Thermal insulation wall body

A technology for thermal insulation walls and walls, applied in thermal insulation, walls, building components, etc., can solve the problems of increasing labor costs in construction processes, increasing materials and production costs, and poor sound insulation, achieving good application prospects and increasing Sound insulation effect, saving construction process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

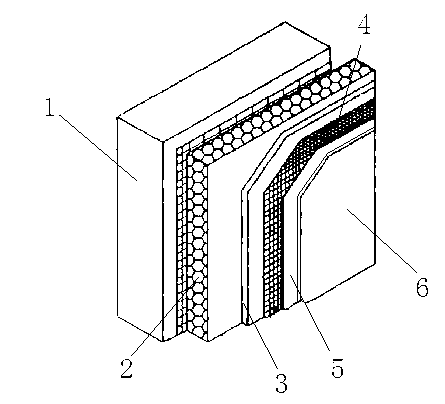

[0016] Such as figure 1 As shown, a thermal insulation wall includes a main wall layer 1, and an insulation board layer 2, a hot-dip galvanized steel wire mesh layer 3, a sound insulation board layer 4, and a glass fiber mesh cloth are sequentially arranged on the outside of the main wall layer 1 Layer 5 and finishing paint layer 6, in which the thermal insulation board layer 2 is made of polystyrene board, which has good thermal insulation; the hot-dip galvanized steel wire mesh layer 3 can increase the firmness of the thermal insulation wall; the sound insulation board layer 4 is made of honeycomb Made of rock wool board, the sound insulation effect is good. The smaller the aperture of the honeycomb, the better the sound insulation effect. The glass fiber mesh cloth layer 5 has good toughness, so it can prevent the insulation wall from cracking and falling off, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com