Furnace temperature control method and control equipment for open fire heating furnace

一种控制方法、加热炉的技术,应用在照明和加热设备、温度控制、热处理设备等方向,能够解决温度设定值变化的前瞻性缺乏预判、炉温过渡时间长、炉温难稳定下来等问题,达到缩小过渡时间、快速性好、超调小的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

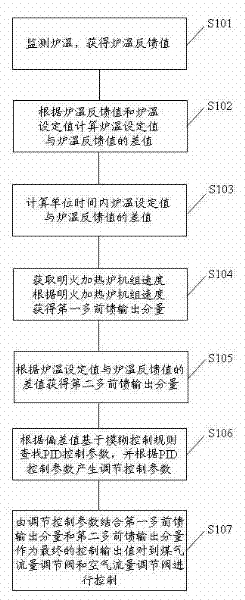

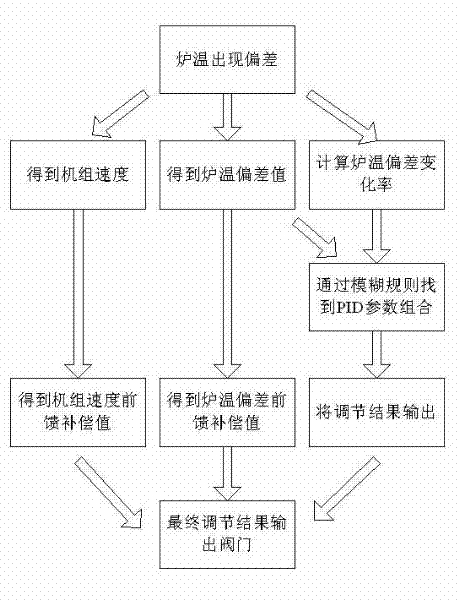

[0034] refer to figure 1 As shown, the present invention discloses a method for controlling the temperature of an open flame heating furnace, comprising the following steps:

[0035] S101. Monitor the furnace temperature to obtain a furnace temperature feedback value.

[0036] S102. Calculate the difference between the furnace temperature setting value and the furnace temperature feedback value according to the furnace temperature feedback value and the furnace temperature setting value, and use the difference as the deviation value DV 1 . In one embodiment, the deviation value DV between the furnace temperature setting value and the furnace temperature feedback value 1 It is set as a fuzzy control subset, fuzzy control subset E = {NB, NM, NS, ZE, PS, PM, PB} = {negative large, negative medium, negative small, zero, positive small, positive medium, positive large }={-18,-12,-6,0,6,12,18}. That is, according to the deviation value DV 1 Compared with the size of the set {-18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com