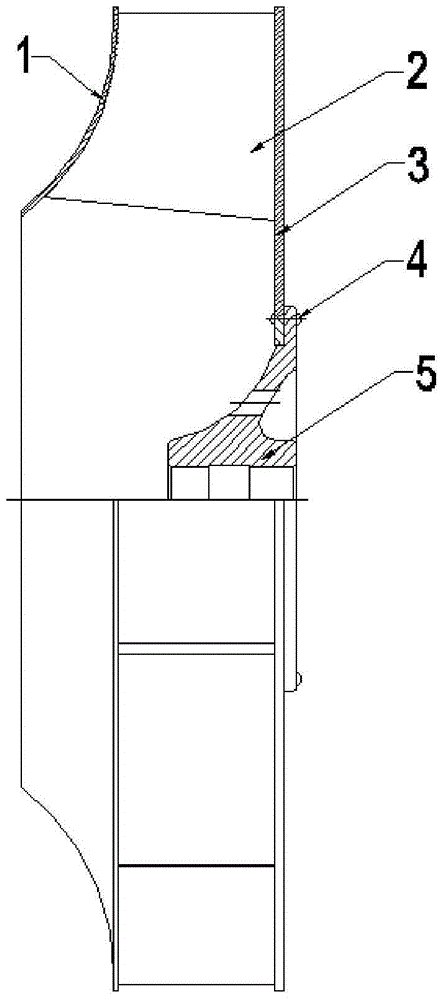

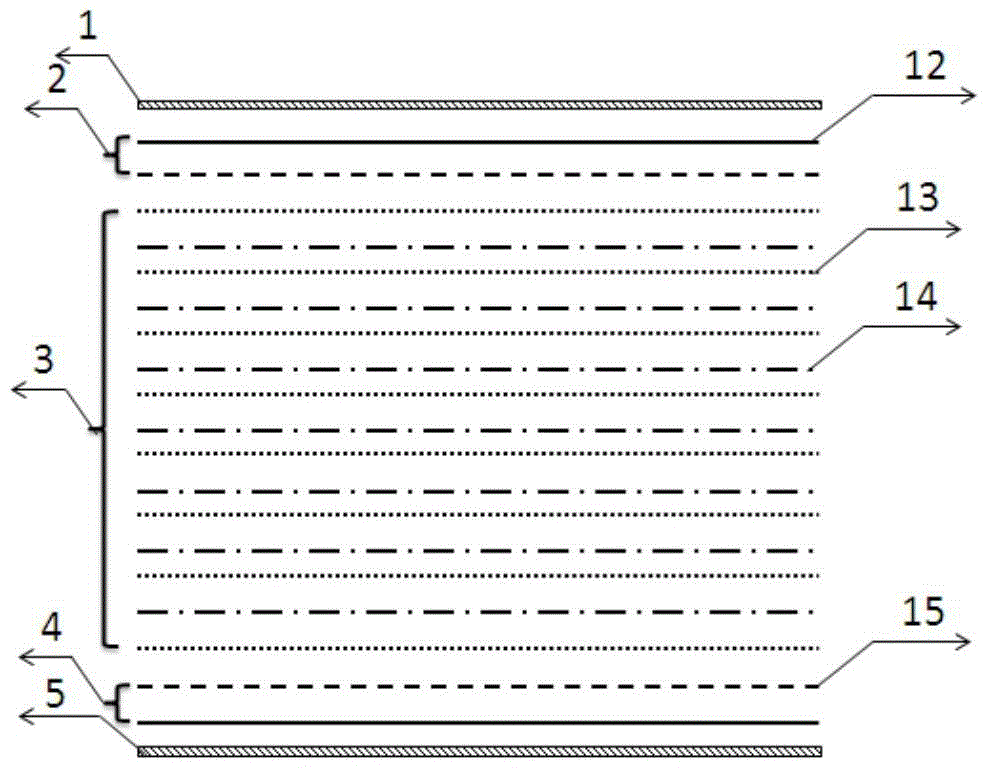

Thermal insulation wall body

InactiveCN103321319AImprove firm performanceImprove sound insulationWallsHeat proofingGlass fiberThermal insulation

The invention discloses a thermal insulation wall body. The thermal insulation wall body comprises a main wall body layer; the external side of the main wall body is sequentially provided with a thermal insulation board layer, a hot galvanizing steel wire mesh layer, an acoustic panel layer, a glass fiber grinding cloth layer and a decorative coating layer; the thermal insulation board layer and the main body wall layer are bounded together through the thermal insulation board adhesive; the thermal insulation board layer, the hot galvanizing steel wire mesh layer, the acoustic panel layer and the decorative coating layer are bounded through the fireproofing glue. The thermal insulation wall body has the advantages of improving firmness, increasing sound insulation effect, avoiding cracking and falling off, saving construction procedures, reducing production materials and having a good application prospect due to the fact that the hot galvanizing steel wire mesh layer, the acoustic panel layer and the glass fiber grinding cloth layer are added to the thermal insulation wall body.

Owner:ZHANGJIAGANG EVERNICE BUILDING MATERIALS

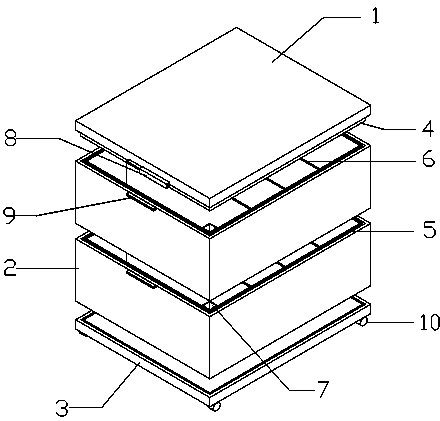

Multi-layer plastic containing box

InactiveCN103640756AImprove sealingStable structureRigid containersInternal fittingsMechanical engineeringEngineering

Owner:SUZHOU CONPLAS TECH

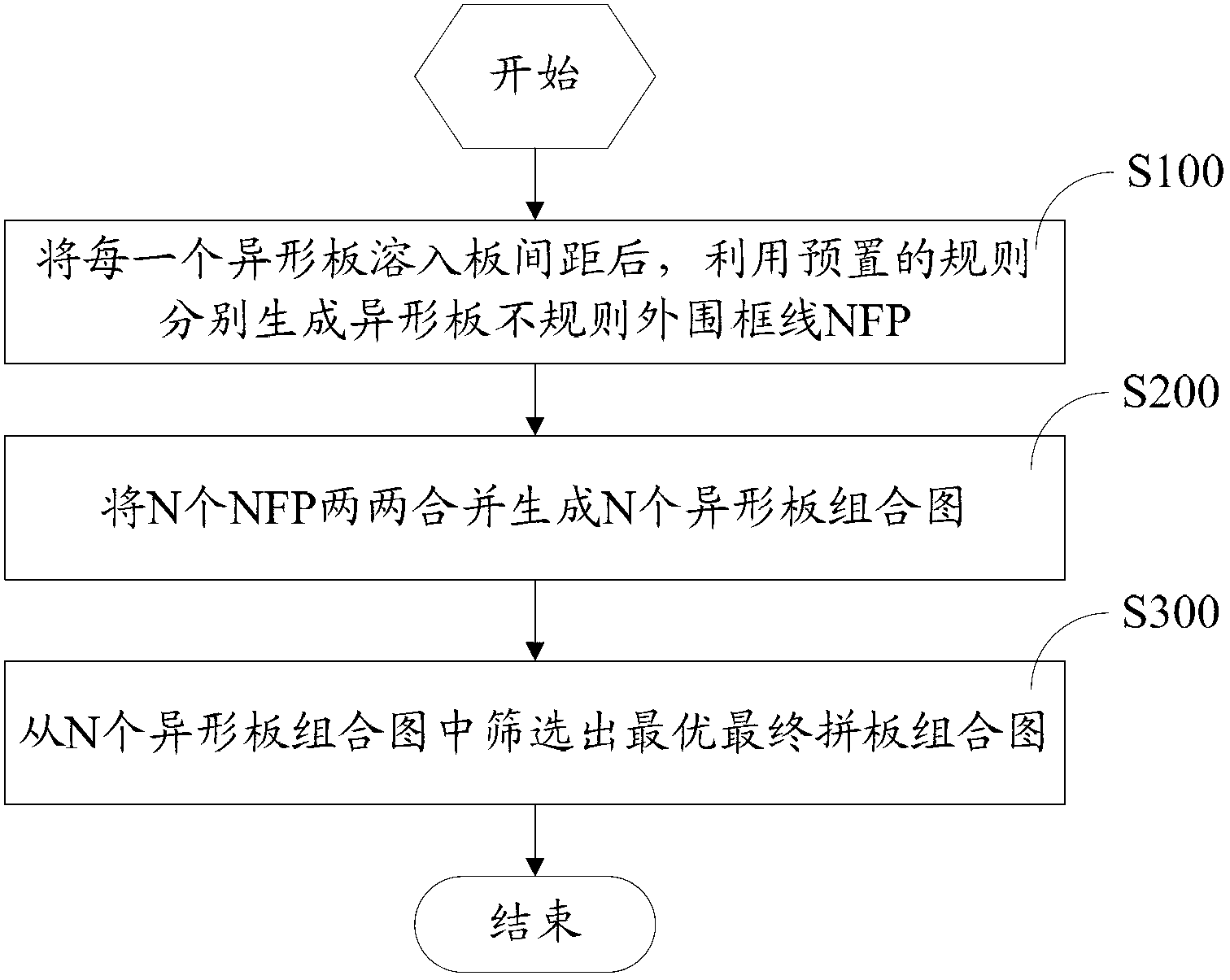

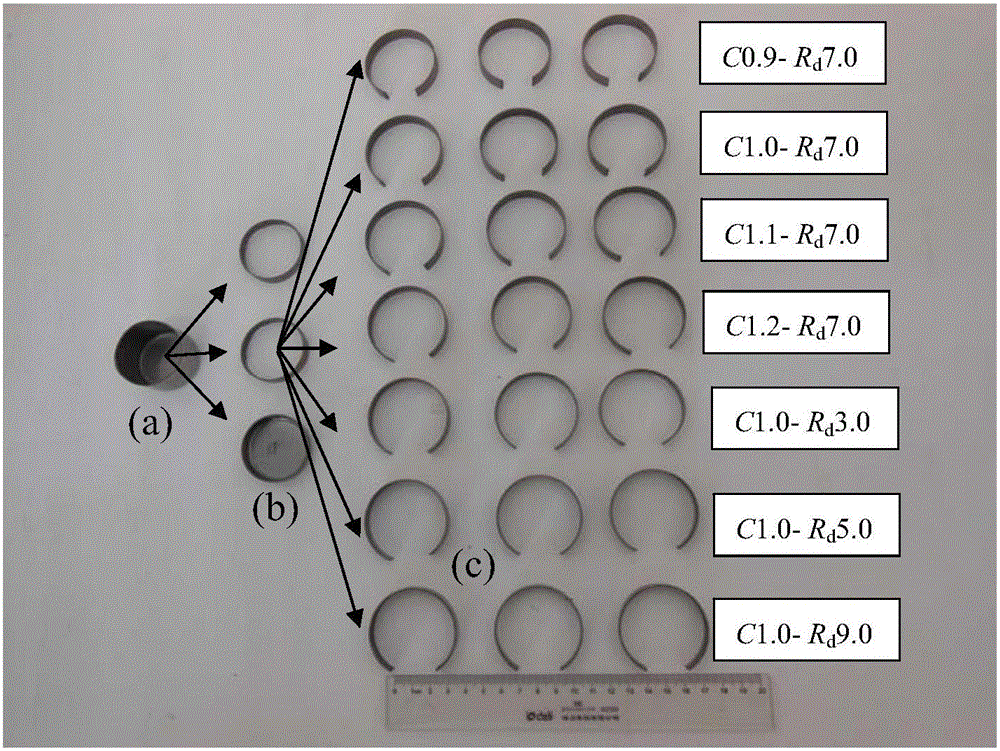

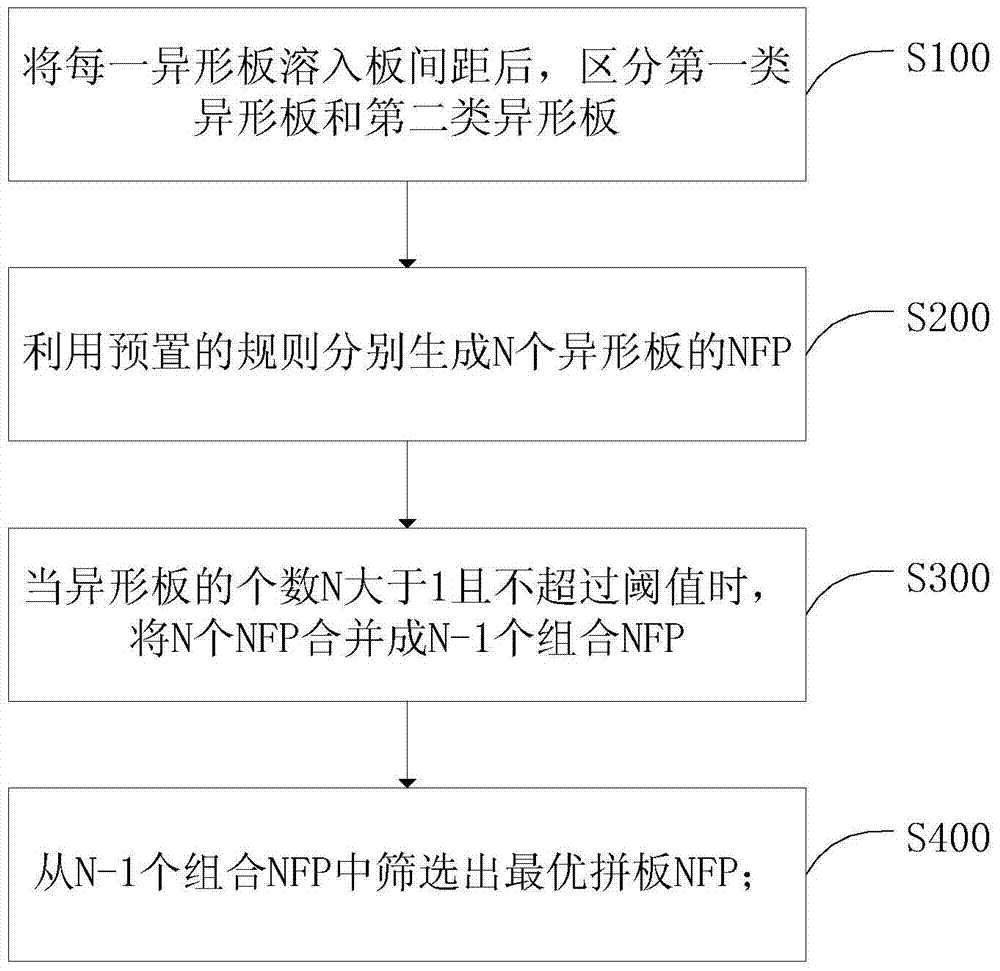

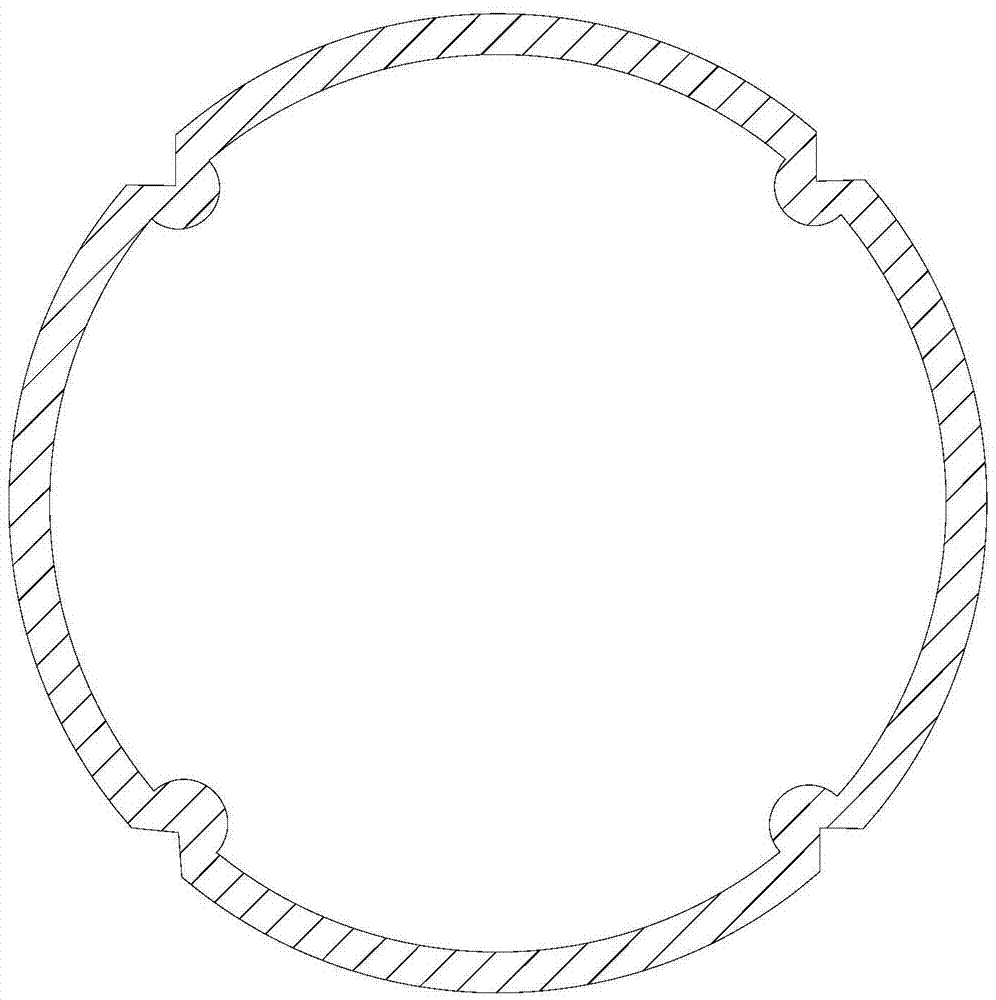

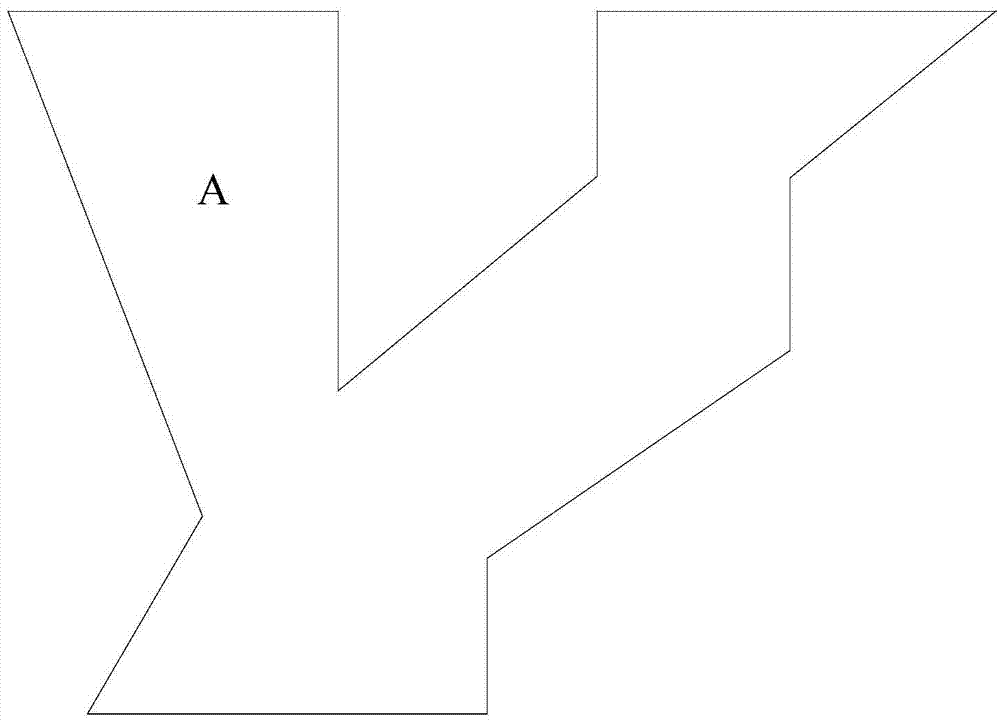

PCB (Printed circuit board) butt welding method and PCB butt welding device

ActiveCN102833961AReduce production materialsIncrease productivityPrinted circuit assemblingPrinted circuit boardEngineering

The invention relates to a PCB (Printed circuit board) butt welding method and a PCB butt welding device. The method comprises the following steps: integrating each irregular plate in the plate spacing, then generating irregular plate NFP (No Fit Polygon) by using a preset rule; combining every two NFP to generate N irregular plate combination charts; screening out the optimal butt welding combination chart from N irregular plate combination charts, wherein, N is an integral number which is larger than 1. According to the PCB butt welding method and the PCB butt welding device, the irregular plate integrated in the plate spacing is combined to generate the butt welding combination chart by using the preset rule, the optimal butt welding combination chart is screened out, the production efficiency of the PCB is improved, and production materials of the irregular plate is reduced, and the cost is reduced.

