Patents

Literature

169results about "Combustion regulation systems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

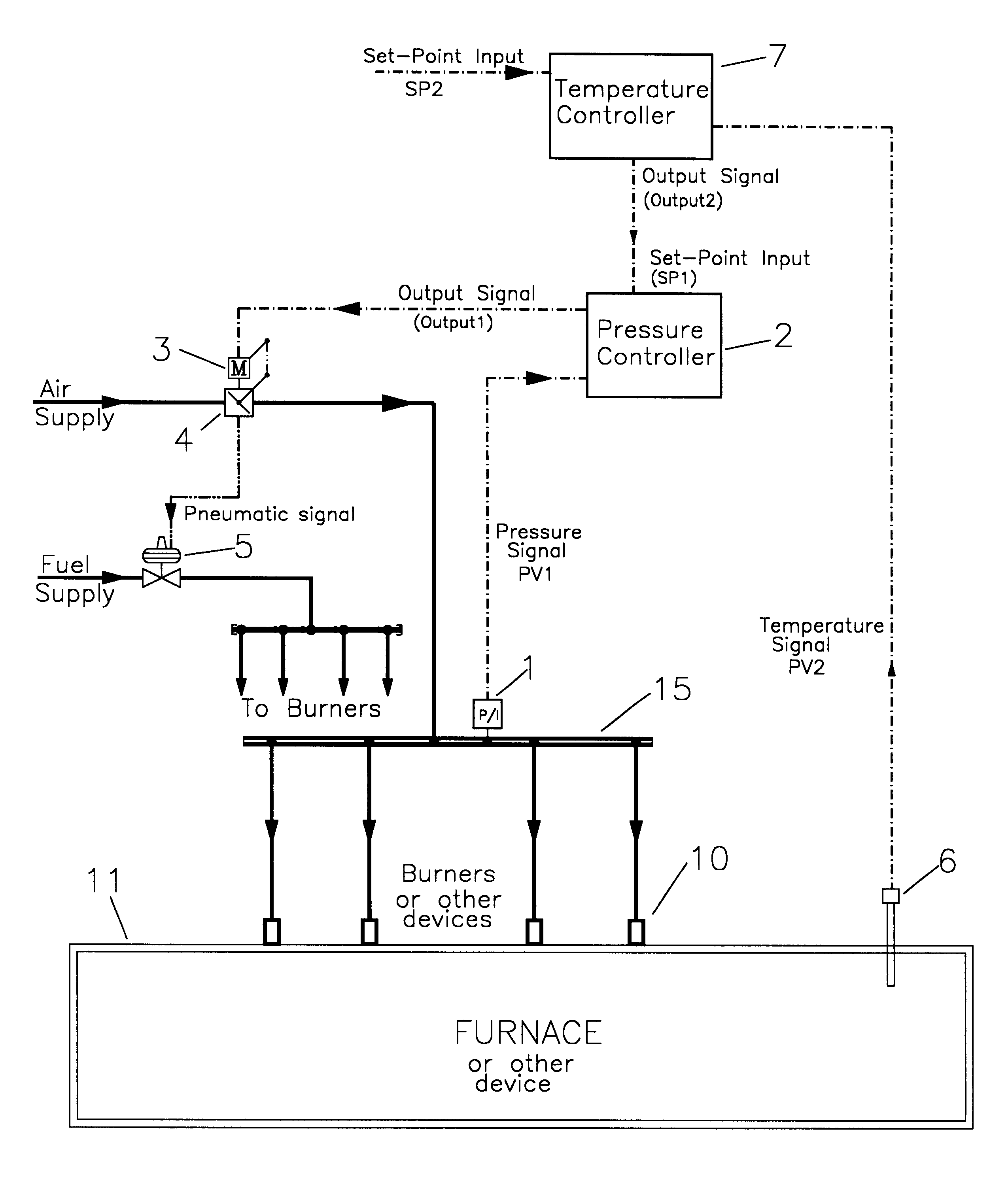

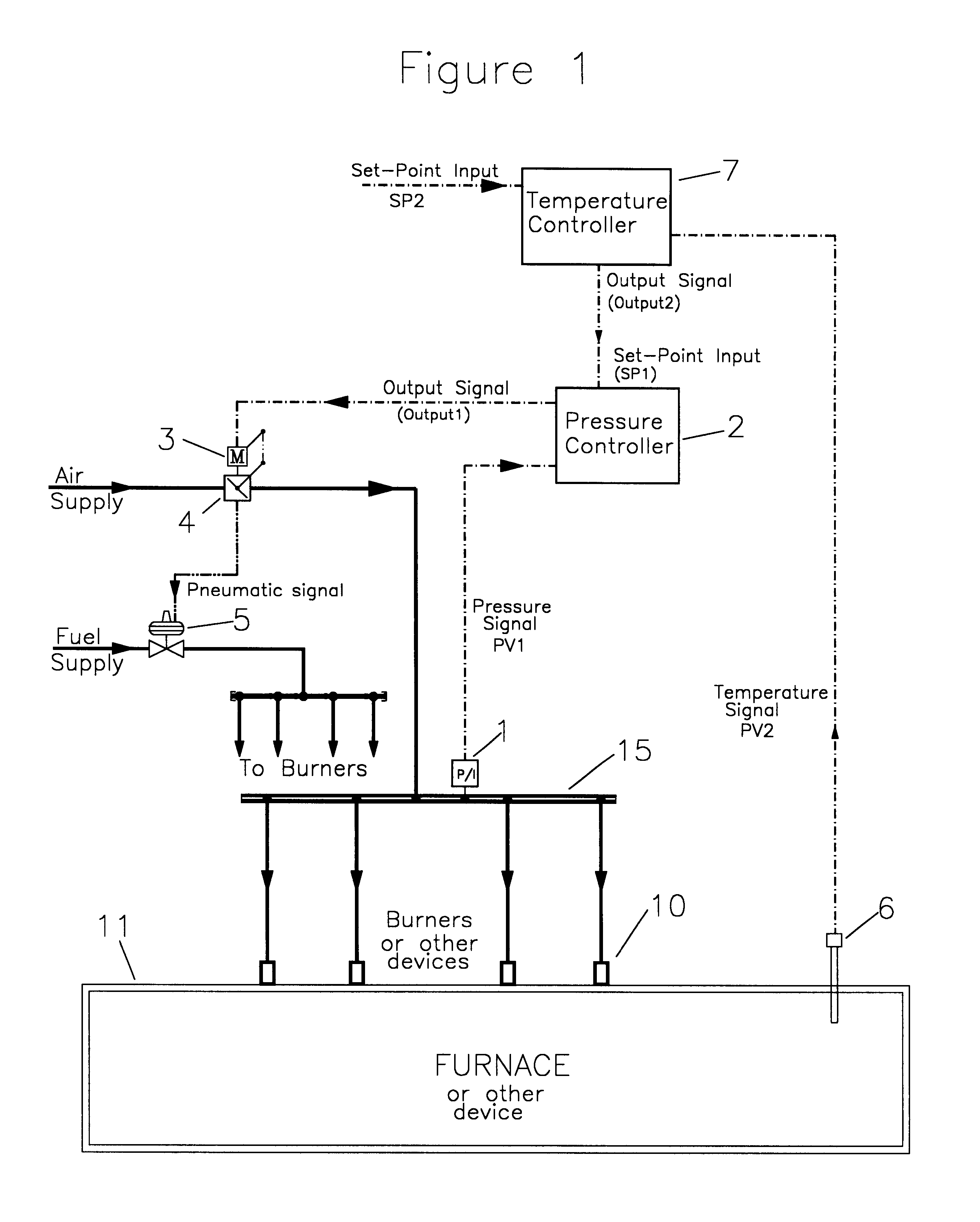

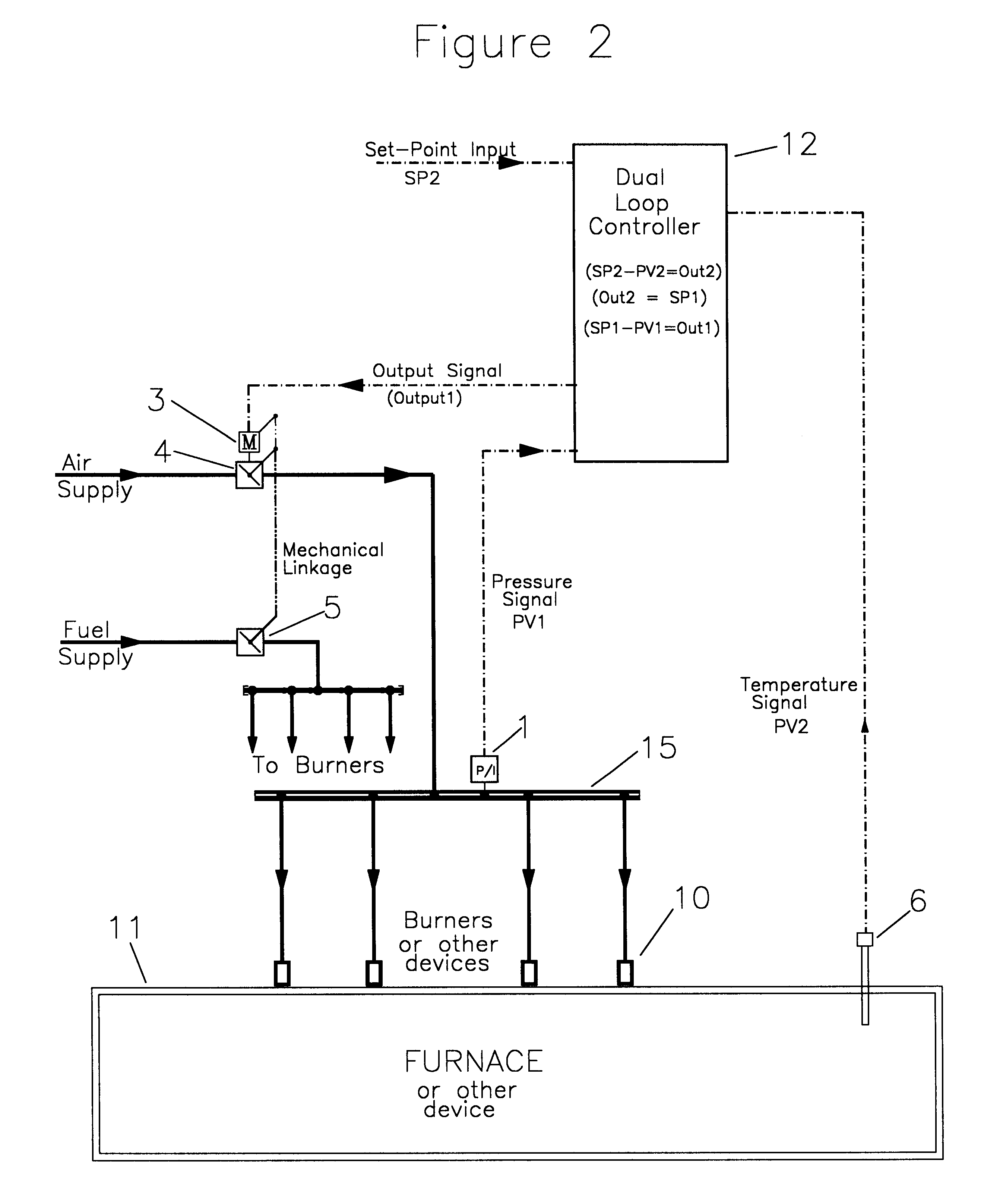

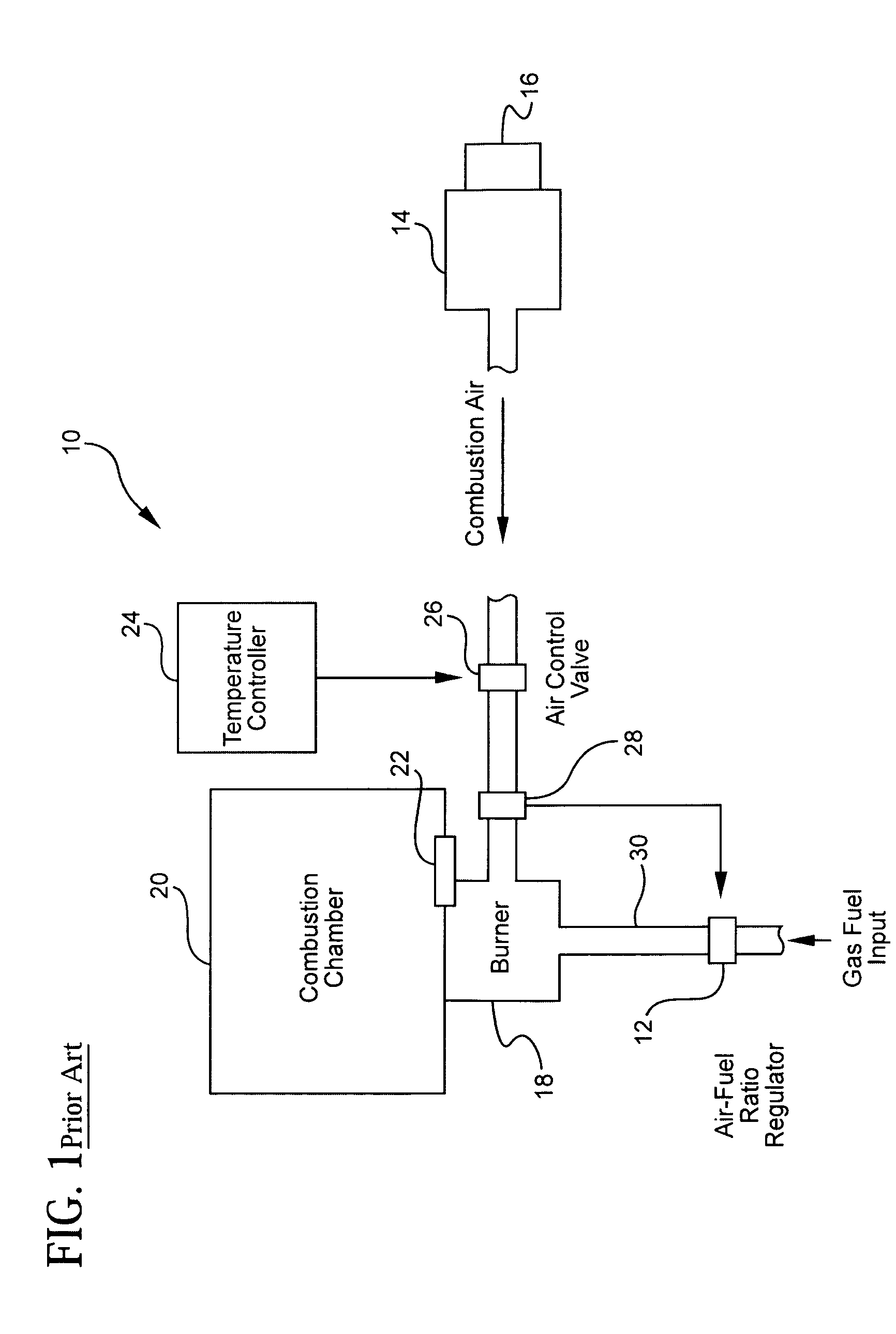

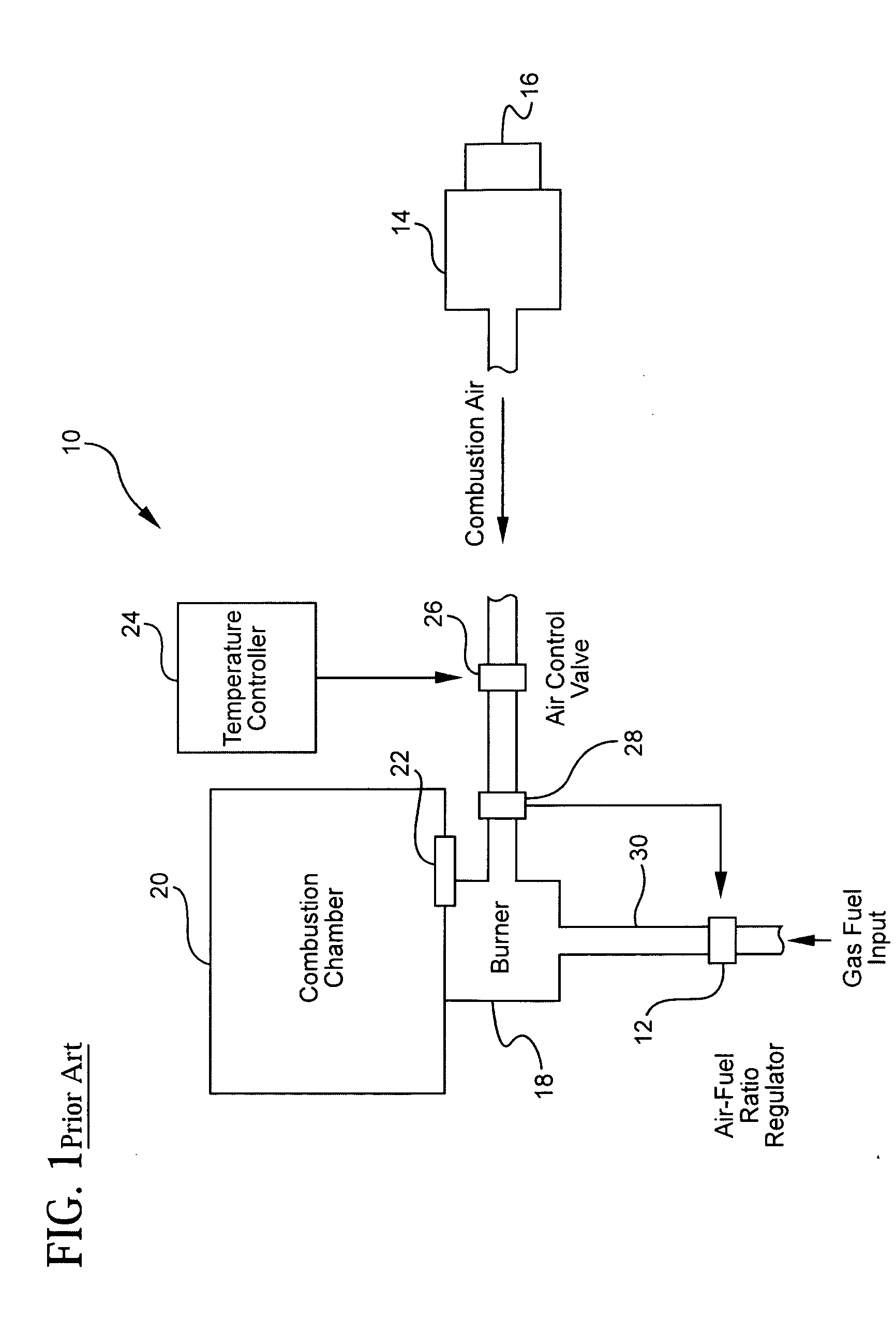

Pressure feedback signal to optimise combustion air control

InactiveUS6332408B2Fuel supply regulationCombustion regulation systemsFurnace temperatureRate change

A novel method of combustion air control for multiple burner furnaces, whereas a pressure transducer is located in the air piping downstream of each zone air flow control device. The pressure transducer sends a feedback signal to a pressure control loop that is in a logical cascade from the furnace temperature control loop. The pressure control loop repositions the air flow control device to compensate for changes in both downstream and upstream conditions. Output from the temperature control loop is interpreted by the pressure control loop as a changing remote set-point value. In one embodiment, the system is ideally suited to compensate for the pressure drop changes that occur across a zone air flow control valve, when flow rate changes occur as burners are started or stopped, thus providing a substantially higher turndown ratio and better control at low fire settings.

Owner:HOWLETT MICHAEL +2

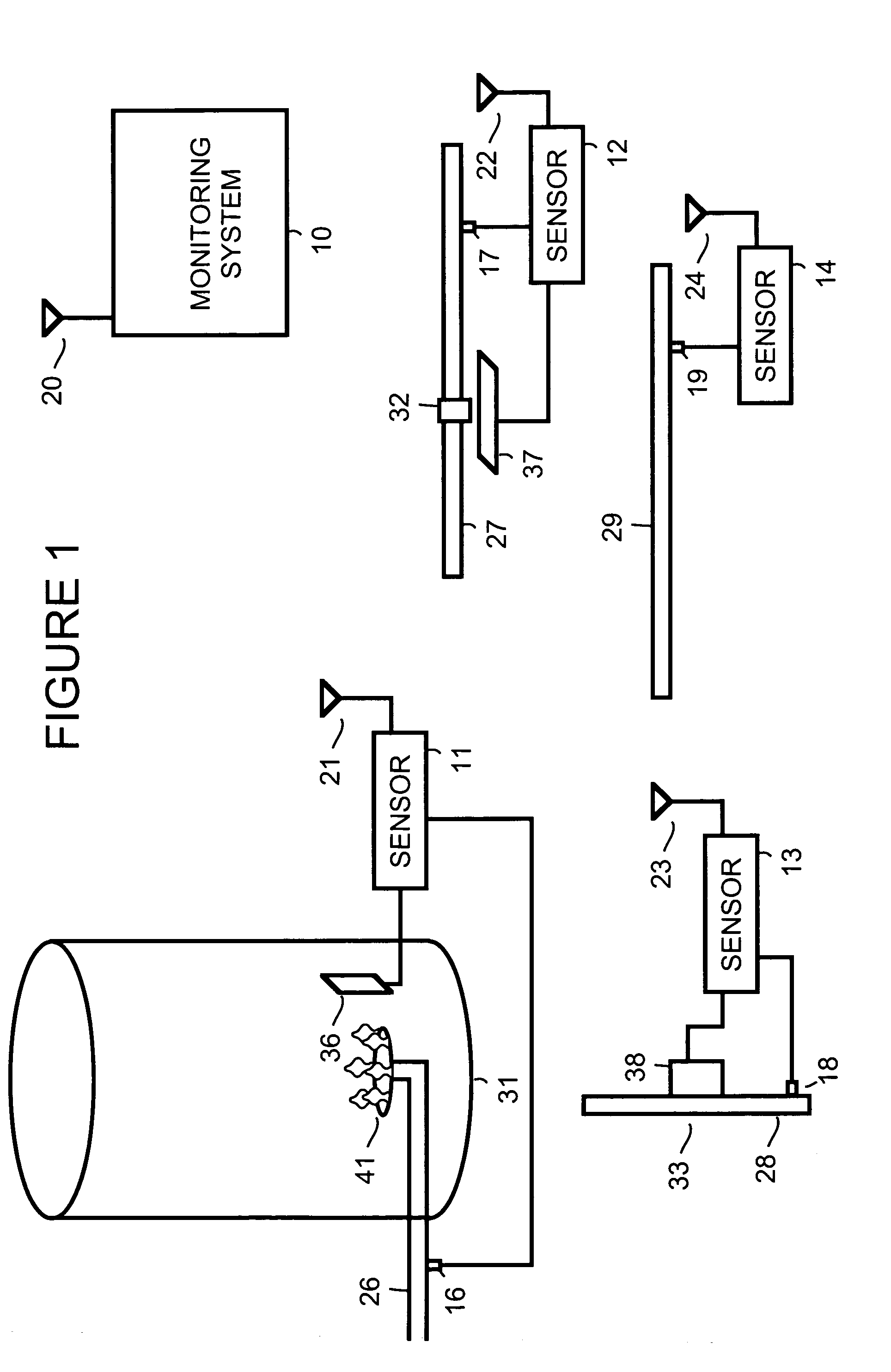

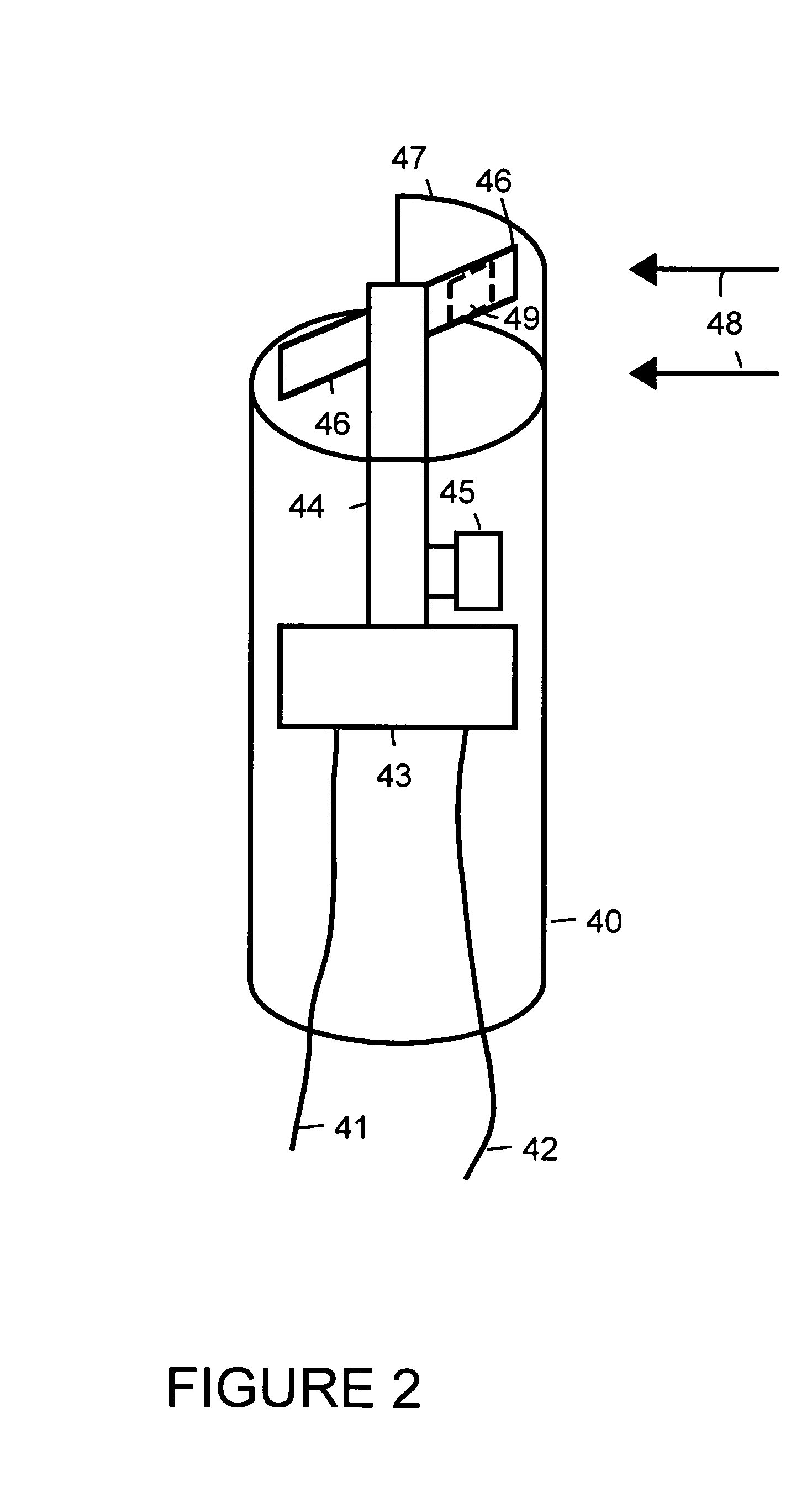

Power source for sensors

InactiveUS7112892B2Machines/enginesEngine componentsMonitoring systemElectrical and Electronics engineering

