Machining method for reducing workpiece burrs for numerical control machine tool

A technology of numerical control machine tools and processing methods, which is applied in the direction of metal processing equipment, milling machine equipment, manufacturing tools, etc., and can solve problems such as workpiece scratches, easy burrs, workpiece appearance and accuracy effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

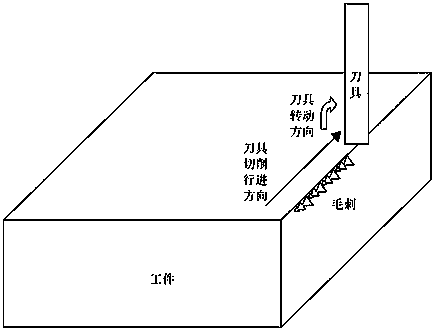

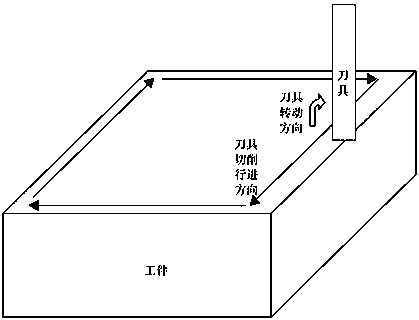

[0012] Such as figure 2 Shown, in this embodiment, the present invention comprises the following steps:

[0013] A. Control the tool to rotate clockwise through the CNC machine tool;

[0014] B. Before normal processing, the tool cuts one circle in the reverse tangential direction around the workpiece, and the reverse cutting direction is a clockwise rotation direction around the workpiece.

[0015] Because the cutting tool of the present invention rotates clockwise, when the edge of the workpiece is processed, the direction of rotation of the cutting tool is inward relative to the workpiece, and no burrs will be generated. Therefore, the present invention can avoid the burrs produced by processing and need to manually remove the burrs, thereby The processing efficiency is improved, and the appearance and precision of the workpiece are also improved.

[0016] The invention is applied to the technical field of numerical control machine tools.

[0017] Although the embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com