Method for preparing latex gloves with surface granular structure

A surface particle and glove technology, applied in the direction of coating, etc., can solve the problems of environmental pollution, operator health, poor anti-skid performance and friction resistance, and cannot be completely removed, achieving good wear resistance, high puncture resistance, and manufacturing low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

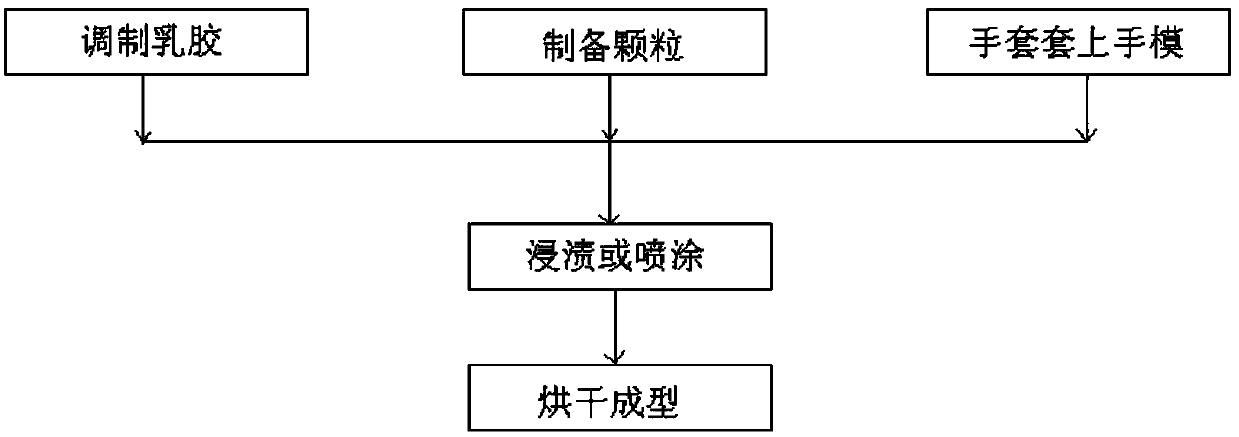

[0012] The specific steps of the preparation method of the rubber-dipped gloves with the surface particle structure involved in the present embodiment are:

[0013] (1) The raw material latex for making gloves is toned and filtered according to different requirements, and then the rubber or reclaimed rubber is crushed into irregular particles of uniform size, and then added to the raw material latex for use;

[0014] (2) Put the fibrous glove on the hand, and then soak it in the latex with particles prepared in step (1) for 0.1-5 minutes, then pick it up to form a uniform non-slip particle layer on the surface of the glove, and then send it to the oven Control the temperature at 80-200°C for drying and molding.

[0015] The particle size range of the anti-slip granular layer prepared in this embodiment is 0.01-5mm; the coverage area of the anti-slip granular layer on the surface of the glove can be adjusted according to different market demands. The coverage area of the n...

Embodiment 2

[0017] The specific steps of the preparation method of the rubber-dipped gloves with the surface particle structure involved in the present embodiment are:

[0018] (1) According to different requirements, the raw material latex for preparing gloves is toned and filtered for use, and then the rubber or reclaimed rubber is crushed into irregular particles of uniform size and placed separately for use;

[0019] (2) Put the fibrous gloves on the hand, and then immerse in the raw latex in step (1) for 0.1-3 minutes to form a latex layer on the surface of the glove, and then spray the prepared particles evenly on the surface of the glove through the spraying device Colloid on the surface of the glove, and then send the glove to an oven with a temperature control of 80-200°C for drying and molding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com