A sensor is placed in wireless communication with a monitoring system. Power for the sensor is generated by scavenging power from fluid flow within a pipe.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

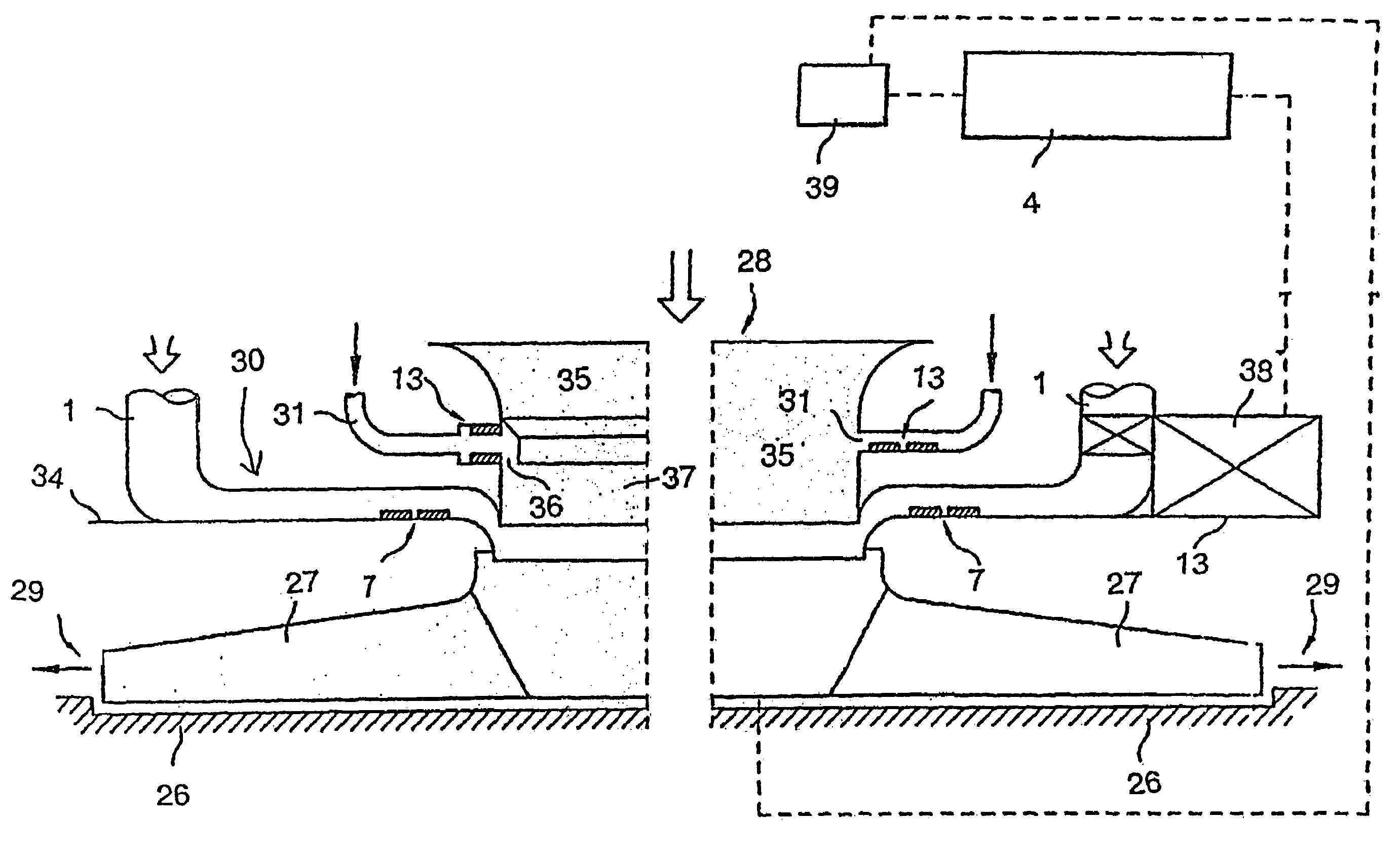

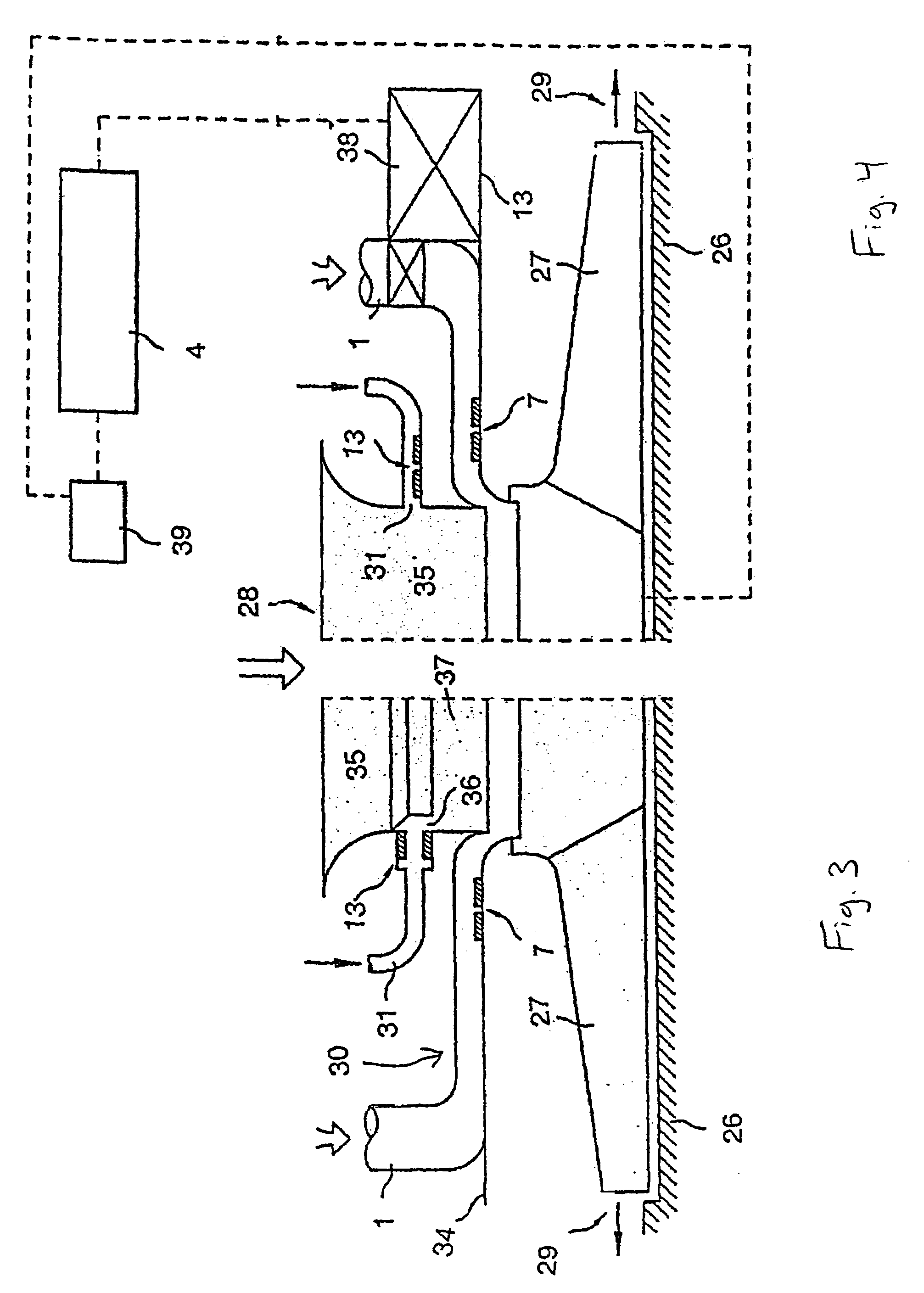

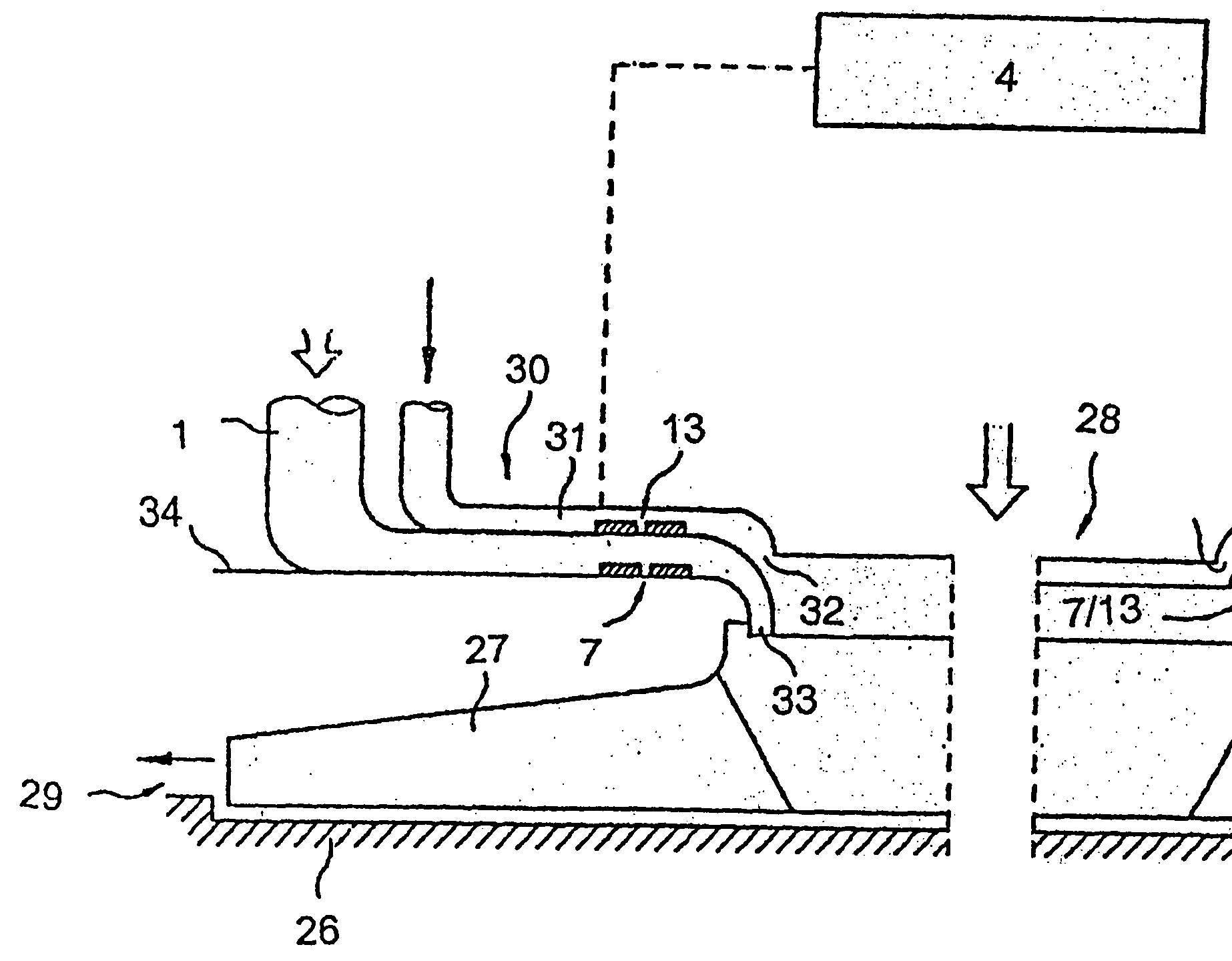

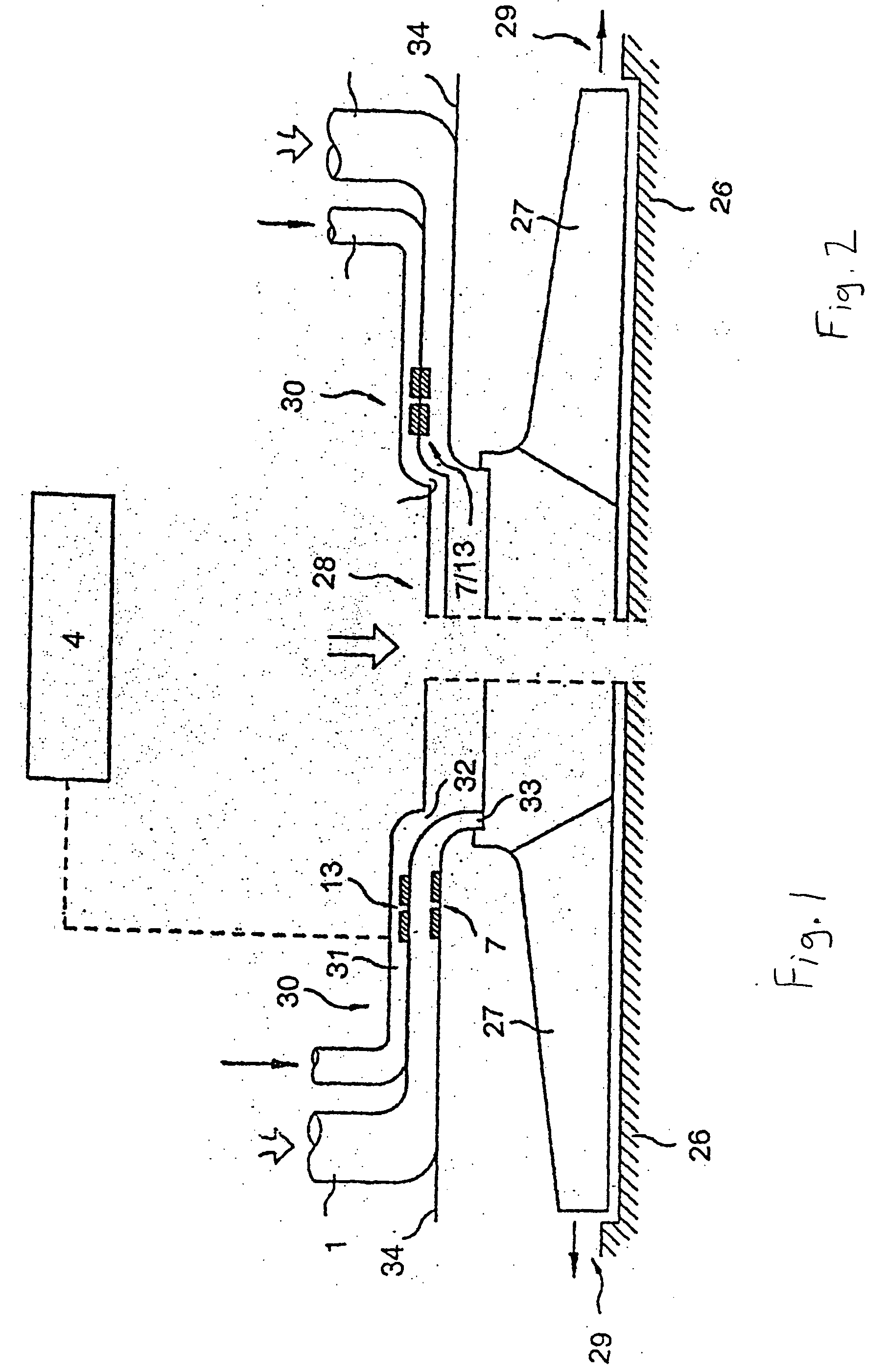

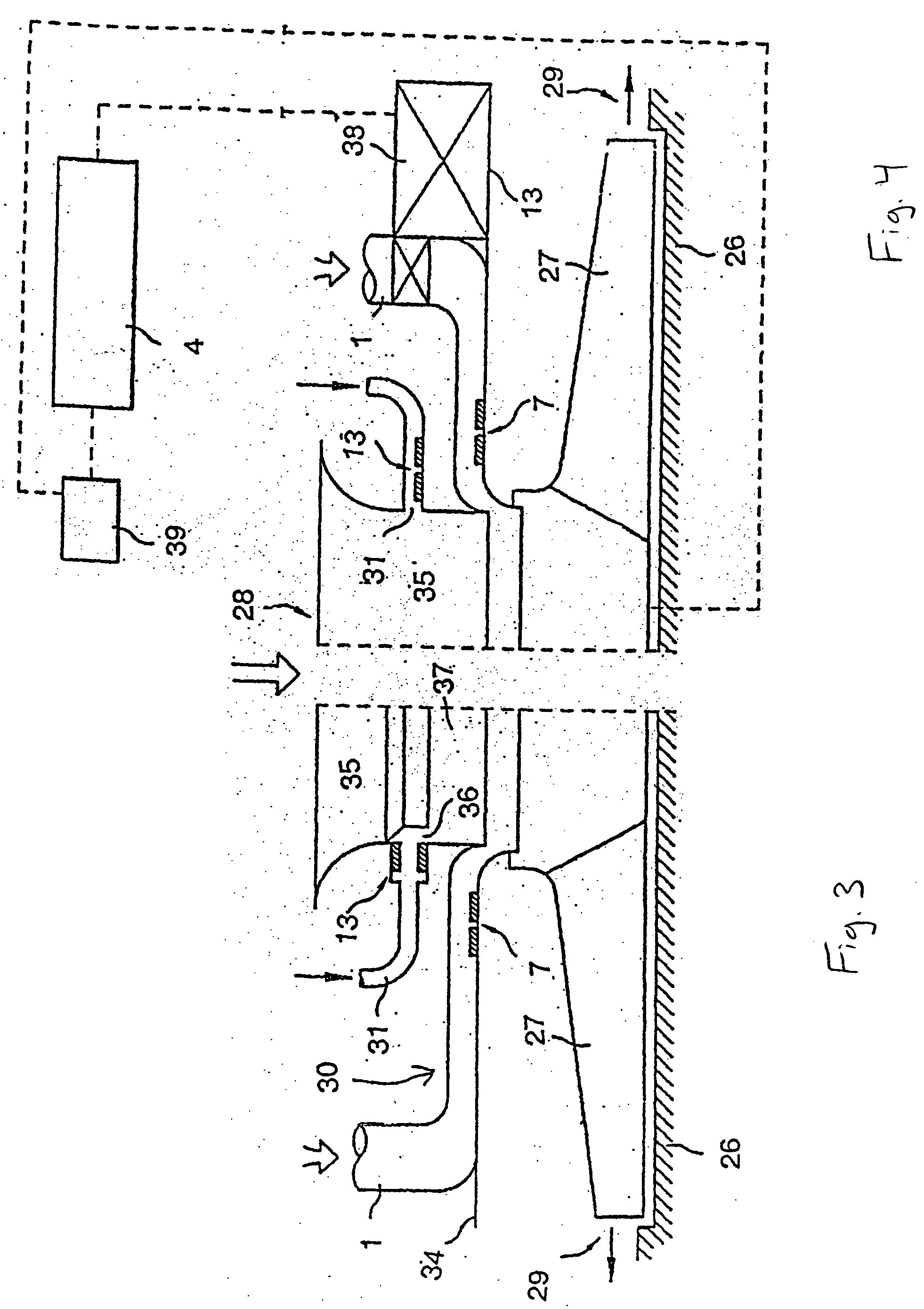

Blower for combustion air

InactiveUS7223094B2Work lessContinuous suctionFuel supply regulationAir supply regulationImpellerCombustion

A blower for combustion air in a wall / floor furnace is provided that includes a blower housing (26), and blower wheel (27), with an air inlet (28) and an air outlet (29), and with a fuel feeder line (1) for fuel, wherein a mass current sensor (13) for determining the air mass current is located on the air inlet (28), which is functionally connected with a data processing device (4) and sends signals to the data processing device for calculation of a ratio of combustion medium to combustion air in dependence on a desired heating capacity.

Owner:EBM PAPST LANDSHUT

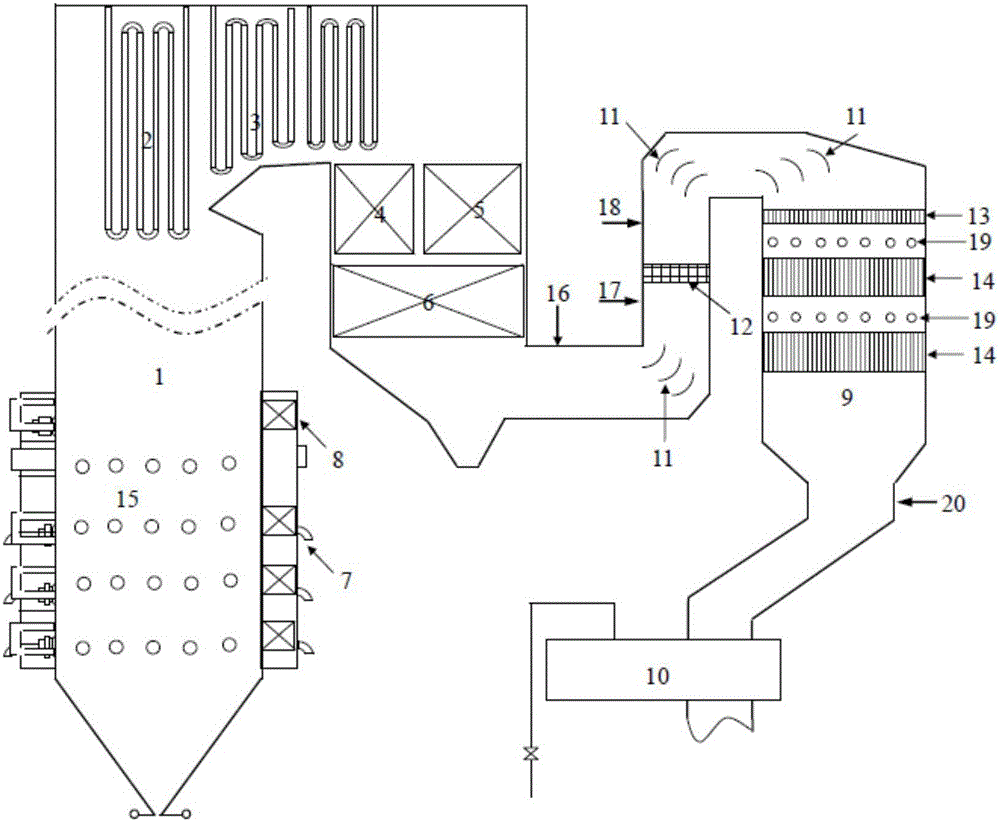

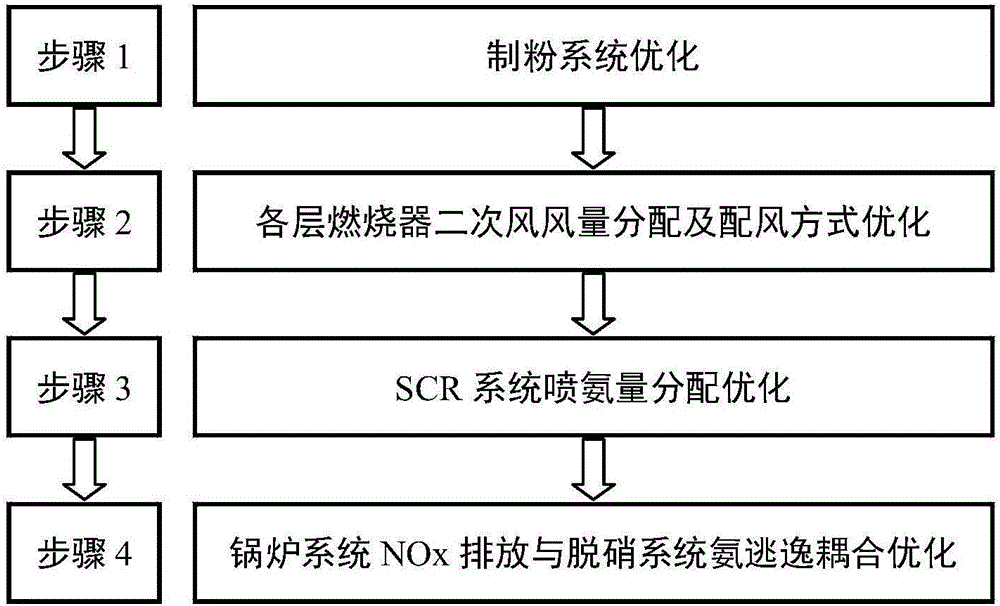

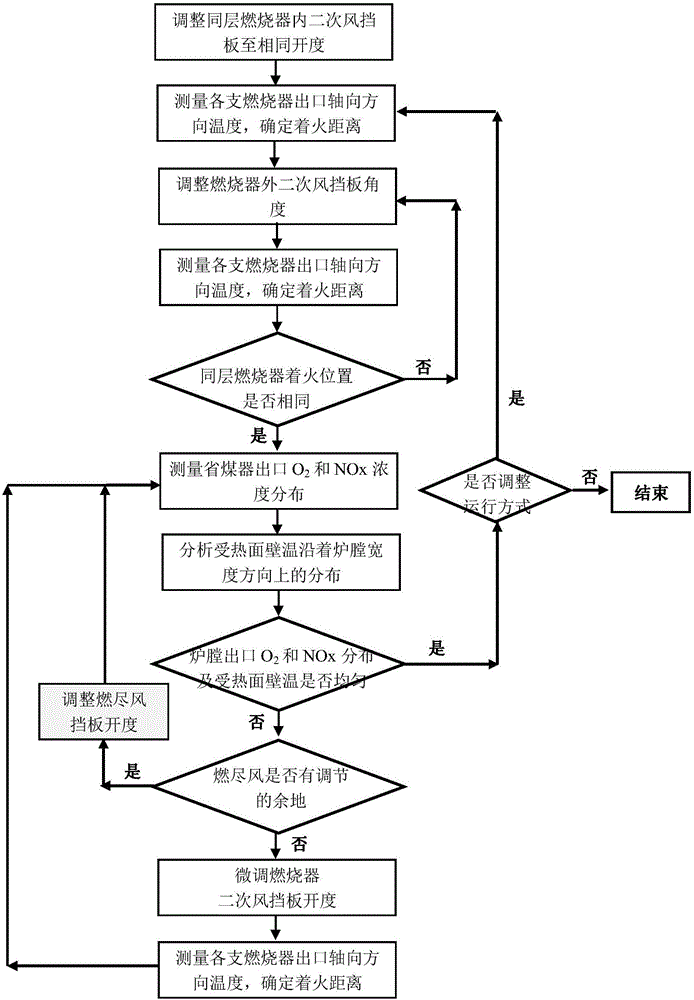

Coal-fired power plant boiler system and denitration system operation collaborative optimization method

ActiveCN105953259AEconomic operation modeGuaranteed operational safetyFuel supply regulationFuel feeding arrangementsOperation modeOxygen

The invention provides a coal-fired power plant boiler system and denitration system operation collaborative optimization method. The method comprises the following steps: the operation of a powder preparation system is optimized and adjusted; the operation of a combustion system is optimized and adjusted; the operation of a denitration system is optimized and adjusted; the coal-fired boiler NOx emission control and the SCR denitration system ammonia escape control are coupled for optimization and adjustment; an optimal operation oxygen quantity range of a coal-fired boiler under different loads and an optimal openness range of a burnt wind nozzle in the optimal oxygen quantity operation range are determined by combining the reductive atmosphere distribution characteristics in a near wall area of a hearth water cooling wall and the denitration ammonia escape conditions; and an optimal denitration efficiency range of the denitration system under different loads is determined. The three system operation collaborative optimization methods, provided by the invention, see the boiler system and the denitration system as a large system; the mutual correlation and influence among the three systems are decoupled from the angle of the large system; and the most economical and safest operation mode of the large system is obtained through optimization.