Owner:SHENZHEN PARTNER INFORMATION TECH

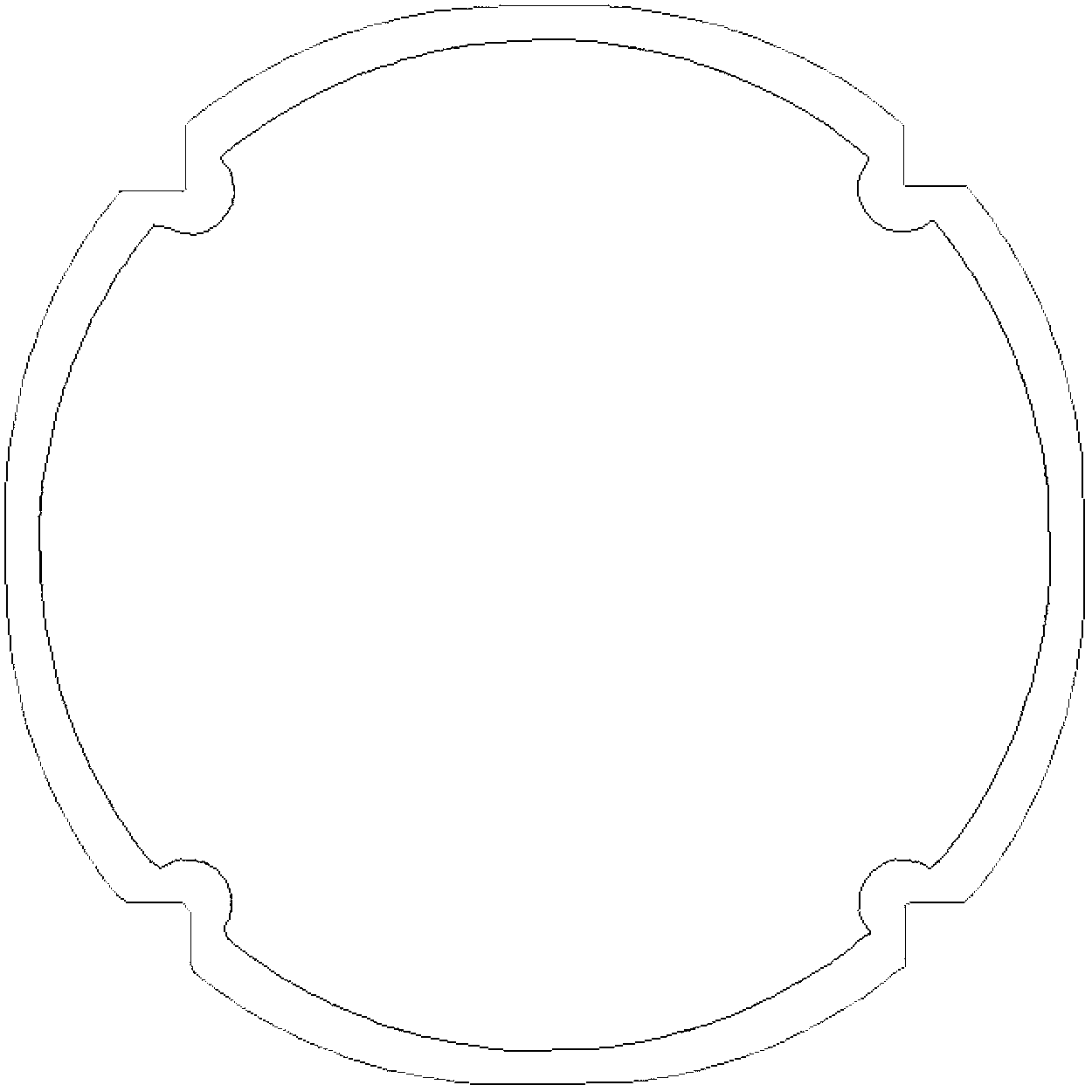

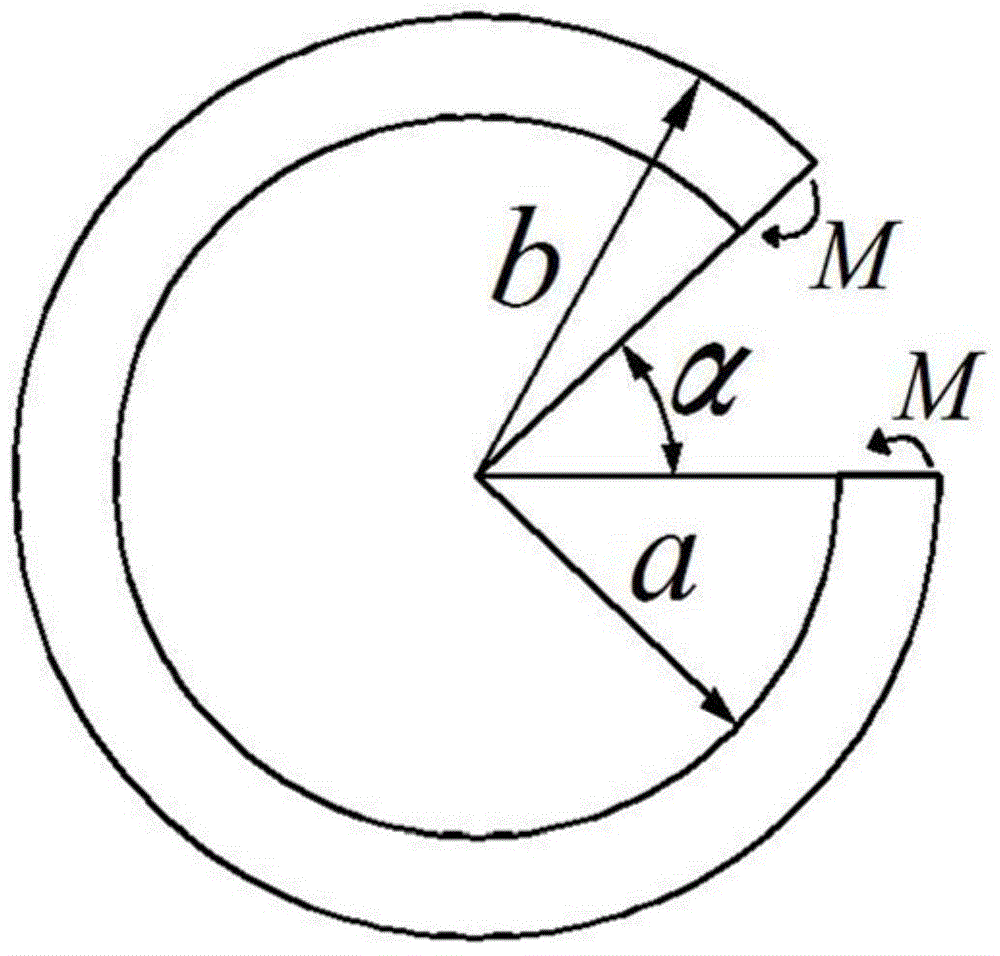

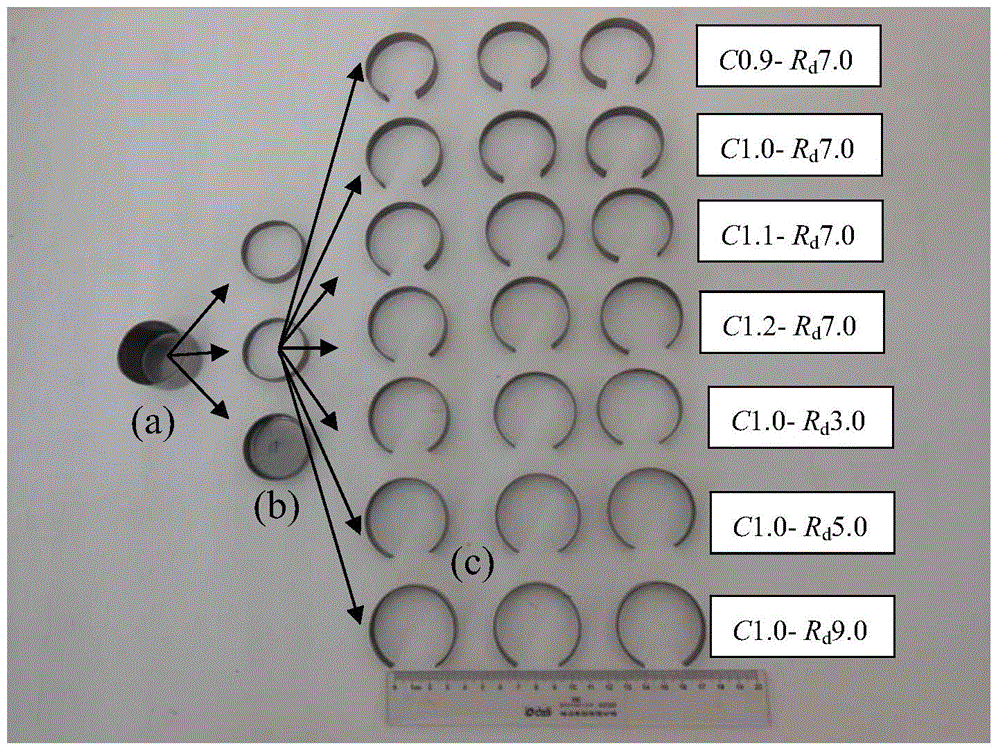

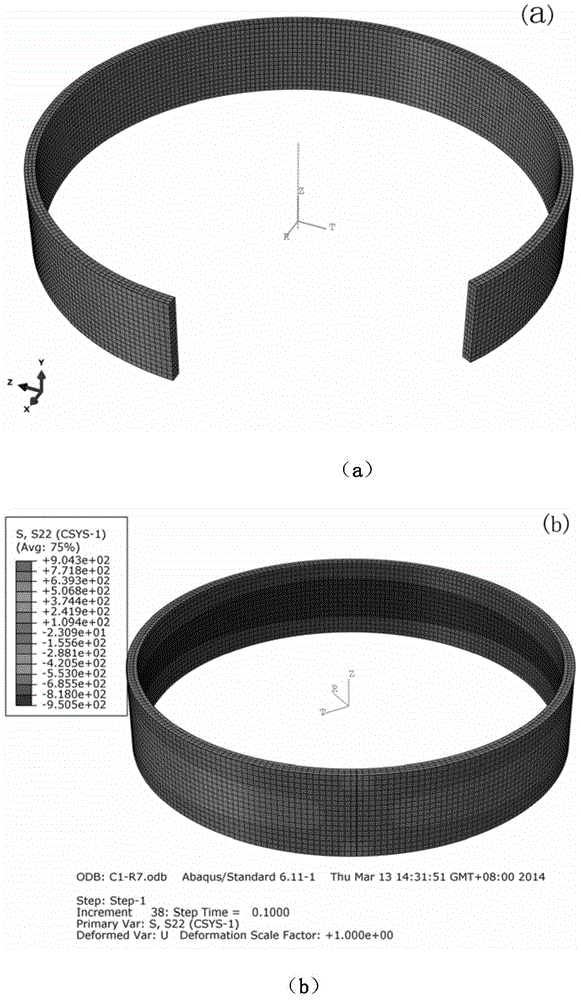

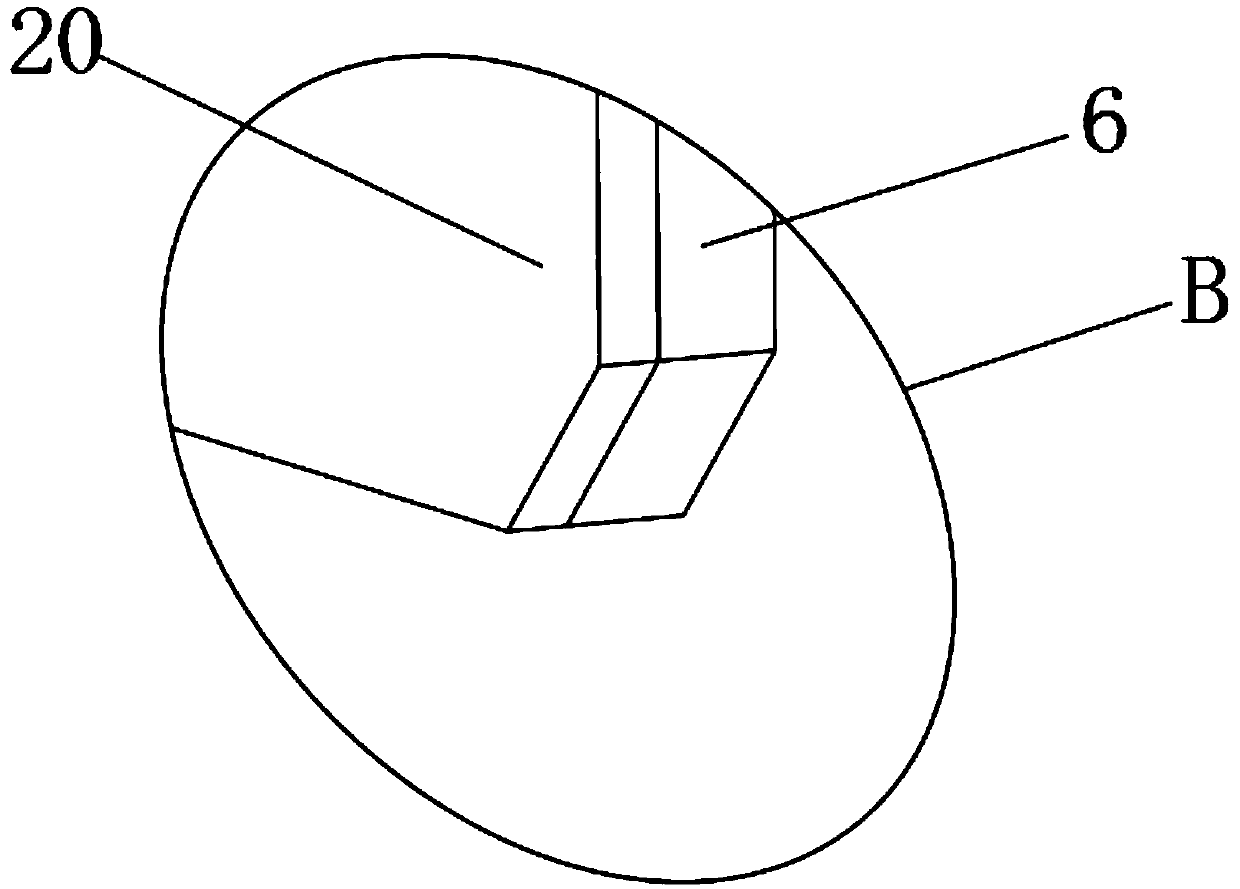

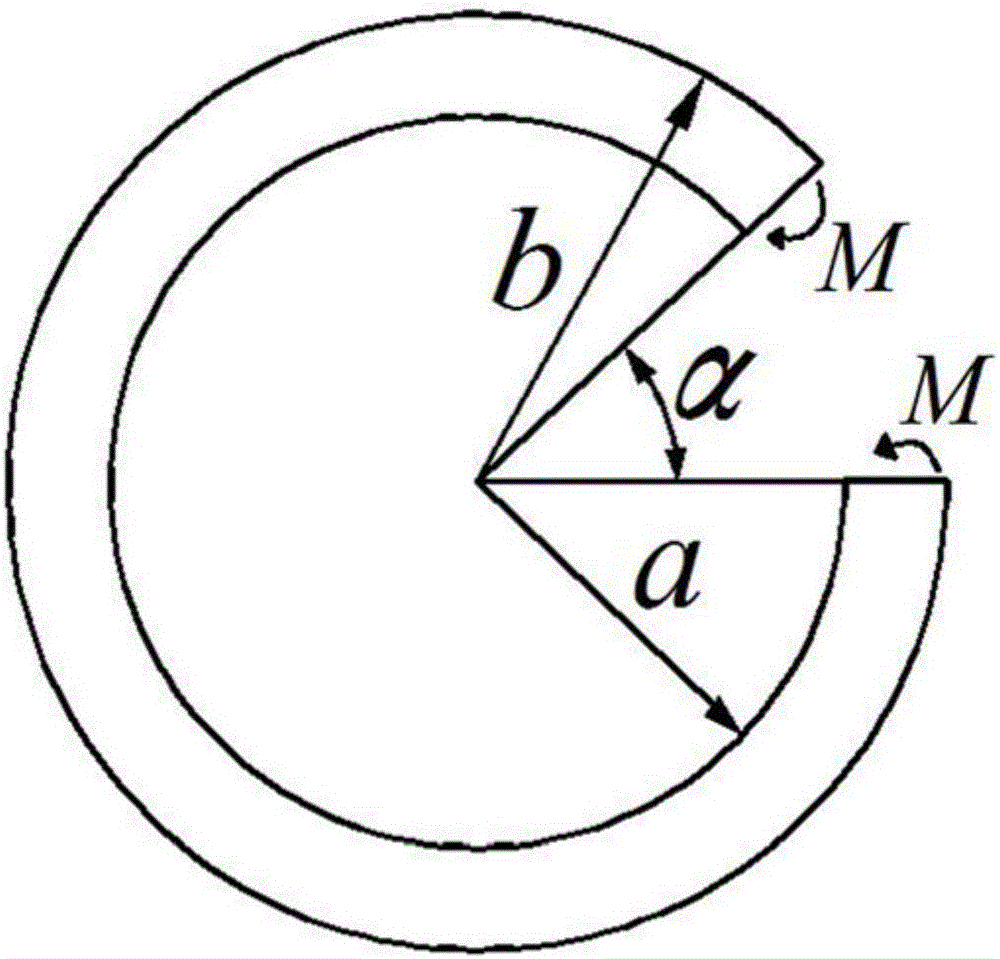

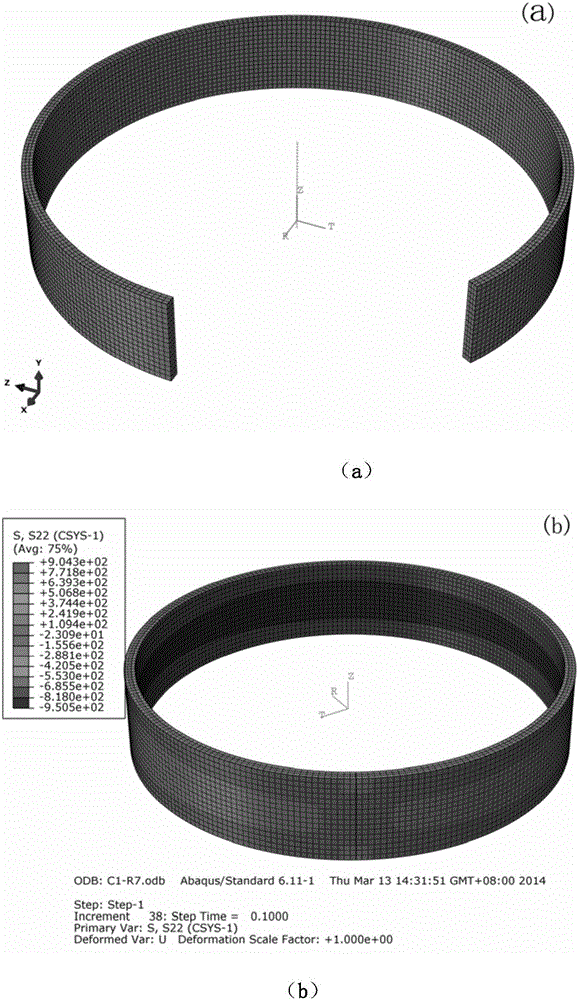

Cutting ring type measurement method for residual stress of cylinder wall of cylindrical part

ActiveCN104483058APrecise measurement of residual stressReduce production materialsApparatus for force/torque/work measurementMeasurement deviceEngineering

The invention discloses a cutting ring type measurement method for residual stress of the cylinder wall of a cylindrical part. The cutting ring type measurement method includes the following steps of (1) forming a cutting ring, wherein a circular ring cut from the cylinder wall of the cylindrical part is used as the circular ring to be cut, and the circular ring to be cut is cut apart in the radius direction to form the cutting ring; (2) calculating the residual stress, wherein in the circular ring to be cut, a calculation formula for the radial residual stress sigma <rr> and a calculation formula for the circumferential residual stress sigma <theta theta> of the position spaced from the center of the circular ring by r in the radius direction are expressed in the specification. Multi-point measurement can be achieved without developing a special measurement device, operation is easy and convenient, efficiency is high, and results are accurate.

