Base plate for cutter machining

A substrate and cutting tool technology, applied in metal processing, grain processing, etc., can solve the problems of increasing economic costs, consuming a lot of labor, electricity and equipment, cutting blades, cutting parts, and wasting steel materials, etc., to improve cutting tool processing efficiency, Improve efficiency and effect, reduce the effect of production materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with embodiment, further illustrate the present invention.

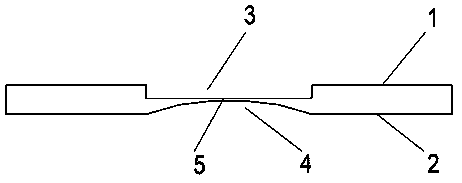

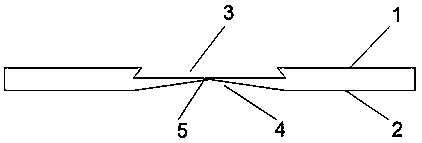

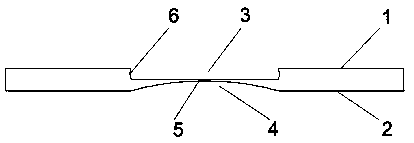

[0046] see Figure 1-Figure 3 It can be known that a substrate for tool processing of the present invention is composed of a substrate main body, an inlay groove 3 and a cutting edge groove 4; the upper surface 1 of the substrate main body is provided with an inlay groove 3, and the inlay groove 3 fixes a high-speed steel bar; The lower surface 2 of the substrate main body is provided with a cutting planer groove 4 , and the cutting planer groove 4 is arranged directly below the embedding groove 3 .

[0047] The groove body of the cutting planer groove 4 gradually becomes deeper from both sides to the middle, so that a relatively thin welded connection support portion 5 is formed between the inlay groove 3 and the cutting planer groove 4 .

[0048] The above-mentioned setting makes the groove cutting planer edge groove 4 form a slope on the substrate main body, that is, the planer edge su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com