Owner:GUODIAN NANJING ELECTRIC POWER TEST RES CO LTD

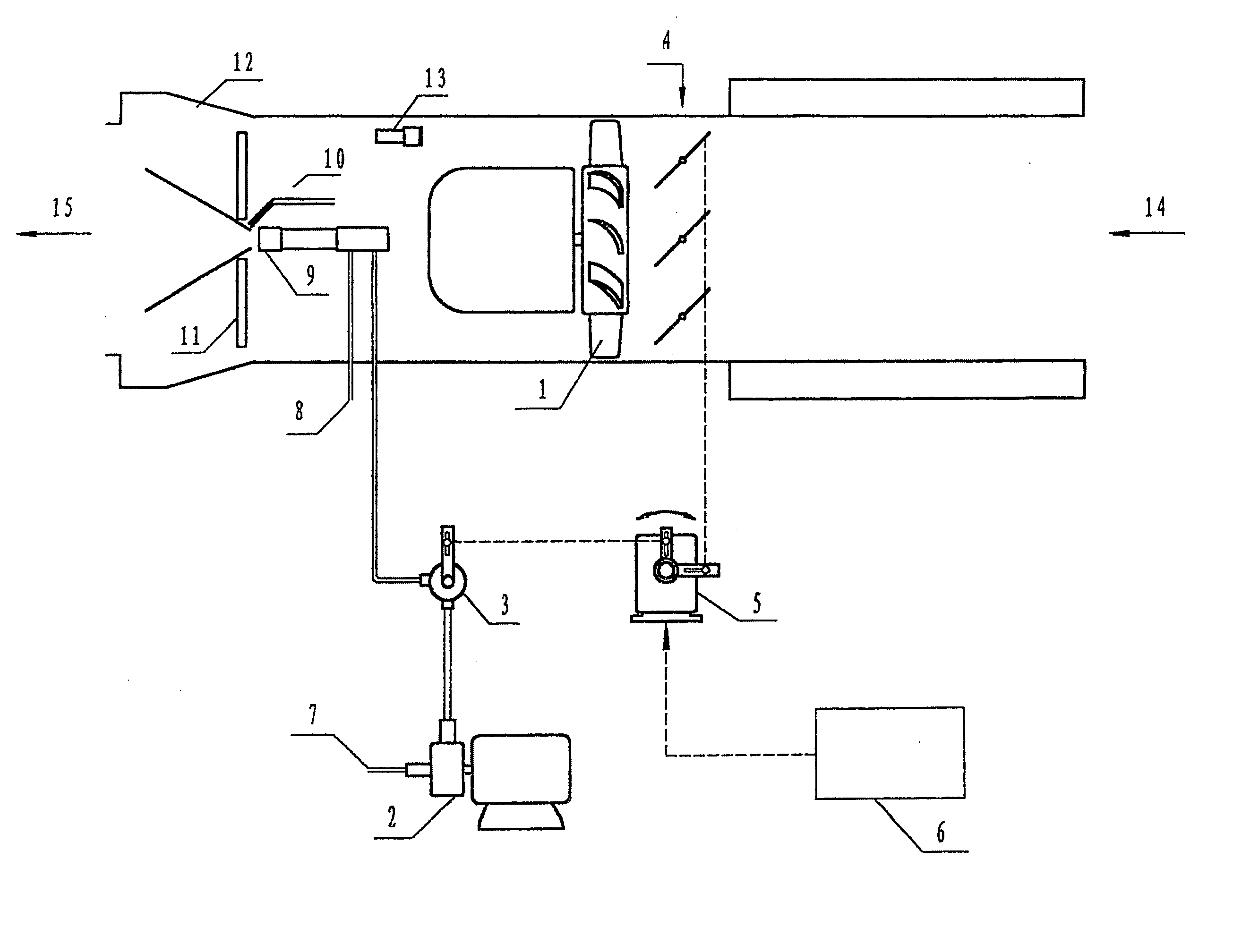

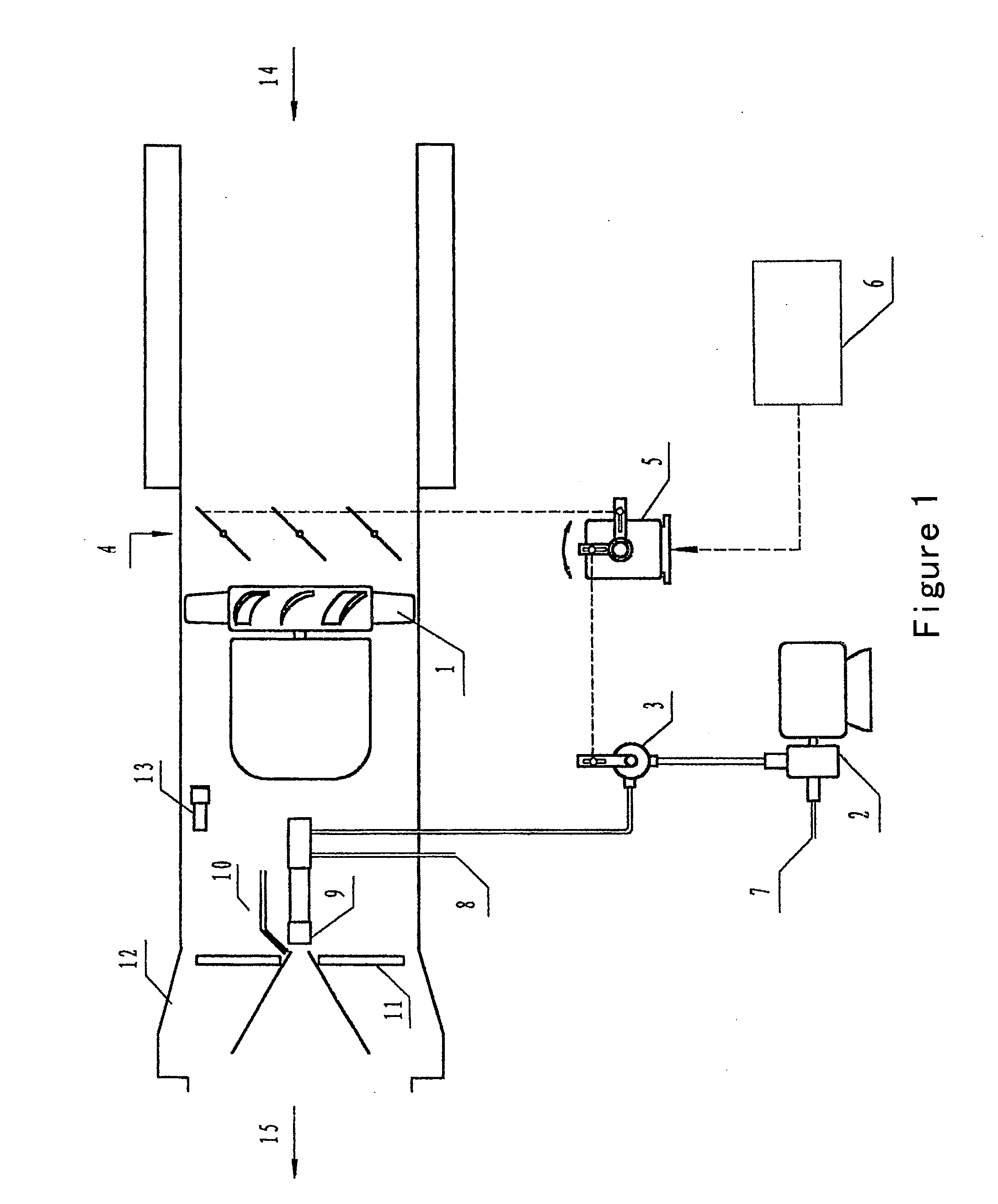

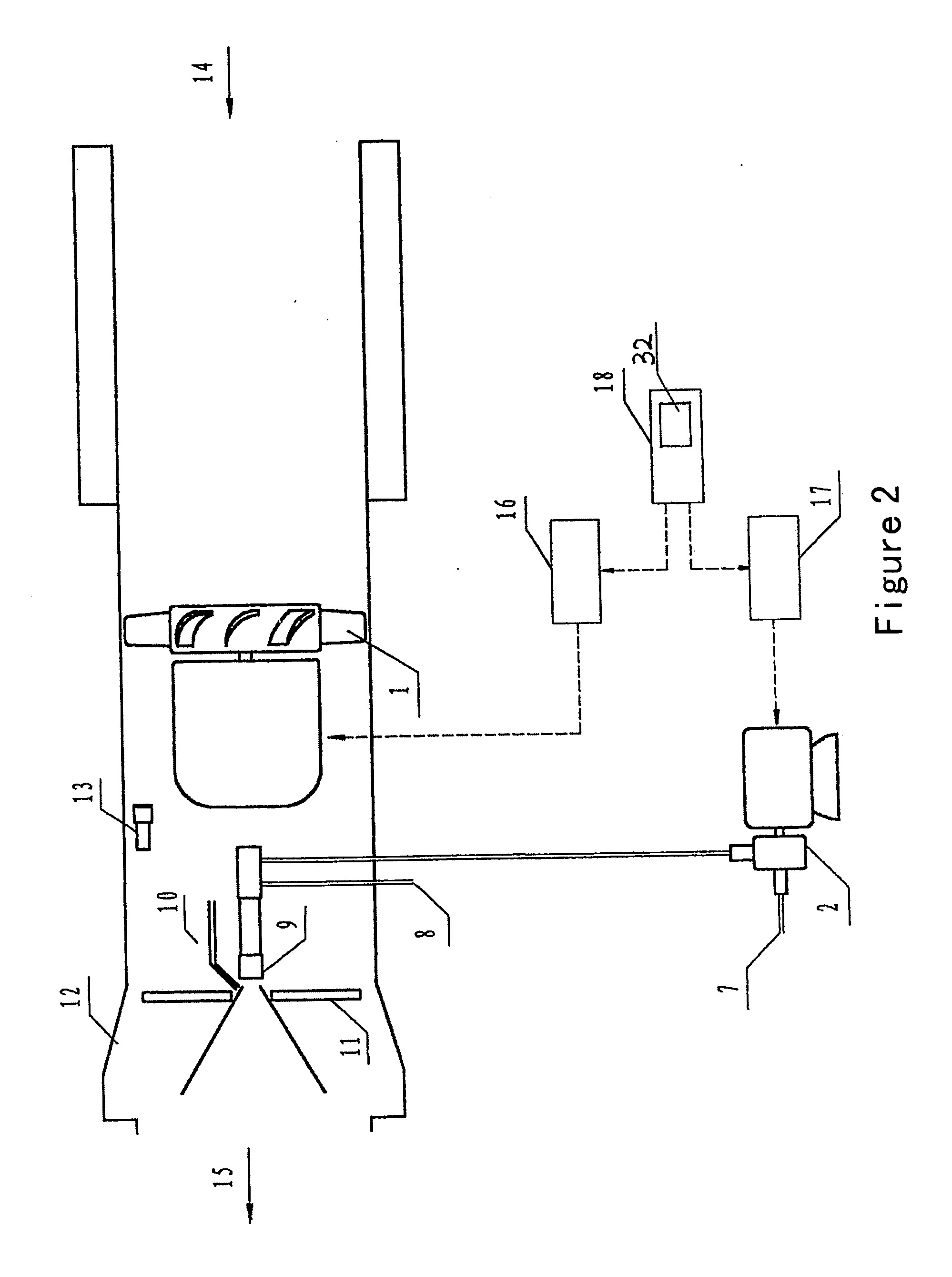

Autocontrol burner and a combustion control method

InactiveUS20060068347A1Improve efficiencyReduce energy consumptionBurnersFuel supply regulationMotor speedCombustor

A combustion control method for a burner comprises: the fuel supplying means outputs a given amount of fuel oil to the fuel oil atomizing means; the fuel atomizing means sprays fuel atomized gas; said gas is ignited by the igniter; the amount of air is sent to facilitate burning by the air blowing means; the outputting flow rate of fuel oil and the flow rate of air are adjusted automatically, simultaneously and proportionally by controlling the rotating speed of the electric motors of the fuel supplying means and the air blowing means. An autocontrol burner comprises a main body, an oil pump (2), a blower fan (1), a spray gun (9) and an ignition gun (10), and further comprises a programmable control unit (18), motor speed controller (16,17) and a signal acquisition assembly. The output port of the signal acquisition assembly is connected with the input port of the programmable control unit (18). The oil pump (2) and the blower fan (1) are connected with the programmable control unit (18) by the motor speed controller (16, 17).

Owner:LI YANXIN

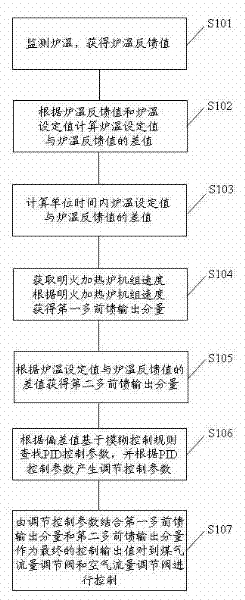

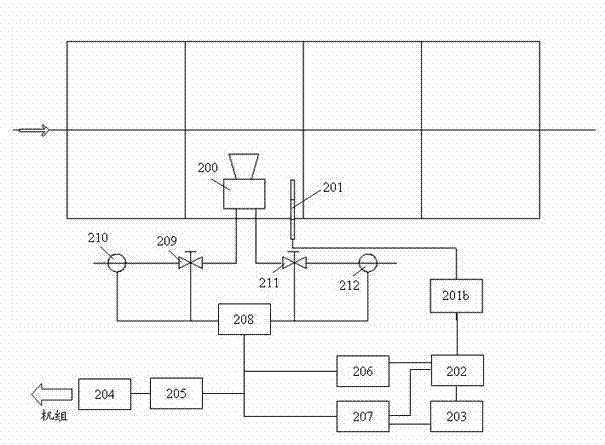

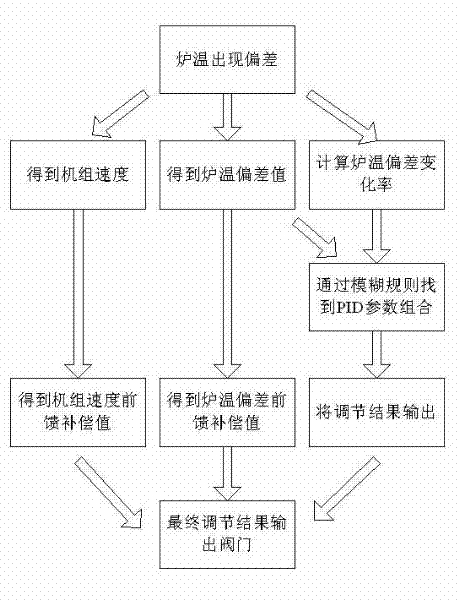

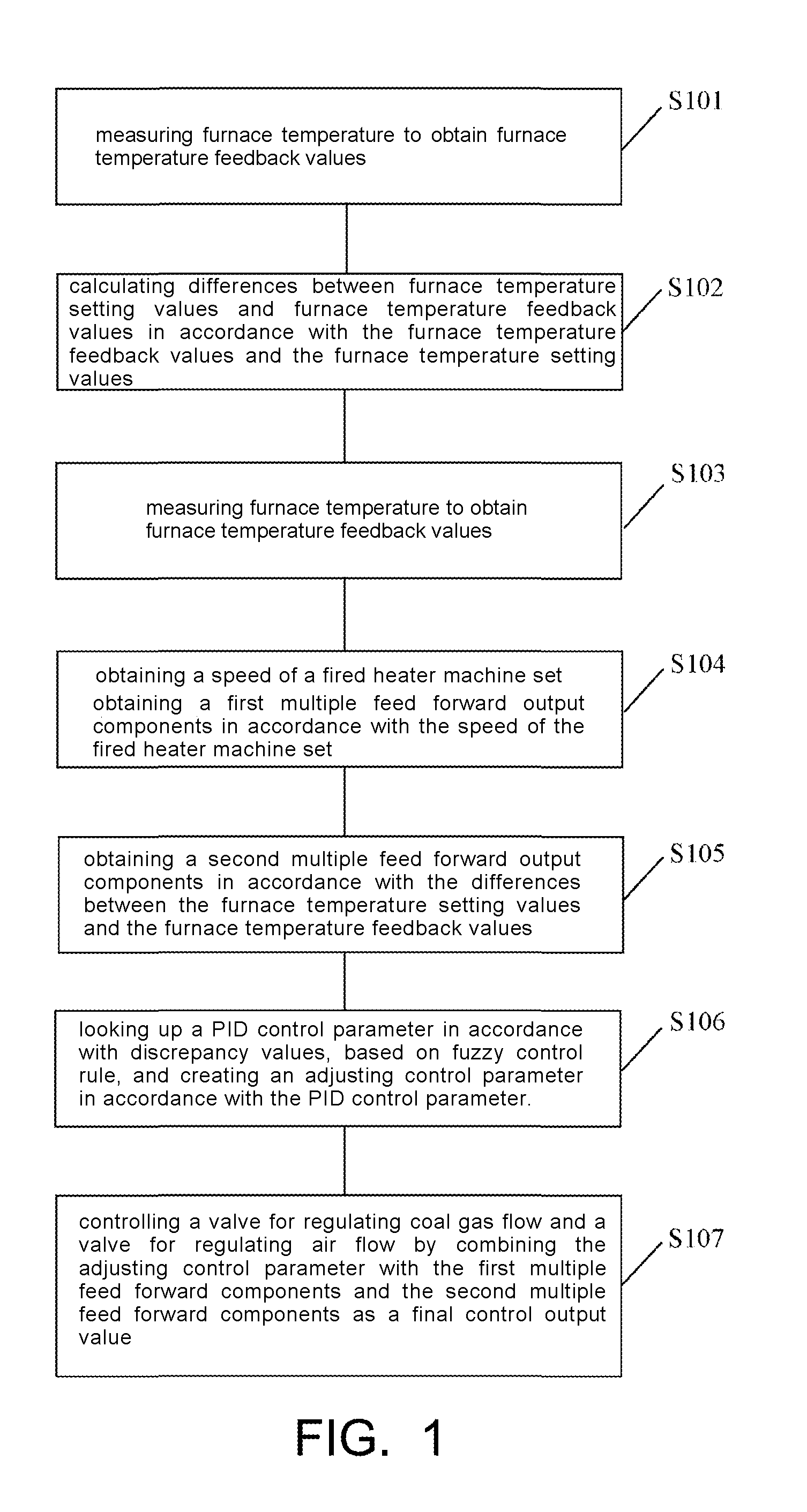

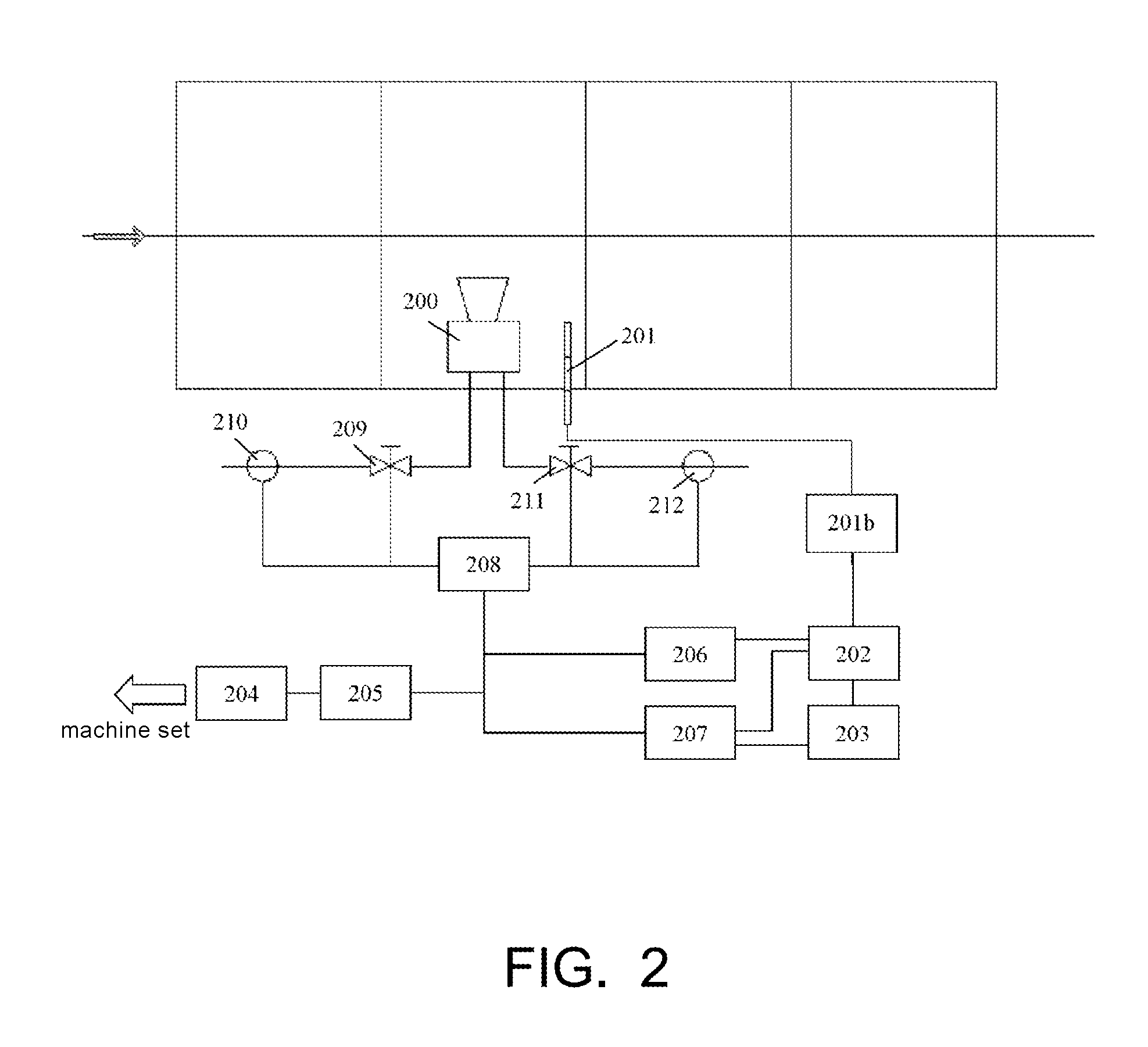

Furnace temperature control method and control equipment for open fire heating furnace

ActiveCN102455135AFuel supply regulationTesting/monitoring control systemsFurnace temperatureThermodynamics

The invention discloses a furnace temperature control method for an open fire heating furnace, comprising the steps of monitoring the furnace temperature to obtain a furnace temperature feedback value; calculating the difference of a furnace temperature setting value and a furnace temperature feedback value according to the furnace temperature feedback value and the furnace temperature setting value as a deviation value DV1; calculating the difference of the furnace temperature setting value and the furnace temperature feedback value in a unit time, namely, the rake ratio of a furnace temperature change value is used as a deviation value DV2; obtaining the speed V of an open fire heating furnace unit from a speed regulator of the open fire heating furnace unit and obtaining a first multi-feed-forward output component FFV according to the unit speed V; obtaining a second multi-feed-forward output component FFT according to the difference of the furnace temperature setting value and the furnace temperature feedback value as a deviation value DV1; searching a PID (proportion integration differentiation) control parameter based on a fuzzy control rule according to the deviation value DV1 and the deviation value DV2 and generating a modulating control parameter OP1 according to the PID control parameter; making the finally control output value by combining the modulating control parameter OP1 with the first multi-feed-forward output component FFV and the second multi-feed-forward output component FFT to control a gas flow rate adjusting valve and an air flow rate adjusting valve.

