Construction technology for formwork making and filling among gob-side entry retaining supports

A technology of construction technology and empty entry retaining, which can be used in fillings, safety devices, mining equipment, etc., can solve problems such as hidden safety hazards and delay in support, and achieve improved safety, improved work efficiency, and saved production materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

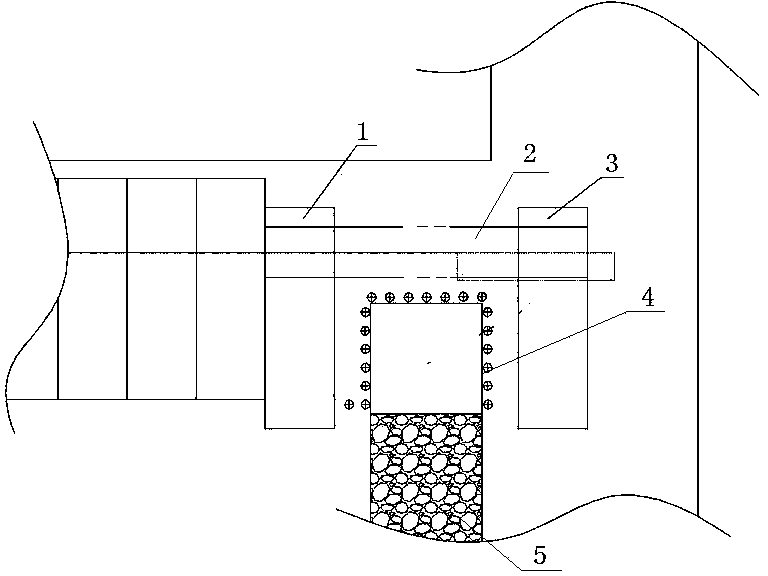

[0008] Such as figure 1 As shown in the figure, a construction process of moulding and filling between the frames of the roadway remaining along the goaf is to leave a space in the support group of the tunneling face where the support needs to be reserved, and the support 1, 3 on both sides of the space The supporting frame 2 is installed on the upper part, and then the mold 4 filling operation is performed in the safe space formed between the supporting frame 2 and the two brackets 1 and 3.

[0009] After the mold is completed, the filling operation will be carried out. After the filling is completed, the normal coal cutting operation will start. When the coal mining face is advanced enough for the mold making distance and the filling material is solidified, the mold will be demolded for the next mold making operation. When the shearer cuts enough for 4 cycles and reaches enough molding space, mold making and filling in time; after filling, continue cutting coal, and work in thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com