Owner:XIANGTAN UNIV

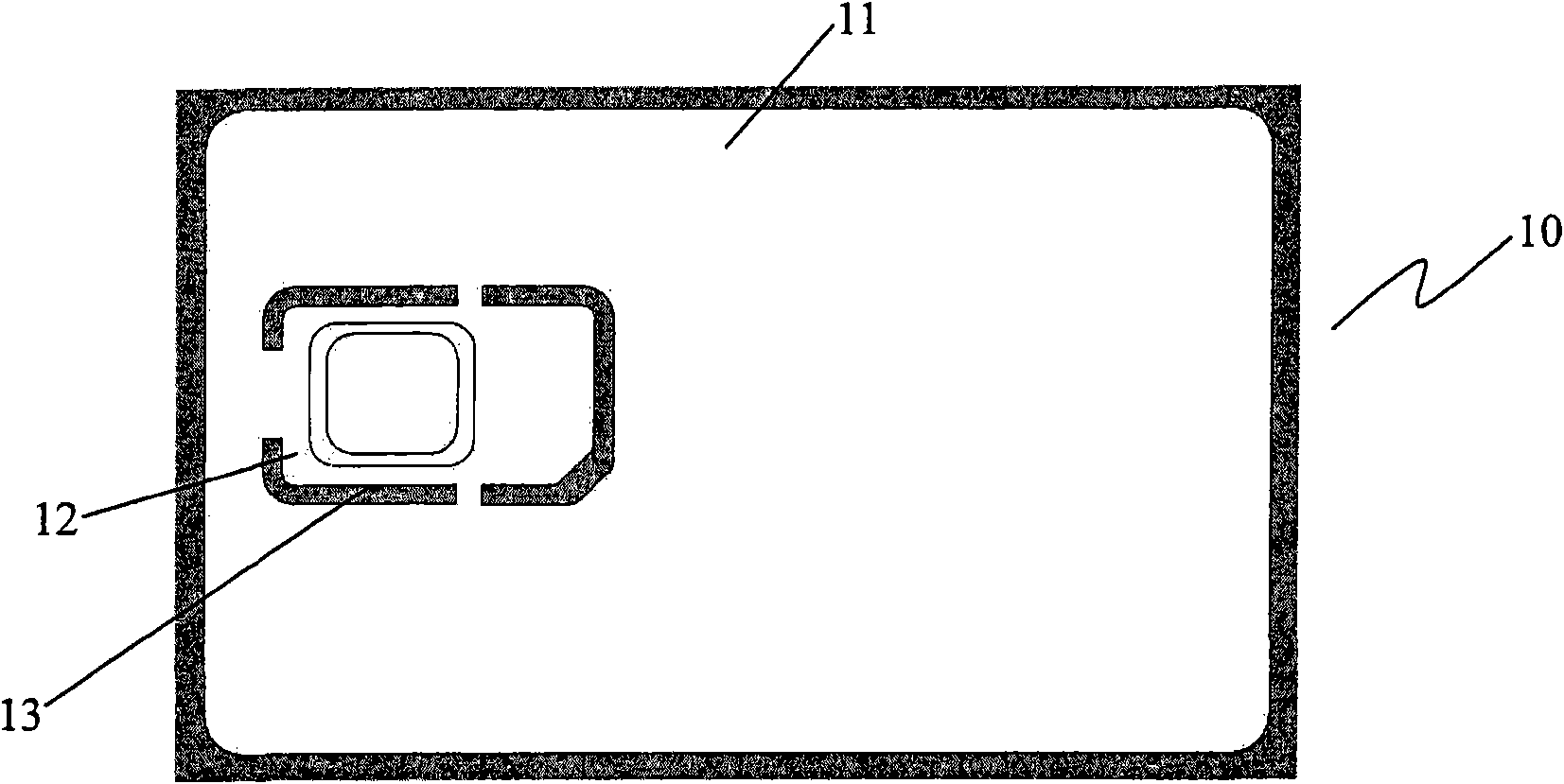

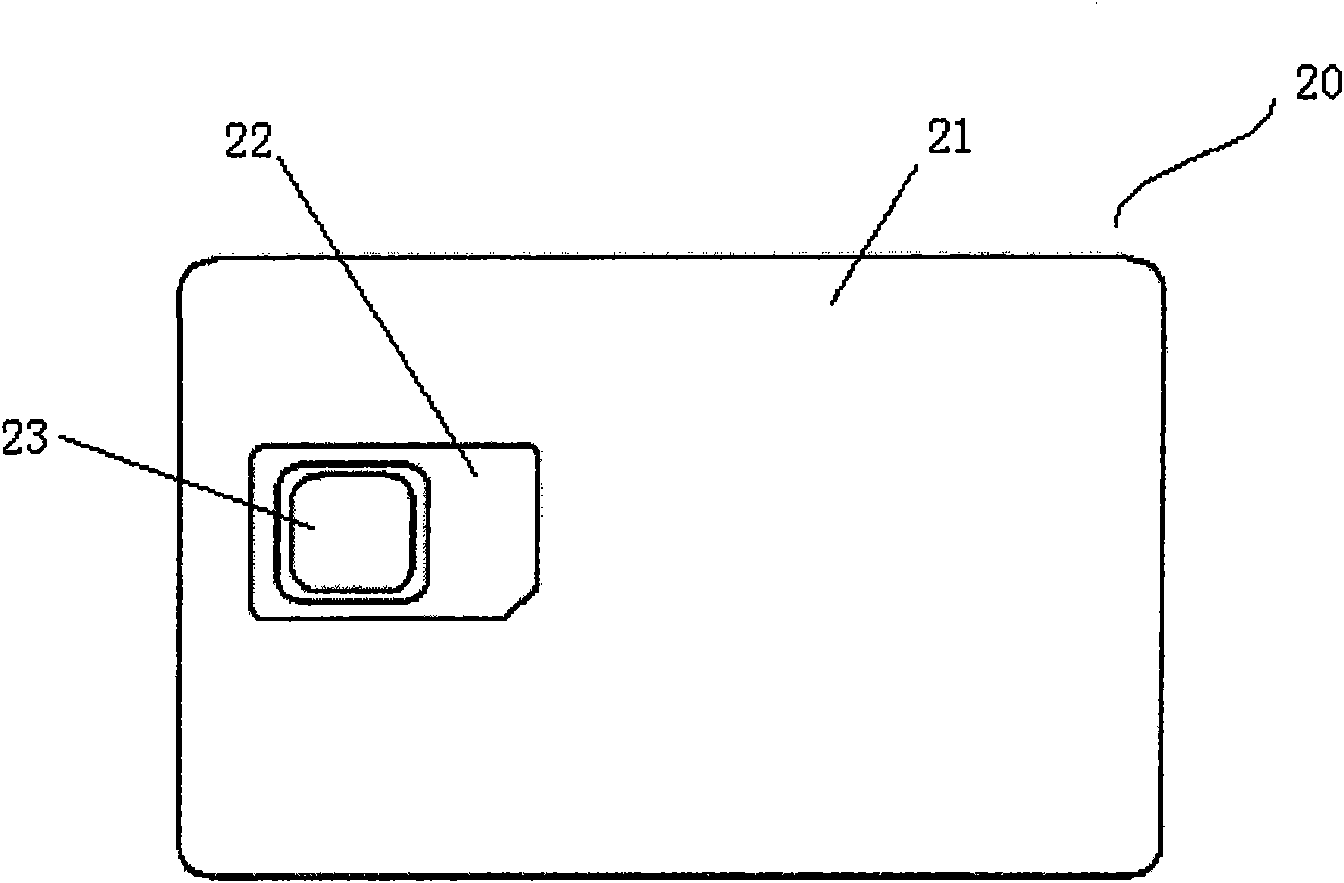

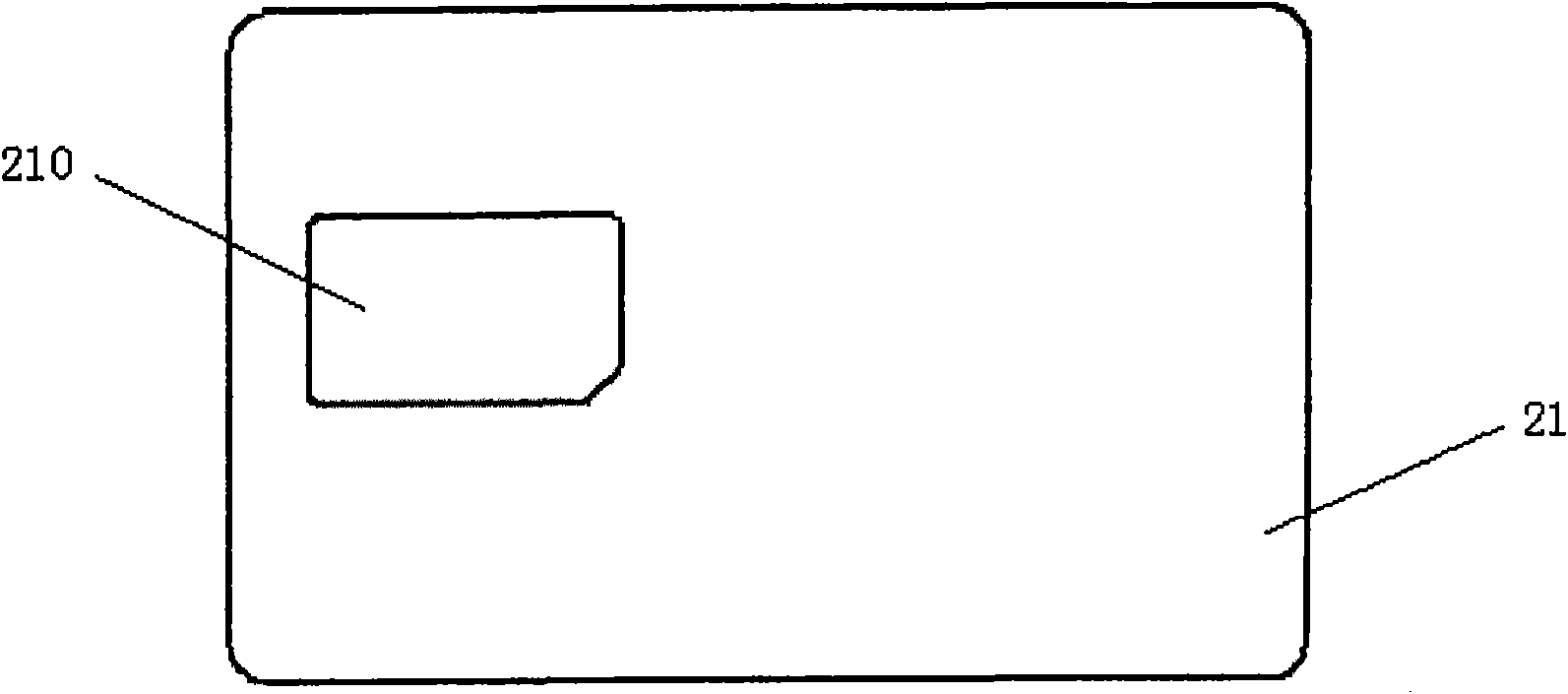

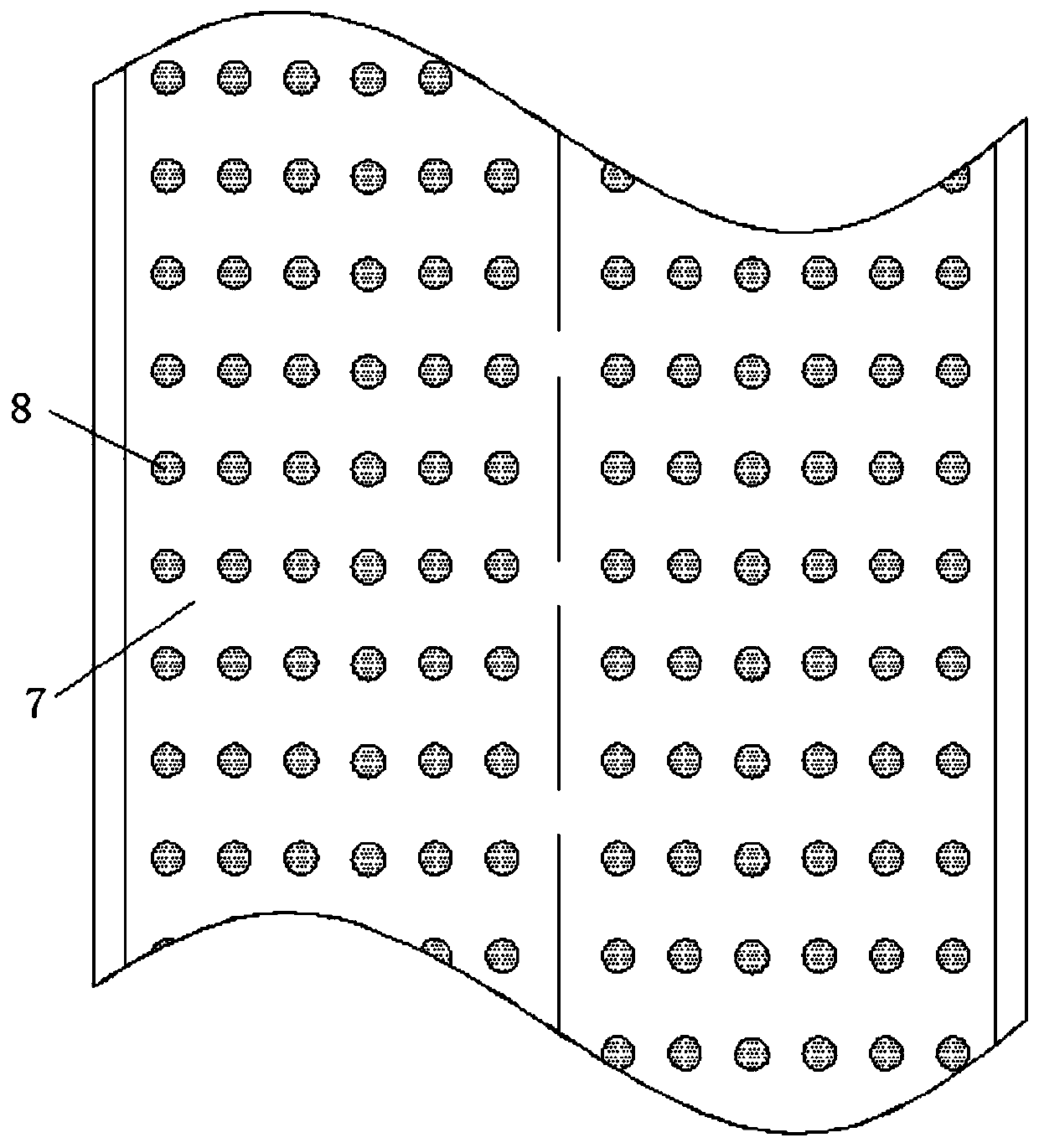

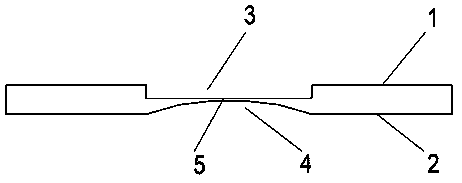

Embedded intelligent card matrix and manufacturing method thereof

InactiveCN101582127AReduce pollutionReduce energy consumptionRecord carriers used with machinesMaster CardEngineering

The invention relates to an embedded intelligent card matrix and a manufacturing method thereof. The embedded intelligent card matrix comprises a master card matrix and a small card matrix which is arranged in the master card matrix and can be separated, wherein the master card matrix is formed by compounding more than one layer of paper and is provided with at least one encapsulation hole; and the small card matrix is made of a high molecular polymeric material, the shape of the small card matrix is matched with the encapsulation hole on the master card matrix, the small card matrix is embedded into the encapsulation hole, and the periphery of the small card matrix is connected with the master card matrix. The production cost of the intelligent card matrix is reduced, the pollution of wastes of the intelligent card matrix to the environment is furthest reduced, the efficiency is improved by 10 times compared with the current known injection molding production process, and the embedded intelligent card matrix and the manufacturing method thereof also have the advantages of high labor productivity, low defective rate and easy control of product size; and the production precision can reach the level of 0.01 millimeter, and the maximum allowable tolerance range is + / - 0.05 millimeter. The product fully accords with the standard requirement.

Owner:北京大拙至诚科技发展有限公司

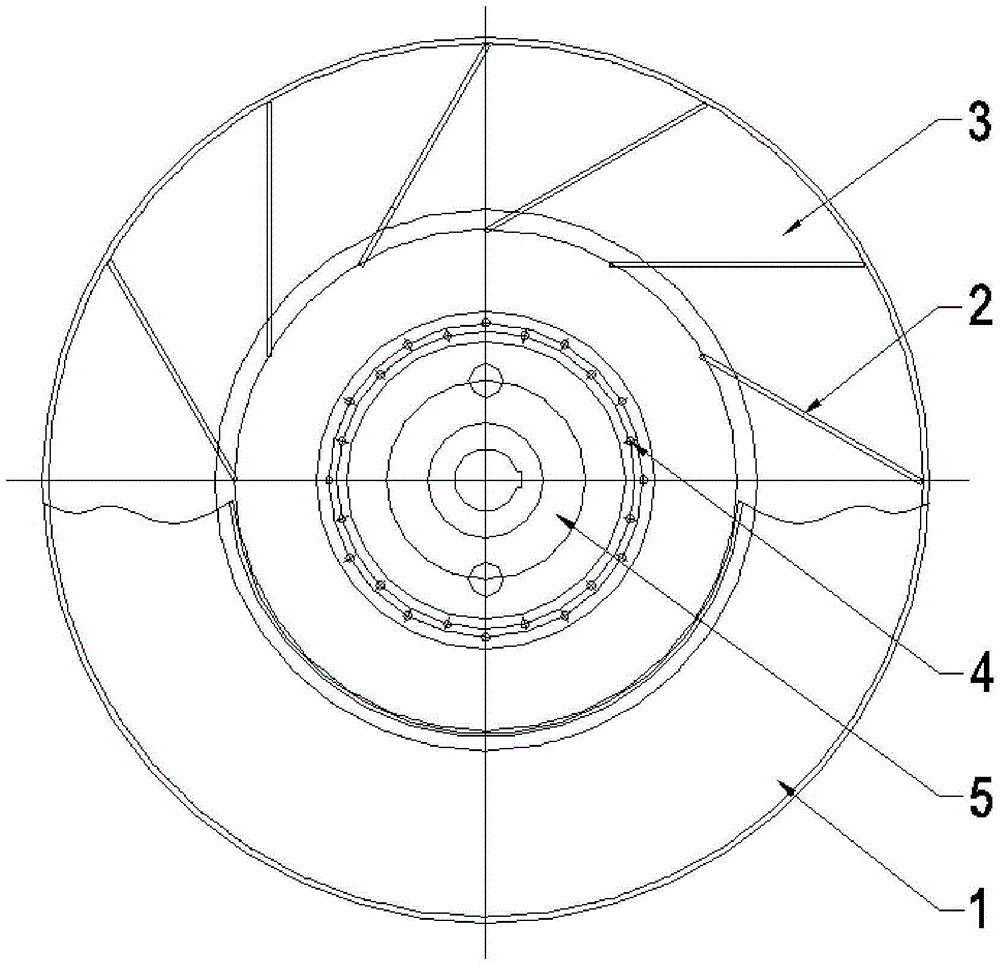

Impeller device

InactiveCN105179312AImprove work efficiencySimple structurePump componentsPumpsImpellerHigh volume manufacturing

The invention discloses an impeller device comprising a front disc and a rear disc, wherein the rear disc is fixedly connected with a wheel hub through a connecting piece, the wheel hub is located in the center of the rear disc, and the rear disc is fixedly provided with blades by taking the central axis of the rear disc as a reference axis; the blades are shaped like straight plates, the outer side edges of the blades form a round, the blades are provided with intersection points on the round, and the extension lines of the blades and the tangent lines at the intersection points of the round form an included angle of 59-61 DEG; and an air outlet is formed in the middle of the front disc, the periphery of the front disc is fixedly connected with the blades to form a closed structure, the periphery of the front disc is shaped like a circular arc, and the circle center of the circular arc is located at the side far away from the blades. The impeller device has the beneficial effects that the blades arranged at the included angle ensure that air flow more smoothly enter the blades, air resistance is reduced, and the noise is effectively reduced. The blades are simple in structure, easy to machine and beneficial to large-scale production, so that the production cost can be effectively reduced. The impeller device is of the closed structure and capable of effectively avoiding air flow loss so as to be relatively high in air outlet volume and higher in working efficiency.

Owner:天津尼特风机有限公司

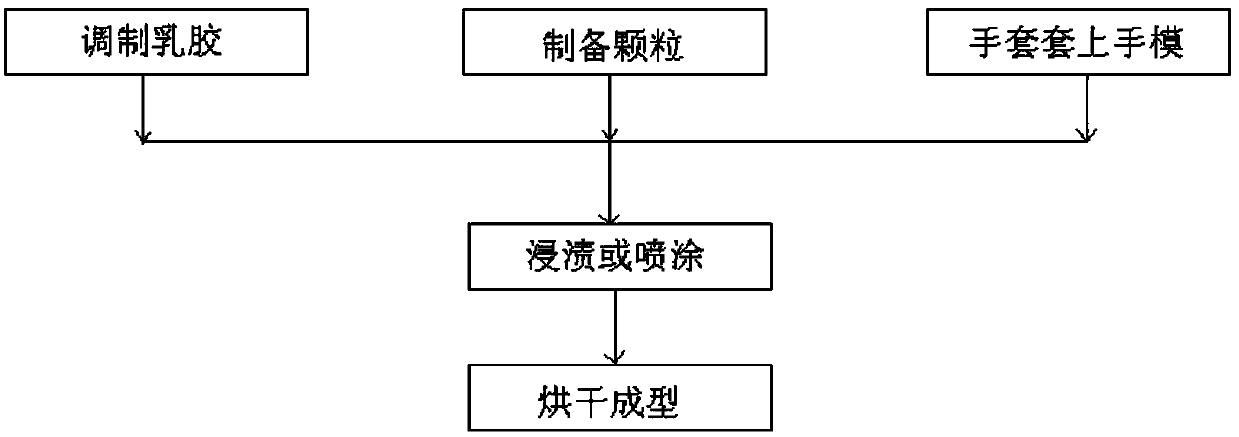

Method for preparing latex gloves with surface granular structure

InactiveCN103802254AIncrease coefficient of frictionImprove wear resistanceCoatingsFiberPolymer science

The invention belongs to the technical field of preparation of latex gloves, and relates to a method for preparing a pair of latex gloves with a surface granular structure. The method comprises the steps of firstly regulating color of a raw material latex for preparing the gloves according to requirements and filtering the raw material; then smashing rubber or reclaimed rubber to form irregular particles with uniform size and reserving separately for later use, or adding the particles into the raw material latex so as to form the latex with particles for later use; sheathing a hand die with the fiber gloves, and then dipping in the prepared latex with particles for 0.1-5 minutes so as to form a uniform antiskid particle layer on the surface of the gloves, or uniformly spraying the prepared irregular particles with uniform size onto the latex on the surface of the gloves by a spraying device, then transferring into an oven, drying at 80-200 DEG C, and molding. The method is simple, has a safe and non-polluted process, has low manufacture cost, is simple to operate, and has an environment-friendly effect.