Owner:BAOSHAN IRON & STEEL CO LTD

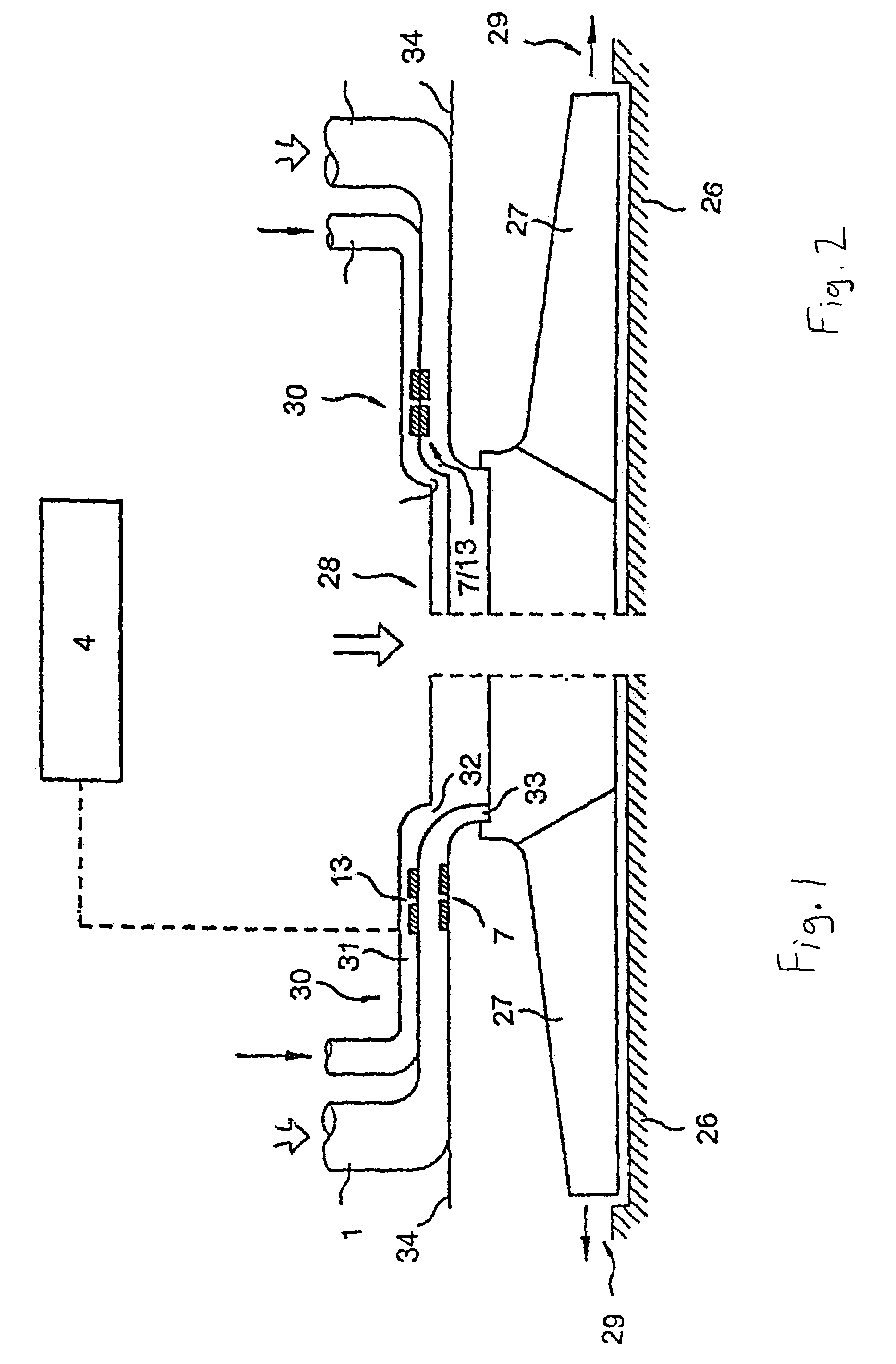

Blower for combustion air

InactiveUS20050255418A1Improve combustion conditionsContinuous suctionPump componentsMachines using electric/magnetic effectsImpellerCombustion

A blower for combustion air in a wall / floor furnace is provided that includes a blower housing (26), and blower wheel (27), with an air inlet (28) and an air outlet (29), and with a fuel feeder line (1) for fuel, wherein a mass current sensor (13) for determining the air mass current is located on the air inlet (28), which is functionally connected with a data processing device (4) and sends signals to the data processing device for calculation of a ratio of combustion medium to combustion air in dependence on a desired heating capacity.

Owner:EBM PAPST LANDSHUT

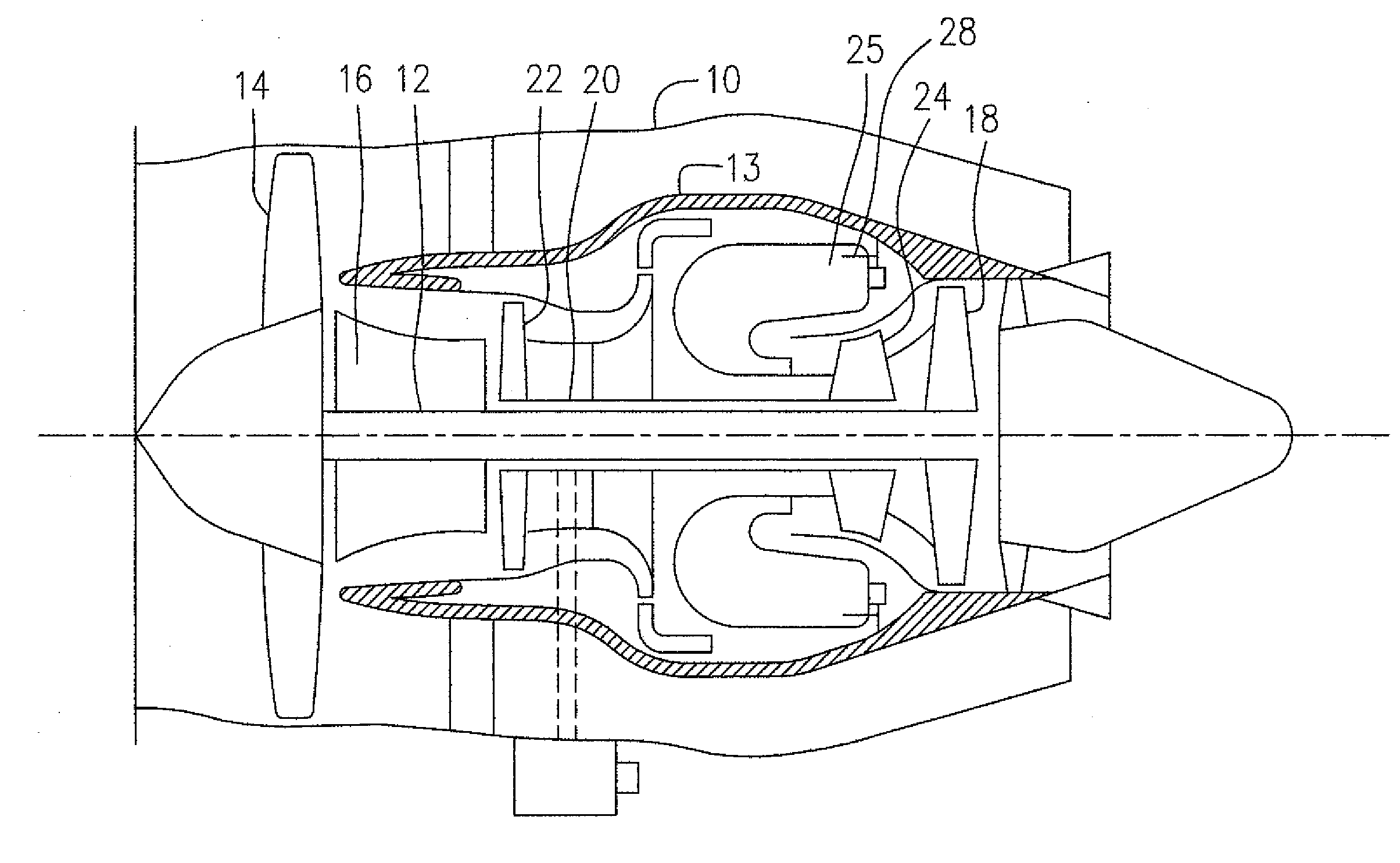

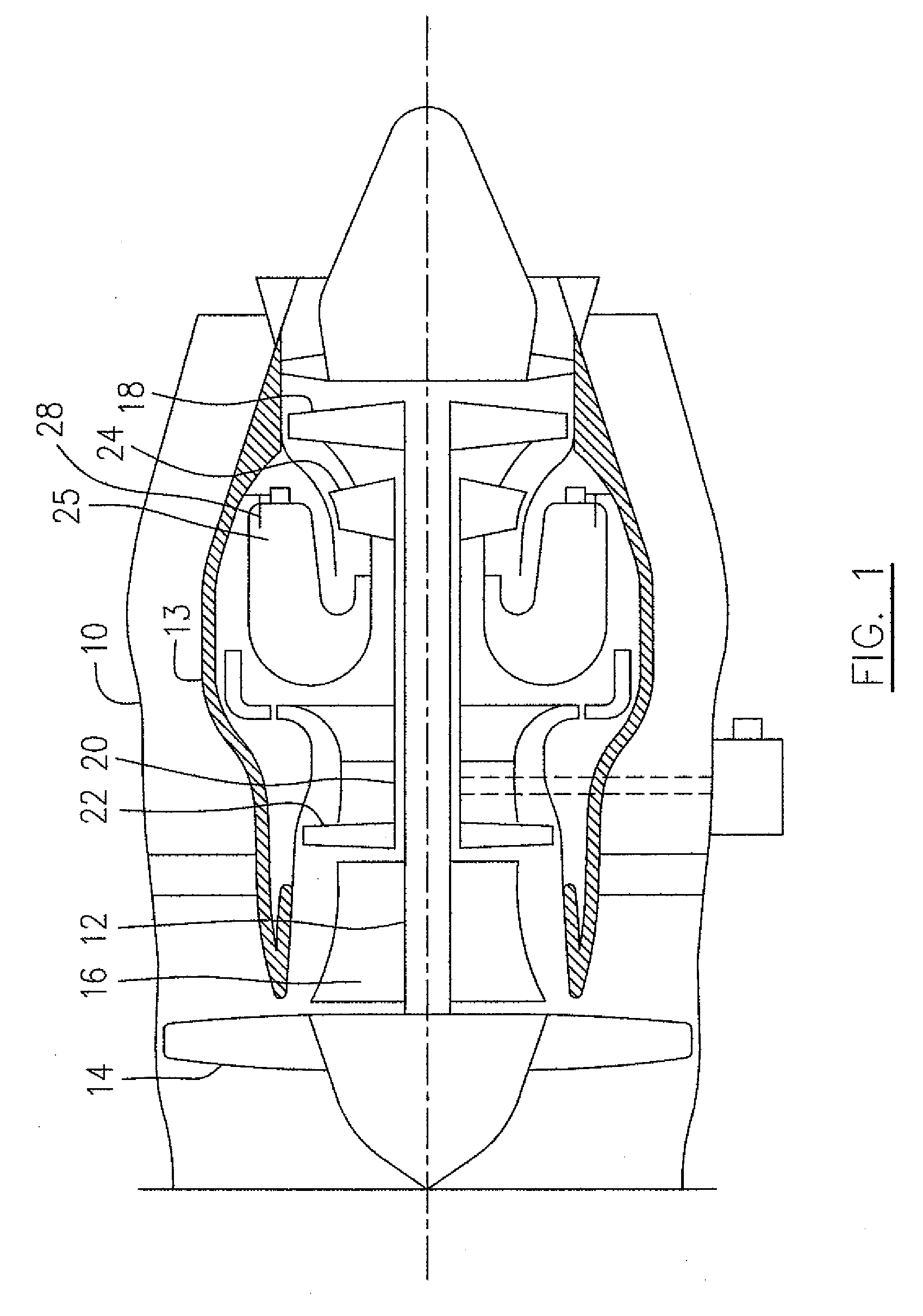

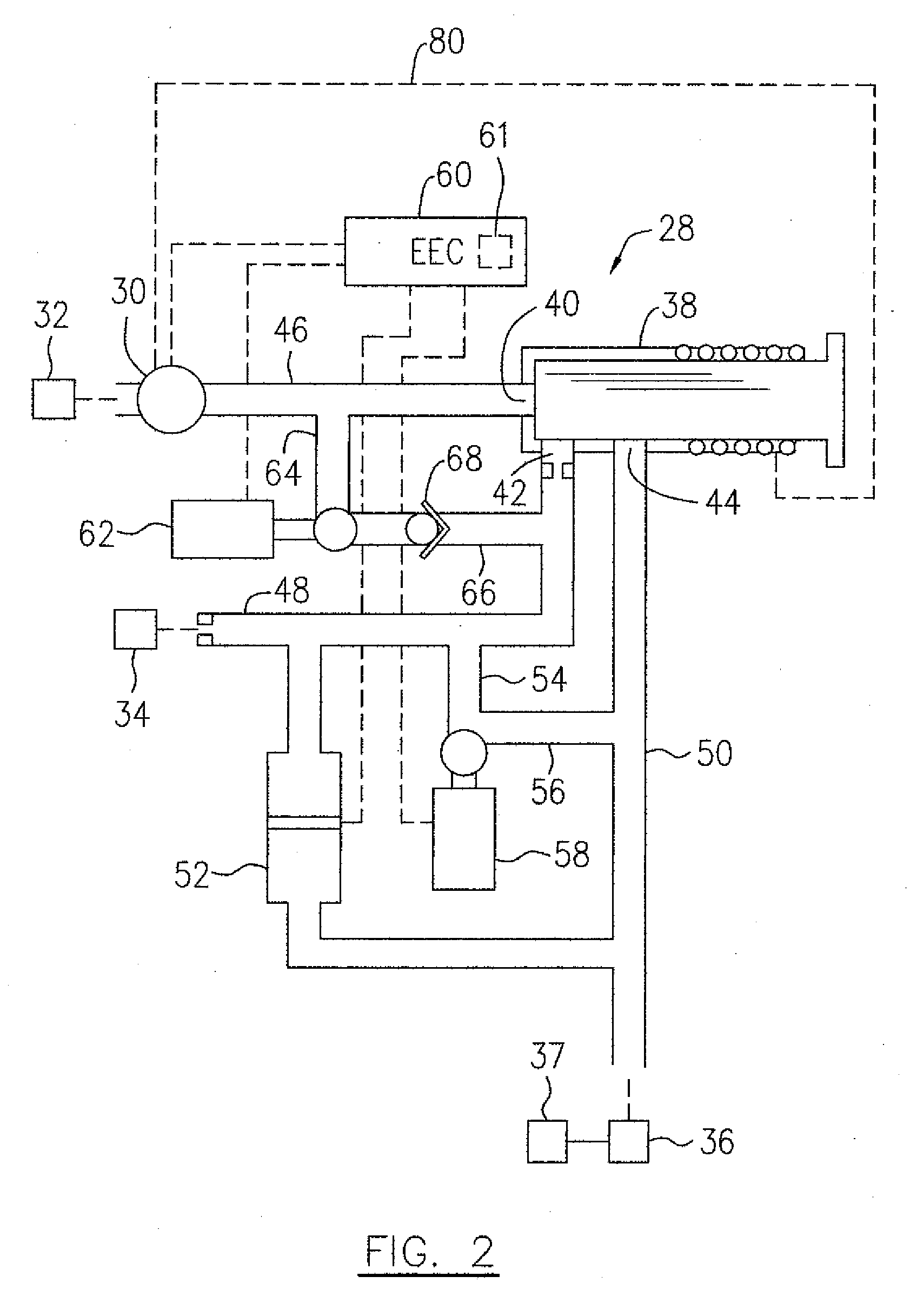

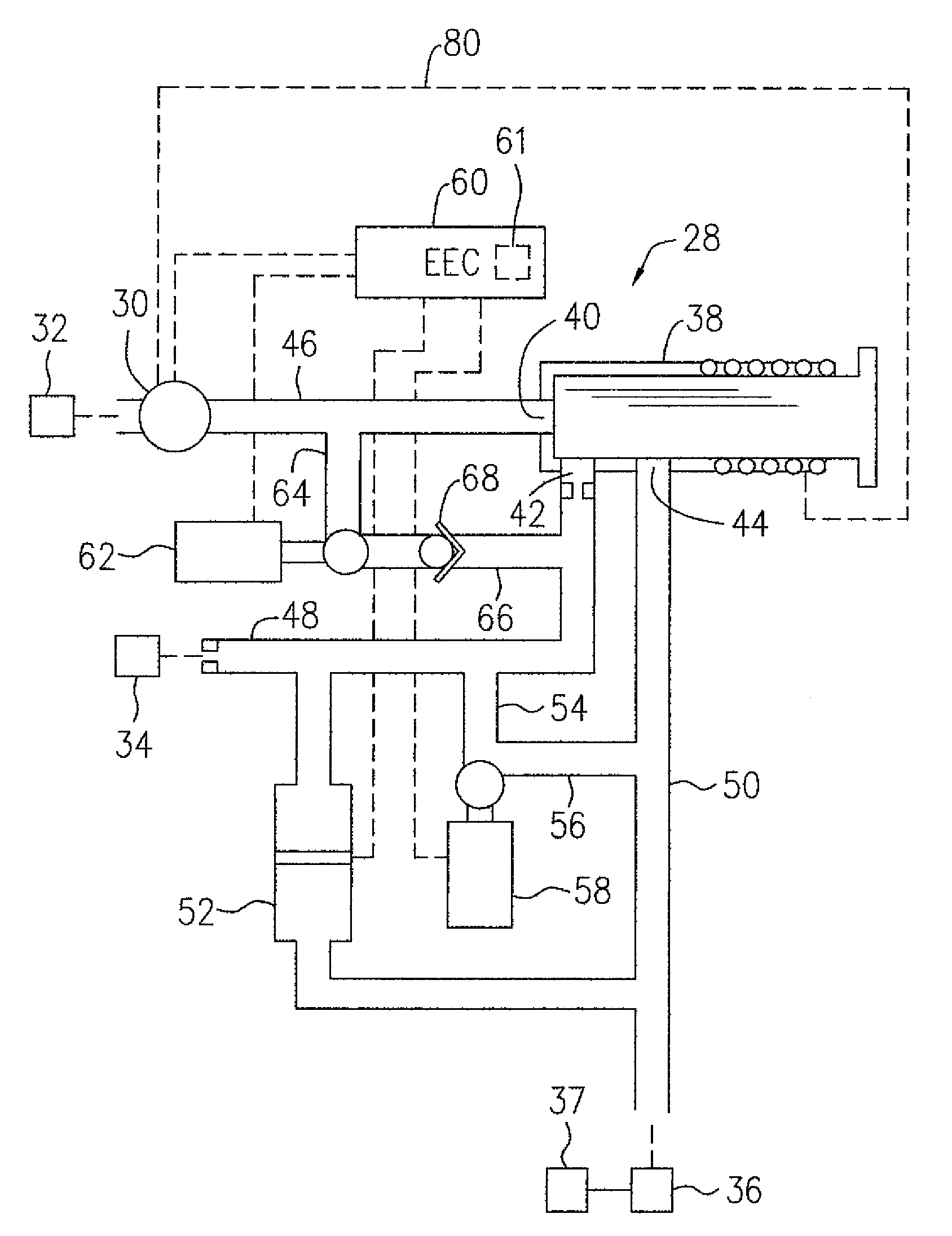

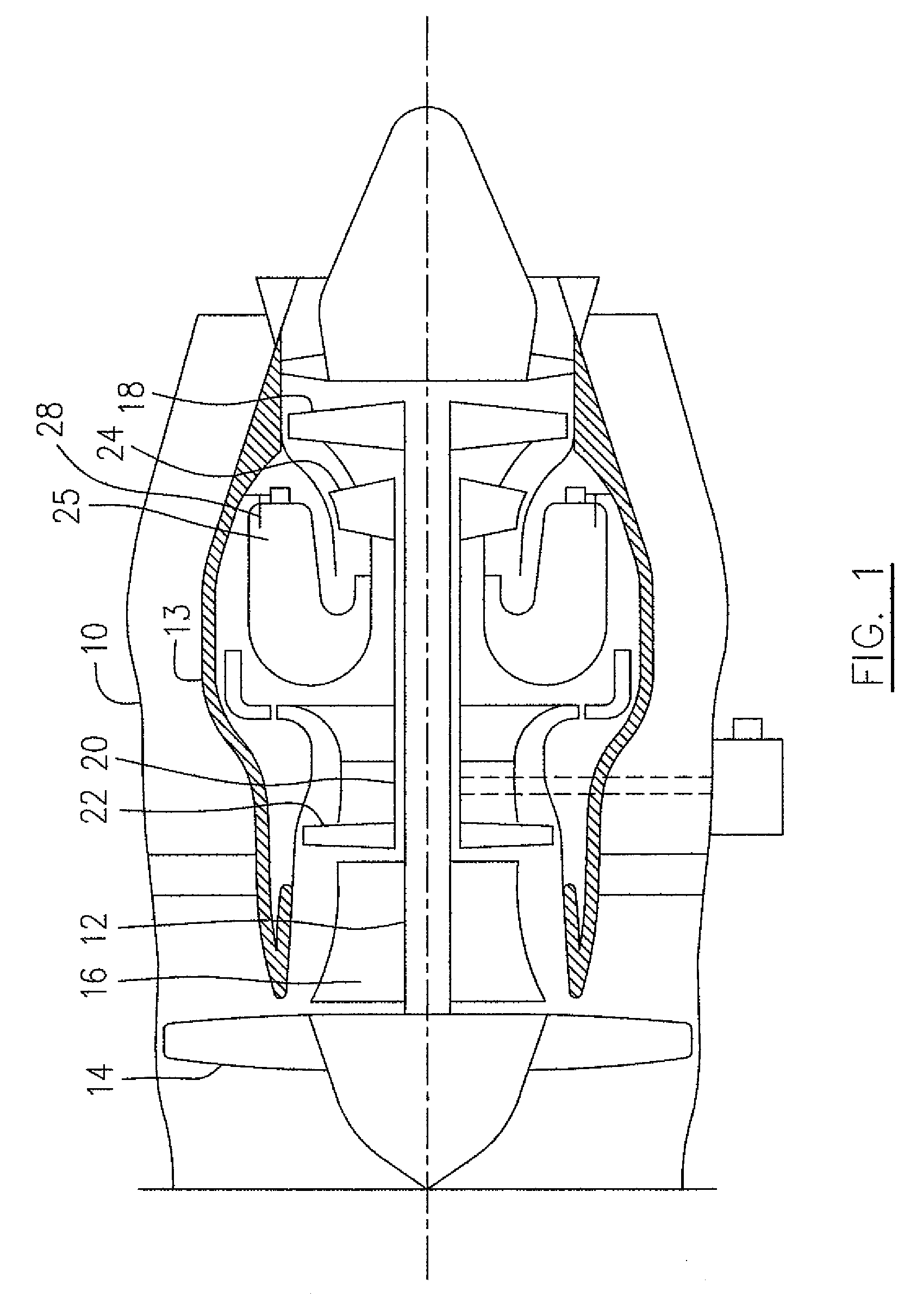

Start flow measurement

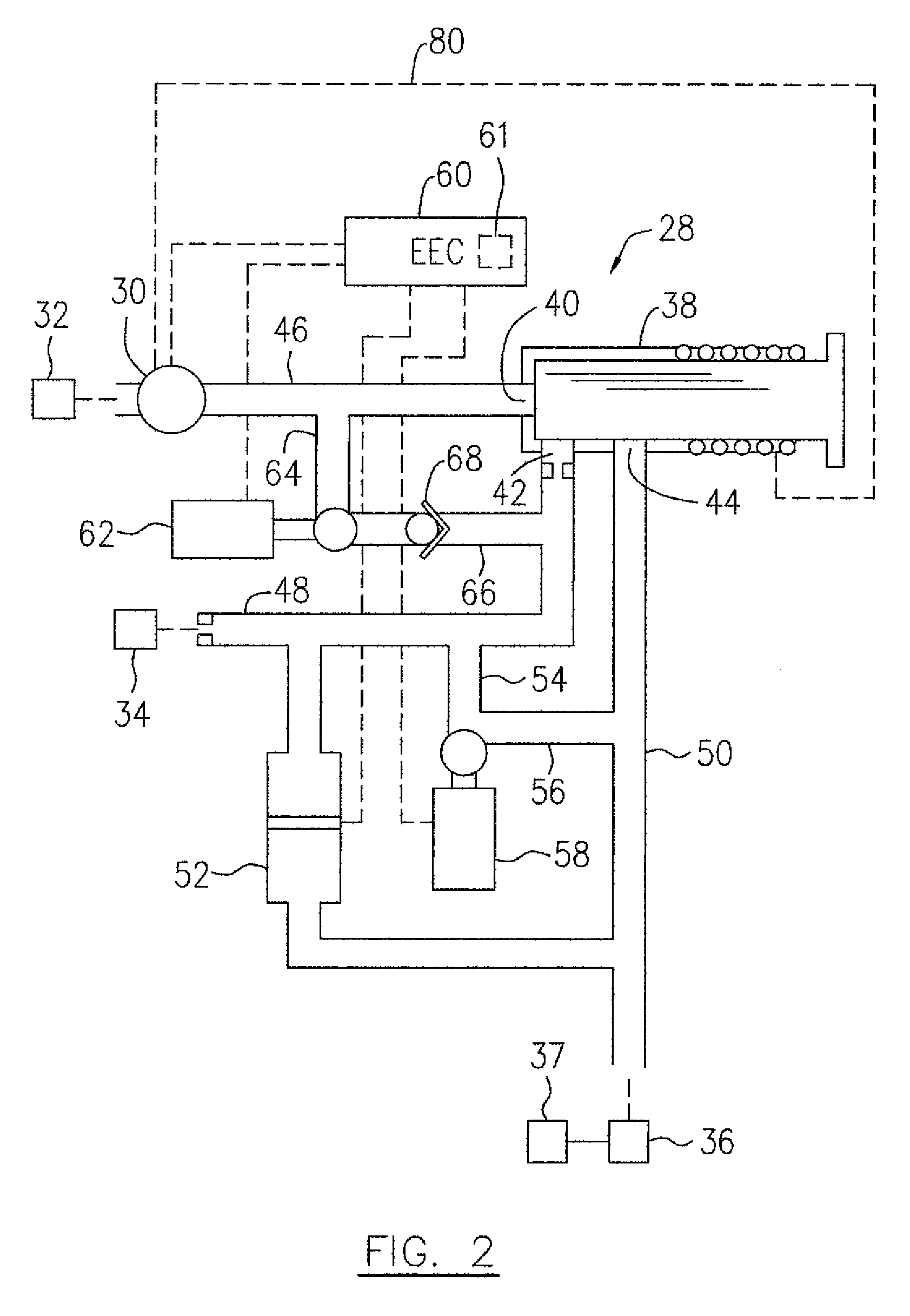

ActiveUS20080256954A1Analogue computers for vehiclesTurbine/propulsion fuel flow conduitsPressure differenceStreamflow

Owner:PRATT & WHITNEY CANADA CORP

Burner control systems and methods of operating a burner

InactiveUS20120107753A1Easy to controlSimple methodFuel supply regulationAir supply regulationCombustorControl system

