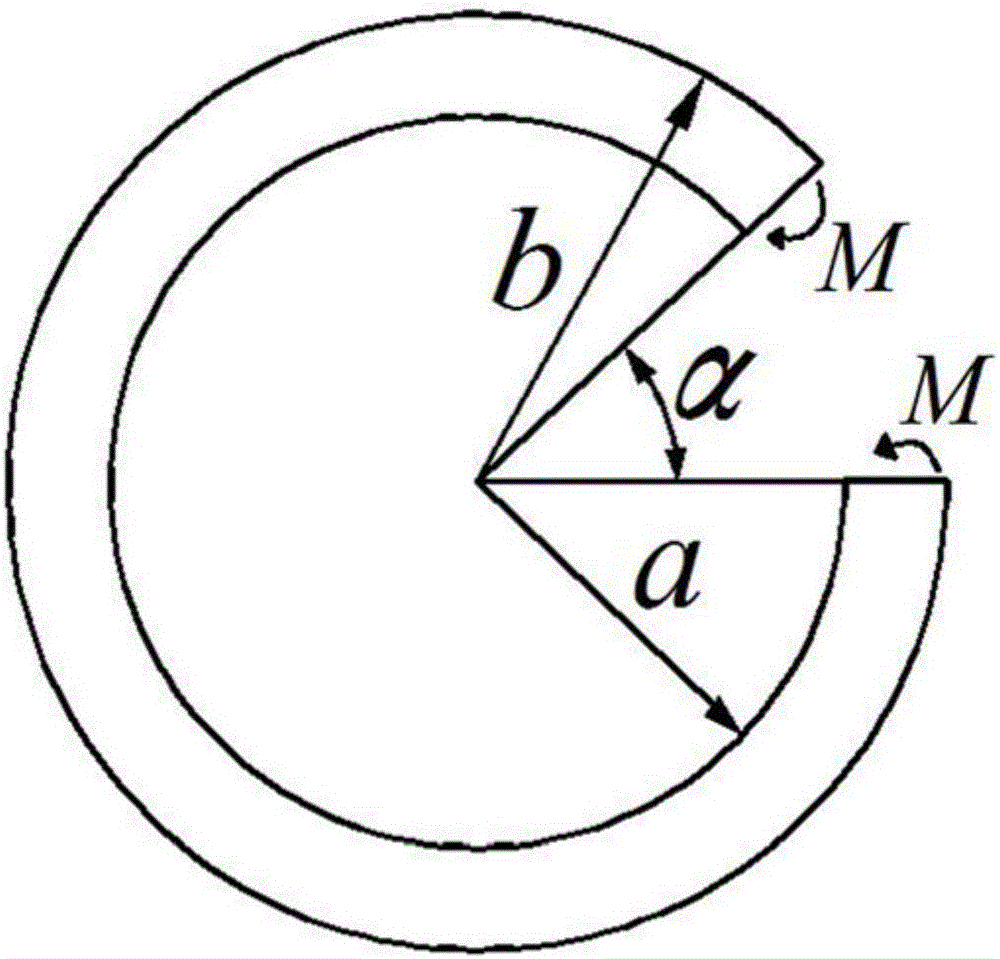

A cutting-ring measurement method for the residual stress of the cylinder wall of cylindrical parts

A technology of residual stress and measurement method, applied in the direction of force/torque/work measuring instrument, measuring device, instrument, etc., which can solve the problems of high cost, complicated test equipment, and difficult implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