Owner:GAOMI LICHANG LABOR PROTECTION PROD IND & TRADE

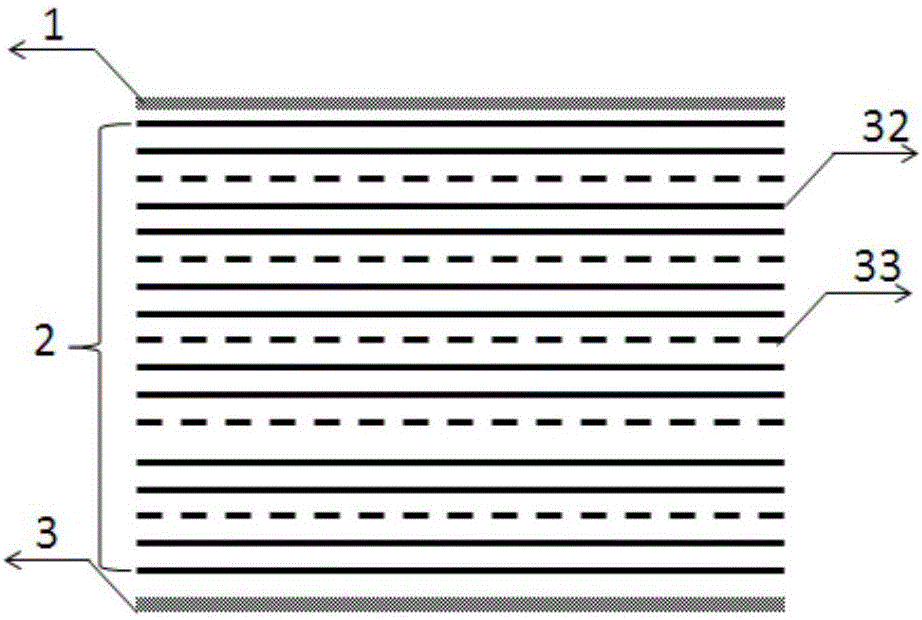

Manufacturing technology for bamboo plate body

InactiveCN107498654AEasy to moveEasy to transportWood treatment detailsCane mechanical workingManufacturing technologyBrick

The invention discloses a manufacturing technology for bamboo plate bodies. The manufacturing technology comprises the following steps of pretreatment, specifically, an original bamboo is sawed and cut, and then bamboo bundle curtains are ground; tailoring, specifically, the multiple bamboo bundle curtains which are distributed longitudinally and parallelly in sequence are connected into bamboo mats of integrated mat structures through tailoring lines; disinfecting carbonizing, specifically, the bamboo mats are sent to a drying disinfecting carbonizing machine to be carbonized and then to be taken out; gluing after primary drying and then secondary drying; assembling, specifically, a certain amount of bamboo mats are unfolded and then stacked in sequence to form plate bricks, and the two adjacent bamboo mats are distributed parallelly or crosswise according to patterns; hot pressing, the blank bricks are put into a hot pressing plate, staged heating temperature rise is conducted on the plate bricks, pressure of the hit pressing plate on the plate bricks is increased in a staged mode, and when the plate bricks are formed, the plate bricks are cooled; and pressure releasing, specifically, the plate bricks are taken out of a hot pressing machine, edge trimming is conducted, and the bamboo plate bodies of the same specification are obtained.

Owner:蒋红卫

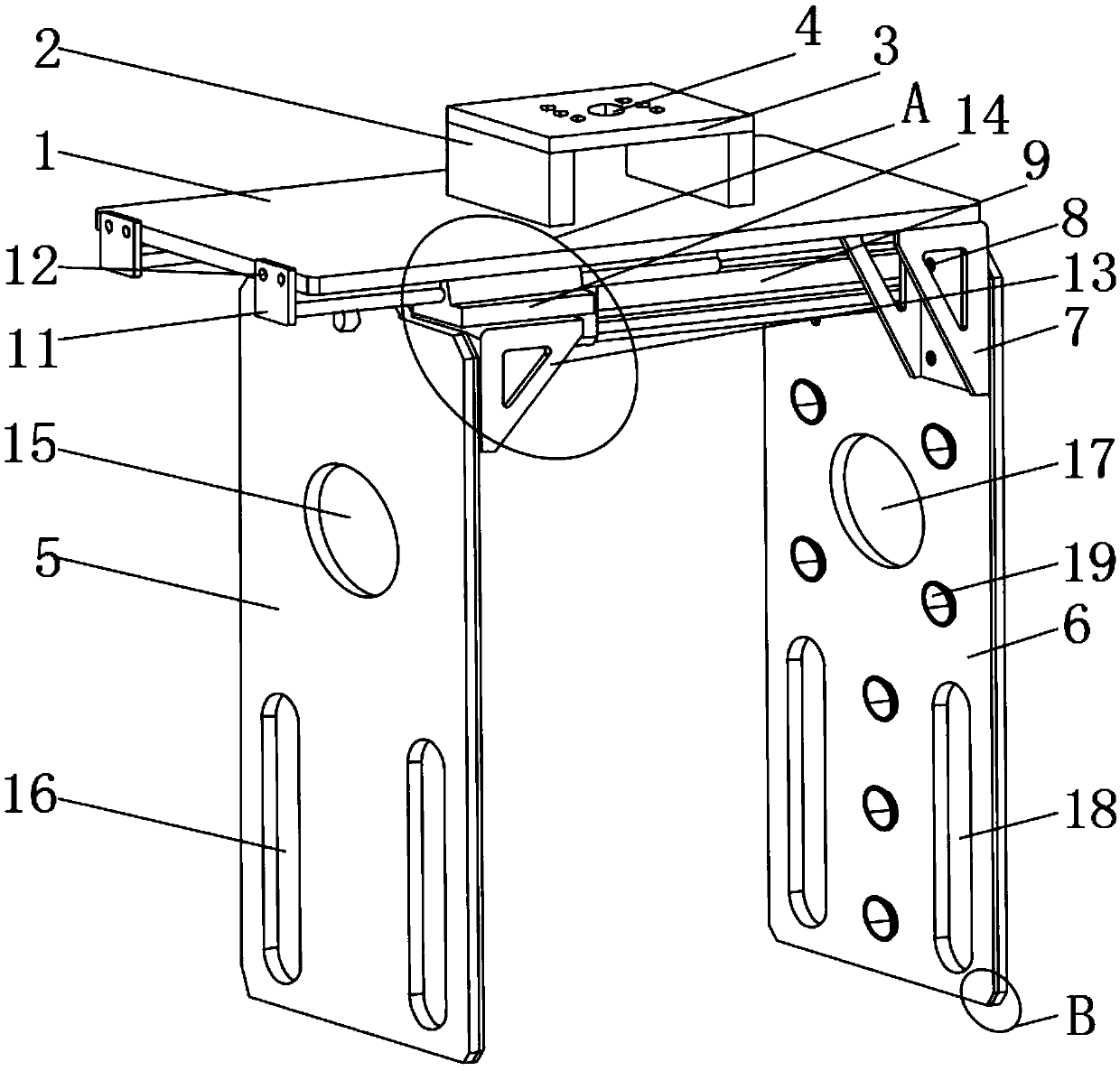

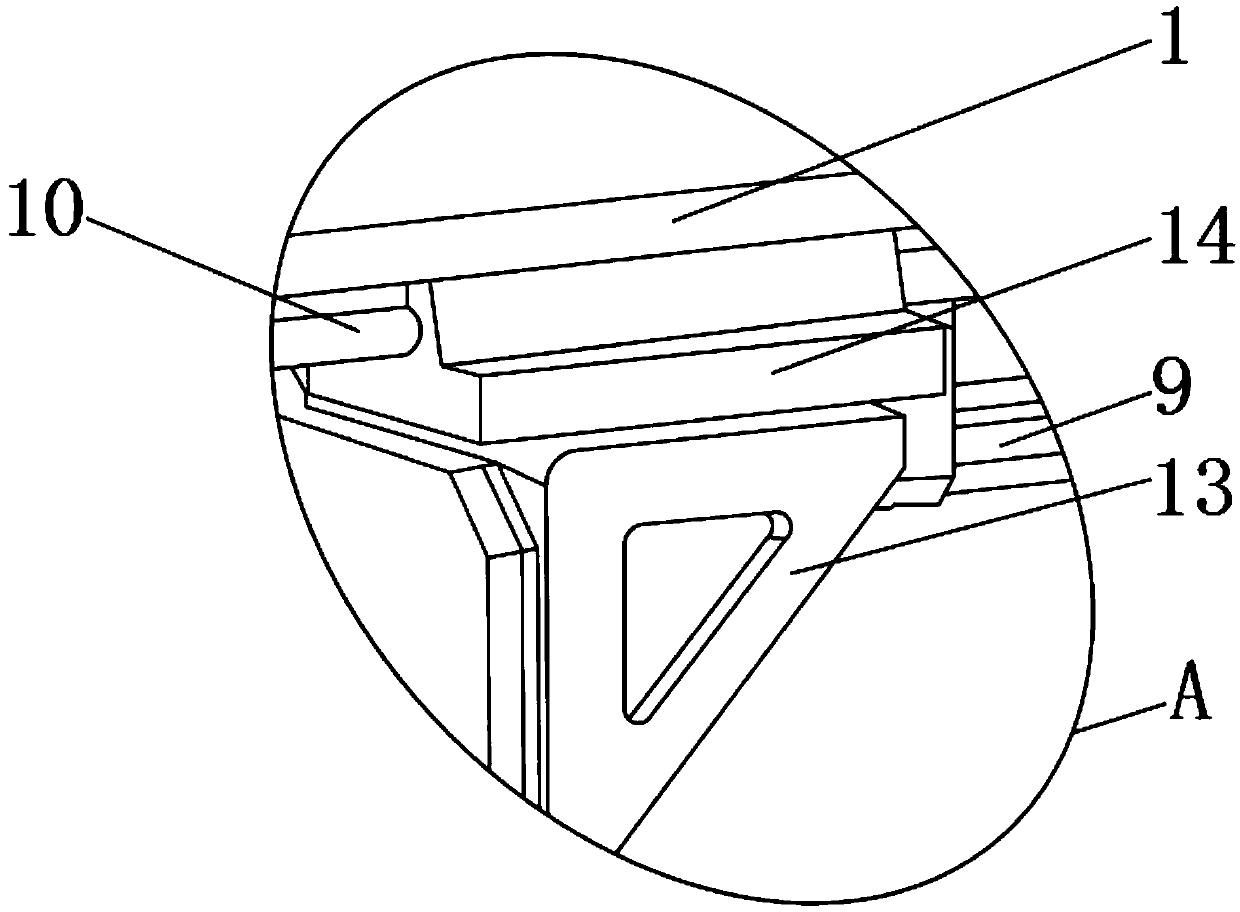

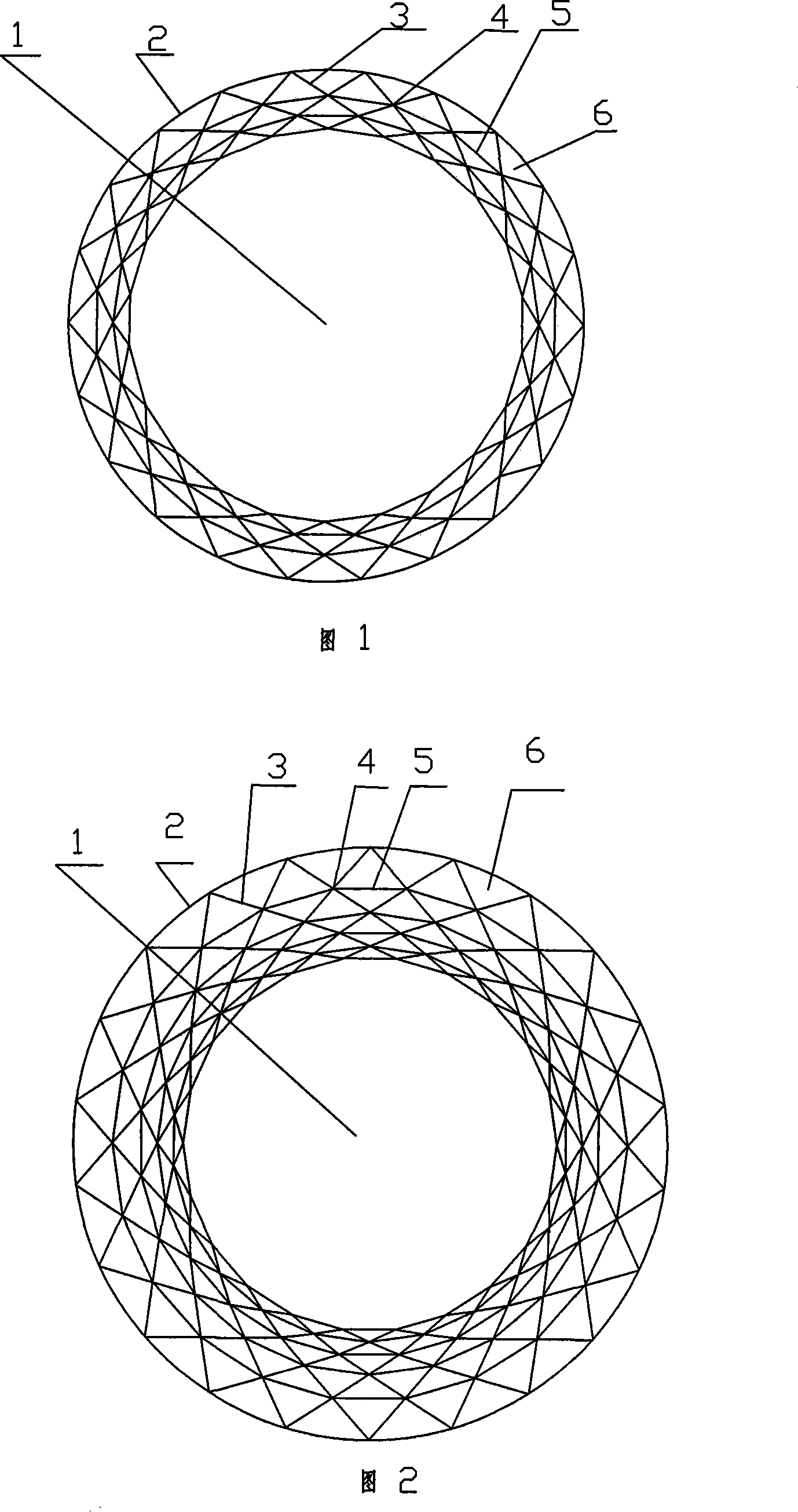

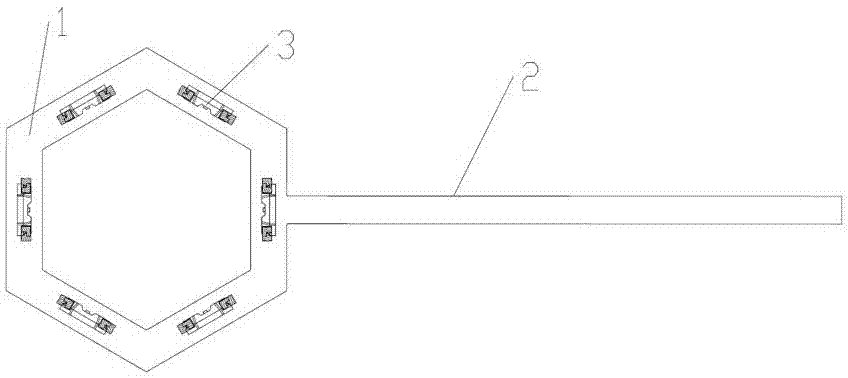

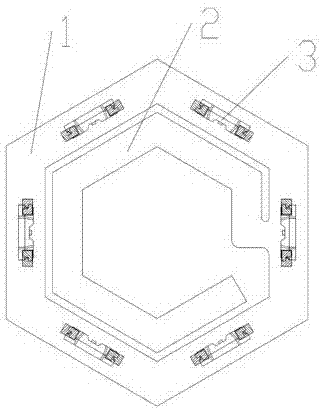

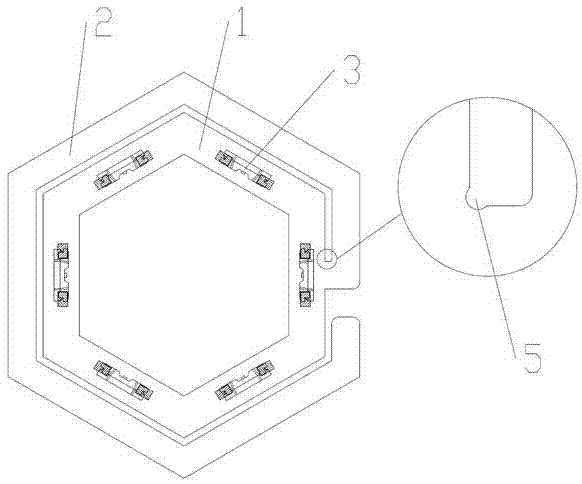

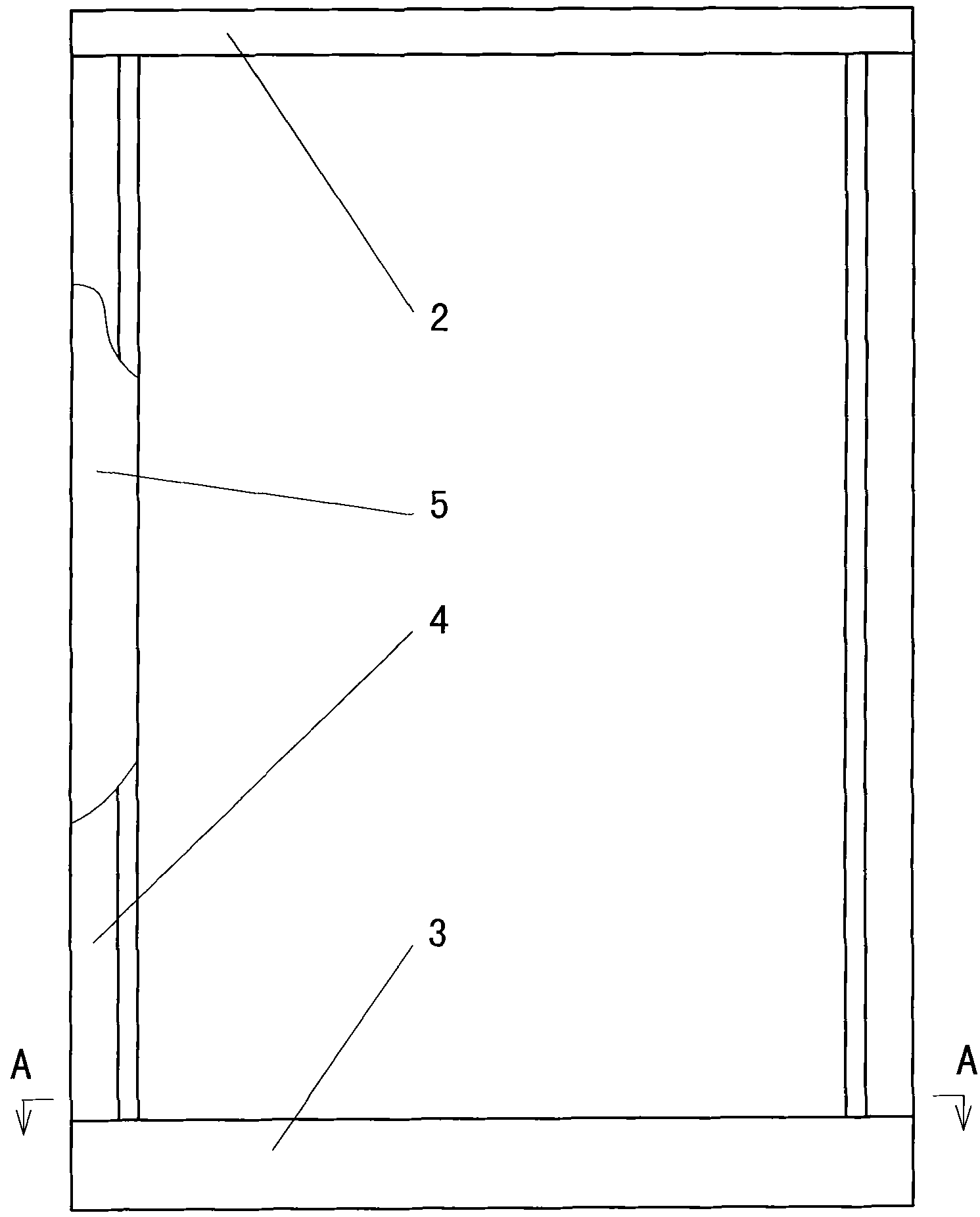

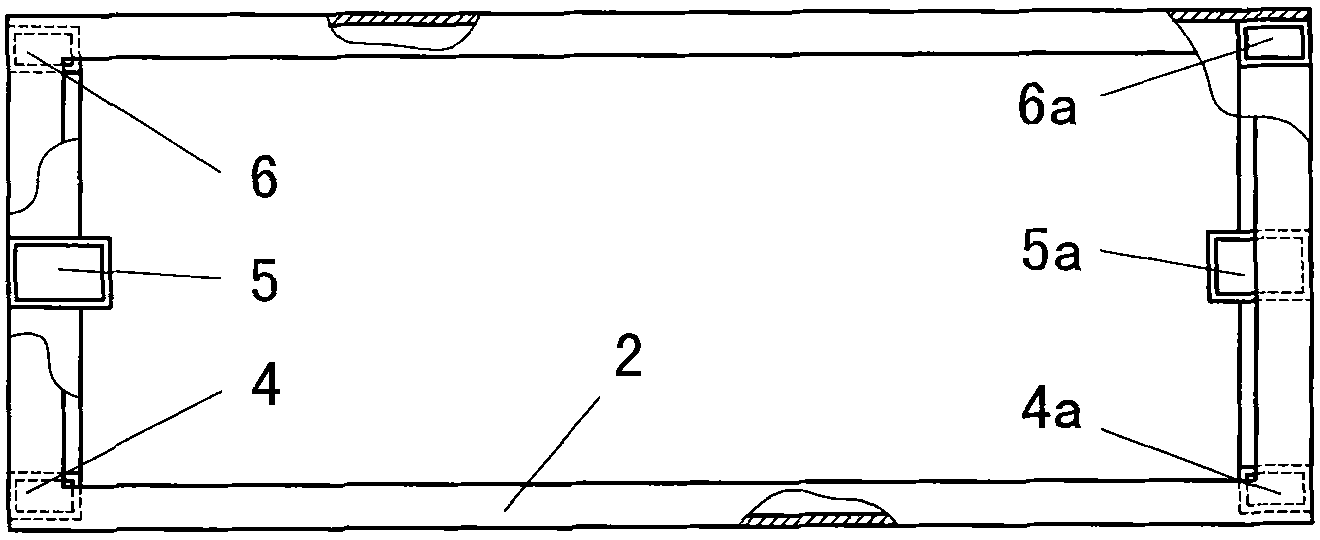

Robot gripper convenient to operate and applied to logistics transportation

PendingCN109573610AReduce weightReduce production materialsConveyor partsLogistics managementEngineering

The invention discloses a robot gripper convenient to operate and applied to logistics transportation. The robot gripper comprises a top plate, wherein two support blocks are fixedly mounted at a center position of the top plate; a connection block is fixedly mounted at the tops of the two support blocks; a mounting hole is formed in the upper surface of the connection block; a movable clamping plate is arranged at a position of one side of the lower part of the top plate. According to the robot gripper convenient to operate and applied to logistics transportation, a first through hole, firstthrough grooves, suction cups and rubber mats are arranged; firstly, the self weight of the robot gripper can be reduced, the production materials can also be reduced, the robot gripper has higher practicability, the stability can be improved, and the phenomenon that the robot gripper falls can be avoided; secondly, the protection performance is improved, and the damage to the clamped articles canbe avoided; in addition, according to the whole robot gripper, a single cylinder is just used for driving the movable clamping plate to move on a fixed rail by means of a movable rail, so that the capability of gripping cargos can be achieved; the robot gripper is simple in structure and convenient to operate, and can bring a better application prospect.