Owner:AUTOFLAME ENG

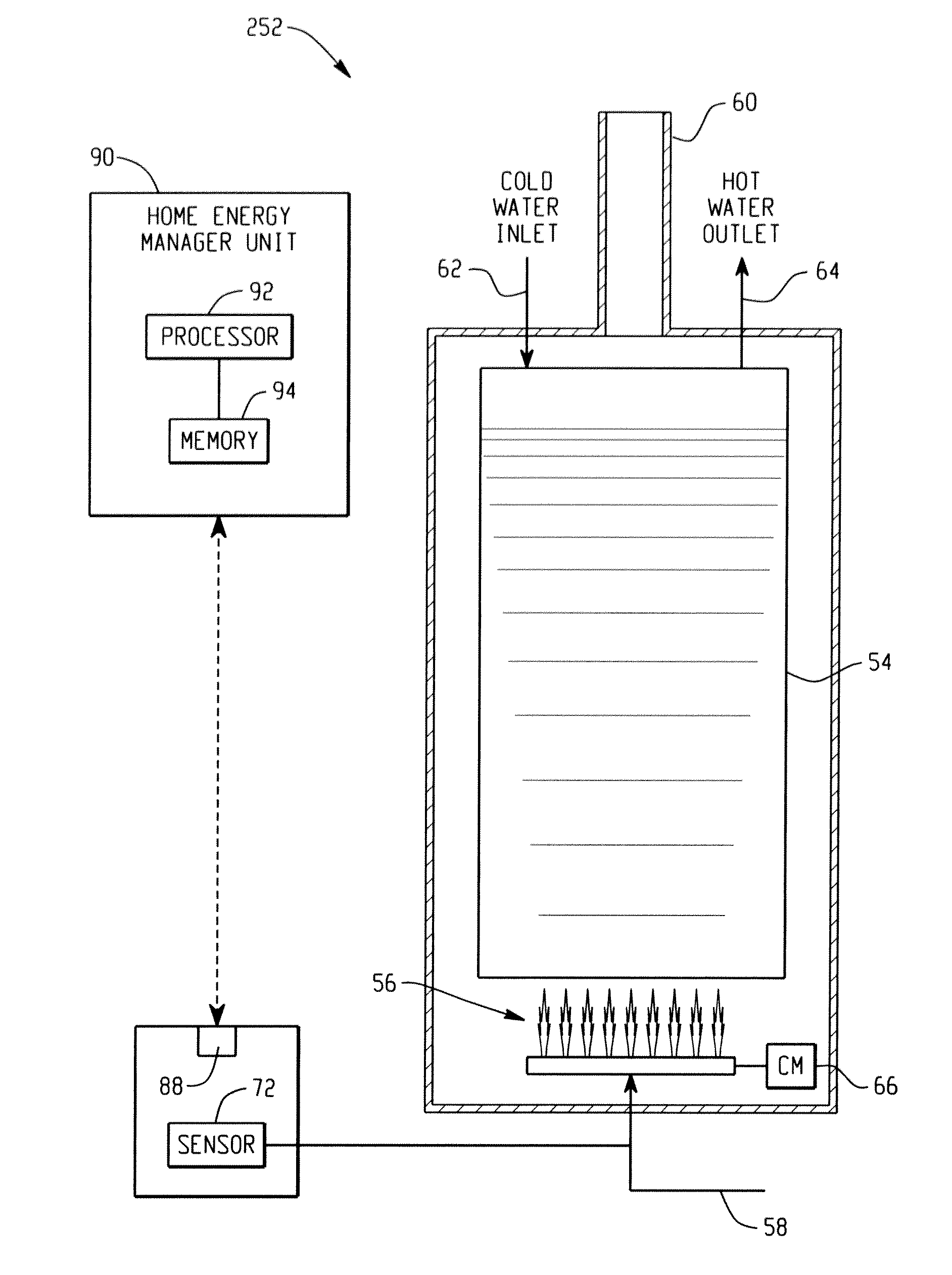

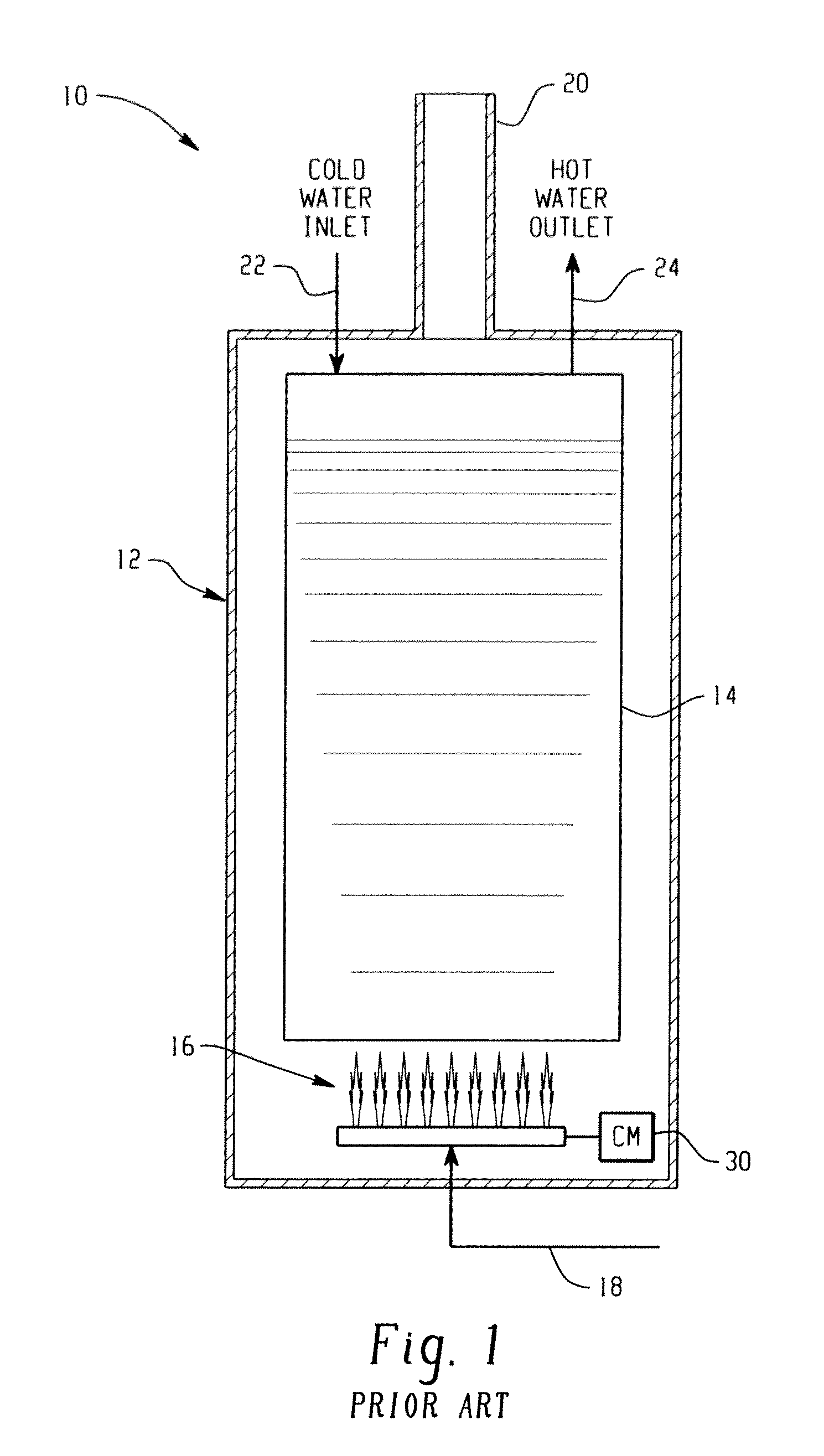

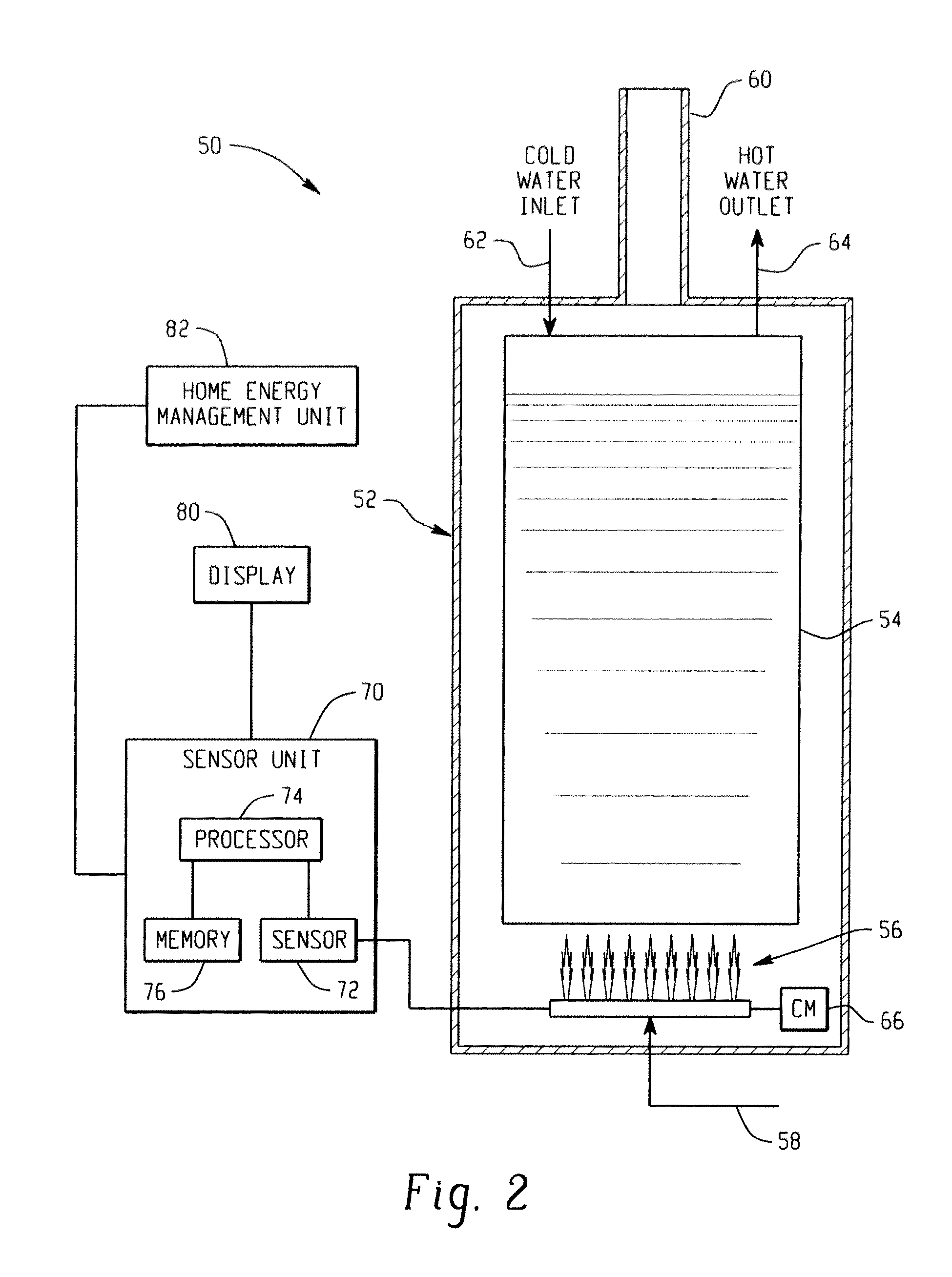

Submetering hydrocarbon fueled water heaters with energy manager systems

ActiveUS20120052453A1Good understand and control energy usageGood understand and control and efficiencyCentral heating componentsVolume/mass flow by dynamic fluid flow effectCommunication interfaceCombustor

A hydrocarbon-fueled hot water heater for supplying hot water includes a cold water inlet, a hot water outlet, a selectively activatable burner for applying heat to a volume of water between the inlet and the outlet, a sensor for sensing activation of the at least one burner, and a communication interface for communicating data corresponding to the activation of the at least one burner to a processor configured to multiply the amount of time the burner is activated by a known value corresponding to a flow rate of the burner to estimate an amount of fuel consumed by the hydrocarbon-fueled hot water heater. Other devices and methods of submetering hydrocarbon fueled water heaters are also included.

Owner:HAIER US APPLIANCE SOLUTIONS INC

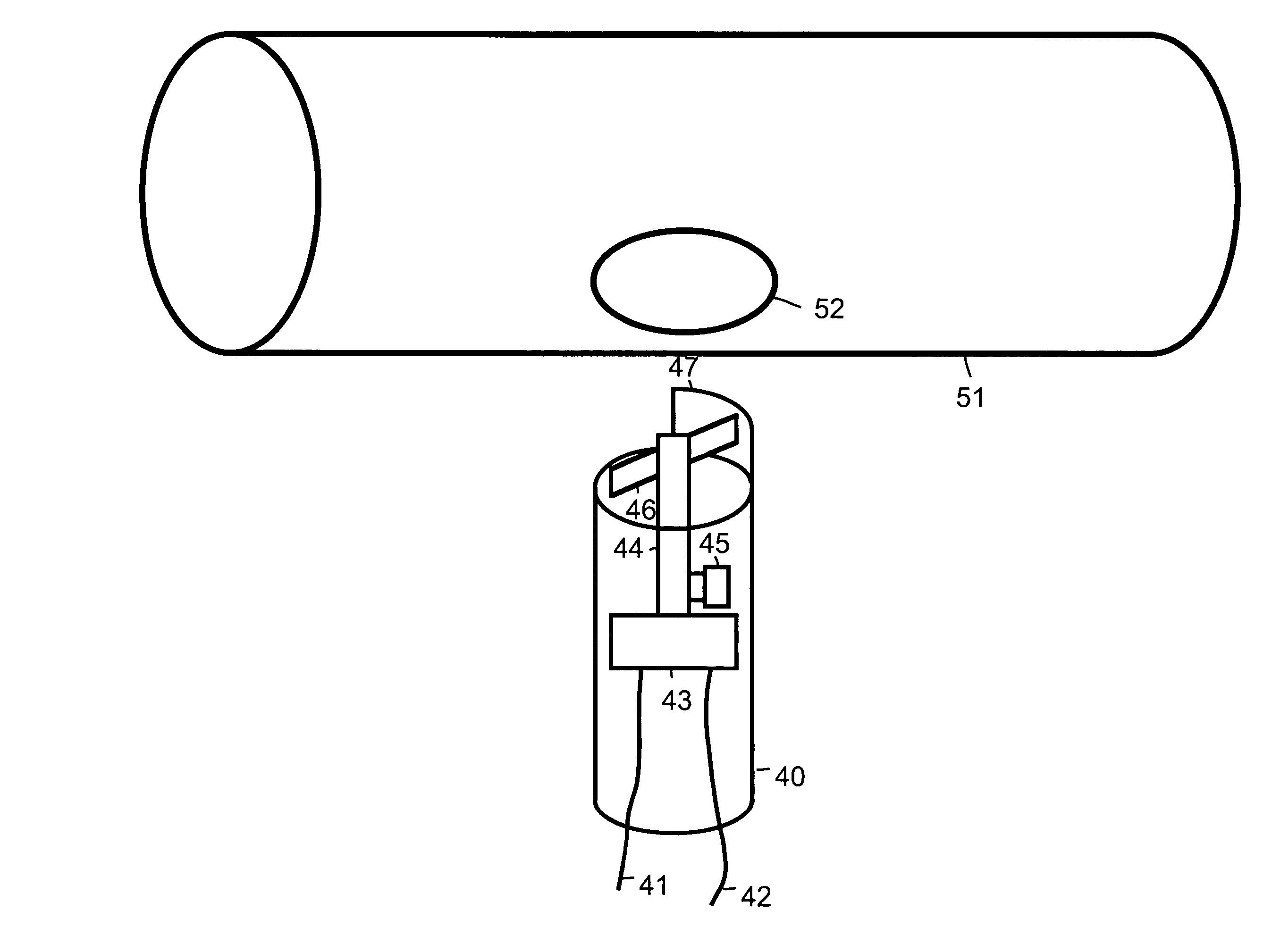

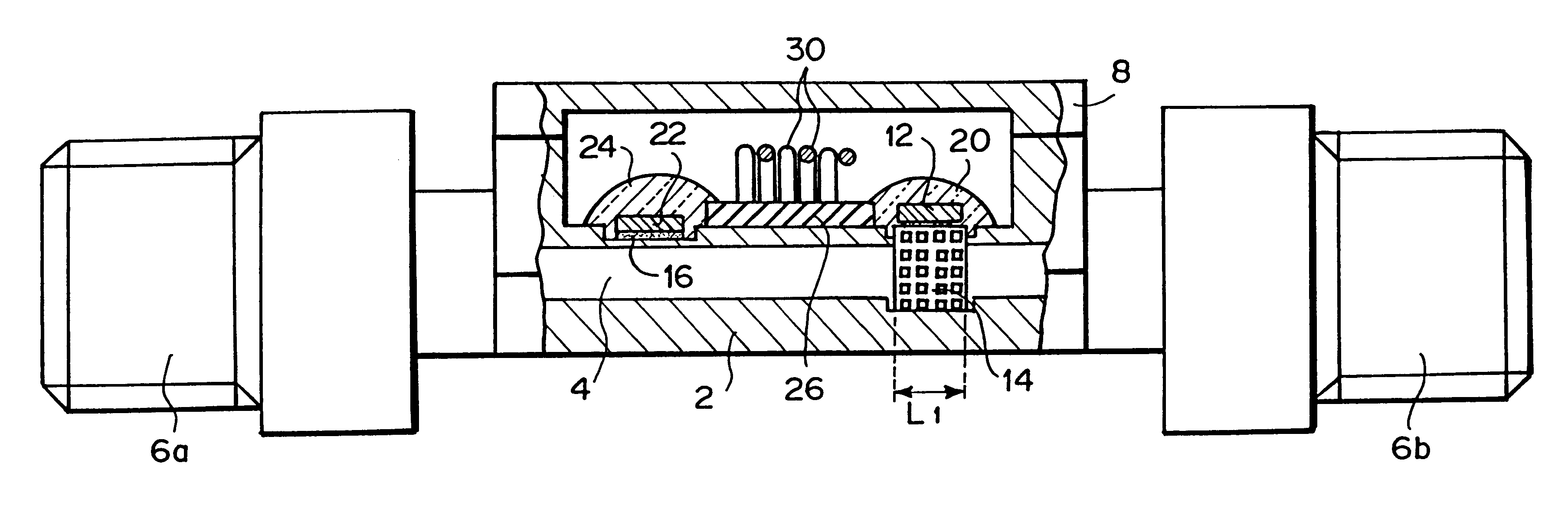

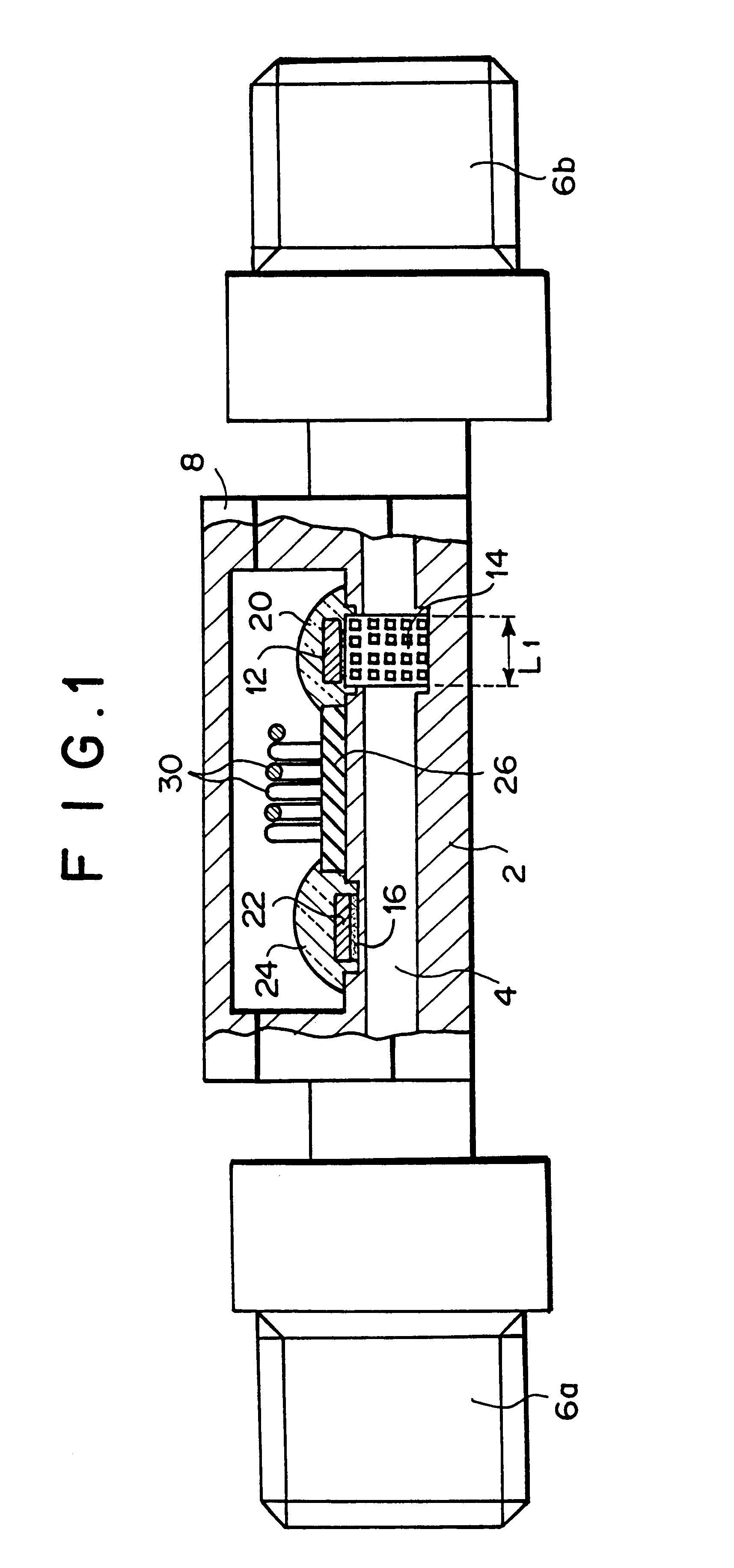

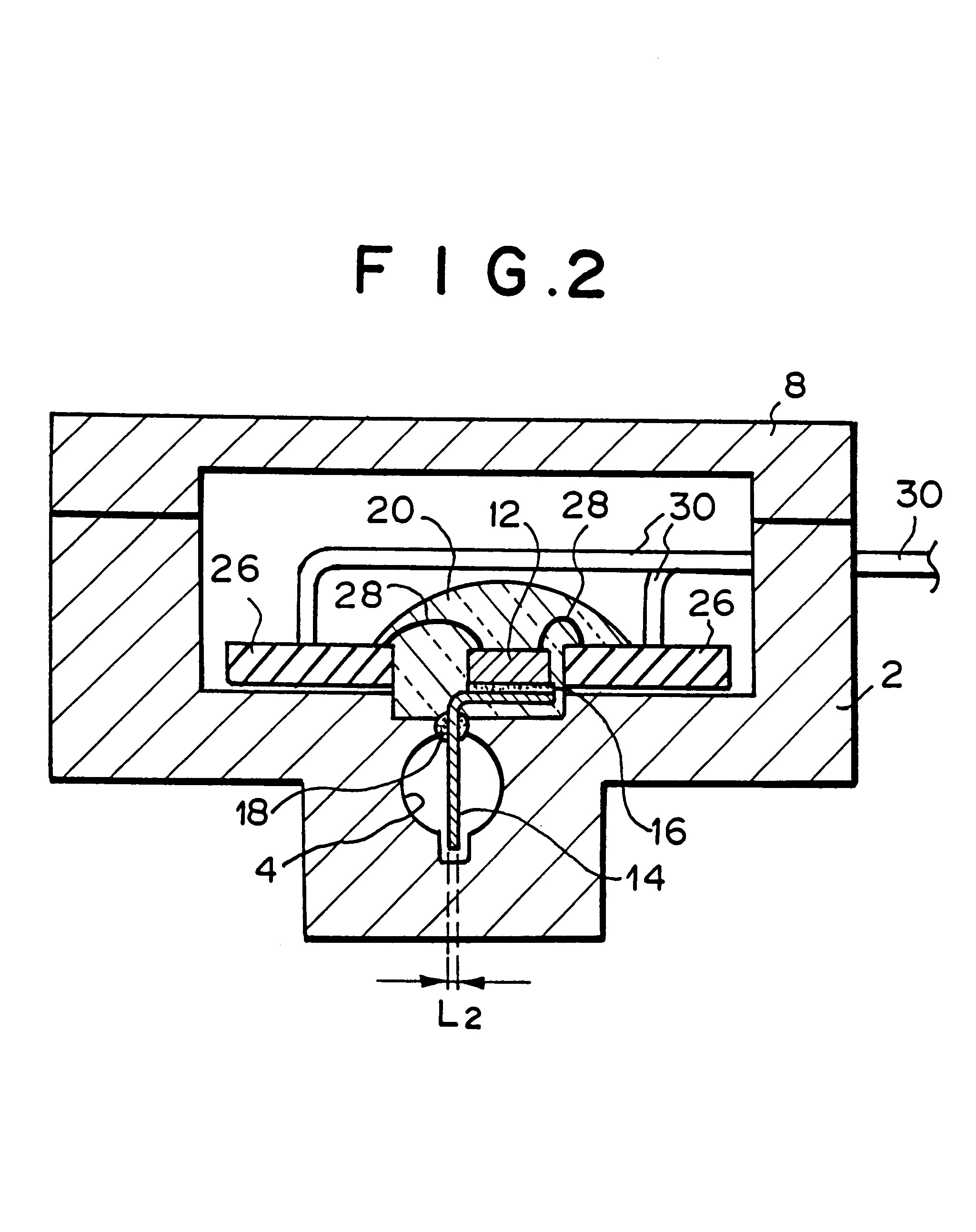

Flow rate sensor, flow meter, and discharge rate control apparatus for liquid discharge machines

InactiveUS6647777B1Accurately measure flow rate of fluid flowingAccurate flowBurnersLiquid fuel feeder/distributionLine tubingEngineering

A pipe line for fluid to be detected is formed so that heat from a flow rate detector in which a thin-film heating element and a thin-film temperature sensing element are laminated on a first surface of a substrate through an insulating layer is transferred to and absorbed by the fluid. In the flow rate detector, the temperature sensing which is affected by the heat absorption of the fluid due to the heating of the thin-film heating element is executed by the thin-film temperature sensing element, and the flow rate of the fluid in the pipe line is detected on the basis of the temperature sensing result. A fin plate extending into the pipe line is joined to a second surface of the substrate of the flow rate detector by a joint member, and the fin plate extends so as to pass through the central portion on the circular section of the pipe line. The dimension of the fin plate in the direction of the pipe line is larger than the dimension L2 of the thickness. Accordingly, even when the fluid is viscous fluid having relatively high viscosity, and further even when the flow rate is relatively small or under a broad environmental temperature condition, the flow rate of the fluid-flowing in the pipe line can be accurately measured.