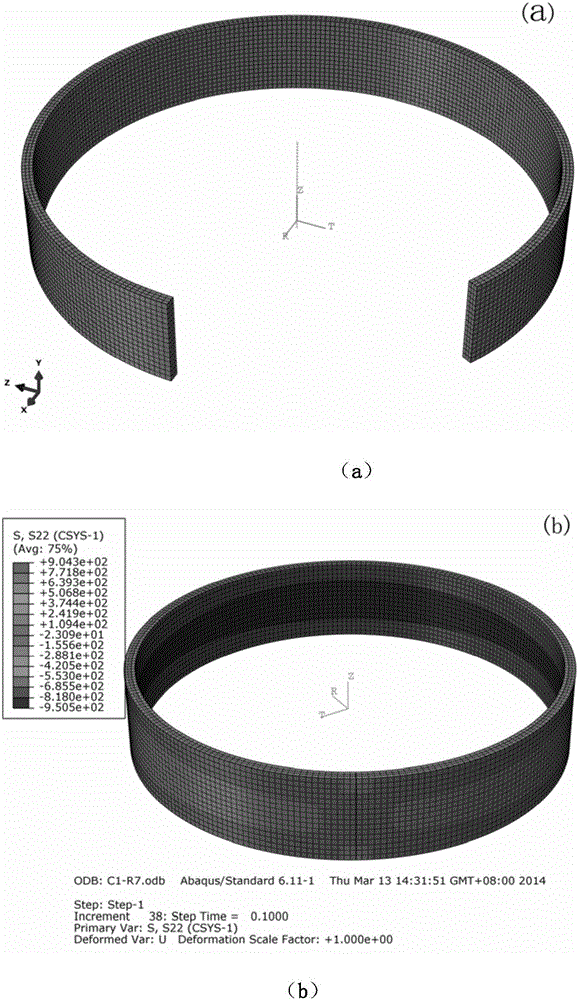

Method used

Image

Examples

Embodiment Construction

[0093] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment:

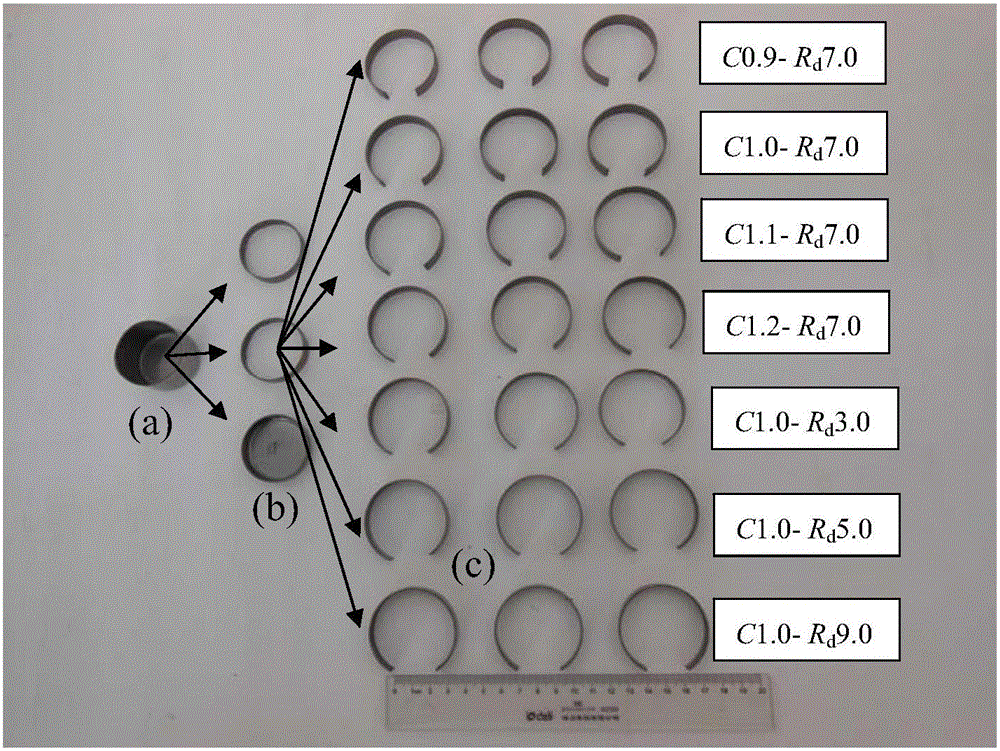

[0094] The following takes the deep drawing of 304 stainless steel cylindrical parts and the subsequent ring cutting test as an example to illustrate the specific implementation of the ring cutting test for measuring the residual stress of the cylindrical part wall:

[0095] The first step, the preparation of cut ring sample

[0096] The 304 stainless steel cylindrical deep-drawing part is a 304 stainless steel circular flat blank with a thickness of 0.94mm (nominal thickness 1.0mm) and a diameter of φ72mm, which is drawn on a YB32-40A hydraulic press with a nominal pressure of 400KN using a deep-drawing die. shaped.

[0097] The geometric dimensions of the deep drawing die and the parameters of the deep drawing forming process are shown in Table 1. Among them, the diameter of the drawing die is φ40.8mm, and the fillet radius of the drawi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com