Owner:UNIV OF SCI & TECH LIAONING

Bamboo plate manufacturing process

ActiveCN102744760AEasy to moveEasy to storeWood working apparatusFlat articlesWear resistanceEnergy conservation

The invention discloses a bamboo plate manufacturing process. The bamboo plate manufacturing process comprises the following steps of manufacturing cut bamboo, i.e. raw bamboo, into a bamboo plate through the following processes sequentially: post-processing the raw bamboo, sewing the raw bamboo, drying the raw bamboo for the first time, gluing the raw bamboo, drying the raw bamboo for the second time, making the raw bamboo into a blank, and thermally rolling the blank. Bamboo curtains are sewed into bamboo curtain mats; in the gluing process, the liquid glue is dried according to a centrifugal principle; and in the thermally rolling process, a thermal-in and thermal-out process, a phased temperature increasing and decreasing and pressure increasing and decreasing method and the like are adopted. The technical bias of the prior art is overcome, the production cost can be also effectively reduced, the production efficiency is improved, the energy source consumption is effectively reduced, energy conservation and emission reduction are achieved, and the environment is protected. At the same time, a product manufactured by the process is lighter in mass, more stable in performance, good in surface flatness, good in abrasion performance and longer in service life.

Owner:洪敏雄

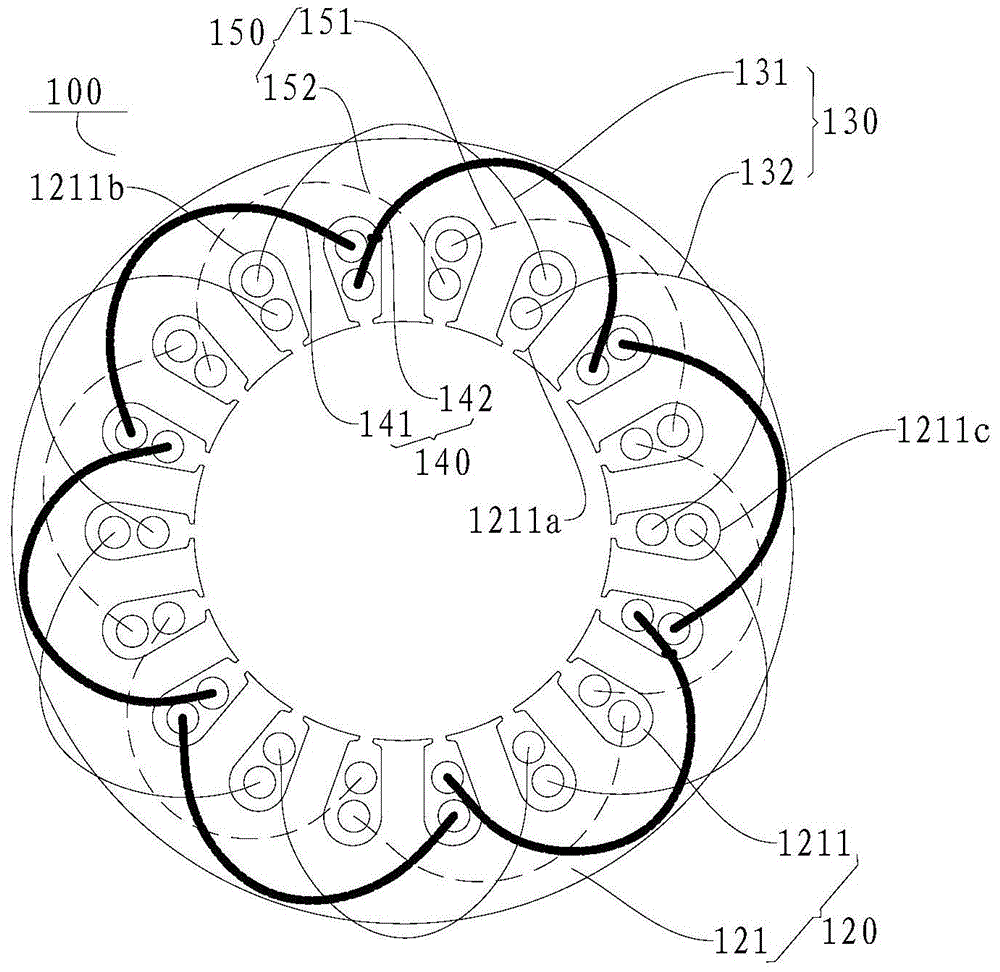

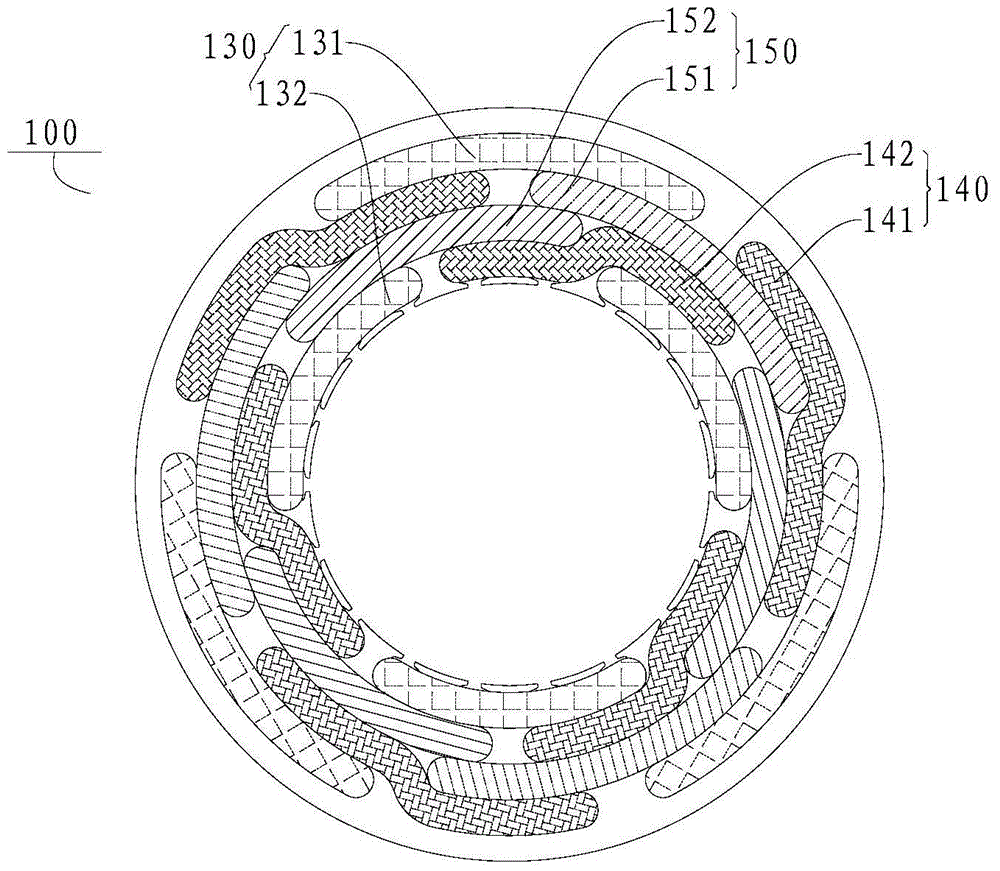

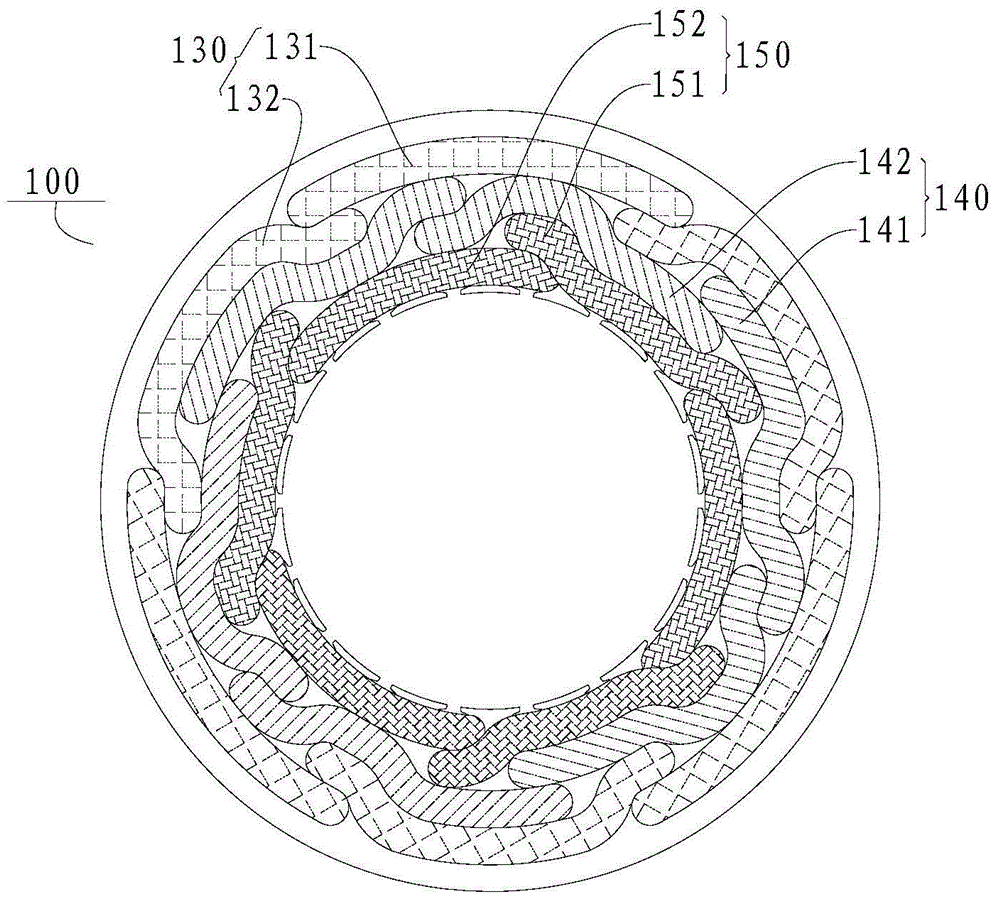

Motor applied to rotary compressor and compressor with motor

ActiveCN104467231AImprove efficiencyLow costWindings conductor shape/form/constructionControl theoryConductor Coil

The invention discloses a motor applied to a rotary compressor and the compressor with the motor. The motor applied to the rotary compressor comprises a stator and a rotor, wherein the stator comprises a stator iron core and windings, the stator iron core is provided with a plurality of stator grooves, the windings are arranged in the stator grooves, each stator groove only contains same-phase windings with the current in the same direction, the windings in each stator groove comprise a first coil and a second coil, and the ends of the first coils and the ends of the second coils are distributed in the different stator grooves reversely in the peripheral direction of the stator at certain pitch intervals. According to the motor applied to the rotary compressor, the interference space in the intersection process of two phases of windings can be effectively reduced, an receding space needing to be set on the windings on the outer side is reduced, the size of the ends of the windings is reduced, the total length of the windings is shortened, the resistance of the windings is lowered, materials used are saved, and therefore the efficiency of the motor is improved, and meanwhile the cost of the motor is reduced.

Owner:GUANGDONG MEIZHI COMPRESSOR

Method for killing fly type pests in trapping device through diatomaceous earth in non-toxic mode

InactiveCN105104322ALeading technologyReduce usageInsect catchers and killersSocial benefitsPaleontology

A method for killing fly type pests in a trapping device through diatomaceous earth in a non-toxic mode includes the steps of firstly, forming the waterproof fly trapping device through waterproof materials; secondly, throwing the diatomaceous earth in a pest collection device or a collection area of the trapping device or spraying the diatomaceous earth to the outer surface of the fly trapping device. Once flies enter and set foot on the pest collection device or the collection area in the trapping device, fine particles of the diatomaceous earth can be instantly attached to body surfaces of the flies, the flies can instantly feel uncomfortable and can not struggle at the moment, and therefore the flies can not escape and can die from body dehydration within a short period of time, an extremely small number of flies can escape but can automatically die within a short period of time as well after escaping, and death of the escaped flies can not be influenced by any external environment. The method has the advantages of being advanced in science and technology, environmentally friendly, free of toxin, capable of saving energy, reducing cost and reducing pollution, high in killing rate, beneficial to scientific research, remarkable in effect, capable of purifying the environment, and the like, and the method has extra economic and social benefits.

Owner:刘源

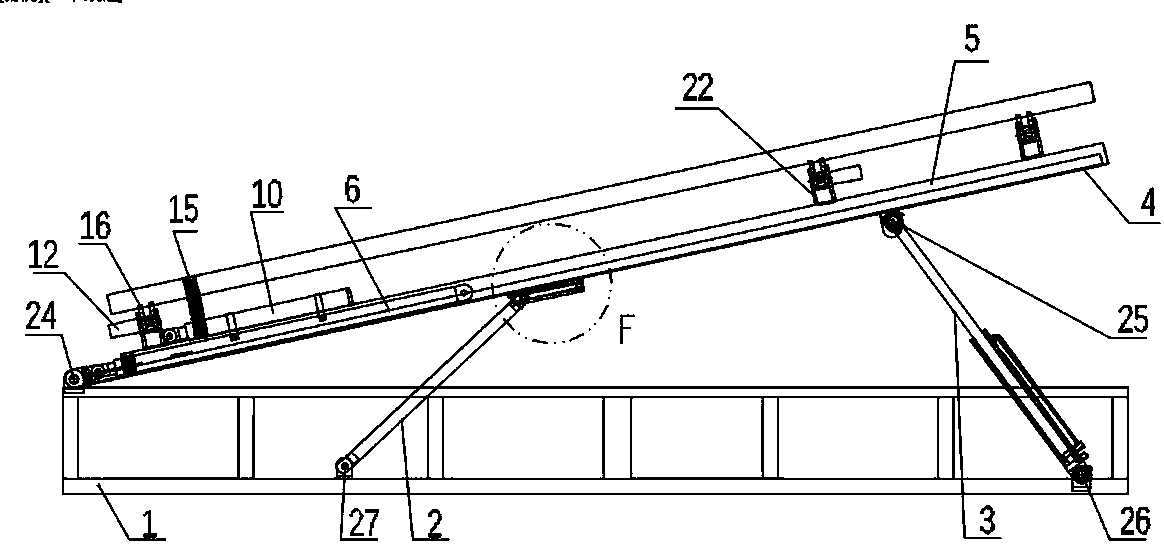

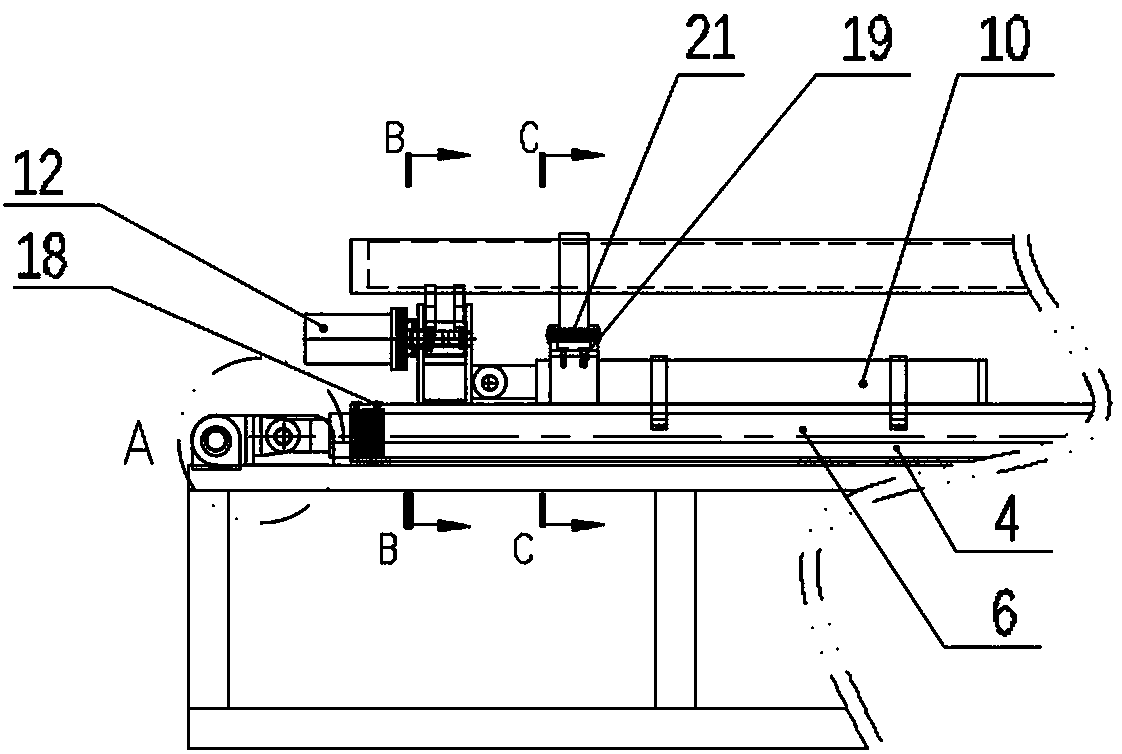

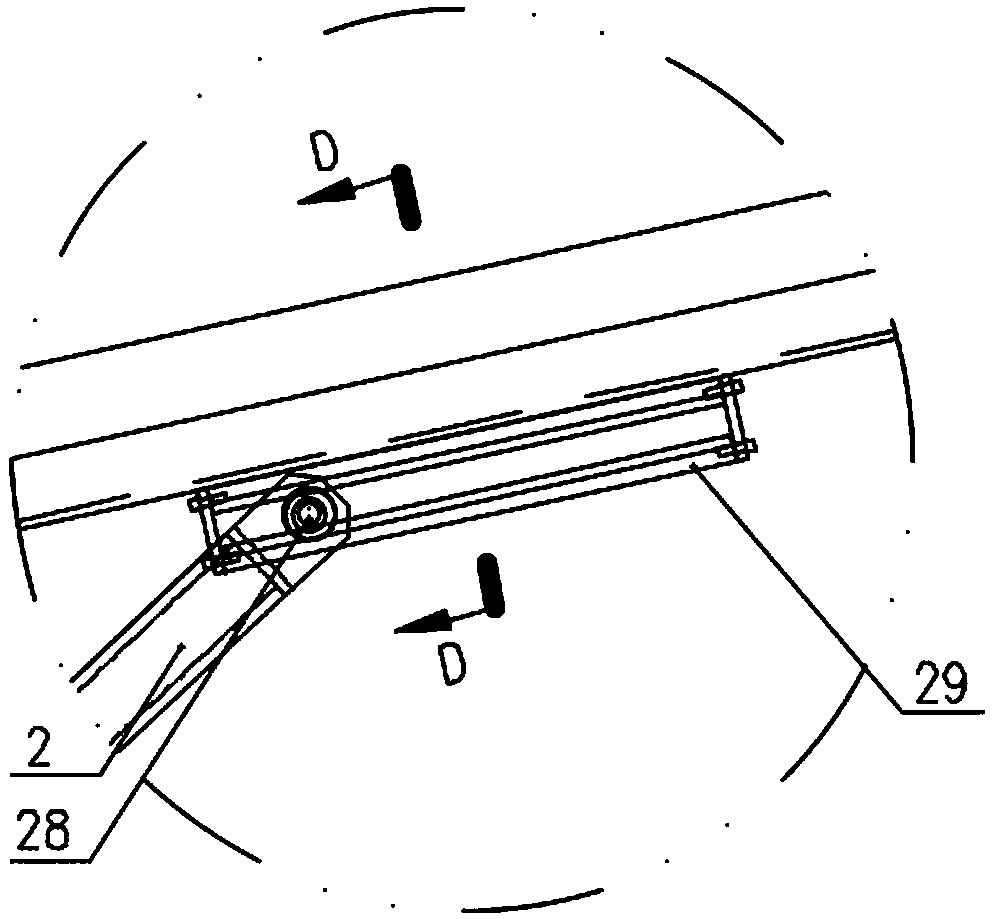

Light-small pipe rod conveying device and working method thereof

PendingCN108425645AStable supportReduce use costDrilling rodsDrilling casingsEngineeringMechanical engineering

The invention discloses a light-small pipe rod conveying device which comprises a frame, a lifting device, a sliding base, a sliding part and a pushing device. The sliding part linearly moves on the sliding base under the action of the pushing device, a feeding structure is arranged above the sliding part and connected with the sliding part through an overturning and sliding device, the overturning and sliding device comprises a supporting plate, an overturning drive device and a sliding drive device, the overturning drive device and the sliding drive device are arranged on the supporting plate, the feeding structure comprises an upper feeding groove and a lower feeding groove, the upper feeding groove is connected with the sliding drive device through a first swinging plate, and the lowerfeeding groove is connected with the overturning drive device through a second swinging plate. Sufficient total pushing strokes and stability in the conveying process of pipe rods are ensured when the total length and total weight of the device are decreased, and energy consumption and cost in use are reduced.