Owner:SAN-A

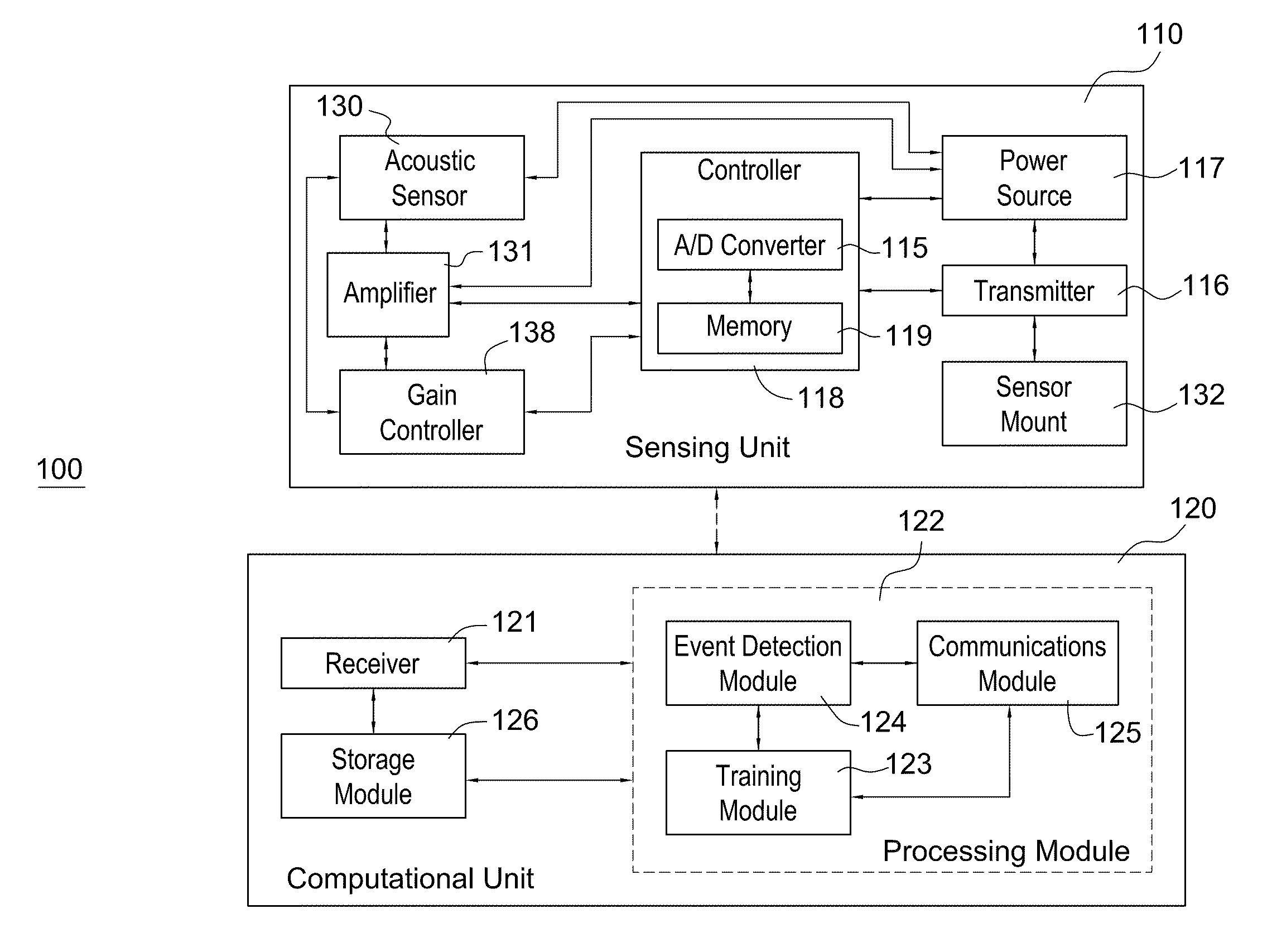

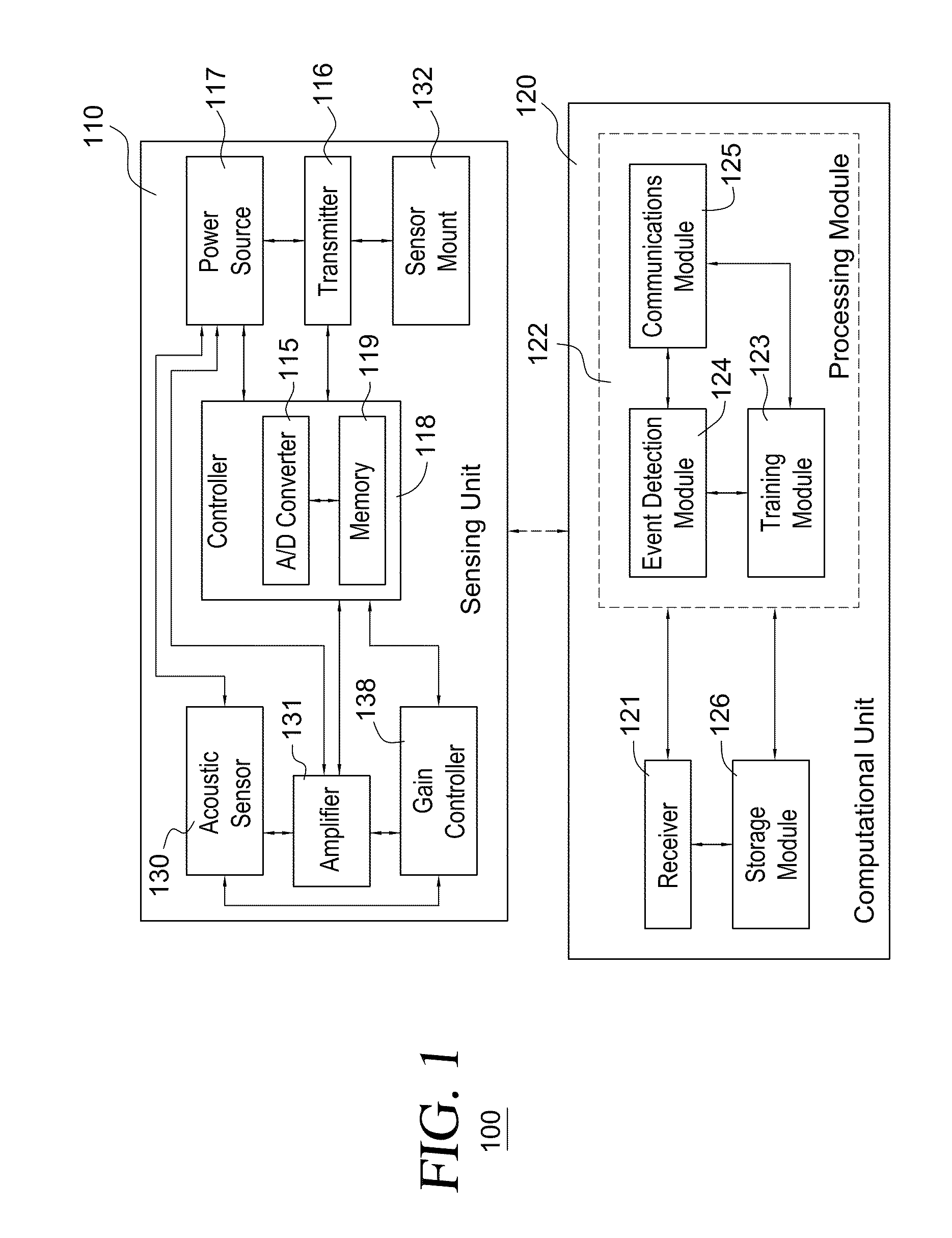

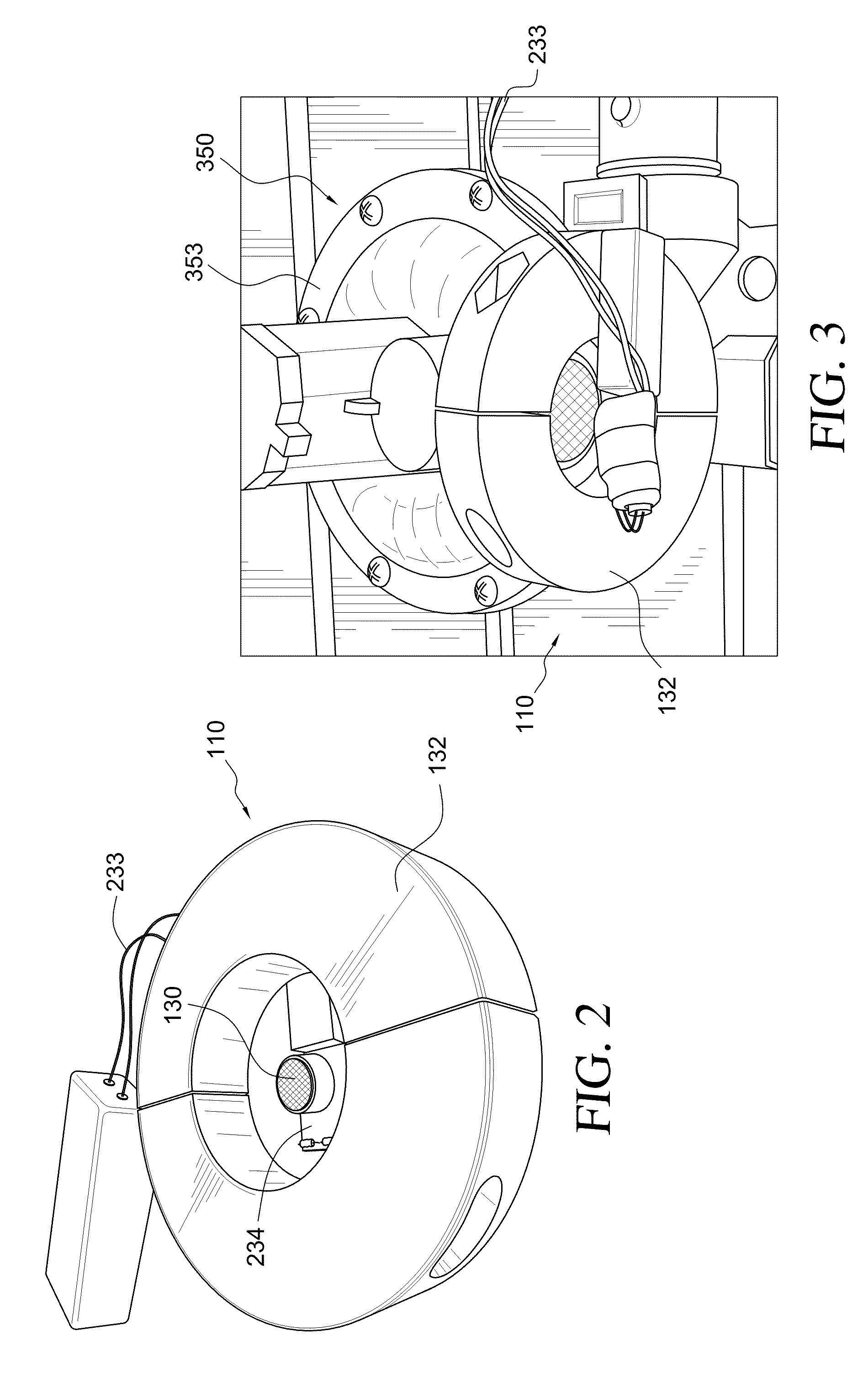

Apparatus Configured to Detect Gas Usage, Method of Providing Same, and Method of Detecting Gas Usage

In some embodiments, an apparatus can be configured to detect gas usage. The apparatus can include: (a) a processing module configured to run on a computational unit; and (b) a sensing unit configured to be coupled to a gas regulator, the sensing unit having: (1) at least one acoustic sensor configured to detect two or more acoustic signals produced by the gas regulator and convert the two or more acoustic signals into one or more first data signals; and (2) a transmitter electrically coupled to the at least one acoustic sensor and configured to transmit the one or more first data signals to the computational unit. The processing module is configured to use the one or more first data signals to determine the gas usage. Other embodiments are disclosed.

Owner:BELKIN INT

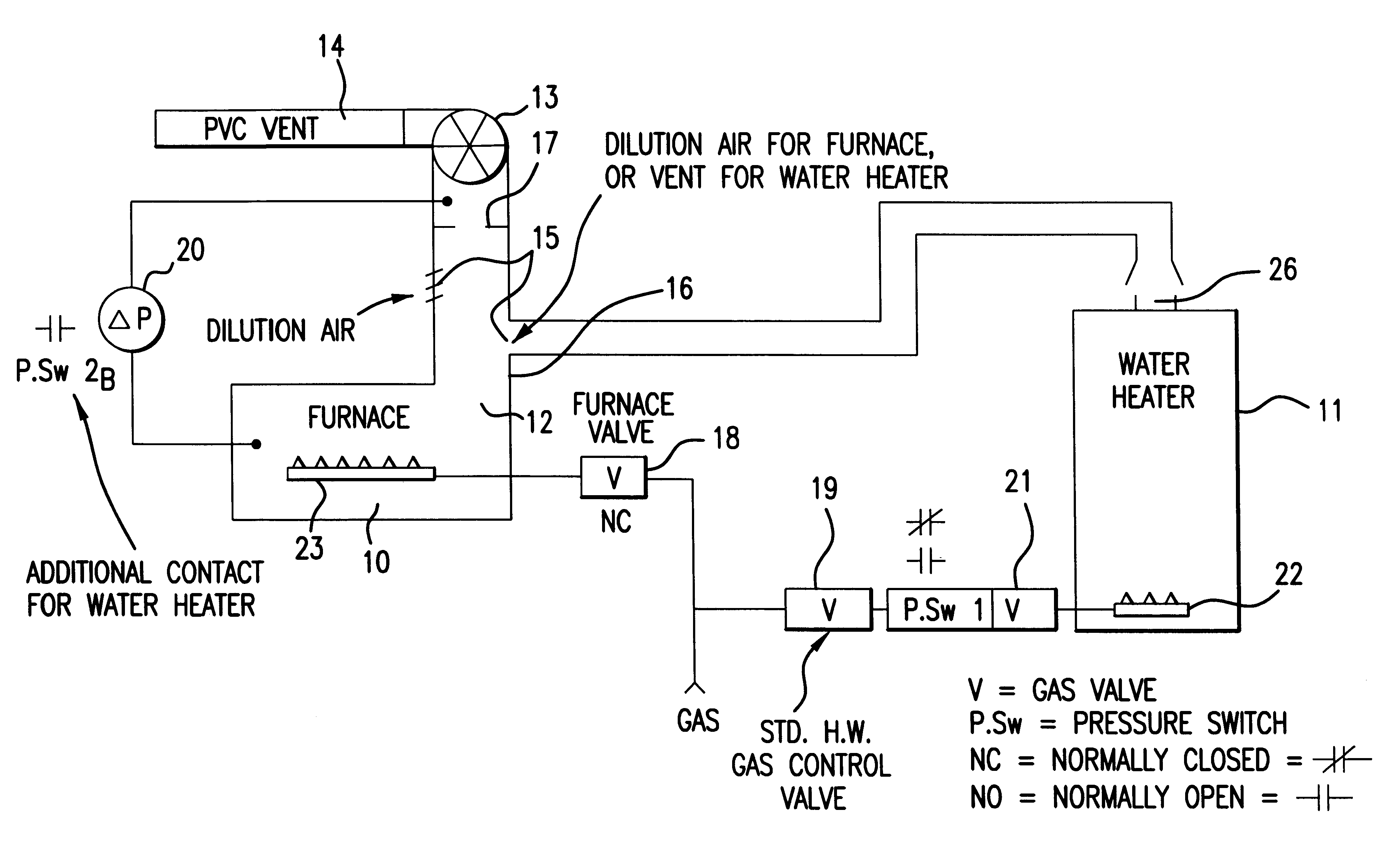

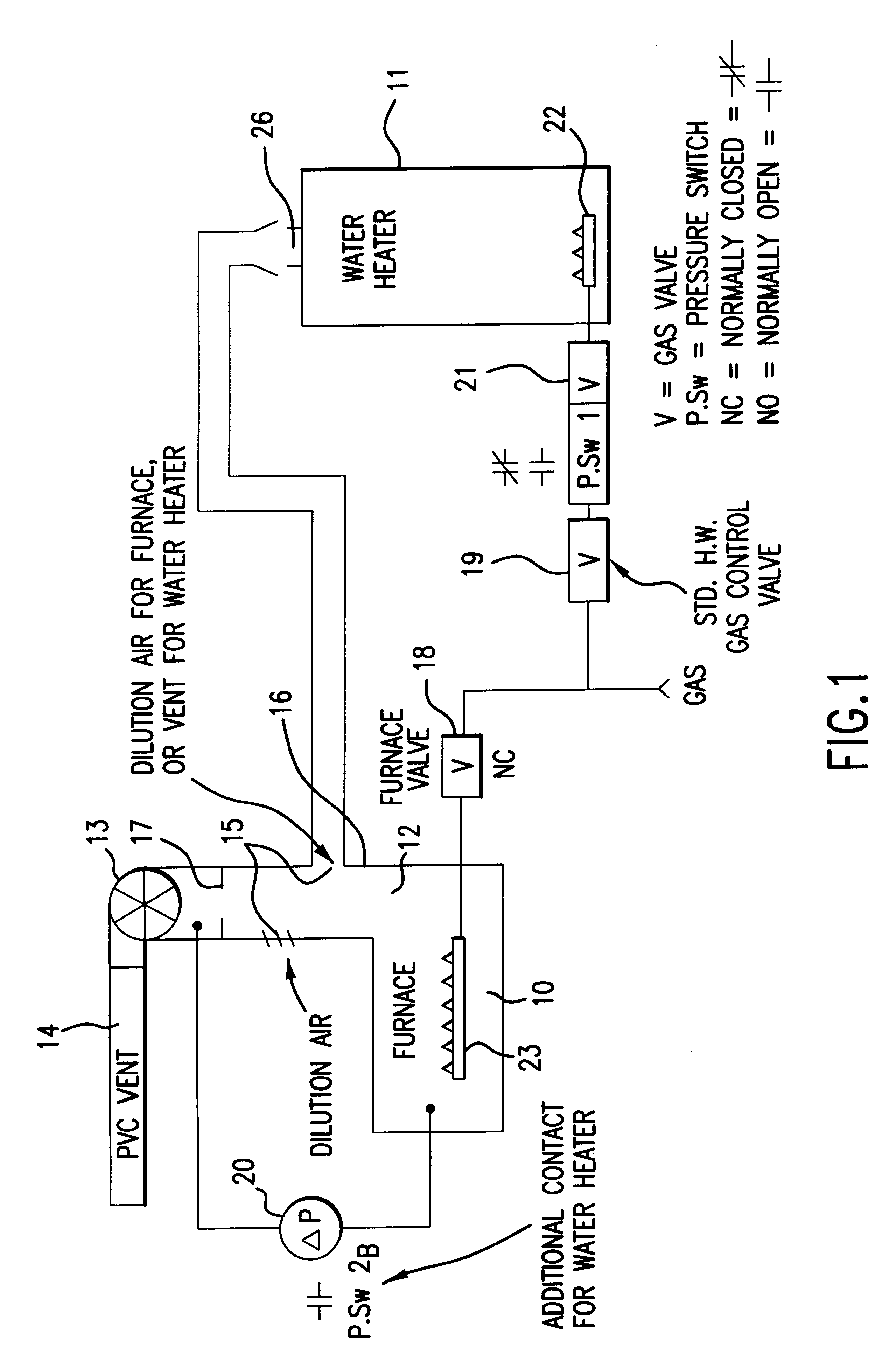

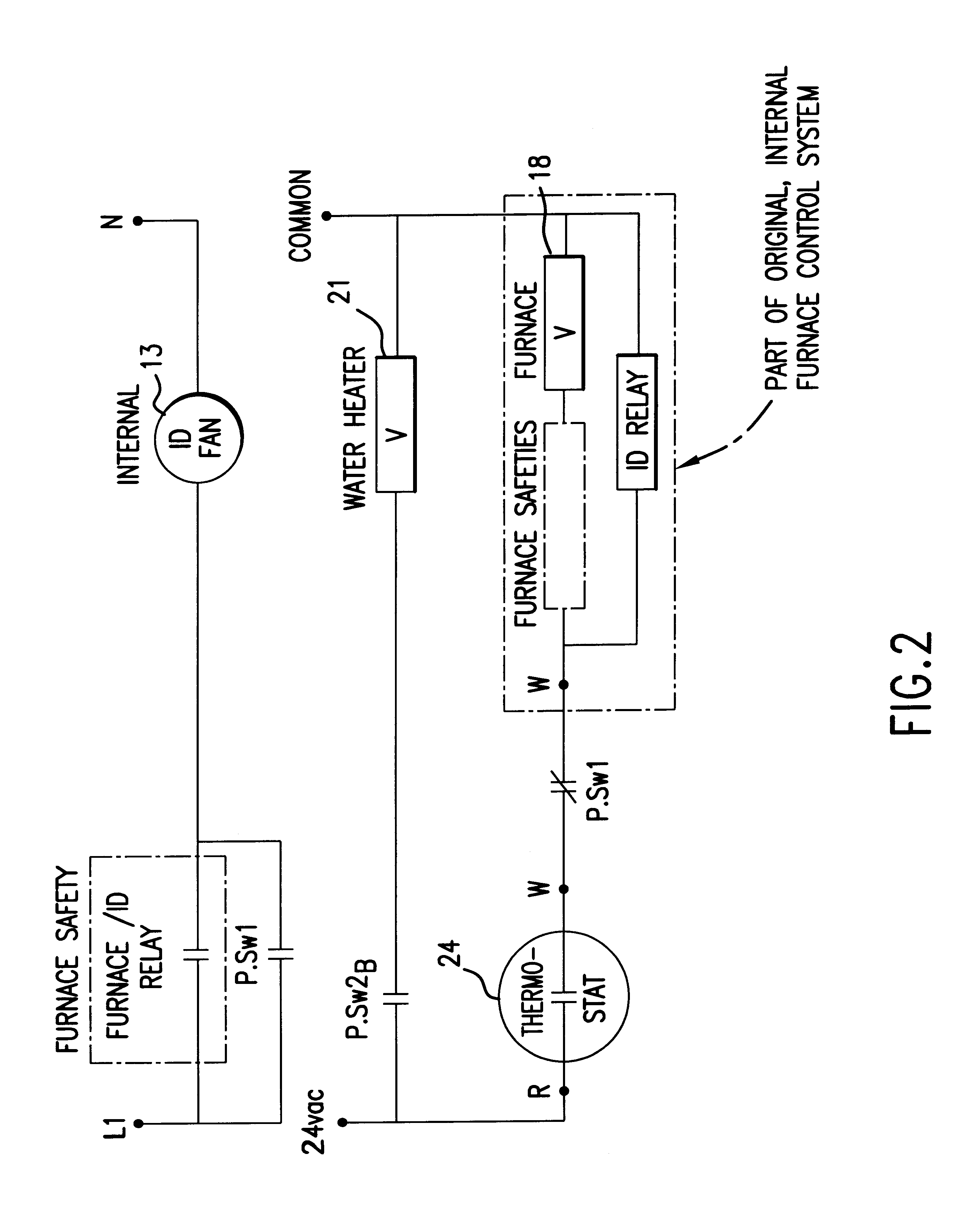

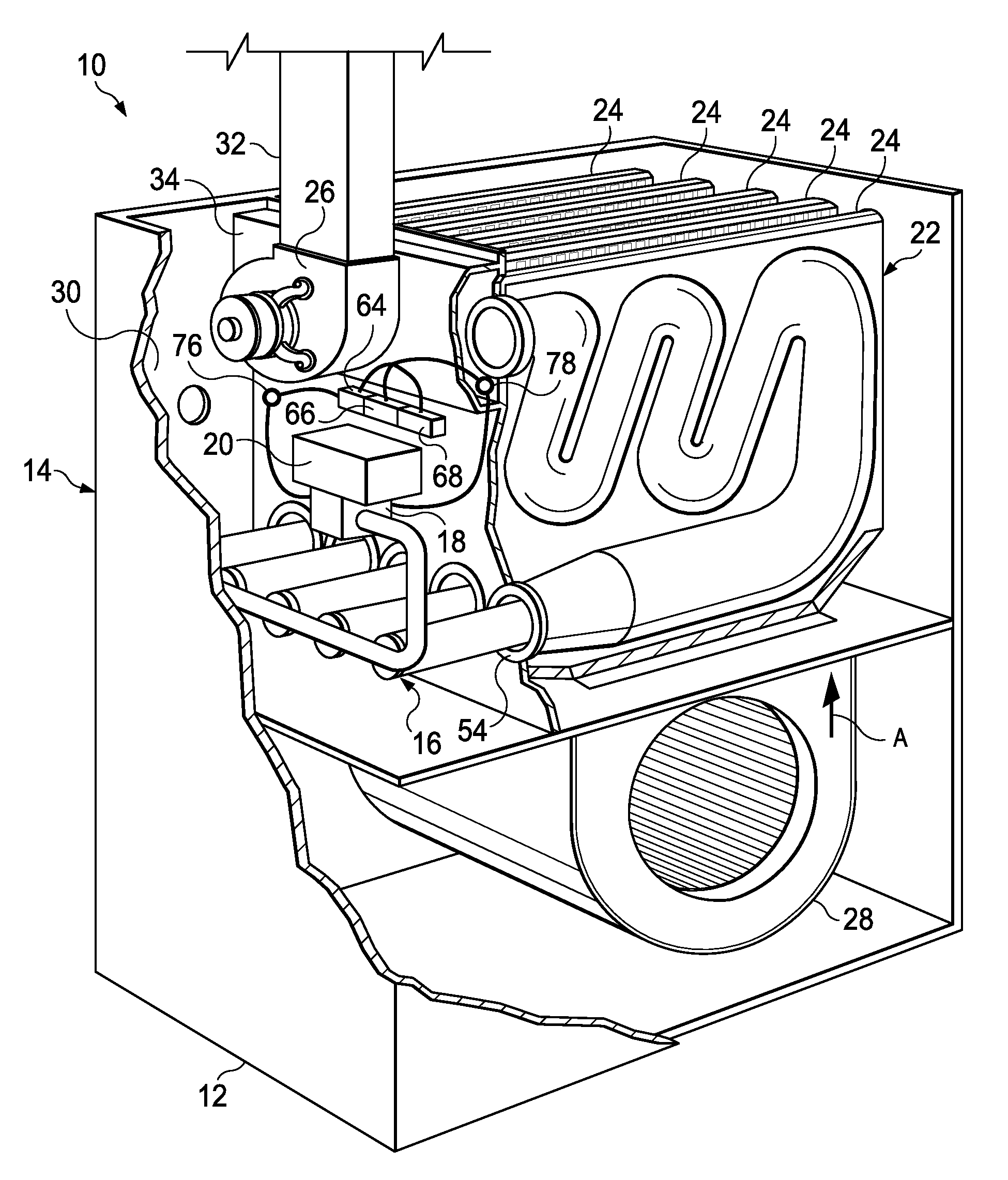

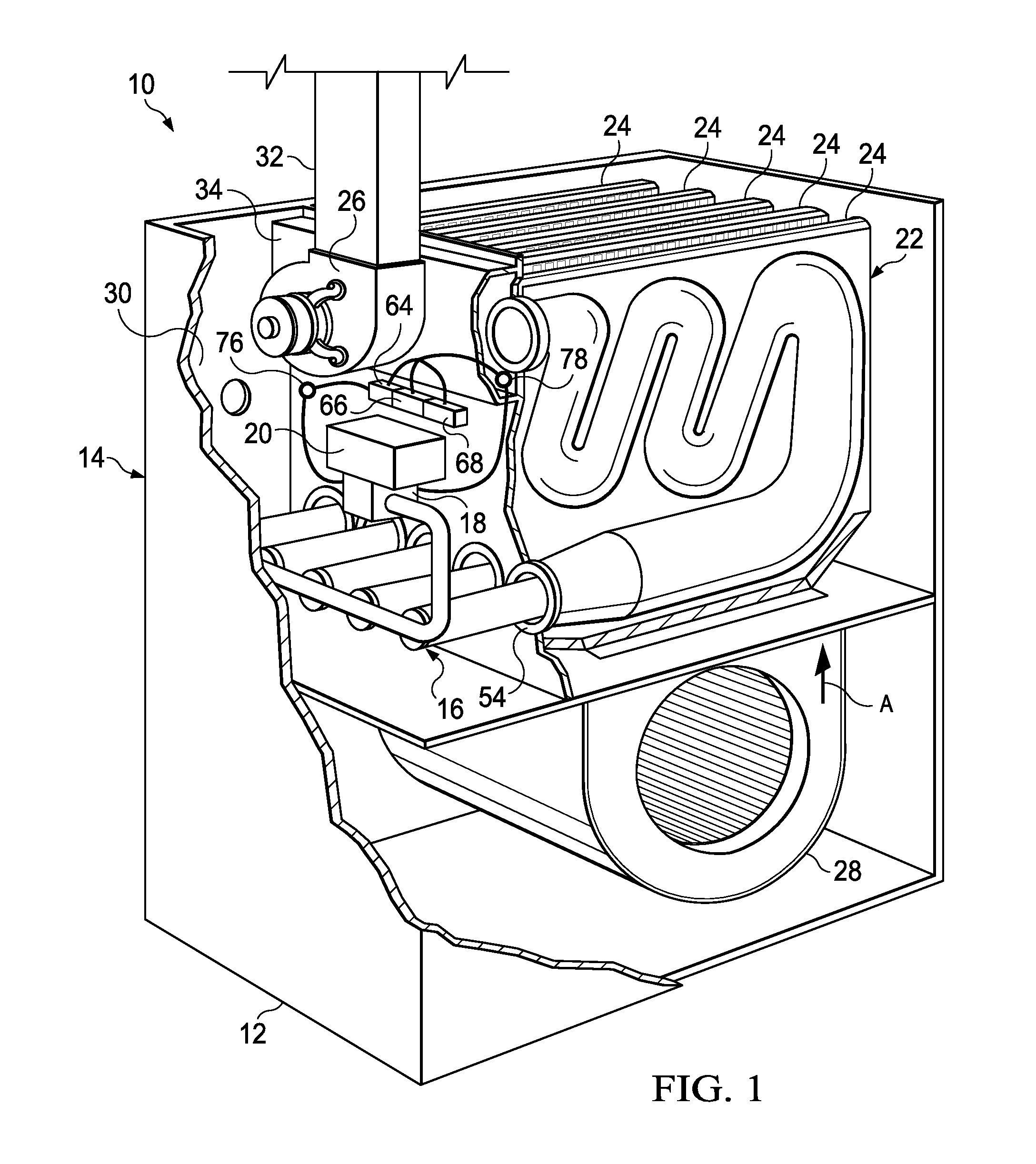

Common venting of water heater and induced draft furnace

A common, side-wall, Category III or Category IV-vented gaseous fuel-fired furnace and gaseous fuel-fired water heater system having a gaseous fuel-fired furnace having a furnace combustion products exhaust, a gaseous fuel-fired water heater having a water heater combustion products exhaust, and a Category III or Category IV vent in communication with the furnace combustion products exhaust and the water heater combustion products exhaust for venting of the combustion products from the furnace and water heater.

