A kind of Longquan celadon tireless glaze wall and its production method and application

A production method and fetal glaze technology are applied in the field of Longquan celadon, which can solve the problems of difficulty in grinding, difficulty in forming ceramic ornaments, and low yield of finished products, and achieve the effect of overcoming the difficulty in forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043]A method for making Longquan celadon tireless glazed wall, comprising the following steps:

[0044] (1) Prepare the glaze according to the following formula:

[0045] In terms of mass fraction, the formula of the glaze is: 50% potassium feldspar, 15% quartz, 15% limestone, 10% purple gold soil, and 10% lingen glaze soil;

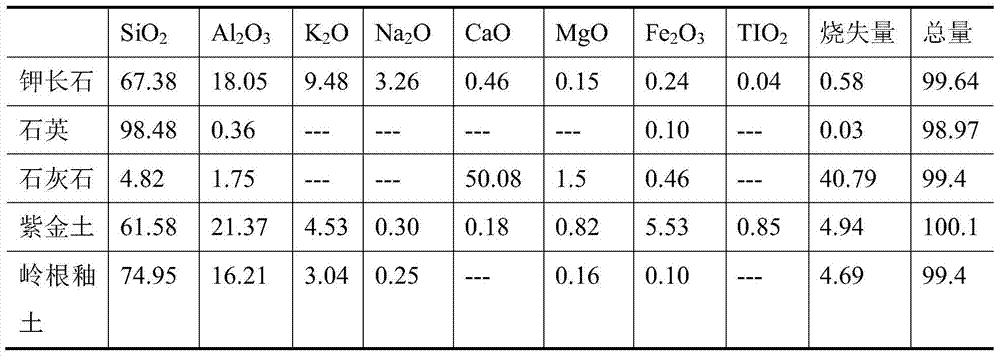

[0046] The chemical composition of each component is shown in Table 1:

[0047] Table 1

[0048]

[0049] The preparation method of the glaze is as follows: mix the mixture of the above raw materials, balls: water at a weight ratio of 1:1:0.8, and mill for 30 minutes; Carry out three-stage iron removal, each iron remover has a strength of 15,000 gauss; divide the iron-removed materials into a blast dryer, and dry them at a constant temperature of 110°C for 30 hours;

[0050] (2) Using the dry powder pressing method, the dried glaze is made into a cylindrical glaze column with the same diameter and height;

[0051] (3) Using the printing blank me...

Embodiment 2

[0064] A method for making Longquan celadon tireless glazed wall, comprising the following steps:

[0065] (1) Prepare the glaze according to the following formula:

[0066] In terms of mass fraction, the formula of the glaze is: 40% potassium feldspar, 18% quartz, 18% limestone, 12% purple gold soil, and 12% lingen glaze soil;

[0067] The preparation method of the glaze is as follows: mix the mixture of the above raw materials, balls: water in a weight ratio of 1:1:0.8, and ball mill for 35 minutes; Carry out three-stage iron removal, each iron remover has a strength of 15,000 gauss; divide the iron-removed materials into a blast dryer, and dry them at a constant temperature of 110°C for 25 hours;

[0068] (2) Using the dry powder pressing method, the dried glaze is made into a cylindrical glaze column with the same diameter and height;

[0069] (3) Using the printing blank method, using conventional ceramic mud to make a round thin tire pad cake, the diameter of the pad c...

Embodiment 3

[0082] A method for making Longquan celadon tireless glazed wall, comprising the following steps:

[0083] (1) Prepare the glaze according to the following formula:

[0084] In terms of mass fraction, the formula of the glaze is: 60% potassium feldspar, 20% quartz, 10% limestone, 5% purple gold soil, and 5% lingen glaze soil;

[0085] The preparation method of the glaze is as follows: mix the mixture of the above raw materials, balls: water at a weight ratio of 1:1:0.8, and mill for 40 minutes; Carry out three-stage iron removal, each iron remover has a strength of 15,000 gauss; divide the iron-removed materials into a blast dryer, and dry them at a constant temperature of 110°C for 28 hours;

[0086] (2) Using the dry powder pressing method, the dried glaze is made into a cylindrical glaze column with the same diameter and height;

[0087] (3) Using the printing blank method, using conventional ceramic mud to make a round thin tire pad cake, the diameter of the pad cake aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com