Owner:JIANGSU SHENLIDA MACHINERY MFR

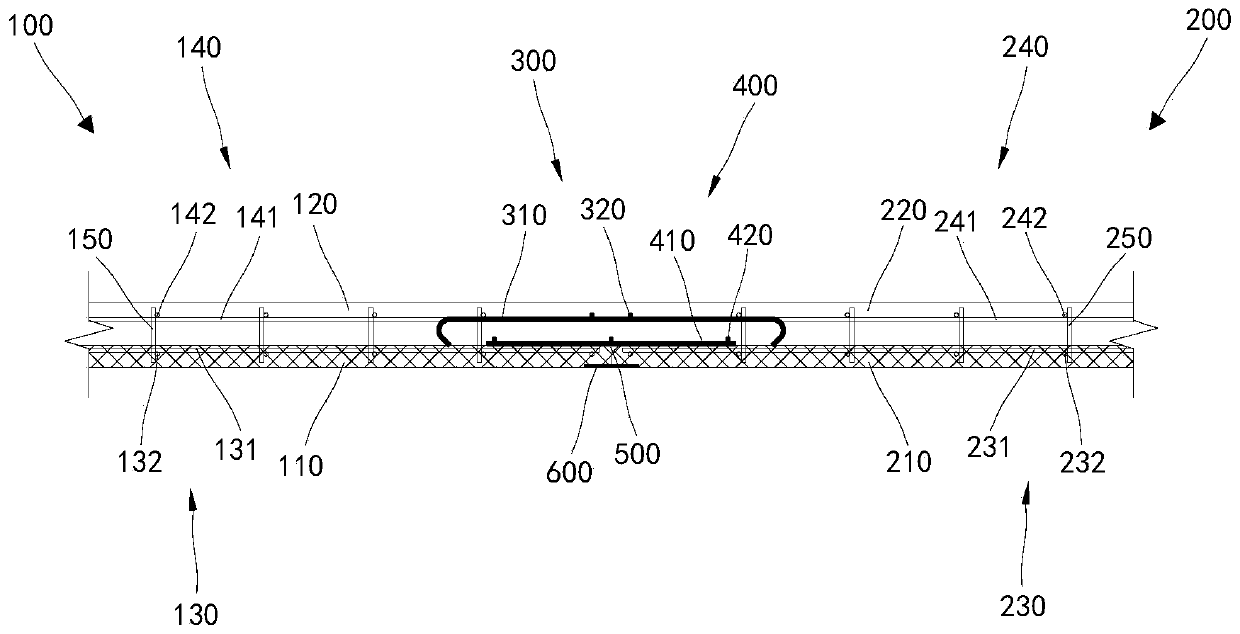

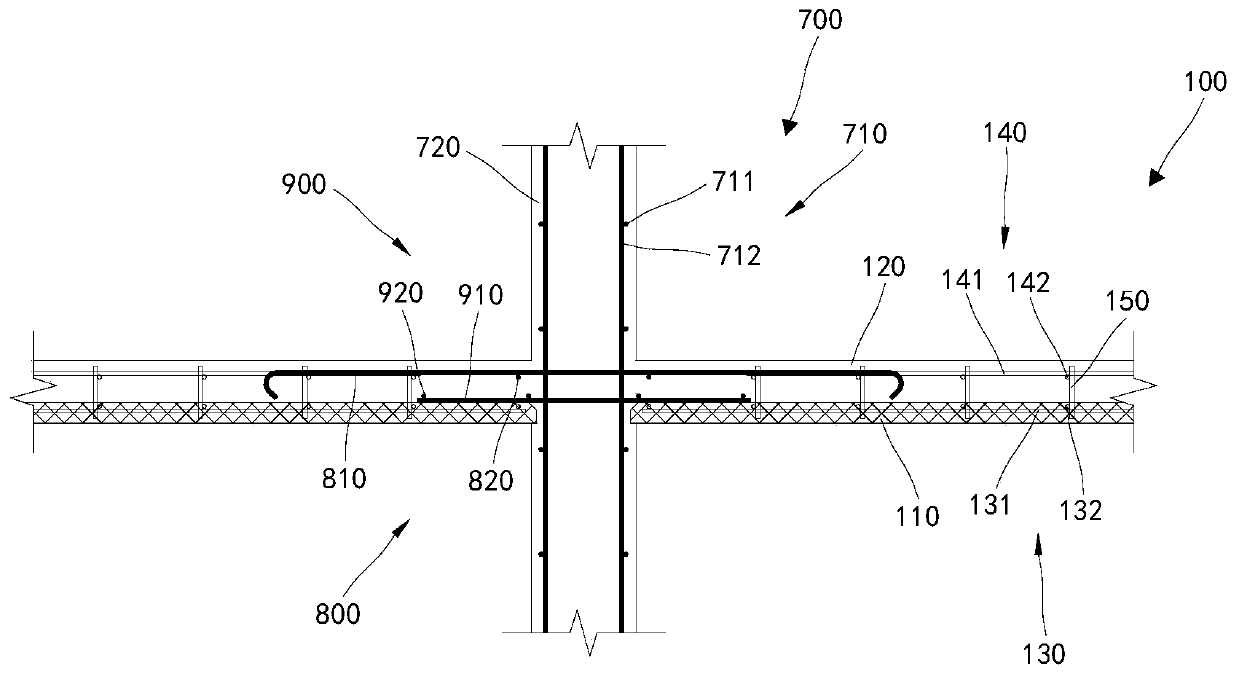

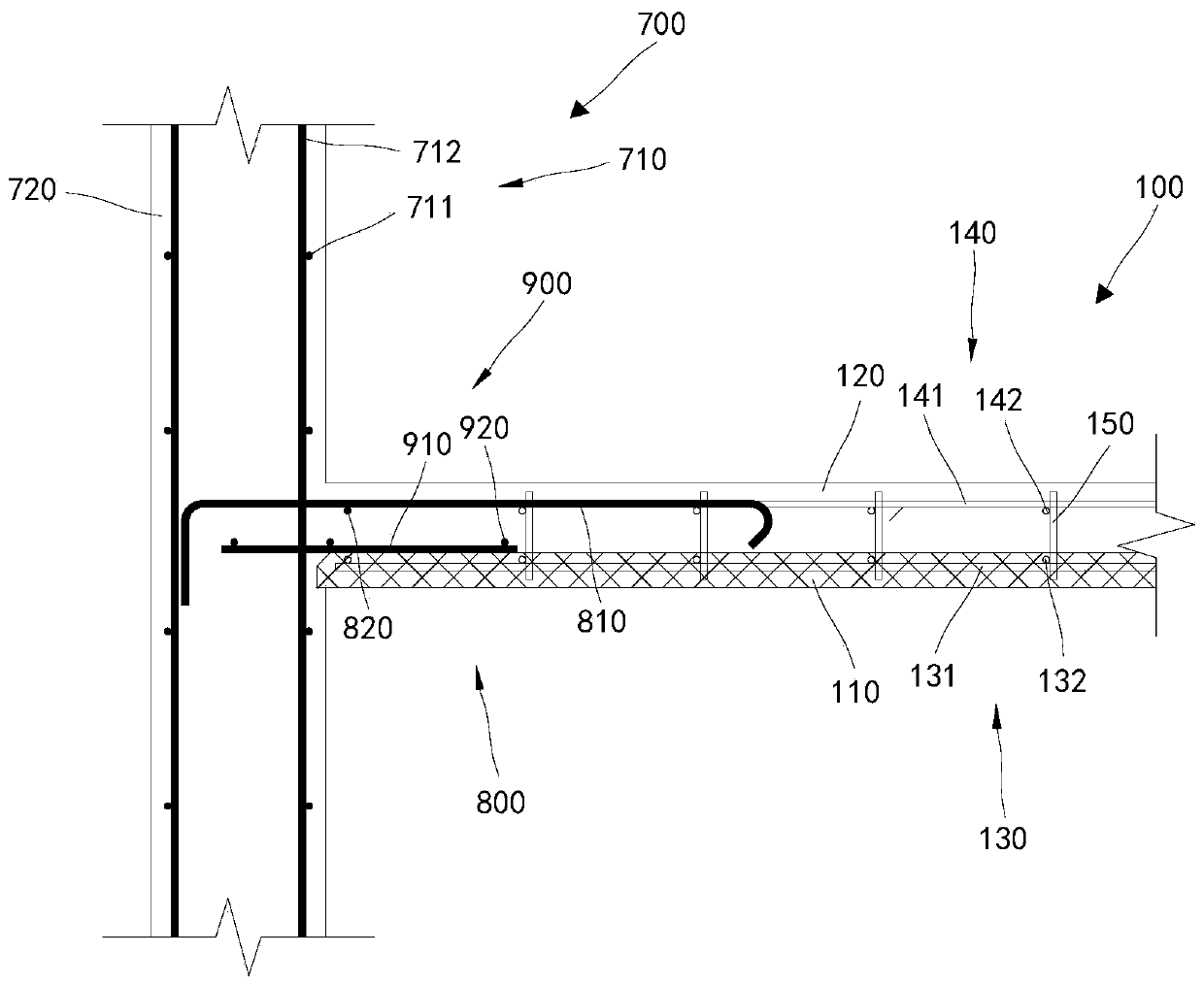

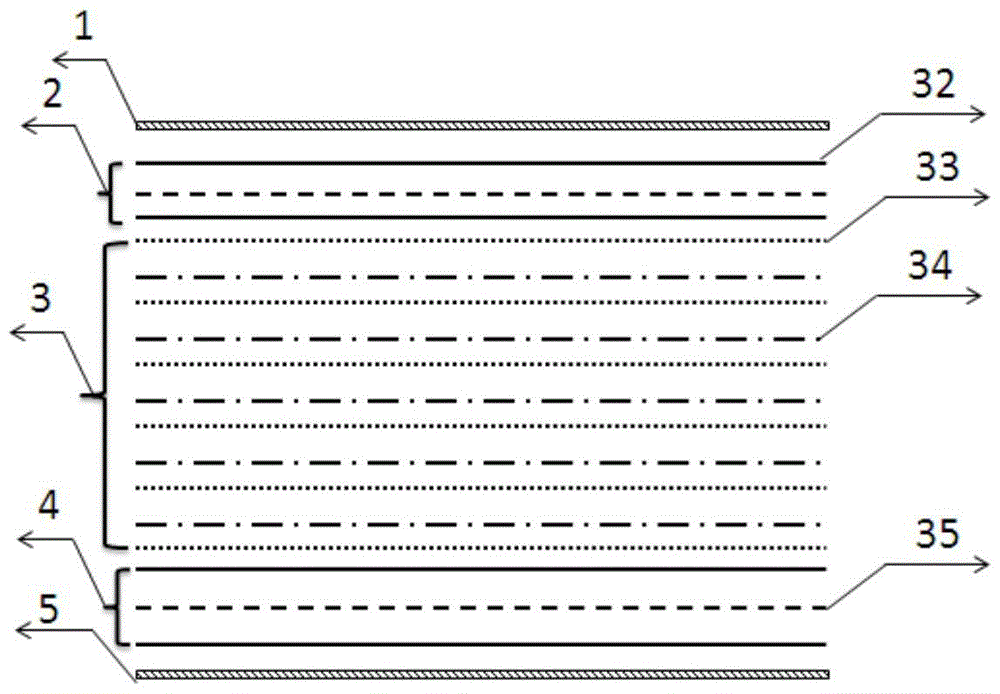

Spliced composite slab structure

PendingCN111379367APlay a pulling roleReduce tensionFloorsBuilding reinforcementsArchitectural engineeringMesh reinforcement

The invention relates to the technical field of buildings, and discloses a spliced composite slab structure. The structure comprises a first composite slab and a second composite slab; the first composite slab comprises a first prefabricated slab, a first cast-in-place composite layer and a first welded steel bar frame; the second composite slab comprises a second prefabricated slab, a second cast-in-place composite layer and a second welded steel bar frame; a first stressed steel bar assembly and a first connecting steel bar net are arranged between the first composite slab and the second composite slab; the first prefabricated slab abuts against the second prefabricated slab; and the first cast-in-place composite layer and the second cast-in-place composite layer are integrated by pouring. According to the structure, the first welded steel bar frame and the second welded steel bar frame are of integral grid steel bar structures and play a role in welding fixing so that the thicknessof the first prefabricated slab and the second prefabricated slab can be reduced when being manufactured, the anti-shearing effect is evenly achieved, a large number of steel bars do not need to be bound on site, the workload on a construction site is greatly reduced, and the construction efficiency is improved.

Owner:ELITE ARCHITECTURAL CO LTD

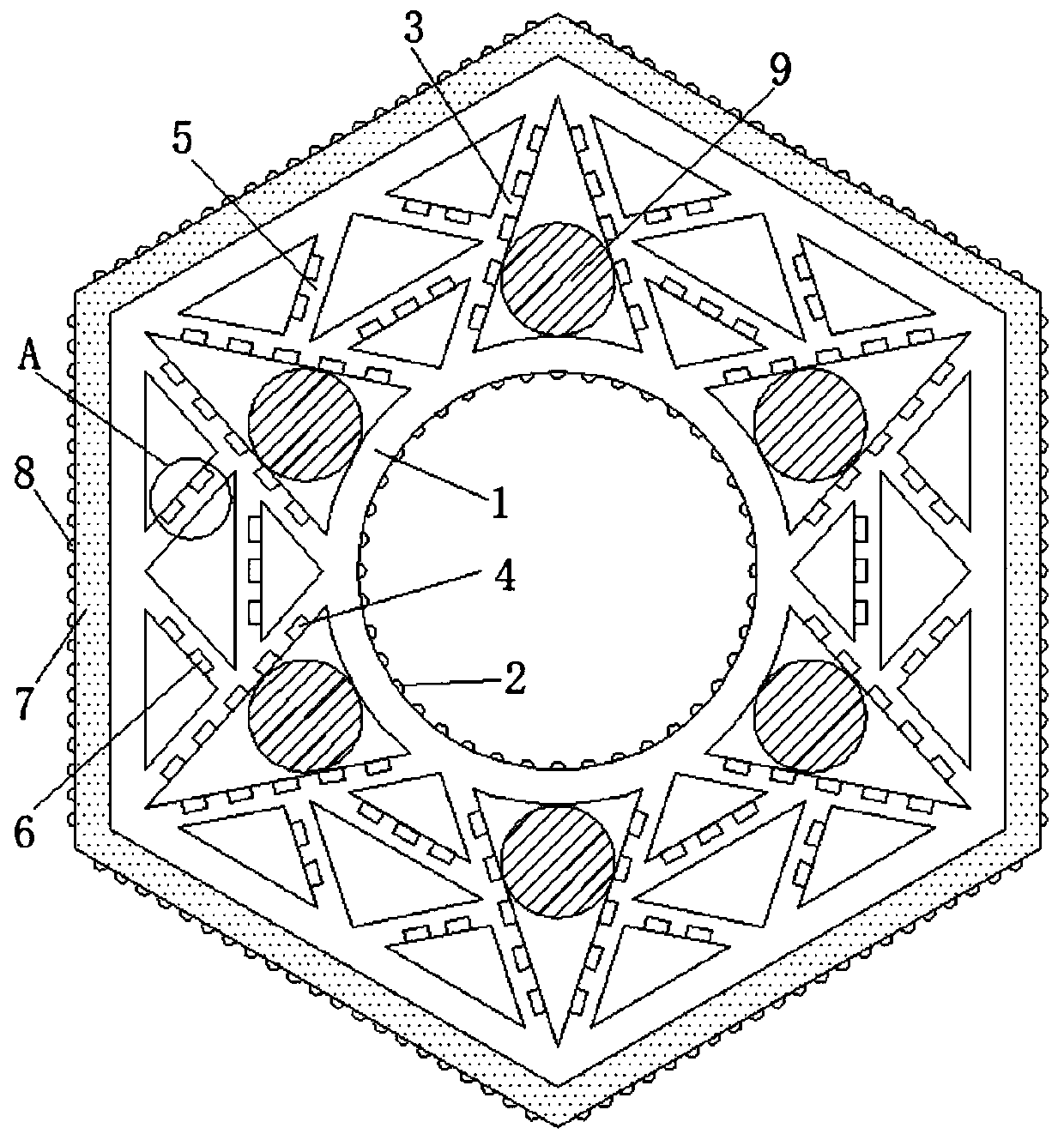

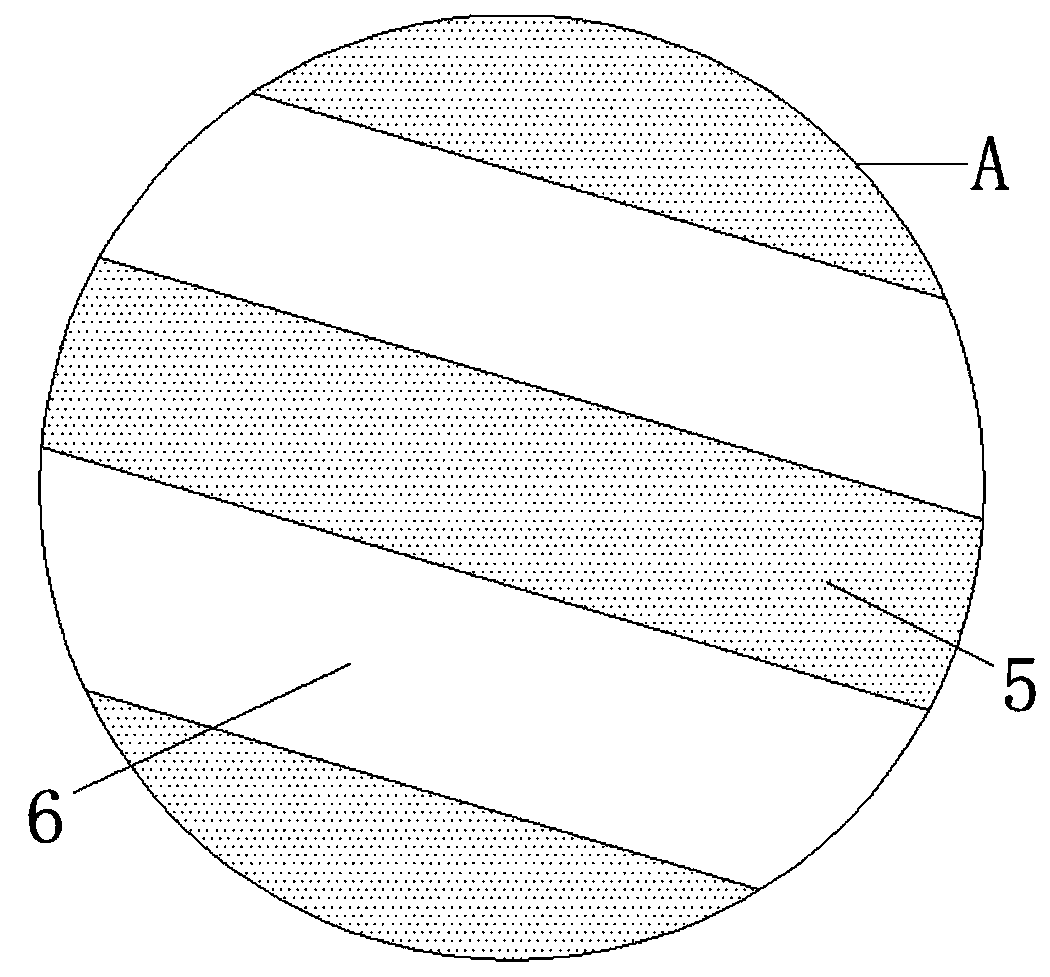

Hexagonal steel pipe not easy to bend and deform

InactiveCN109780413AHigh strengthImprove support strengthElongated constructional elementsArchitectural engineeringSilica gel

The invention discloses a hexagonal steel pipe not easy to bend and deform. The hexagonal steel pipe comprises an inner pipe, first stable steel pipes and an outer pipe. Internal friction convex points are uniformly fixed and welded on the inner wall of the inner pipe. The internal friction convex points are circumferentially and equidistantly arranged along the inner wall of the inner pipe from front to back. The first stable steel pipes are annularly arranged on the outer side of the inner pipe. The number of the first stable steel pipes is six groups. Second stable steel pipes are insertedinto the inner parts of the first stable steel pipes. The outer side of the inner pipe is sleeved with the outer pipe. External friction convex points are uniformly fixed and welded on the outer surface of the outer pipe, the external friction convex points are equidistantly arranged along the outer surface of the outer pipe from front to back, and six groups of silica gel rods are annularly and equidistantly arranged on the outer side of the inner pipe. The hexagonal steel pipe is hollowed-out in structure, light in weight, capable of greatly reducing production materials, high in strength and not easy to bend and deform due to the influence of external factors.