Owner:GAS TECH INST

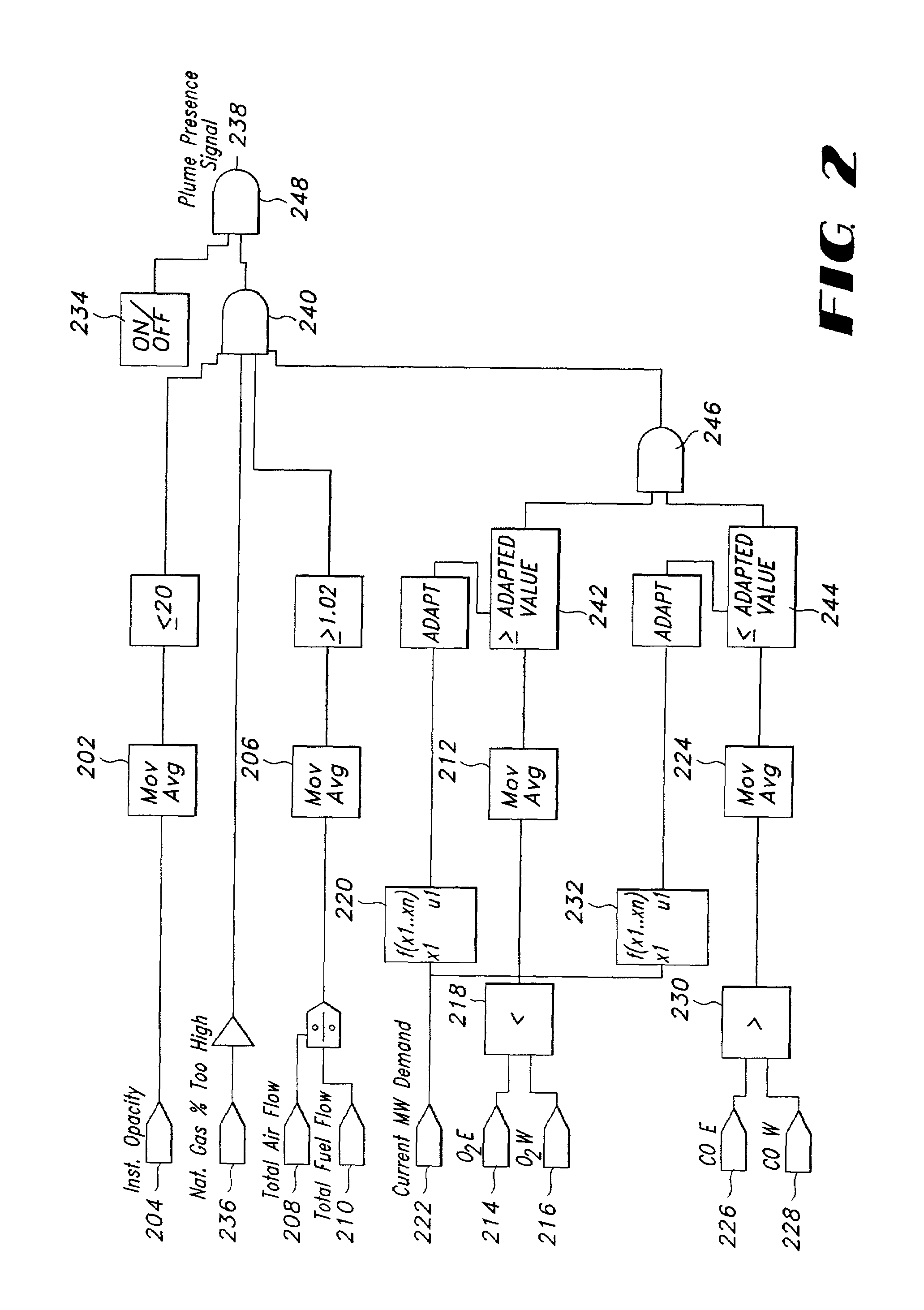

Systems and methods for determining the existence of a visible plume from the chimney of a facility burning carbon-based fuels

Excess oxygen in the combustion process of a facility that bums carbon-based fuels may cause a visible plume in the atmosphere at the stack of the facility. Traditional optical based opacity monitors may be unable to detect this plume or the plume may form at a location downstream from the opacity monitor toward the stack. The present invention discloses methods to utilize common combustion control variables to detect and signal the presence of a visible plume of exhaust gasses. Also disclosed are systems that detect the visible plume and provide a signal so that the combustion process may be manually or automatically adjusted to reduce or eliminate the visible plume.

Owner:FLORIDA POWER & LIGHT

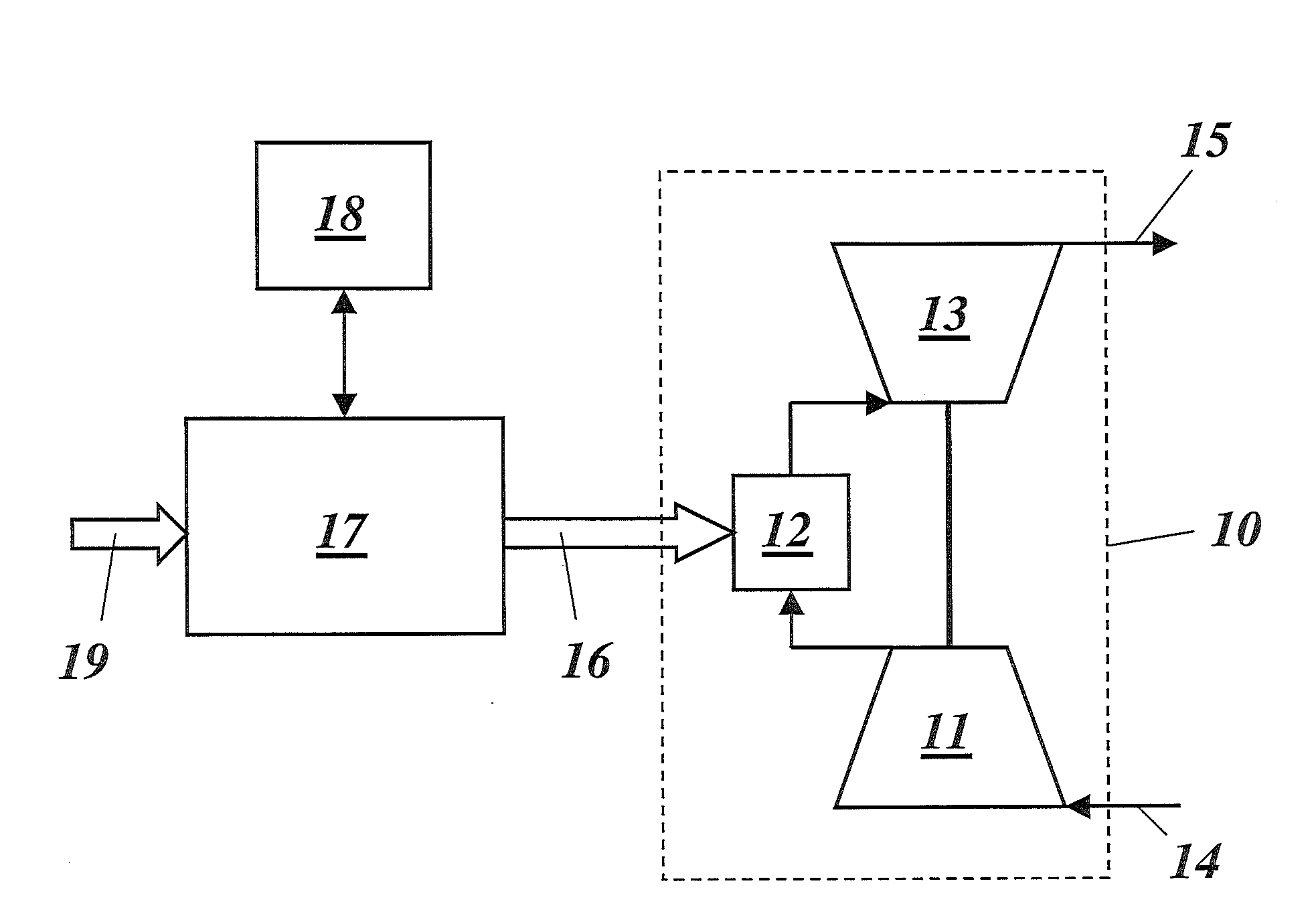

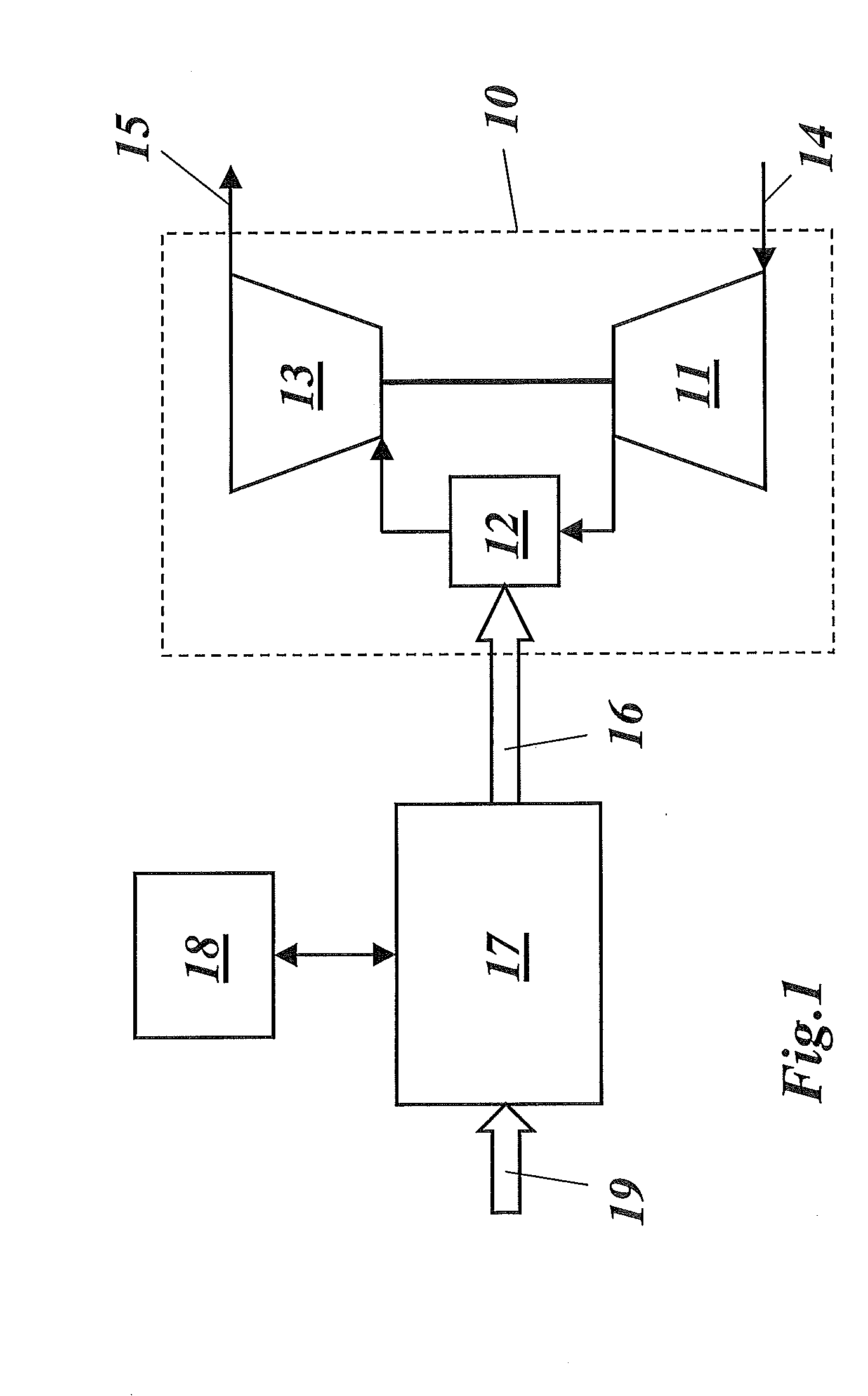

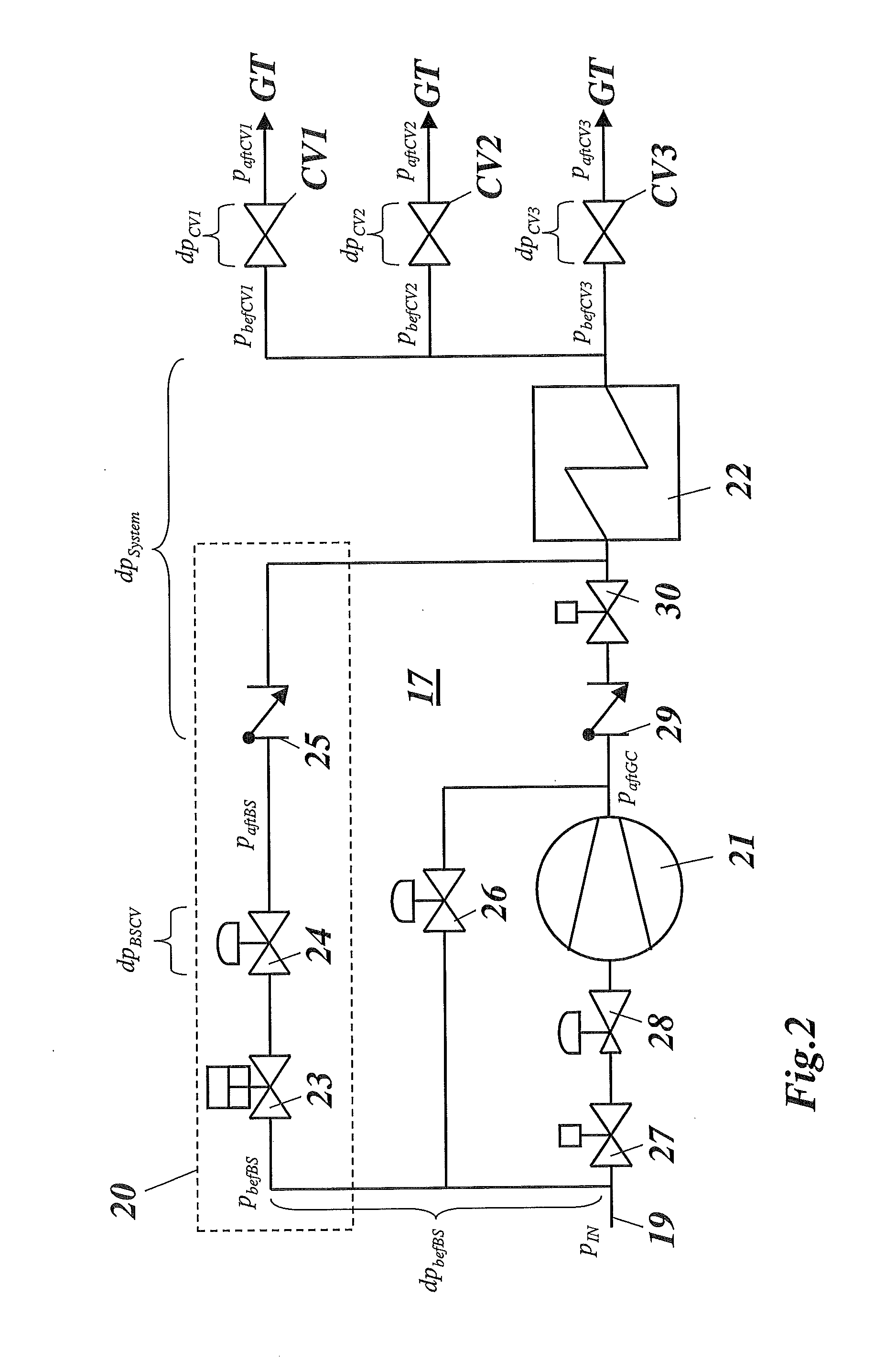

Method for operating a gas turbine plant with a compressor station for gaseous fuel

InactiveUS20100287945A1Fuel supply regulationTurbine/propulsion fuel supply systemsCombustion chamberProduct gas

The disclosure relates to a method for operating a gas turbine plant which is supplied with a fuel gas via a compressor station. The compressor station includes a compressor which compresses the fuel gas which is fed via a gas feed line and delivers it via at least one control valve to a combustion chamber of the gas turbine plant. A bypass system is arranged in parallel to the compressor via which fuel gas can be directed in a switchable manner past the compressor to the at least one control valve. An energy-saving operation can be achieved in a simple manner by continuously measuring the fuel gas pressure at the outlet of the at least one control valve. A minimum fuel gas pressure, which is desired (e.g., necessary) for operation of the gas turbine, at the inlet of the at least one control valve is determined from the measured pressure values in each case. The compressor station can be switched over to bypass operation when the fuel gas pressure which reaches the inlet of the at least one control valve via the bypass system is greater than or equal to the minimum fuel gas pressure.

