Method for determining furnace-temperature set value of billet heating furnace

A billet heating and setting value technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problem of not considering the measured temperature, etc., and achieve the effect of fully automatic steel burning and meeting the requirements of the rolling process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

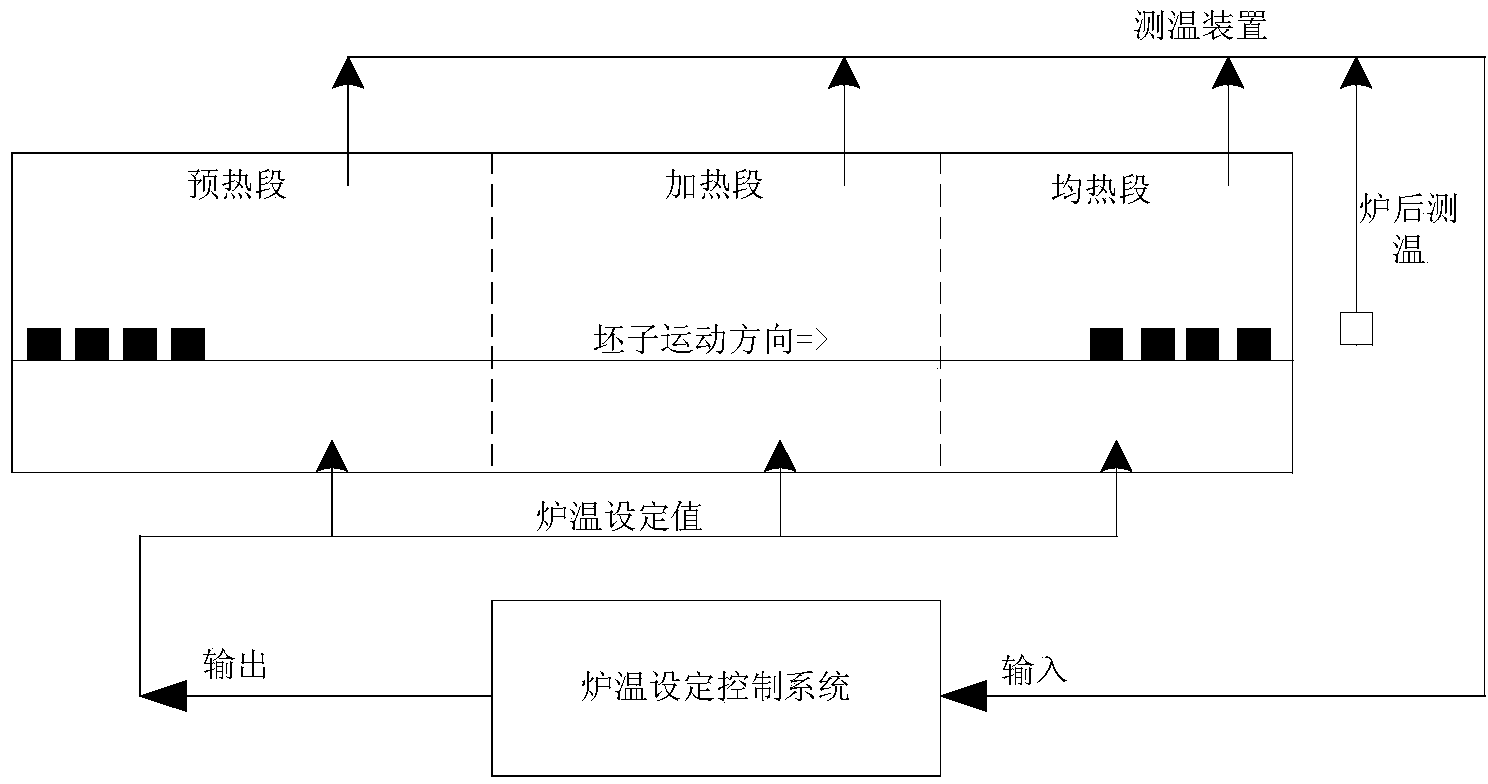

[0029] The heating furnace in this embodiment heats the continuous casting billet, the size of the billet is 150mm×150mm×11500mm, the length of the heating furnace is 20000mm, and the furnace width is 12700mm. Such as image 3 As shown, the furnace temperature control section includes a preheating section, a heating section and a soaking section, the steel type to be heated is HPB300, and the furnace target temperature is 1050°C.