Owner:TIANJIN SHENGXIANG COLD DRAWN

Low-cost high-power modified diesel cylinder block

InactiveCN106246396AAdequate heat dissipationEffective coolingCylinder headsCylindersPulp and paper industryCylinder block

The invention discloses a low-cost high-power modified diesel cylinder block, comprising a cylinder block, a cylinder sleeve arranged inside the cylinder block, and a cylinder cover arranged at the upper end of the cylinder block; a heat-insulating sleeve is disposed between the cylinder block and the cylinder sleeve, the upper end of the cylinder sleeve is supported on the heat-insulating sleeve through a flange, the flange is fixedly connected with the cylinder block through screws, a T-shaped heat-insulating sleeve and the heat-insulating sleeve, an inner annular cooling passage is provided between the heat-insulating sleeve and the cylinder sleeve, sealing slide grooves are arranged in the cylinder sleeve in the upper and lower ends of the inner annular cooling passage respectively, seal rings are arranged slidably in the slide grooves, the outer sides of the seal rings are abutted to the heat-insulating sleeve, the inner sides of the seal rings are connected with the cylinder sleeve through springs, the outer side of the cylinder bock is evenly provided with a plurality of semicircular grooves and semicircular protrusions, the semicircular grooves and the semicircular protrusions are staggered, and stiffeners are arranged between the adjacent semicircular protrusions.

Owner:JIANGYU JIANGSU POWER MACHINERY LIMITED

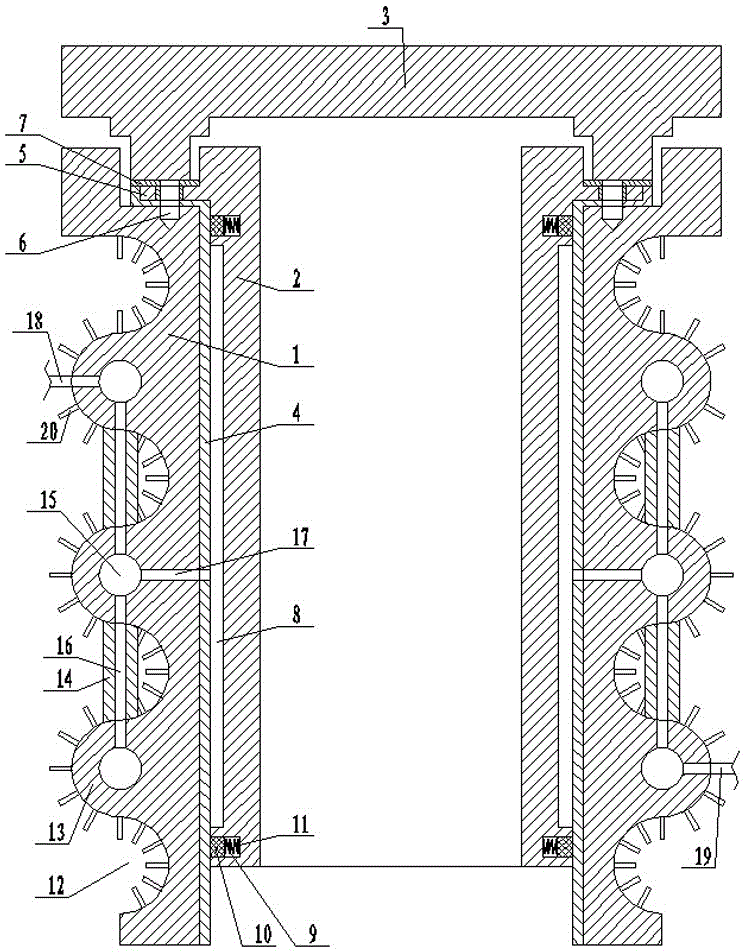

Principal shaft of low-speed direct driving type aerogenerator

InactiveCN101174781ALose weightGuaranteed bending resistanceShaftsMechanical energy handlingWind drivenLow speed

The present invention relates to a wind-driven generator, in particular to a low-speed straight wind-driven generator principal axis, and provides a novel low-speed straight wind-driven generator principal axis with a principal-axis structure and the main body composed of a grid cylinder, including a steel plate and an angle plate. The principal axis is a hollow cylinder and the cross section is circular; the cylindrical part of the cylinder is composed of honeycomb hollow cylinders arranged equidirectionally, thus reducing the deadweight of the principal axis, shortening the production cycle, reliably ensuring the bending and twisting resistance of the axis and decreasing the bearing capacity of the tower without affecting the bearing capacity, mechanical intensity and reliability; the material for producing the principal axis is reduced and no special material is needed, thus reducing the production cost, accelerating the production and shortening the production cycle, so the materials can meet the operational requirement of the straight wind-driven generator without undergoing the forging process; in addition, the grid cylindrical hollow structure is conducive to air radiation, which is economical and reliable.

Owner:刘宝生 +1

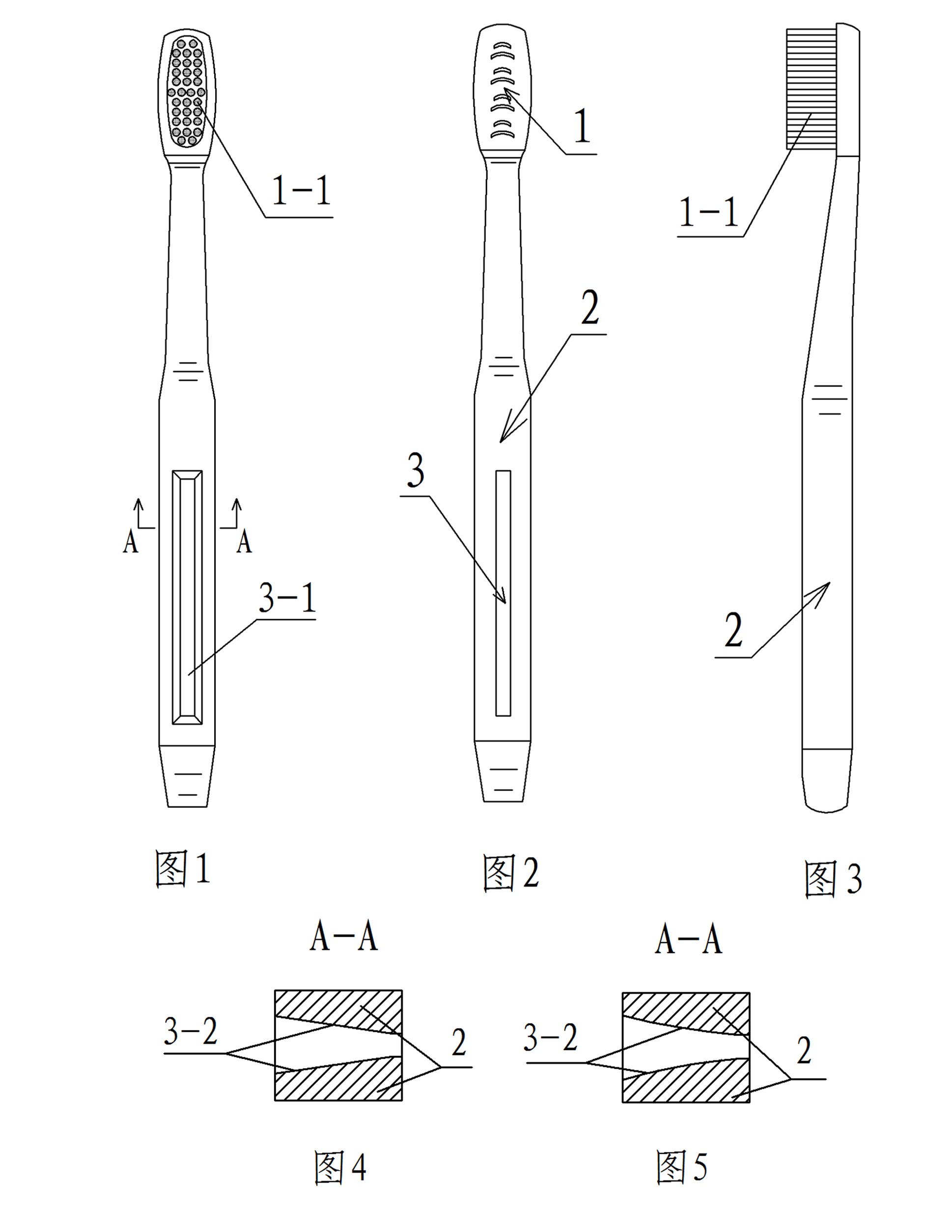

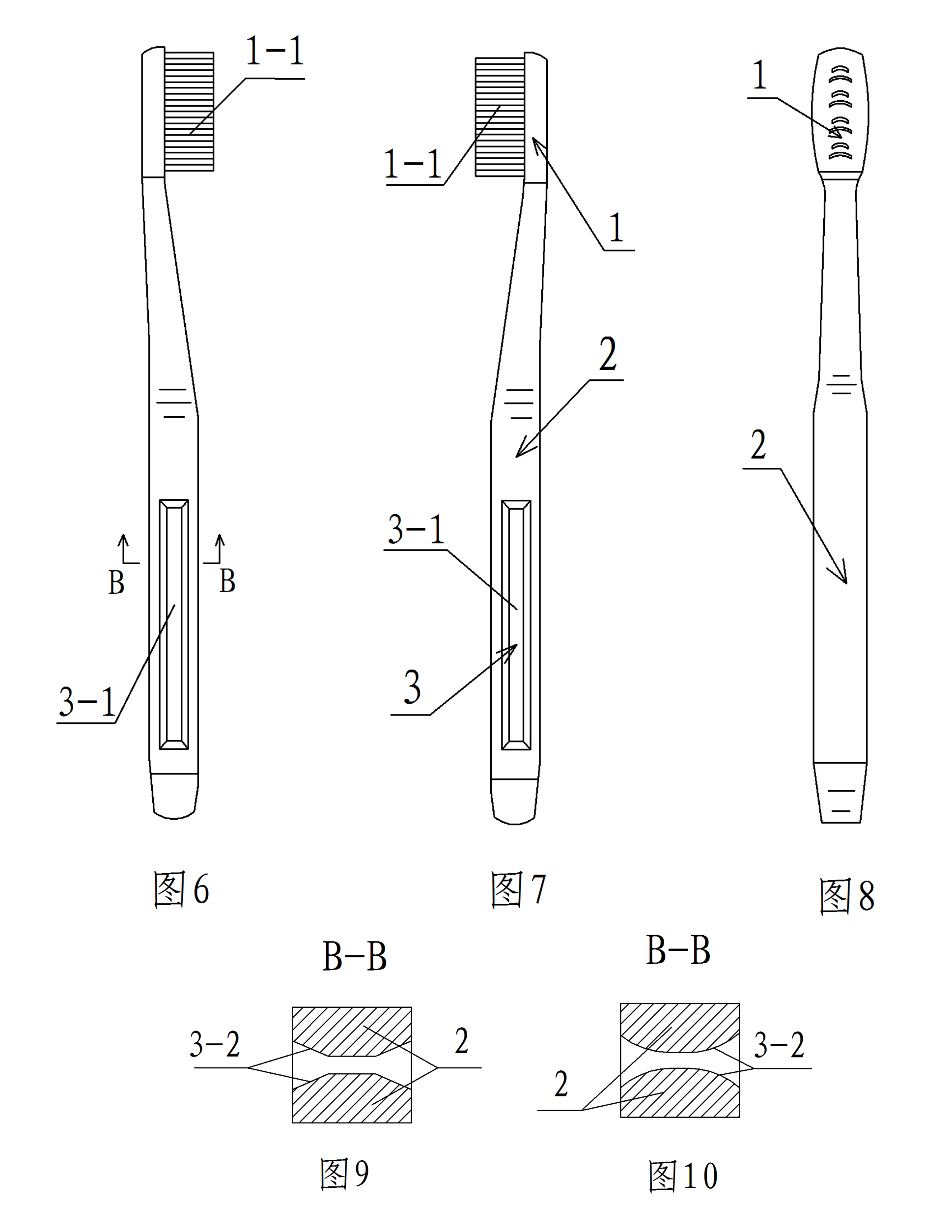

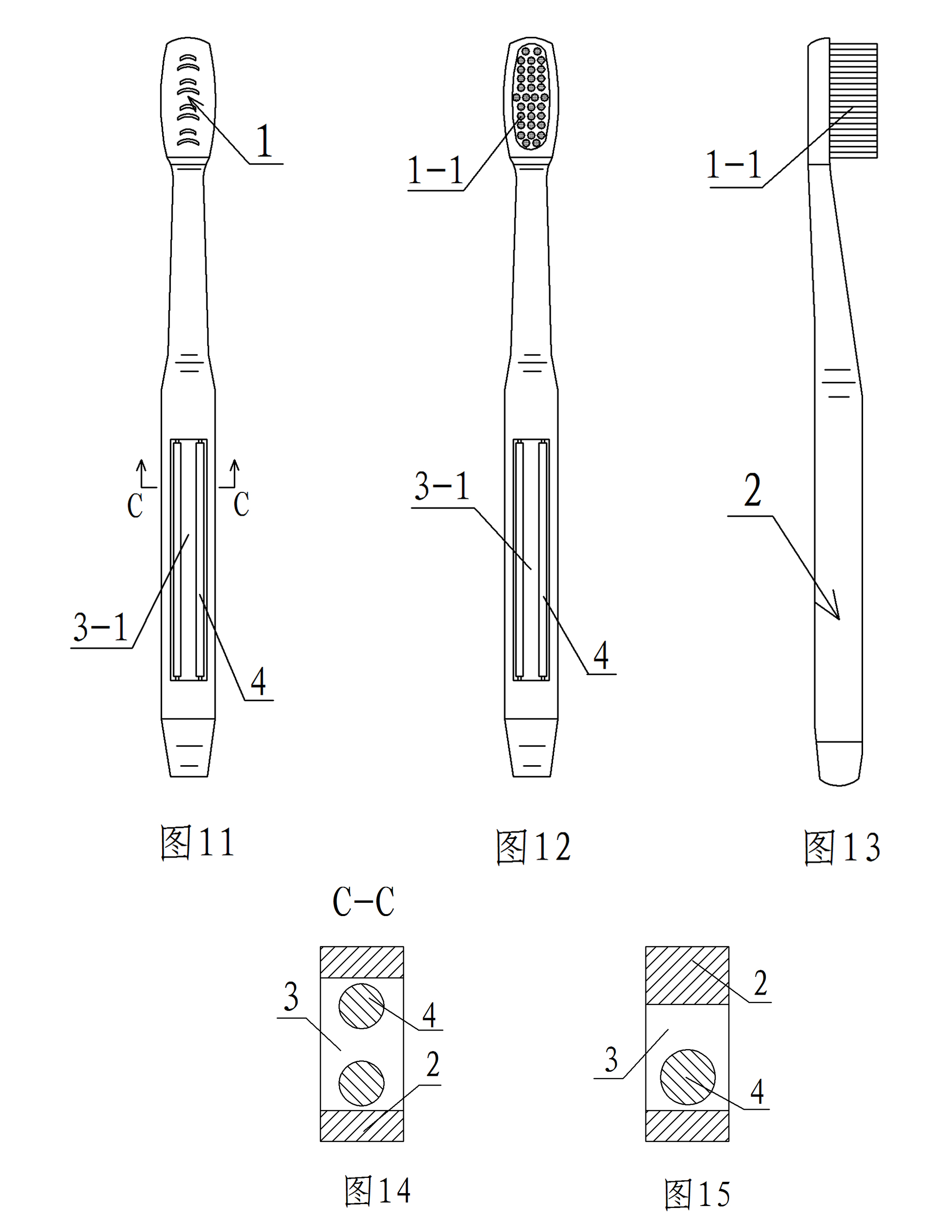

Toothbrush capable of squeezing toothpaste out of a tube

InactiveCN101984876AReduce production materialsReduce wasteBrush bodiesHolders and dispensersBristleToothpaste

The invention relates to a toothbrush capable of squeezing toothpaste out of a tube, which comprises a brush head and a brush holder; and bristle is implanted on the brush head. And the toothbrush is characterized in that a through extruding groove is arranged on the brushing holder along the length direction; the length of the extruding groove is larger than the width of a flatten toothpaste shell which is matched with the extruding groove for use; and the width of the extruding groove is slightly larger than the thickness of the flatten toothpaste shell; and the toothpaste shell can pass through the extruding groove. The toothbrush capable of squeezing toothpaste out of the tube is convenient to squeeze the toothpaste, can completely squeeze the toothpaste out of the tube, and effectively reduce the waste of toothpaste and the pollution of the environment.

Owner:马瑞春

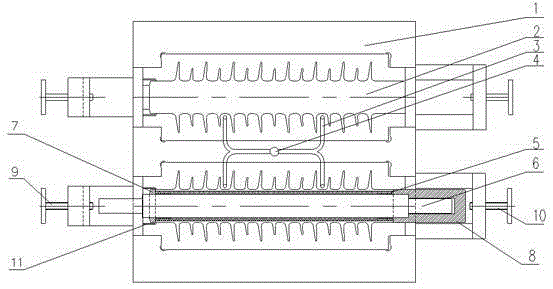

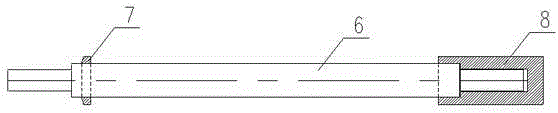

Polymeric housed explosion-resistant glue feeding-resistant forming die

The invention discloses a polymeric housed explosion-resistant glue feeding-resistant forming die. The forming die comprises a die frame, a die cavity, a channel, a glue injection aperture, an insulating cylinder and a lining, the die cavity, the channel and the glue injection aperture are communicated, the lining is placed in the insulating cylinder and is cooperated with the insulating cylinder for usage, the polymeric housed explosion-resistant glue feeding-resistant forming die also comprises a protective sleeve, a telescoping apparatus, a left push rod and a right push rod, the protective sleeve is arranged at left end of the lining, the telescoping apparatus is arranged at right end of the lining, the insulating cylinder is arranged between the protective sleeve and the telescoping apparatus, the left push rod is arranged at the die frame of the left end of the die cavity, and the right push rod is arranged at the die frame of the right end of the die cavity. According to the invention, the polymeric housed explosion-resistant glue feeding-resistant forming die has the advantages of simple structure and convenient operation, generation of explosion phenomenon at end part of the insulating cylinder can be effectively avoided, qualified rate of the product is increased, penetration of the rubber compound in the insulating cylinder can be effectively avoided, optimum application amount of the silicone rubber can be fined according to the glue-spilling amount in a glue-spilling groove, so that the product qualified rate can be increased, and material amount for production can be saved.

