Device for preparing nano fiber twisted structure

A stranded wire and fiber technology, which is applied in the field of devices for preparing nanofiber stranded wire structures using centrifugal electrospinning technology, can solve the problems of high spinning voltage, poor controllability of the number of stranded wire structure nanofibers, and insufficient bonding of fiber bundles. sequence and other issues, to achieve the effect of accurate and controllable number, good structure and shape of twisted wires, and high degree of connection sequence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: Preparation of orderly lapped fibers.

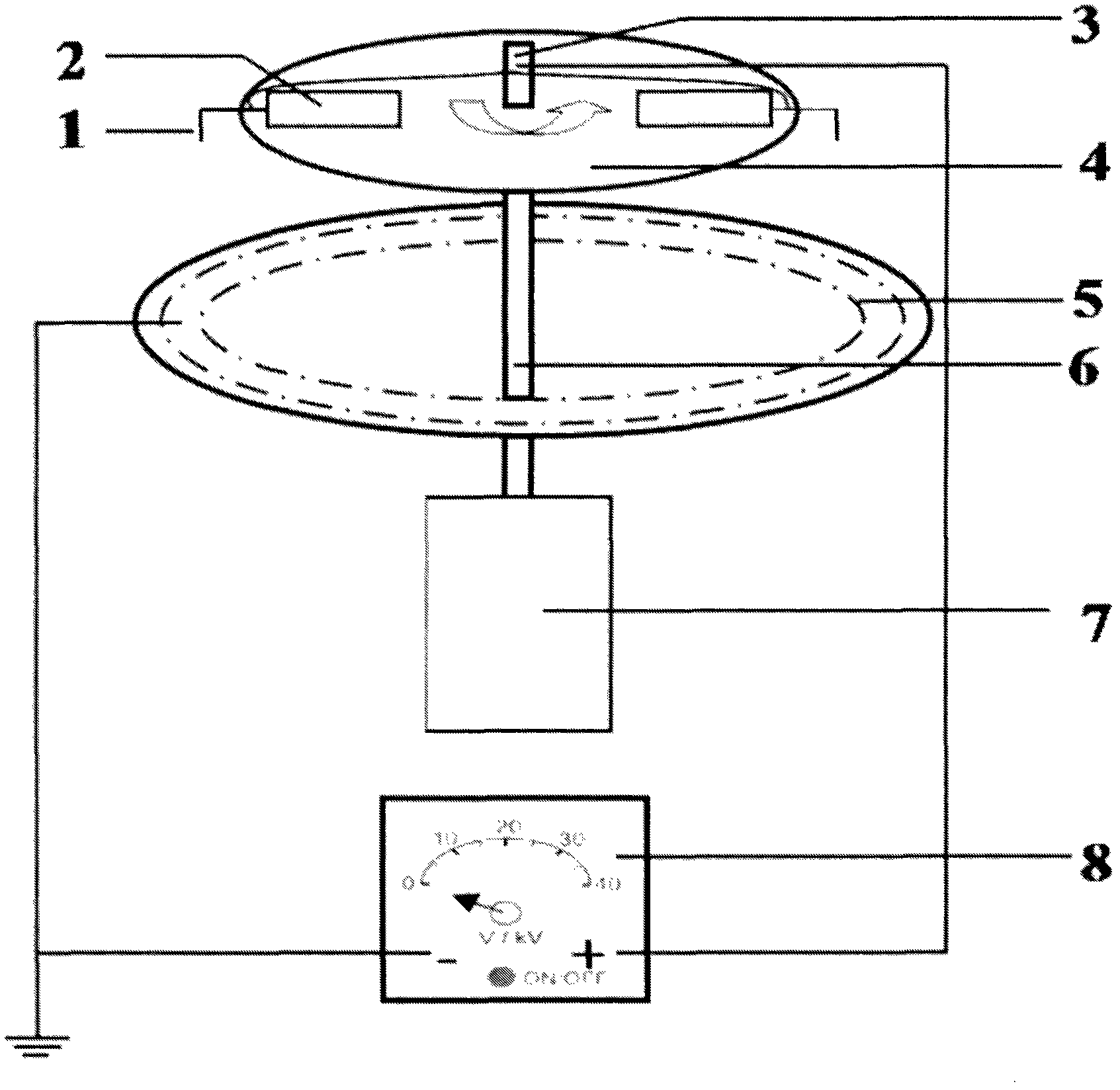

[0015] as attached figure 1 As shown, the positive pole of the high-voltage DC power supply 8 is connected to the metal rod 3, the negative pole is connected to the ring-shaped aluminum foil collecting pole 5 and grounded, and the position of the spinning solution container or the syringe needle tube 2 on the insulating rotating disk 4 is adjusted so that the tip of the spinning nozzle 1 and the The horizontal distance of the metal rod 3 is 15cm; the vertical distance between the tip of the spinning nozzle 1 and the annular aluminum foil collector 5 is 2-3cm, and the spinning solution is injected into the spinning solution container (syringe needle) 2; 8. Insert the plug into the daily 220V power supply, adjust the voltage adjustment knob on the voltage control panel, set the voltage to 2.5-5kV, and press the power switch to make it in the power-on state. At this time, the spinning nozzle 1 is supplied with high voltage...

