Decompression and shock absorption structure between ballast bed and ground beam

A ballast bed and ground beam technology, applied in the field of decompression and shock absorption structures, can solve the problems such as the adverse effects of the normal use of the vehicle vibration upper structure, and achieve the effects of simple and easy construction methods, reduced pressure, and reduced production materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

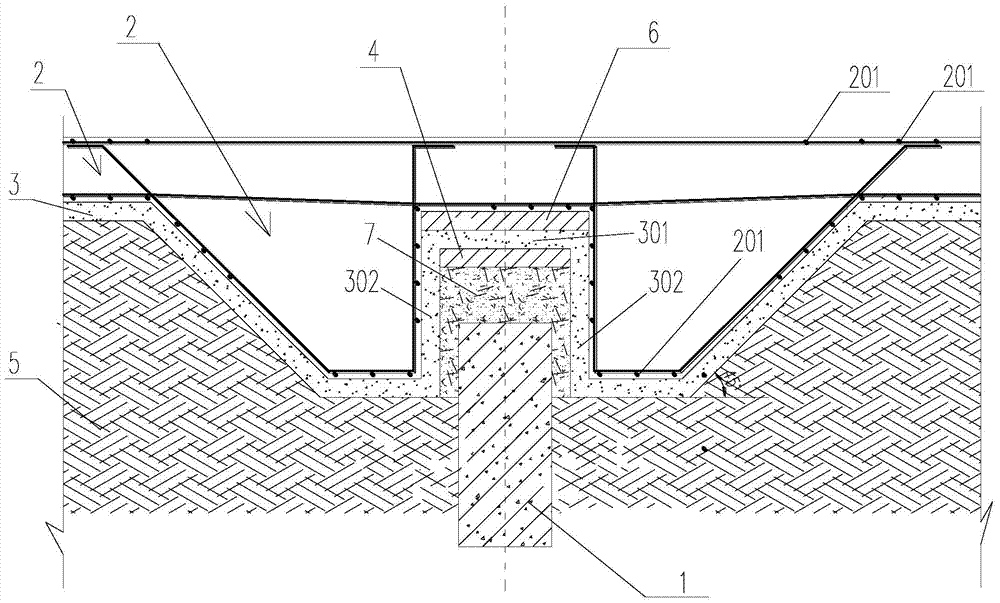

[0023] Example: figure 1 A specific embodiment of the decompression and shock absorption structure between the ballast bed and the ground beam of the present invention is shown, which includes the ground beam 1, and the backfill layer 5 of the ballast bed base (usually earth and rock materials), concrete Cushion 3 and ballast bed bottom 2, wherein ballast bed base backfill layer 5, concrete cushion 3 and ballast bed bottom 2 are all part of the ballast bed, ballast bed bottom 2 is a reinforced concrete structure, and concrete cushion 3 is made of C15 concrete material.

[0024] The key improvement of this embodiment is: the first vibration isolation plate 4 next to the bottom of the concrete cushion 3 is arranged directly above the ground beam 1, and the first vibration isolation plate 4 and the concrete cushion 3 All are separated from the ground beam 1 by a certain gap, and a loose soil backfill layer 7 is arranged in the gap.

[0025] Because in this embodiment, there is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com