Owner:JIANGDONG FITTINGS EQUIP

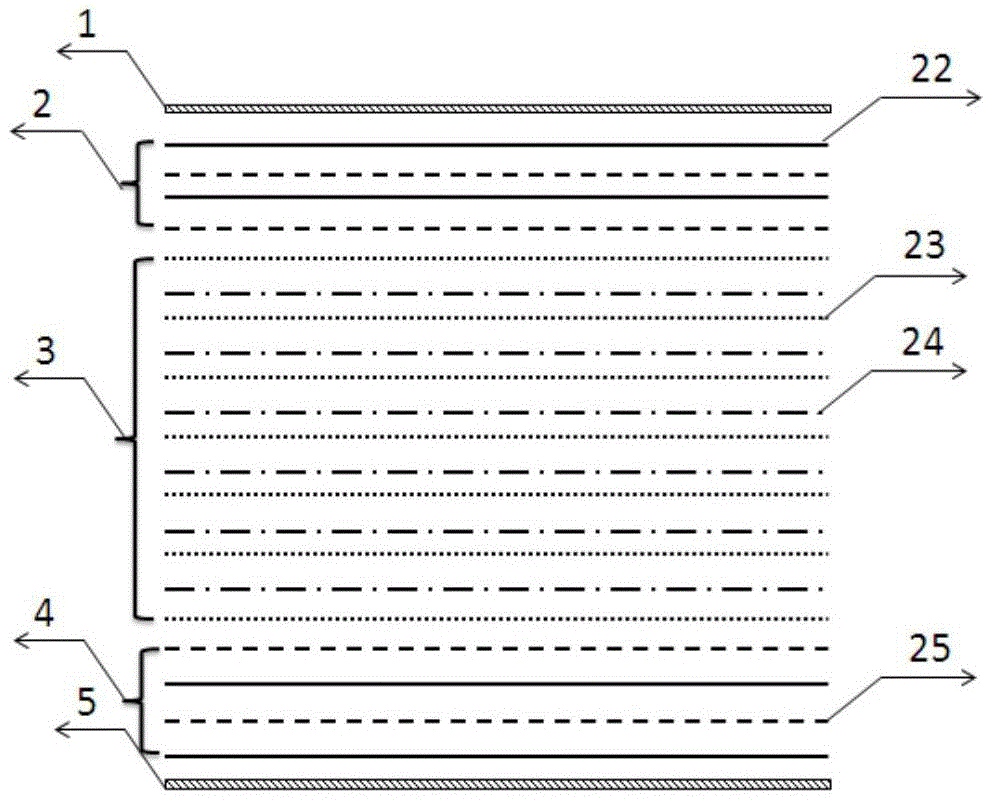

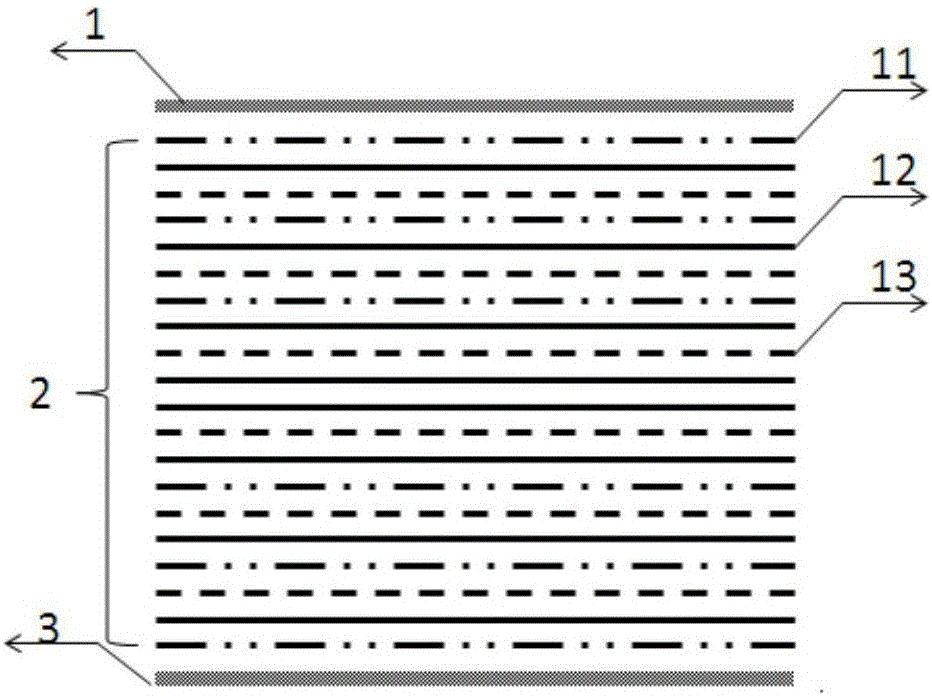

A kind of composite plate, preparation method and application thereof

ActiveCN104802236BStrong designabilityImprove economyLaminationLarge containersSurface layerBaseboard

The invention discloses a composite board. The composite board sequentially includes a surface layer, a sandwich layer, a middle sandwich layer, a bottom sandwich layer and a bottom layer from top to bottom, and all layers are connected in a hot pressing manner. A method for preparing the composite board comprises the following steps: paving the bottom layer on a die; paving the bottom sandwich layer on the upper surface of the bottom layer; paving the middle sandwich layer on the upper surface of the bottom sandwich layer; paving the sandwich layer on the upper surface of the middle sandwich layer; paving the surface layer on the upper surface of the sandwich layer, covering the die, and performing hot pressing and pressure maintaining; depressurizing and exhausting or firstly cooling to ambient temperature and releasing pressure in a segmentation manner to prepare the composite board. The density, strength, elasticity modulus, surface quality and various property indexes of the composite board can meet a composite container baseboard with industry standards of the international container, and the composite board can be used as the container baseboard, has strong design, and can reasonably select thickness and density of the surface layer and the core material according to actual demands, thereby realizing the best economic effect.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

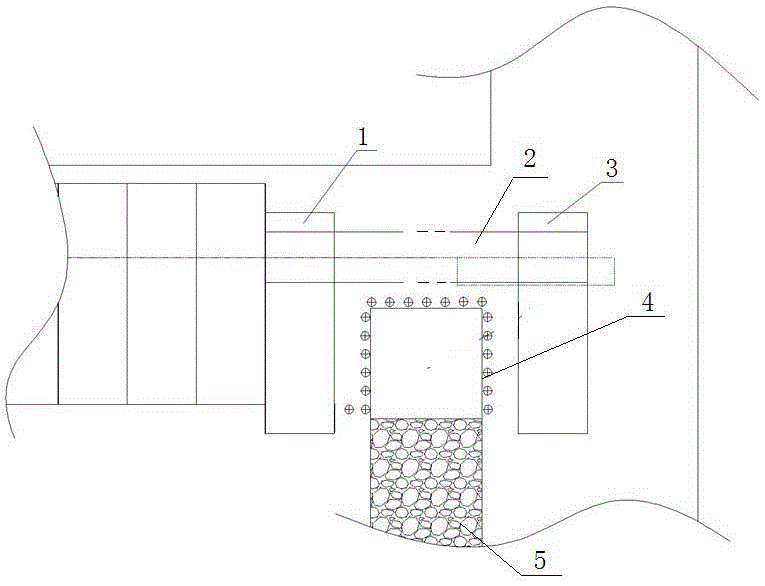

Formwork filling construction technology between gob-side entry retaining frame

ActiveCN103422884BEliminate hidden dangersImprove securityMaterial fill-upFilling materialsEngineering

The invention relates to the supporting technology of roadways of coal mines, in particular to a construction technology for formwork making and filling among gob-side entry retaining supports. The construction technology comprises the steps that a vacant site is reserved at the position needing to be provided with supports in a support set of a tunneling work face, a supporting frame is arranged on the supports on the two sides of the vacant site, and then formwork making operation and the filling operation are carried out in a safe space formed among the supporting frame and the two supports. According to the construction technology for the formwork making and the filling among the gob-side entry retaining supports, the stability of hydraulic supports is used, a traditional timber crib is replaced, the hidden danger that the supporting timber crib is pushed down when pressure is applied to top plates is removed, and the safety of the formwork making and filling process is improved; production using materials such as plates and beams are no longer used, and the production using materials are saved; the influence on coal cutting by solidification of filled materials is reduced, and working efficiency is improved.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

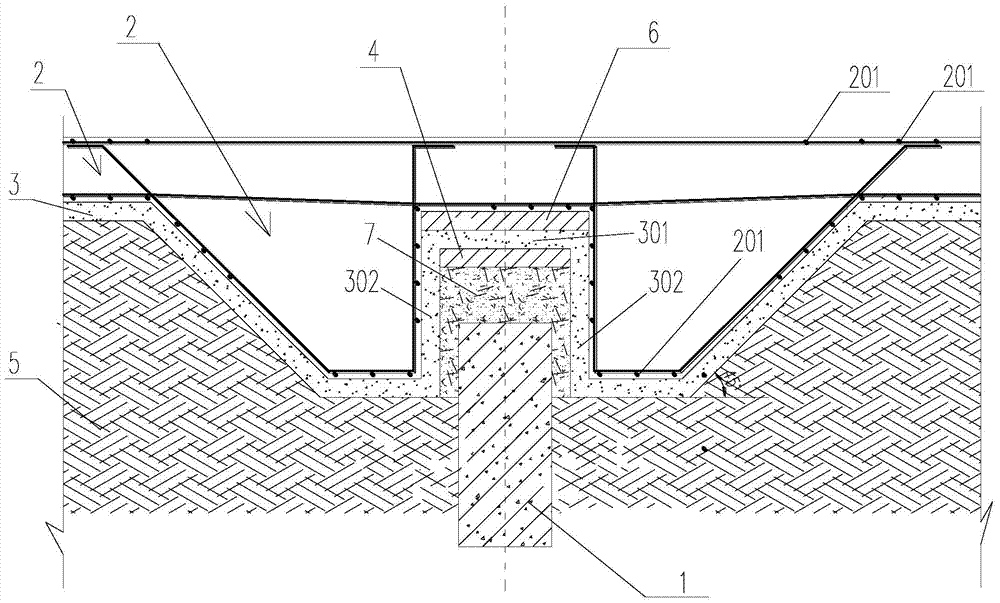

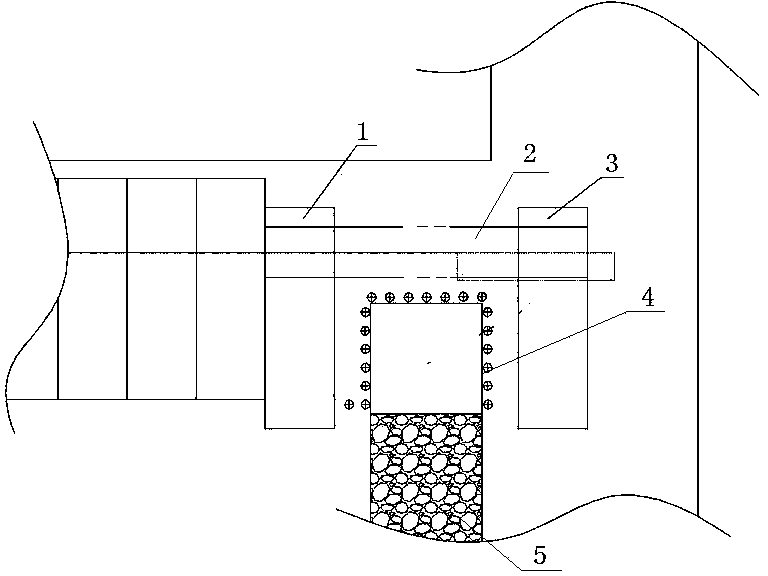

Decompression and shock absorption structure between ballast bed and ground beam

ActiveCN103882784BReduce vibration effectsWith shock absorption functionBallastwayStructural engineeringVibration isolation

Owner:TUS DESIGN GRP CO LTD +1

Base plate for cutter machining

PendingCN109590091AEasy to fixEasy to weldGrain treatmentsMetal working apparatusSocial benefitsEconomic benefits

The invention discloses a base plate for cutter machining. The base plate comprises a base plate main body, an embedding groove is formed in the upper surface of the base plate main body, the embedding groove is used for fixing a high-speed steel bar, a cutting and edge-planing groove is formed in the lower surface of the base plate main body, and the cutting and edge-planing groove is formed under the embedding groove. According to the base plate, in the welding process, the welding quality can be improved, cutting and edge-planing are convenient after welding, so that the cutting and edge-planing efficiency is improved, and consumption on labor, equipment and electric energy in the production process is reduced; and meanwhile, generation of waste materials in the cutting and edge-planingprocess is greatly reduced, the utilization rate of steel materials is effectively improved, and the base plate has very good economic benefit and social benefit.

Owner:DONGE LIYUAN MACHINERY KNIFE

Backlight FPC and display device having the same

PendingCN107360669AReduce production materialsReduce manufacturing costStatic indicating devicesPrinted circuit aspectsDisplay deviceComputer science

Owner:TRULY SEMICON

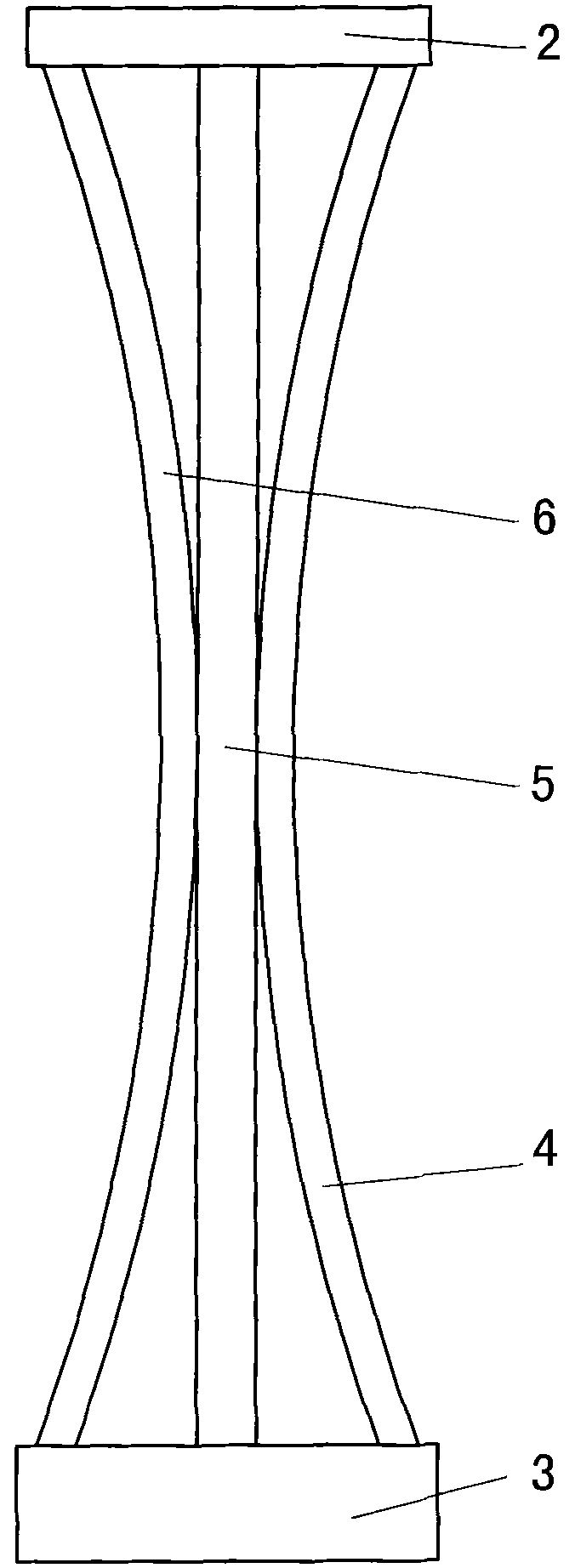

Novel bookshelf

The invention relates to a library device, in particular to a novel bookshelf. The invention provides a technical scheme aiming at solving the problem of lighting shortage of the bookshelf in the prior art. The novel bookshelf is characterized by comprising a bearing frame and a shelf (1), wherein the bearing frame comprises a left-side bearing frame, a right-side bearing frame, a rectangular upper frame (2) and a rectangular lower frame (3); each of the left-side bearing frame and the right-side bearing frame comprises three bearing pillars including a front bearing pillar (4), a middle bearing pillar (5) and a rear bearing pillar (6) according to the positions at the front and rear parts; the middle bearing pillar (5) is straight and vertical; the front bearing pillar (4) and the rear bearing pillar (6) are bent cambers with properties symmetrical to each other. The invention has the advantage that the lighting effect is greatly improved.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

A cutting-ring measurement method for the residual stress of the cylinder wall of cylindrical parts

ActiveCN104483058BPrecise measurement of residual stressReduce production materialsApparatus for force/torque/work measurementMeasurement deviceEngineering

The invention discloses a cutting ring type measurement method for residual stress of the cylinder wall of a cylindrical part. The cutting ring type measurement method includes the following steps of (1) forming a cutting ring, wherein a circular ring cut from the cylinder wall of the cylindrical part is used as the circular ring to be cut, and the circular ring to be cut is cut apart in the radius direction to form the cutting ring; (2) calculating the residual stress, wherein in the circular ring to be cut, a calculation formula for the radial residual stress sigma <rr> and a calculation formula for the circumferential residual stress sigma <theta theta> of the position spaced from the center of the circular ring by r in the radius direction are expressed in the specification. Multi-point measurement can be achieved without developing a special measurement device, operation is easy and convenient, efficiency is high, and results are accurate.

Owner:康硕(山西)低应力制造系统技术研究院有限公司

Method and device for pcb puzzle

ActiveCN103957672BReduce production materialsIncrease productivityPrinted circuit assemblingComputer designed circuitsEngineeringNo fit polygon

A PCB splicing method and device. The method comprises: after sketch plates are integrated into plate gaps, distinguishing sketch plates of a first type and sketch plates of a second type; respectively generating sketch plate no-fit polygons (NFPs)according to a pre-set rule, wherein the sketch plates of the first type generate sketch plate NFPs in corresponding rectangles, and the sketch plates of the second type generate sketch plate NFPs on original sketch plates; when the number N of the sketch plates is greater than 1 and does not exceed a threshold value, combining the N NFPs in pairs to generate N sketch plate combination patterns; and screening out an optimal splicing combination pattern from the N sketch plate combination patterns. The sketch plates which are already integrated into the plate gaps are combined so as to generate and screen out the optimal place splicing combination pattern by means of a combination process using the pre-set rule, and in the combination process, sketch plates which conform to requirements are converted into rectangles for processing, thereby improving the PCB production efficiency and the combination-method calculation efficiency, reducing the production materials of the sketch plates, and reducing the costs.

Owner:SHENZHEN PARTNER INFORMATION TECH

Construction technology for formwork making and filling among gob-side entry retaining supports

ActiveCN103422884AEliminate hidden dangersImprove securityMaterial fill-upFilling materialsEngineering

The invention relates to the supporting technology of roadways of coal mines, in particular to a construction technology for formwork making and filling among gob-side entry retaining supports. The construction technology comprises the steps that a vacant site is reserved at the position needing to be provided with supports in a support set of a tunneling work face, a supporting frame is arranged on the supports on the two sides of the vacant site, and then formwork making operation and the filling operation are carried out in a safe space formed among the supporting frame and the two supports. According to the construction technology for the formwork making and the filling among the gob-side entry retaining supports, the stability of hydraulic supports is used, a traditional timber crib is replaced, the hidden danger that the supporting timber crib is pushed down when pressure is applied to top plates is removed, and the safety of the formwork making and filling process is improved; production using materials such as plates and beams are no longer used, and the production using materials are saved; the influence on coal cutting by solidification of filled materials is reduced, and working efficiency is improved.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

Bamboo plate manufacturing process

ActiveCN102744760BEasy to moveEasy to storeWood working apparatusDomestic articlesWear resistanceEnergy conservation

The invention discloses a bamboo plate manufacturing process. The bamboo plate manufacturing process comprises the following steps of manufacturing cut bamboo, i.e. raw bamboo, into a bamboo plate through the following processes sequentially: post-processing the raw bamboo, sewing the raw bamboo, drying the raw bamboo for the first time, gluing the raw bamboo, drying the raw bamboo for the second time, making the raw bamboo into a blank, and thermally rolling the blank. Bamboo curtains are sewed into bamboo curtain mats; in the gluing process, the liquid glue is dried according to a centrifugal principle; and in the thermally rolling process, a thermal-in and thermal-out process, a phased temperature increasing and decreasing and pressure increasing and decreasing method and the like are adopted. The technical bias of the prior art is overcome, the production cost can be also effectively reduced, the production efficiency is improved, the energy source consumption is effectively reduced, energy conservation and emission reduction are achieved, and the environment is protected. At the same time, a product manufactured by the process is lighter in mass, more stable in performance, good in surface flatness, good in abrasion performance and longer in service life.

Owner:洪敏雄

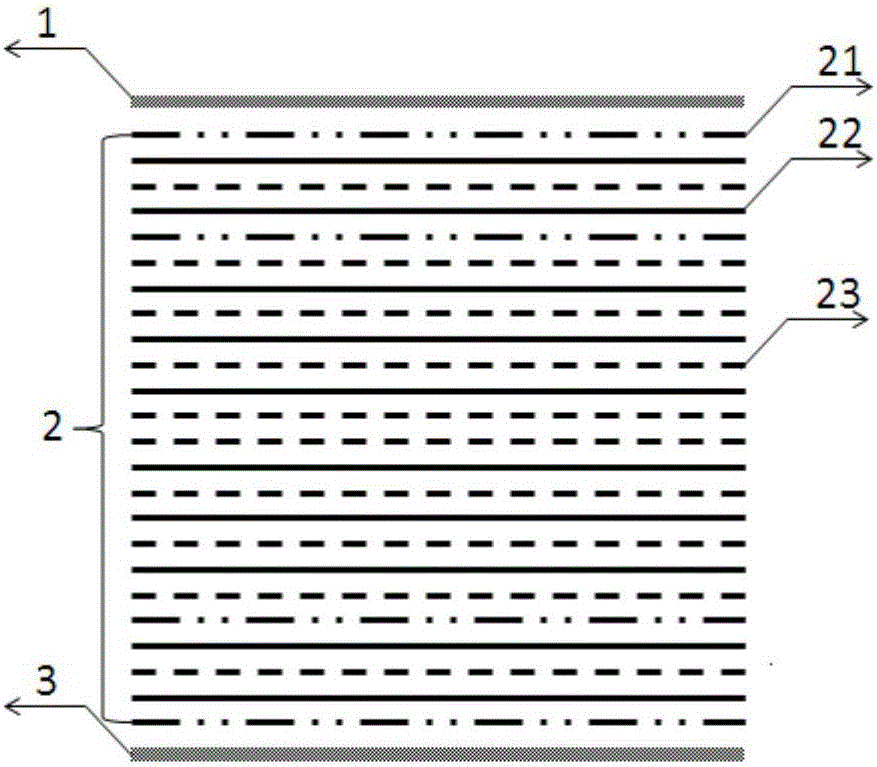

A kind of container bottom plate and preparation method thereof

ActiveCN104802233BStrong designabilityImprove economyLarge containersWood veneer joiningContainerizationSurface layer

The invention discloses a container baseboard. The container baseboard sequentially comprises a surface layer, a sandwich layer and a bottom layer from top to bottom, wherein upper and lower surfaces of the sandwich layer are respectively connected with the surface layer and the bottom layer. The invention further discloses a method for preparing the container baseboard comprises the following steps: paving the sandwich layer on the upper surface of the bottom layer, paving the surface layer on the upper surface of the sandwich layer, and performing hot pressing composite to prepare the container baseboard. The density, strength, elasticity modulus, surface quality and various property indexes of the container baseboard can meet a composite container baseboard with industry standards of the international container, and the container baseboard has strong design, and can reasonably select thickness and density of the surface layer, the bottom layer and the core material according to actual demands, thereby realizing the best economic effect.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com