Embodiment 2

[0016] Example 2: Preparation of nanofiber stranded wire structure.

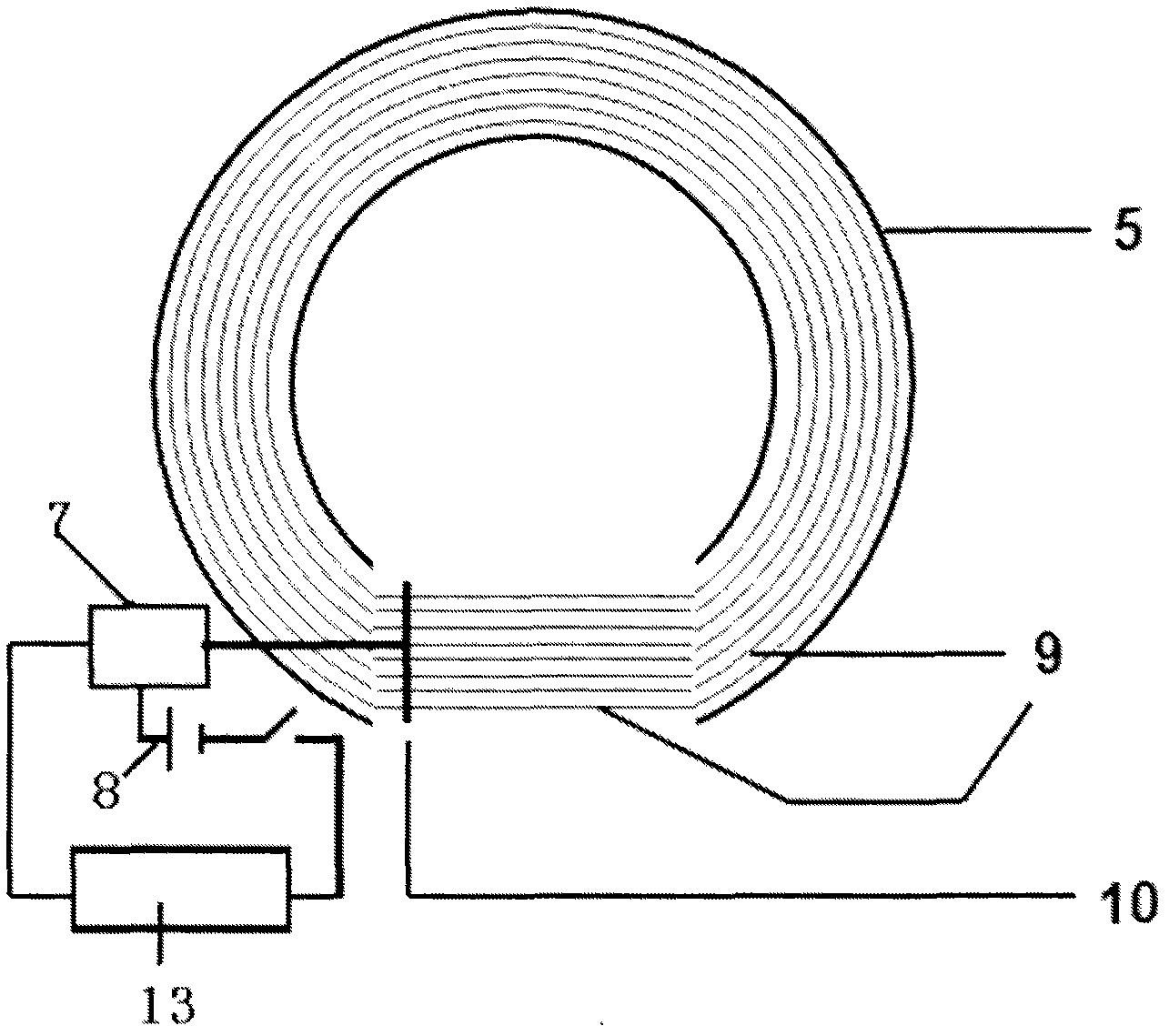

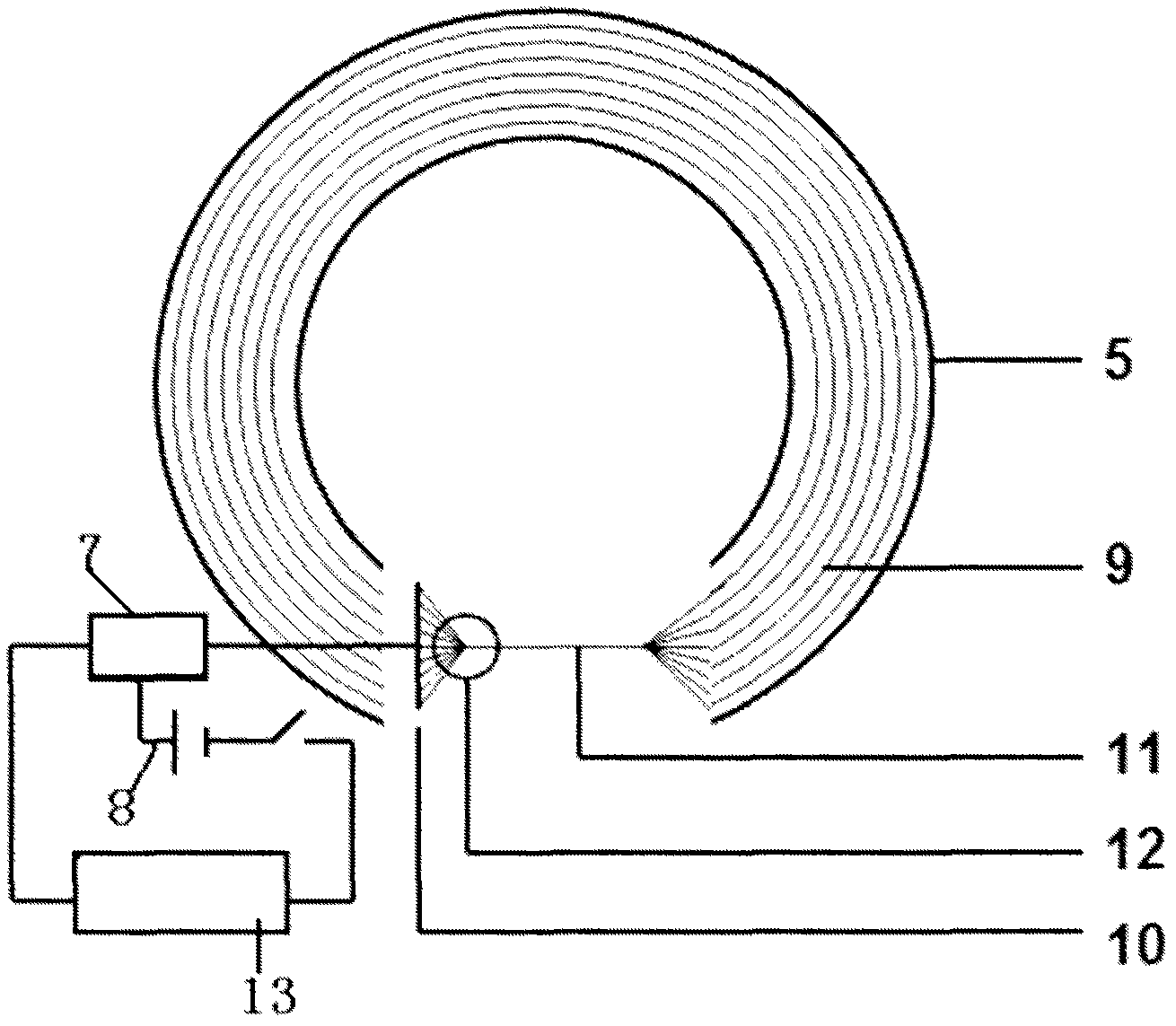

[0017] as attached figure 2 As shown, the spun fibers 9 arranged in an orderly manner are formed on the annular aluminum foil collector 5 by the centrifugal electrospinning method, and at the same time, the gaps of the annular aluminum foil collector 5 are formed to adhere to the T-shaped support 10. An orderly arrangement of overlapping structures. Use a thin rod to remove the fibers with poor shape and too close to the two ends of the T-shaped bracket 10, and cut off the fibers between the T-shaped bracket 10 and the aluminum foil near it, adjust the voltage of the speed regulator to the minimum, and open the Motor switch, adjust the speed to make the motor transition from slow to fast as much as possible, and a stranded wire structure will be formed after 5-60 minutes; if attached image 3 As shown, the nanofiber strand structure 11 and the umbrella structure 12 are held up by a glass slide from bottom...

Embodiment 3

[0019]In the device of this embodiment, 1.3 g of polymethylmethacrylate (polymethylmethacrylate, PMMA) was first dissolved in 8.7 g of N, N-dimethylformamide (N, N-dimethylformamide, DMF) with a mass ratio of 1:1 and tetrahydrofuran (tetrahydrofuran, THF) mixed solution, then add 0.026g fluorescein, stir with a magnetic stirrer for 2 hours, put it into the spinning solution container 2 after standing still for half an hour, and use centrifugal electrospinning method to obtain orderly For the fluorescent fibers that are connected, the DC brushless motor 7 is energized during the implementation process to allow the insulating rotating disk 4 to rotate at a speed of 360rpm, the distance between the spinning nozzle 1 and the annular aluminum foil collector 5 is 3cm, and the high-voltage DC power supply 8 The voltage is 3.5kV, disconnect the power supply 8 of the high-voltage electrostatic generator after 10s, turn off the brushless DC motor 7, remove the fibers with poor shape or t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com