Light-small pipe rod conveying device and working method thereof

A light and small technology for conveying equipment, applied in the direction of drilling equipment, drill pipes, drill pipes, etc., can solve the problems of small turning angle of V-shaped grooves, failure of sucker rods to roll out, poor roundness of sucker rods, etc., to achieve increased The effect of large push stroke, reduction of total equipment length, and reduction of production materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

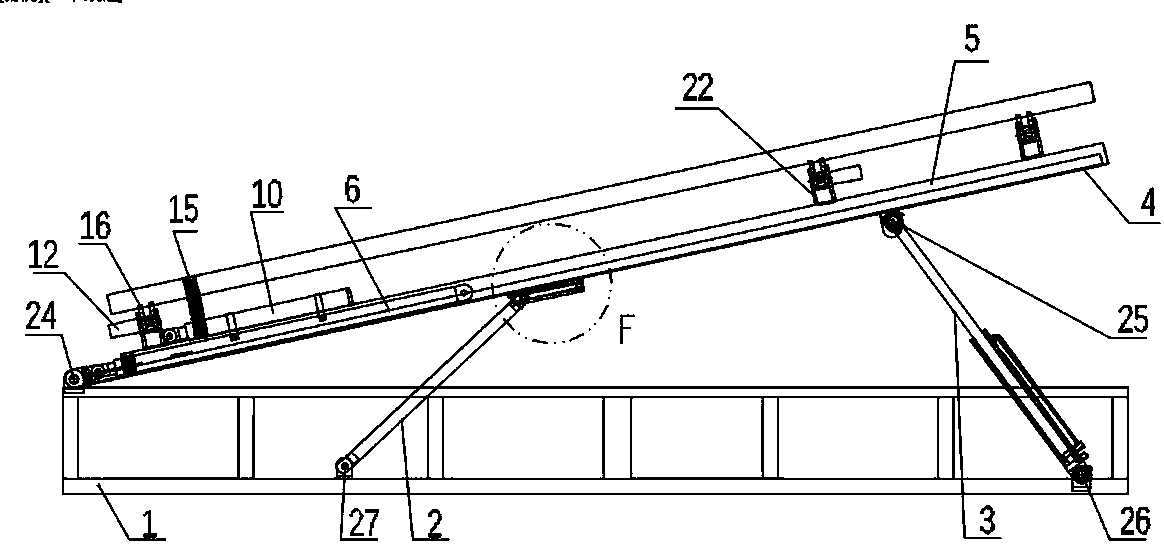

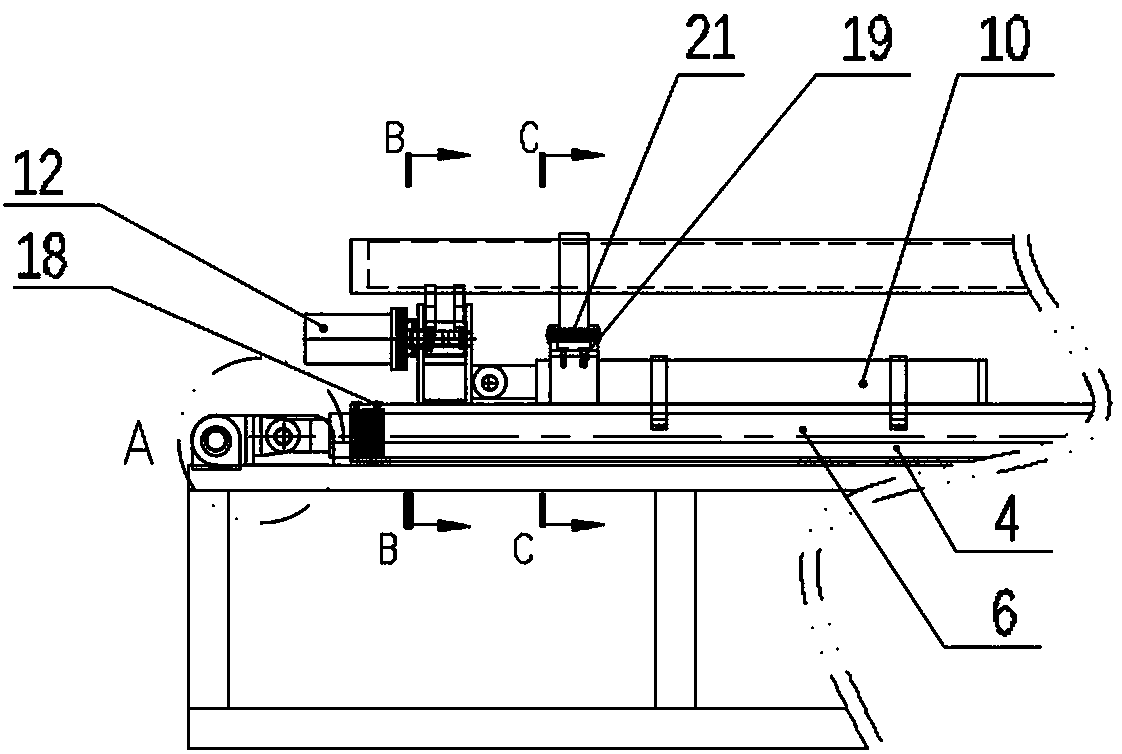

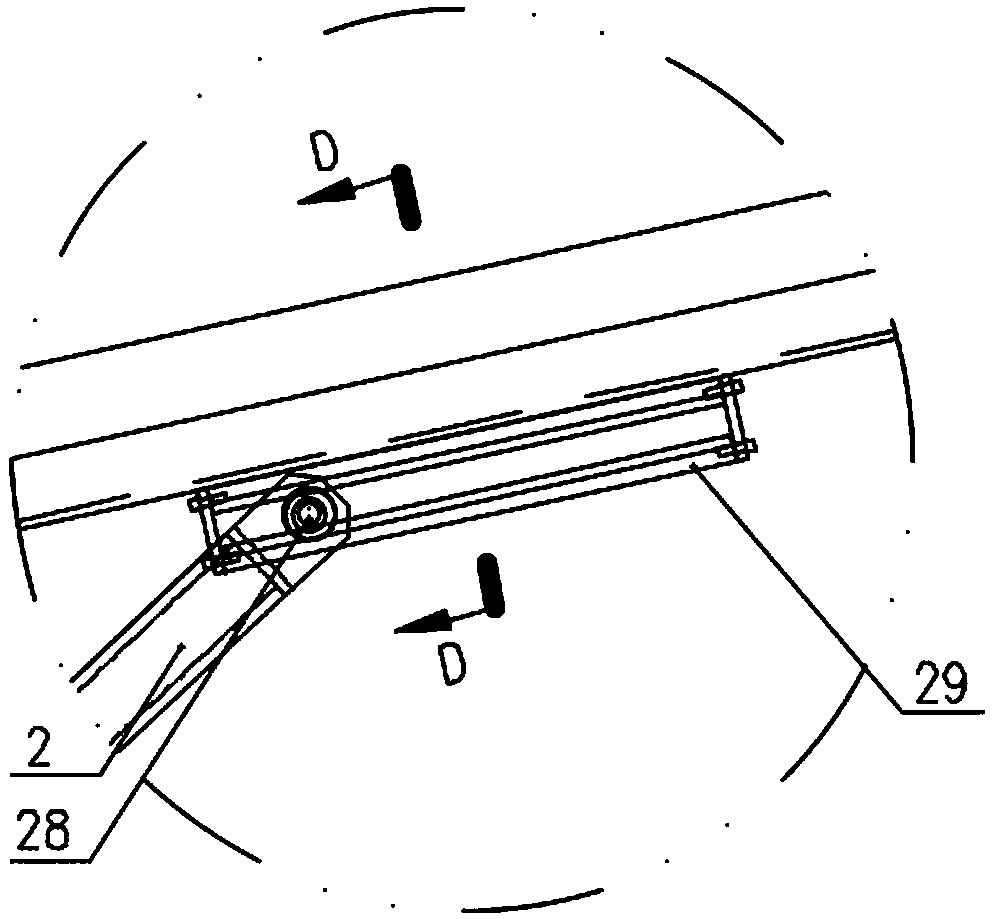

[0034] A kind of light and small pipe rod conveying equipment of the present invention, such as Figure 1 to Figure 8As shown, it includes a frame 1, a lifting device 3, a sliding base 4, a sliding part 5 and a propulsion device 6, and the sliding part 5 moves linearly on the sliding base 4 under the action of the propulsion device 6, and the sliding part 5, a feeding structure is provided above, and the feeding structure is connected with the slider 5 through an overturning and sliding device; Drive device 10, described feeding structure comprises upper feeding chute 9 and lower feeding chute 11; The first wobble plate 15 is connected between described upper feeding chute 9 and sliding driving device 10, and described lower feeding chute 11 is connected with turning drive The devices 12 are connected by a second swing plate 16 . The first wobble plate 15 is V-shaped, and the second wobble plate 16 is Y-shaped.

[0035] In this embodiment, one end of the sliding base 4 is hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com