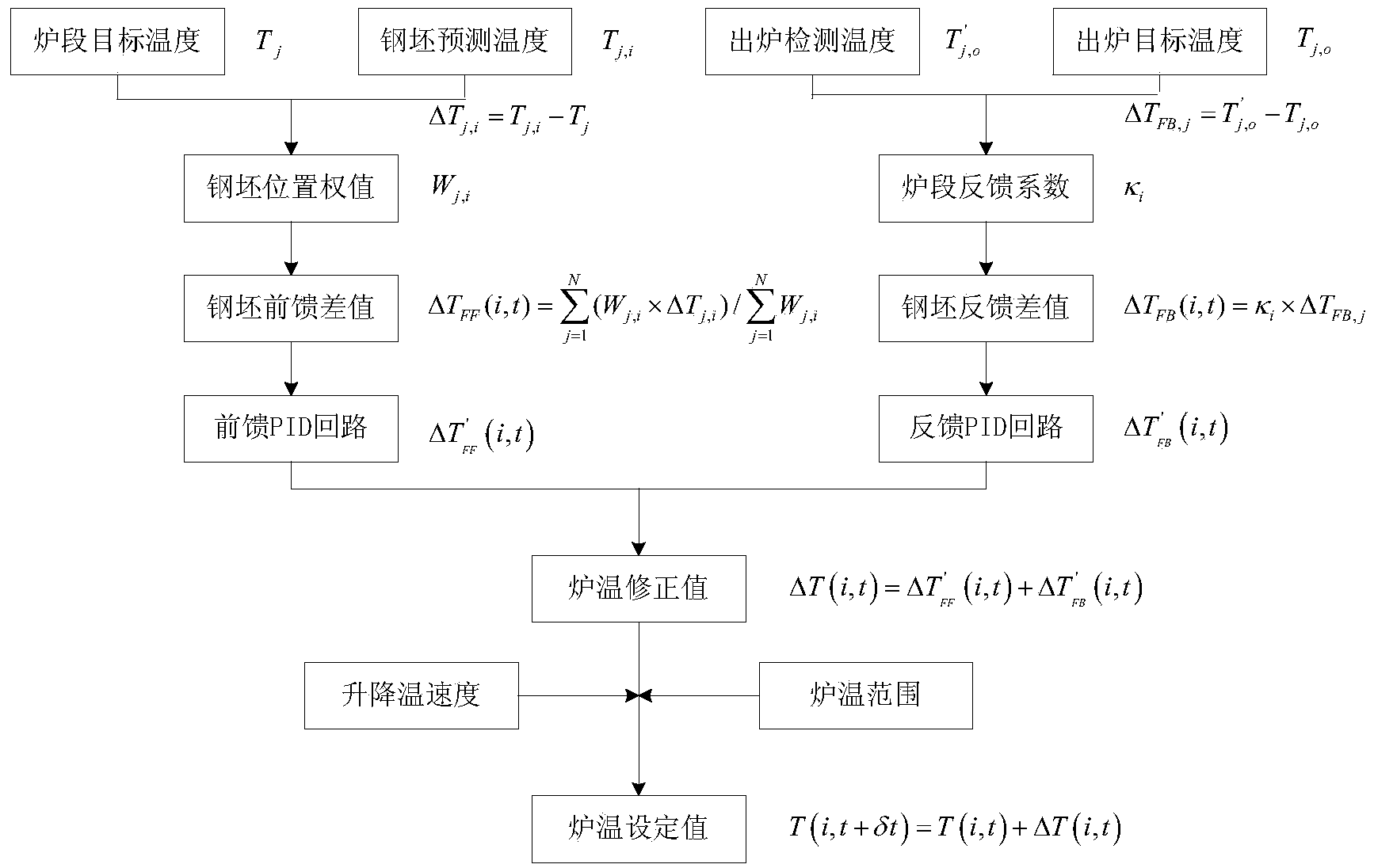

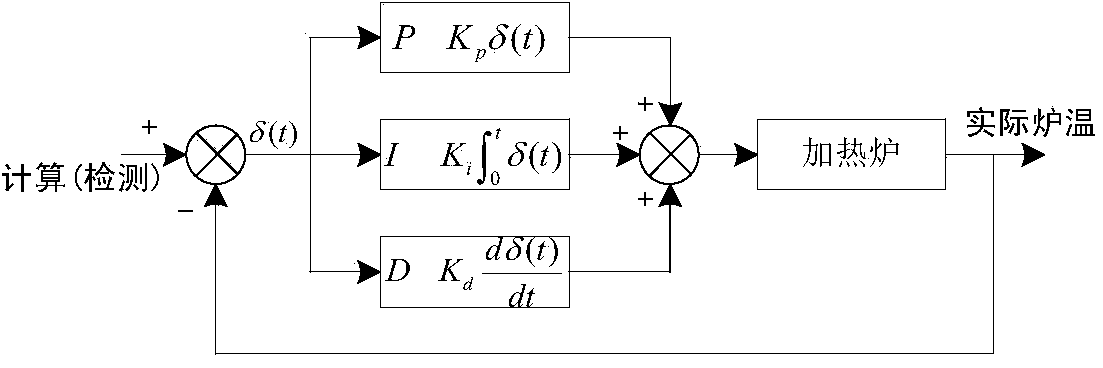

[0030] A method for determining the furnace temperature setting value of a billet heating furnace, specifically comprising the following steps:

[0031] S1: For each control section, predict the difference between the temperature of the bill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com