Owner:ANSALDO ENERGIA IP UK LTD

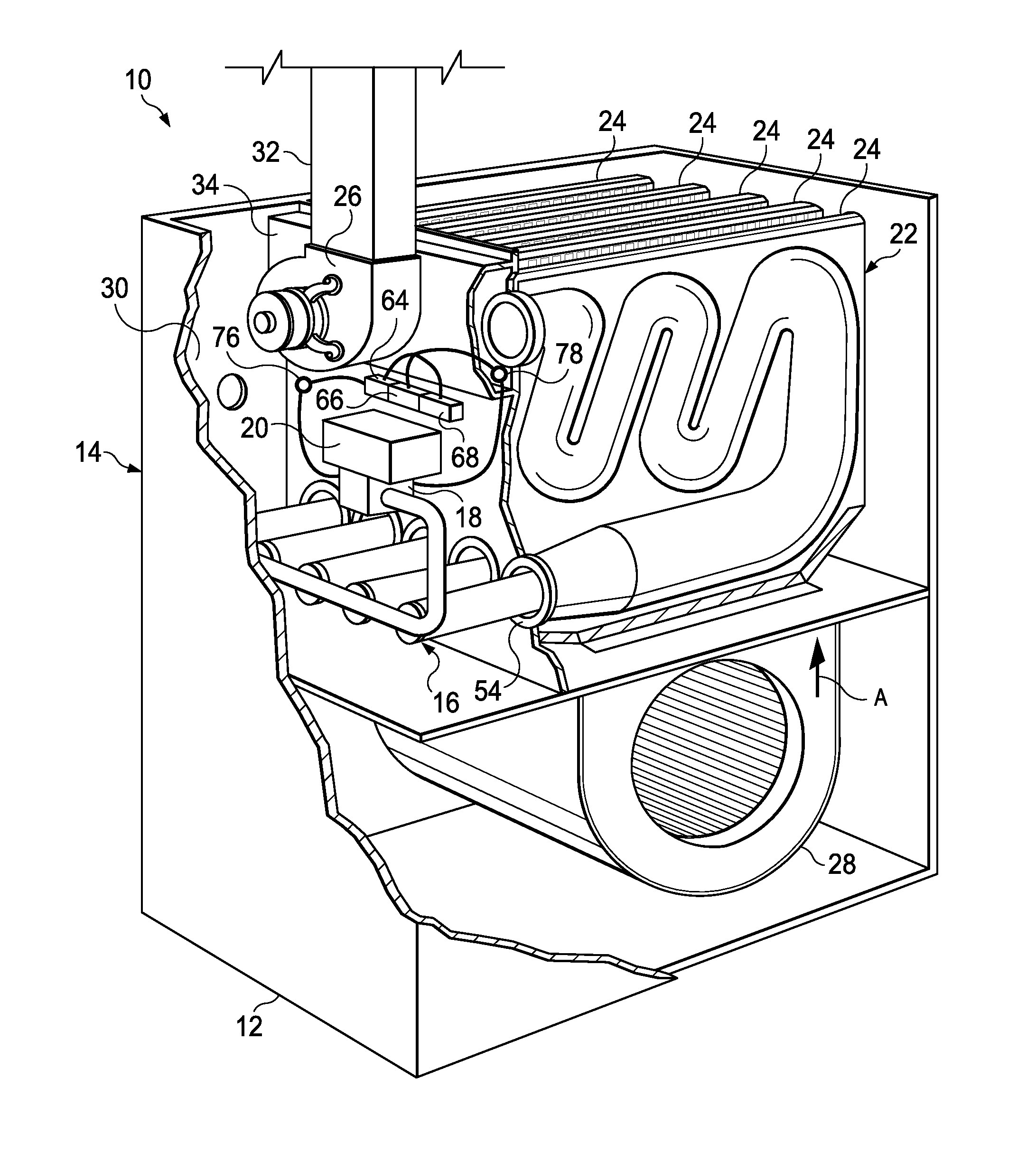

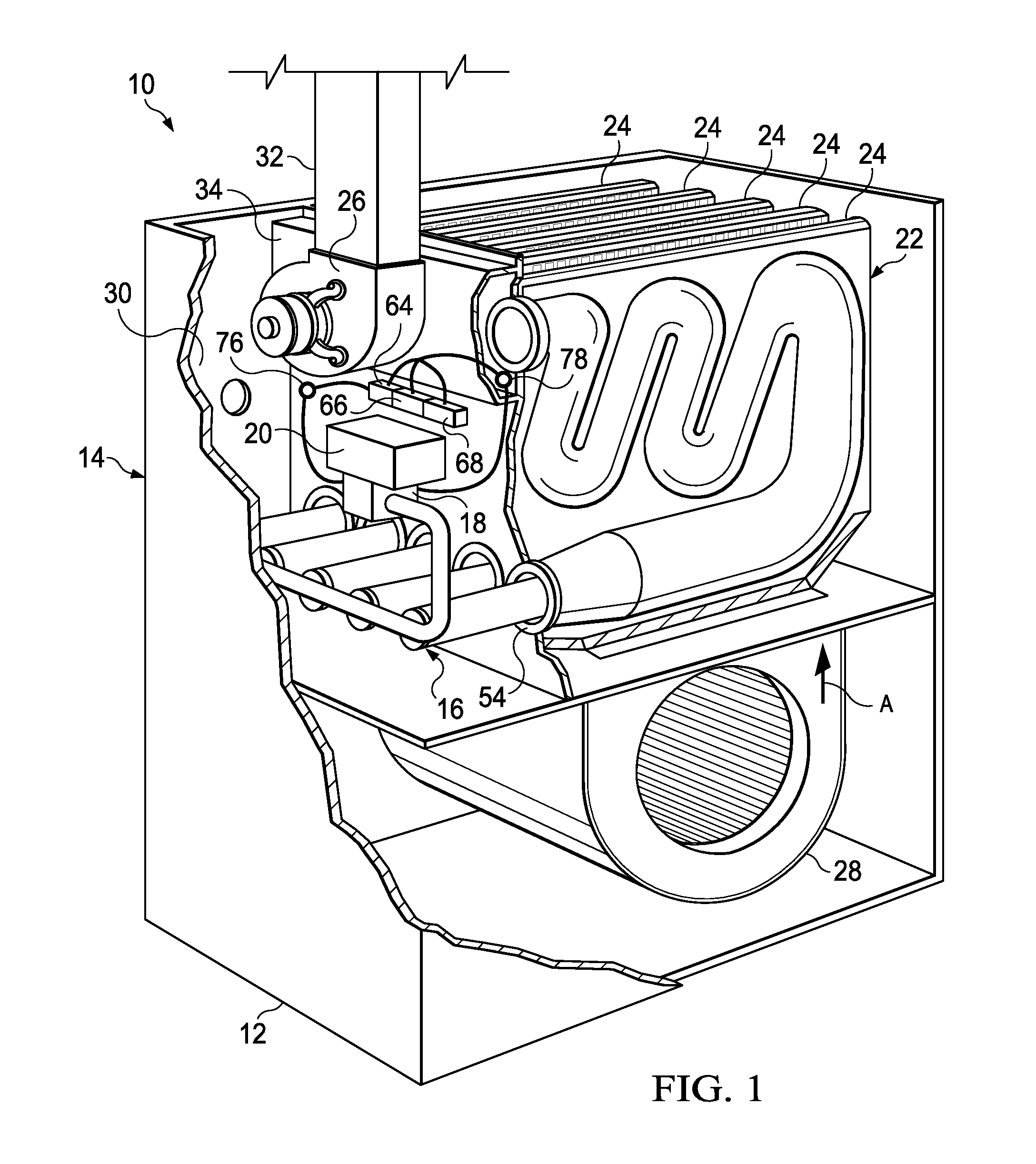

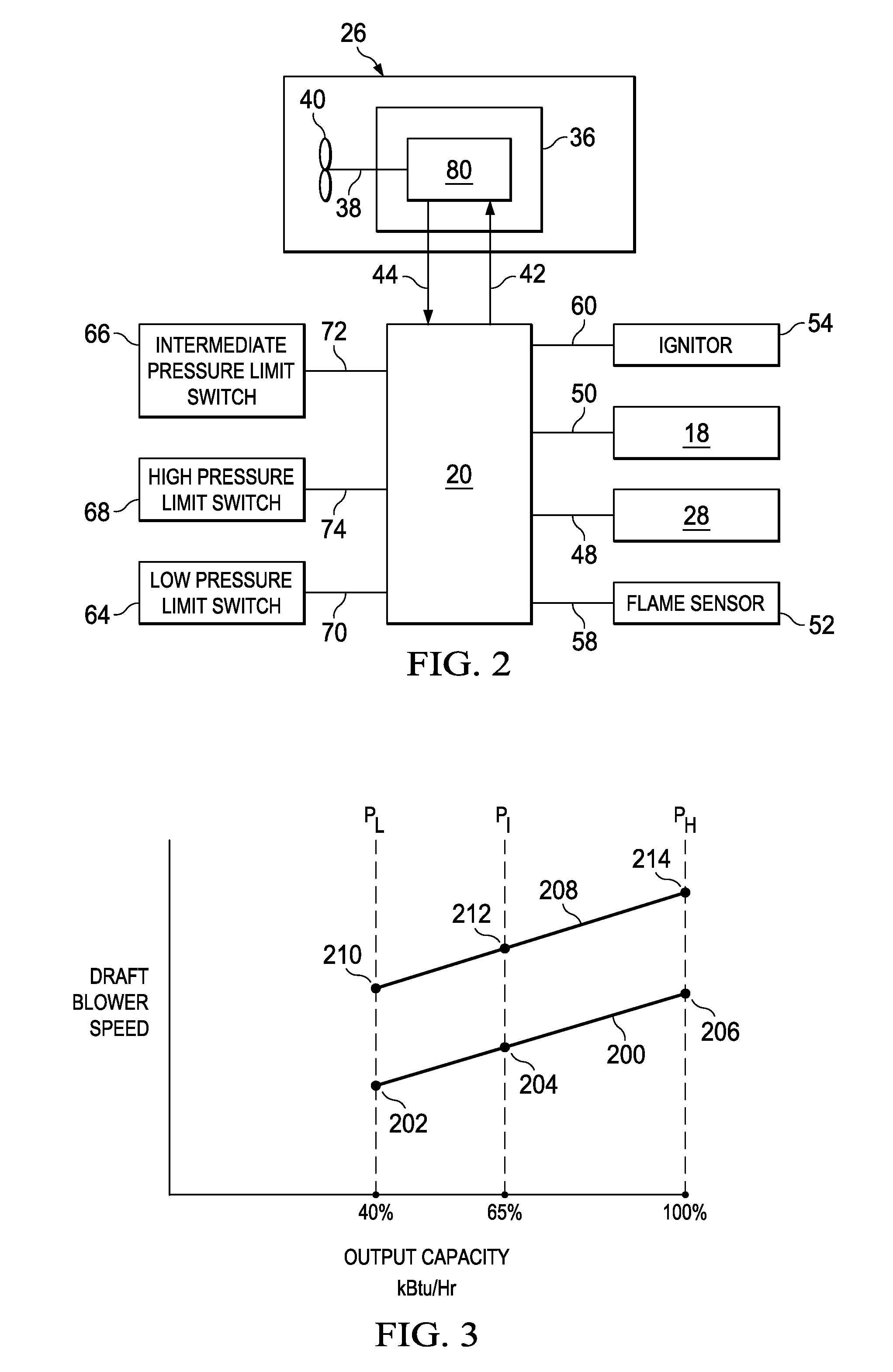

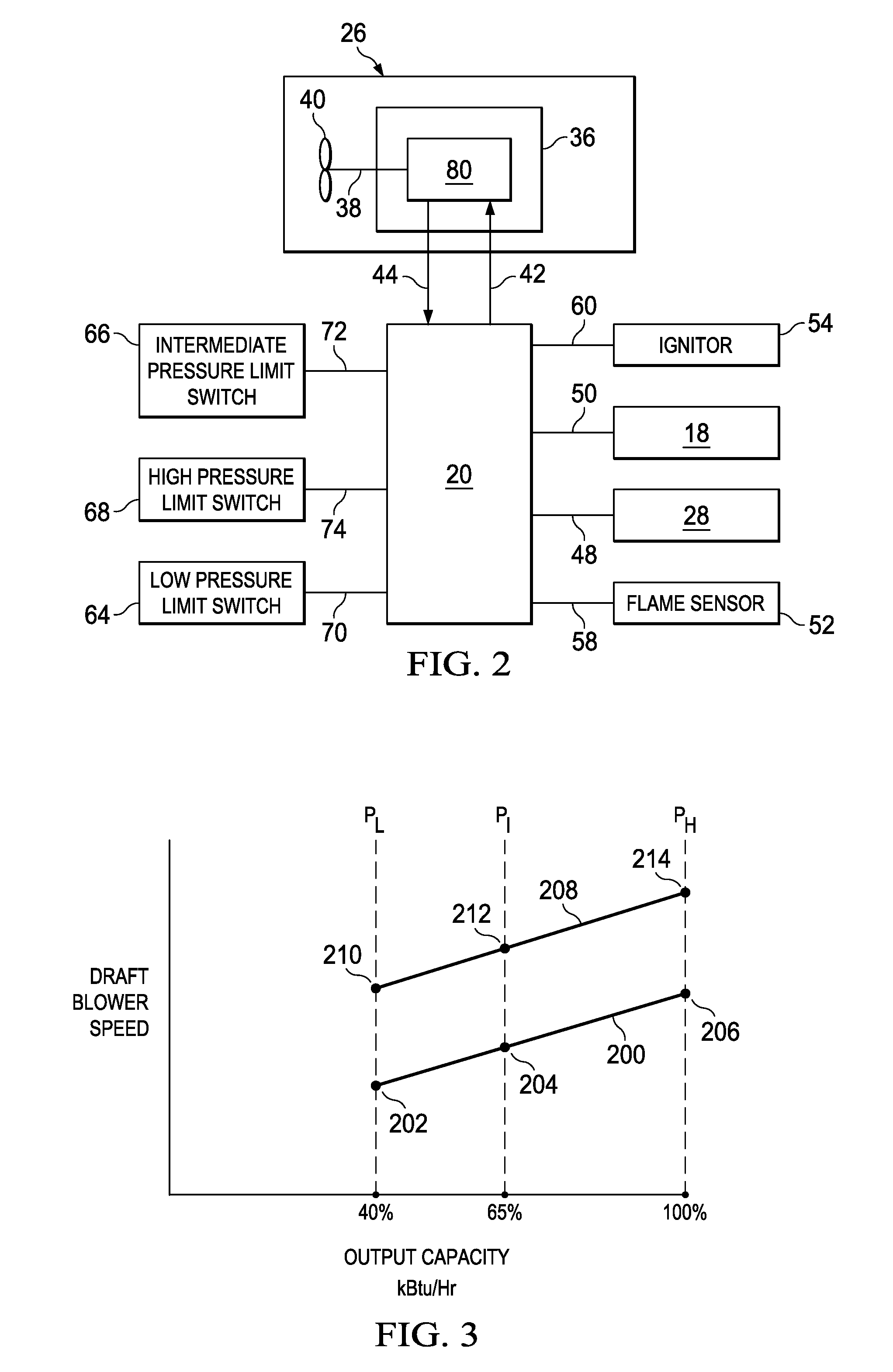

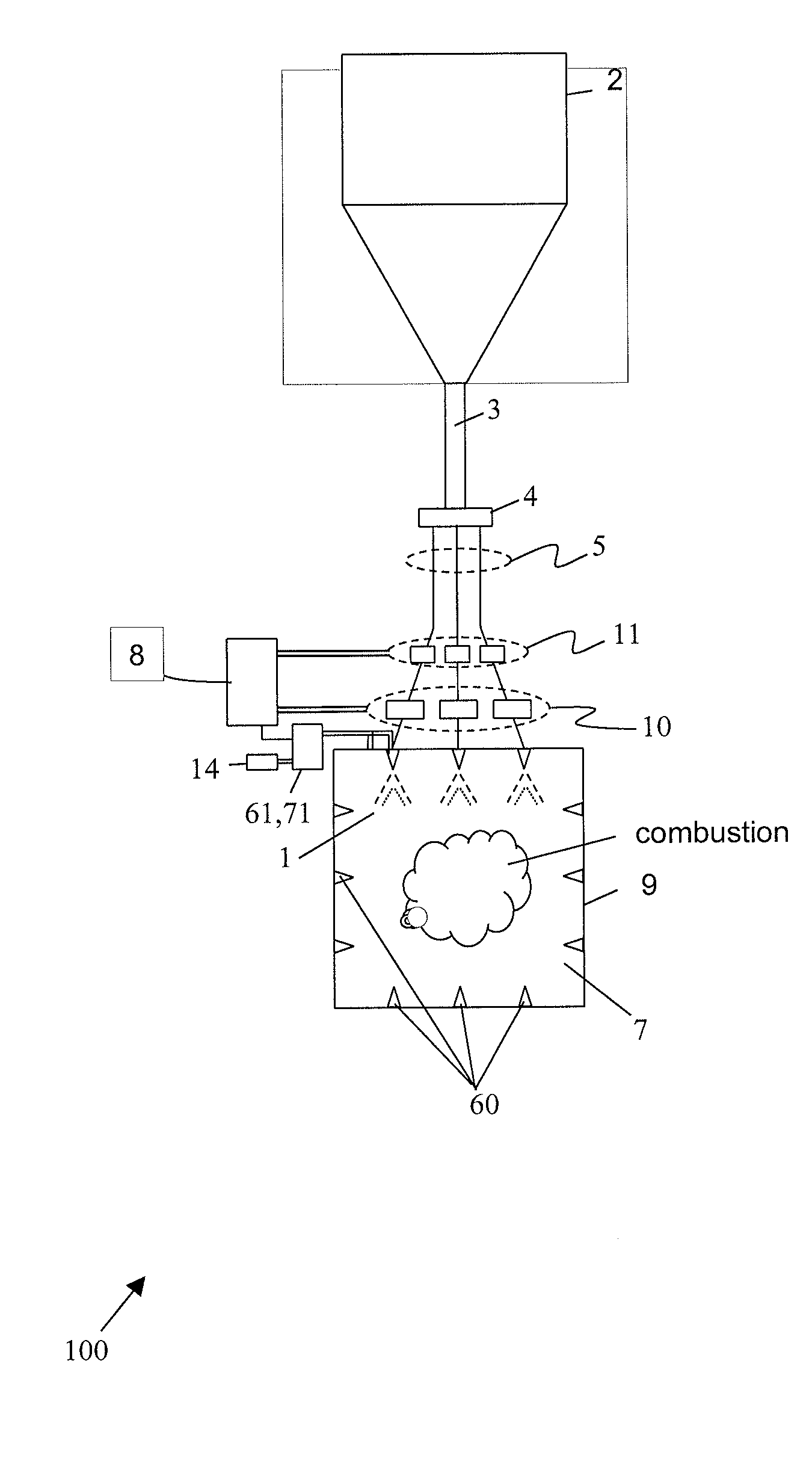

System and method for controlling a furnace

ActiveUS8672670B2Mechanical apparatusSpace heating and ventilation detailsDifferential pressureIntermediate pressure

Controlling a modulating gas furnace by monitoring a differential pressure associated with the modulating gas furnace using a low pressure limit switch configured to actuate at a first pressure, an intermediate pressure limit switch configured to actuate at a second pressure, and a high pressure limit switch configured to actuate at a third pressure, the second pressure being between the first and third pressure, selectively operating the modulating gas furnace in one of a cycling mode, a modulating mode in a lower range, and a modulating mode in an upper range, the modulating mode in the lower range being associated with an output capacity range between the output capacity ranges of the cycling mode and the modulating mode in the upper range, and selectively operating the furnace in response to at least one of the low pressure limit switch, the intermediate pressure limit switch, and the high pressure limit switch.

Owner:TRANE INT INC

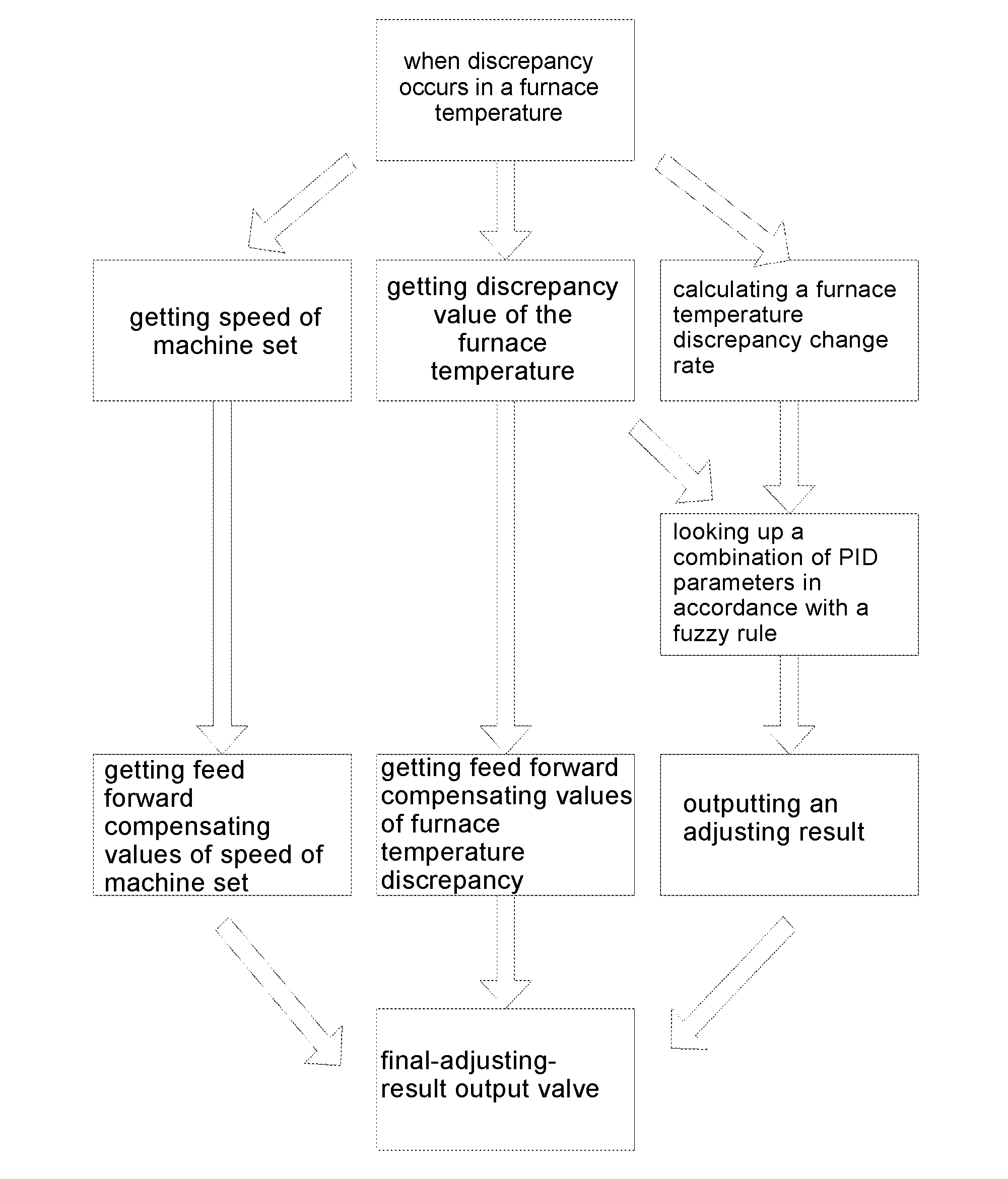

Method and device for controlling furnace temperature of burning heating furnace

ActiveUS20140364994A1Certain adaptive capacityAchieve rapidityFuel supply regulationTesting/monitoring control systemsFurnace temperatureFuzzy control system

A method for controlling furnace temperature of a fired heating furnace is disclosed, comprising: measuring furnace temperatures to obtain furnace temperature feedback values; calculating the differences between furnace temperature setting values and the furnace temperature feedback values as discrepancy values DV1, in accordance with the furnace temperature feedback values and the furnace temperature setting value; calculating the differences between the furnace temperature setting values and the furnace temperature feedback values in a unit time, i.e., the gradient of furnace temperature change values, as discrepancy values DV2; obtaining a speed V of a fired heater machine set from a speed adjuster of the fired heater machine set, and obtaining a first multiple feed forward output components FFV in accordance with the speed V of the machine set (V); obtaining a second multiple feed forward output components FFT in accordance with the differences between the furnace temperature setting values and the furnace temperature feedback values, i.e., the discrepancy values DV1; looking up a PID control parameter in accordance with the discrepancy values DV1 and DV2, based on fuzzy control rule, and creating an adjusting control parameter OP1 in accordance with the PID control parameter; controlling a valve for regulating coal gas flow and a valve for regulating air flow by combining the adjusting control parameter OP1 with the first multiple feed forward components FFV and the second multiple feed forward components FFT as a final control output value.

Owner:BAOSHAN IRON & STEEL CO LTD

System and Method for Controlling A Furnace

ActiveUS20110111352A1Mechanical apparatusSpace heating and ventilation detailsDifferential pressureIntermediate pressure

Controlling a modulating gas furnace by monitoring a differential pressure associated with the modulating gas furnace using a low pressure limit switch configured to actuate at a first pressure, an intermediate pressure limit switch configured to actuate at a second pressure, and a high pressure limit switch configured to actuate at a third pressure, the second pressure being between the first and third pressure, selectively operating the modulating gas furnace in one of a cycling mode, a modulating mode in a lower range, and a modulating mode in an upper range, the modulating mode in the lower range being associated with an output capacity range between the output capacity ranges of the cycling mode and the modulating mode in the upper range, and selectively operating the furnace in response to at least one of the low pressure limit switch, the intermediate pressure limit switch, and the high pressure limit switch.

Owner:TRANE INT INC

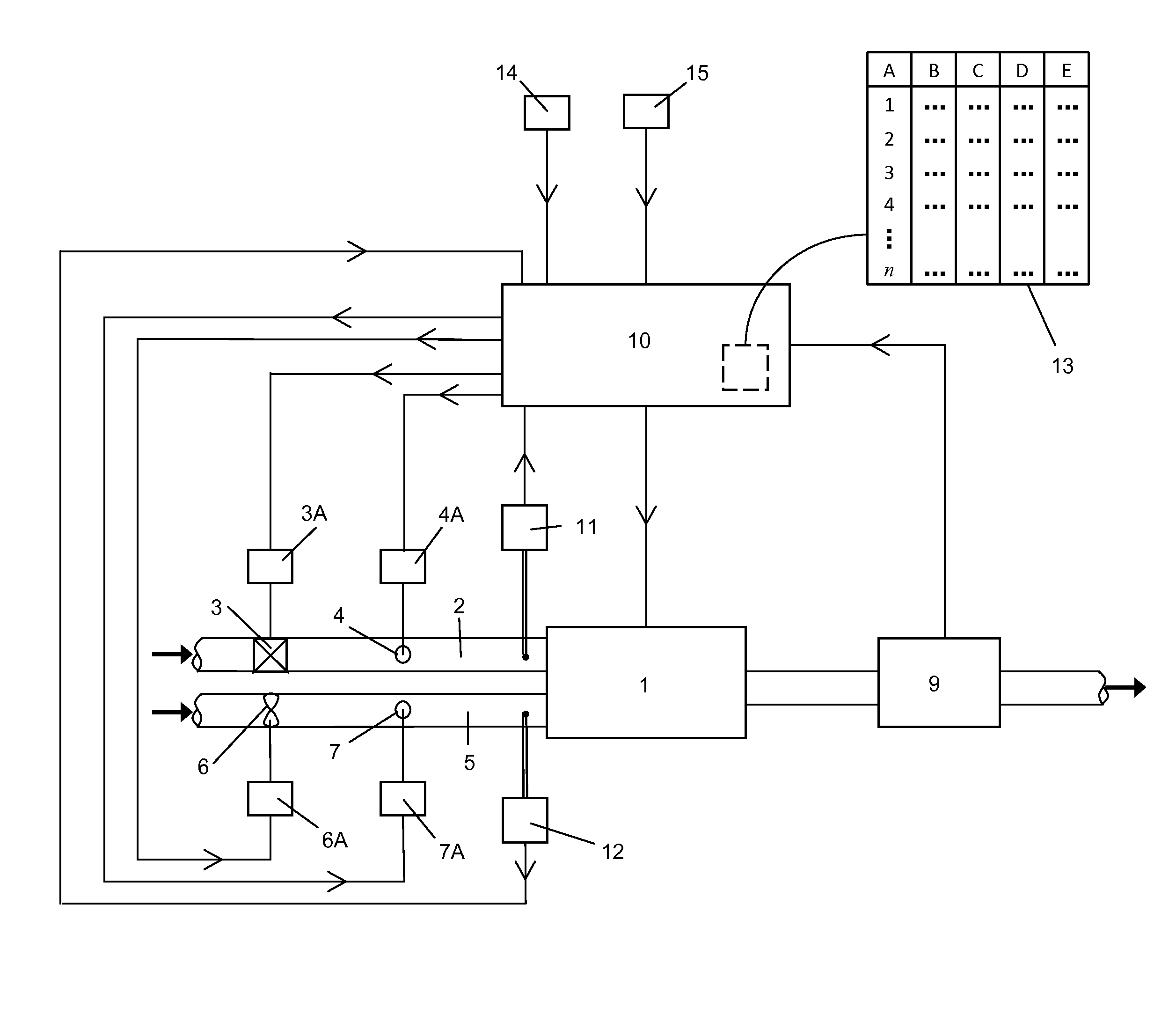

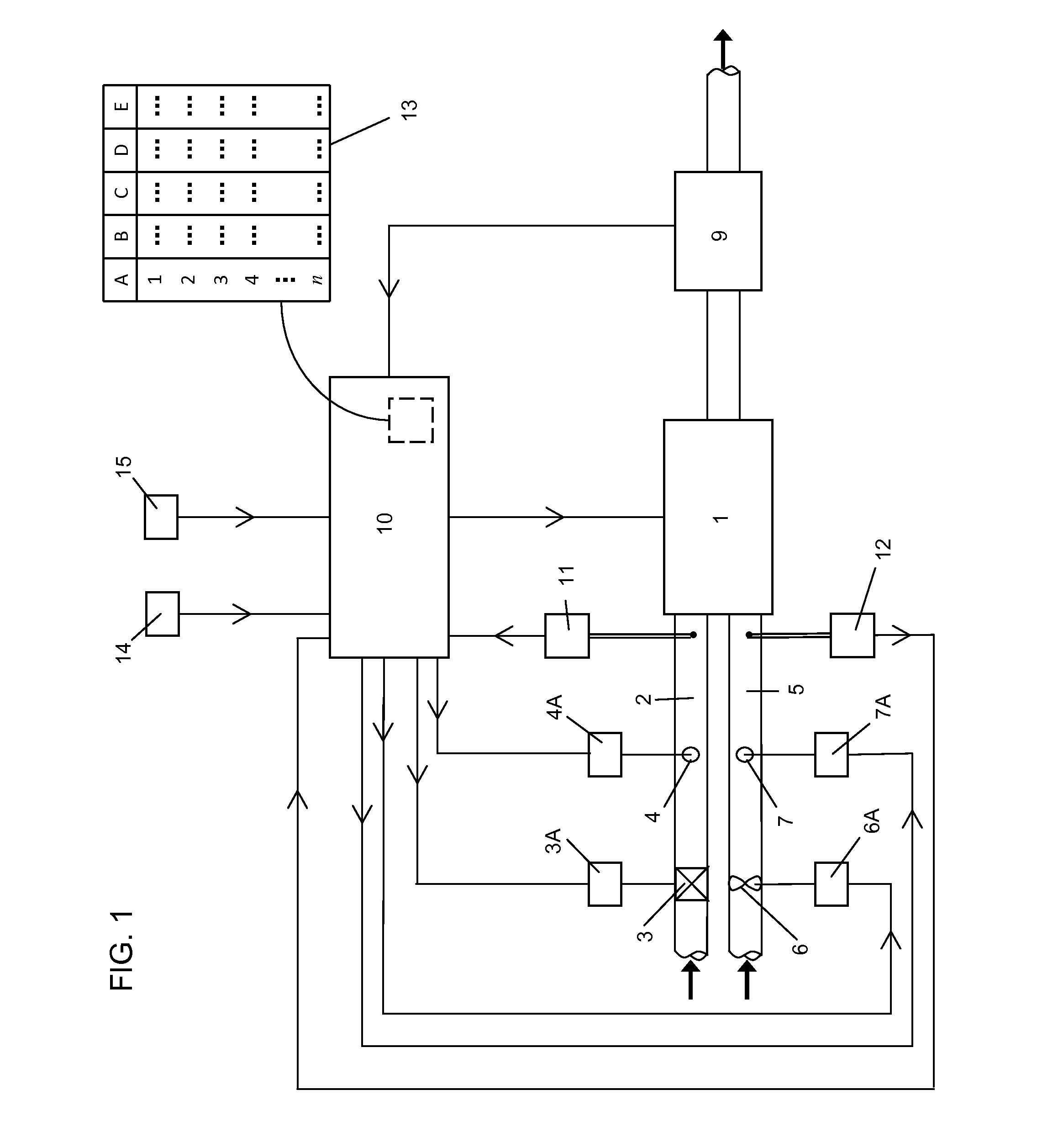

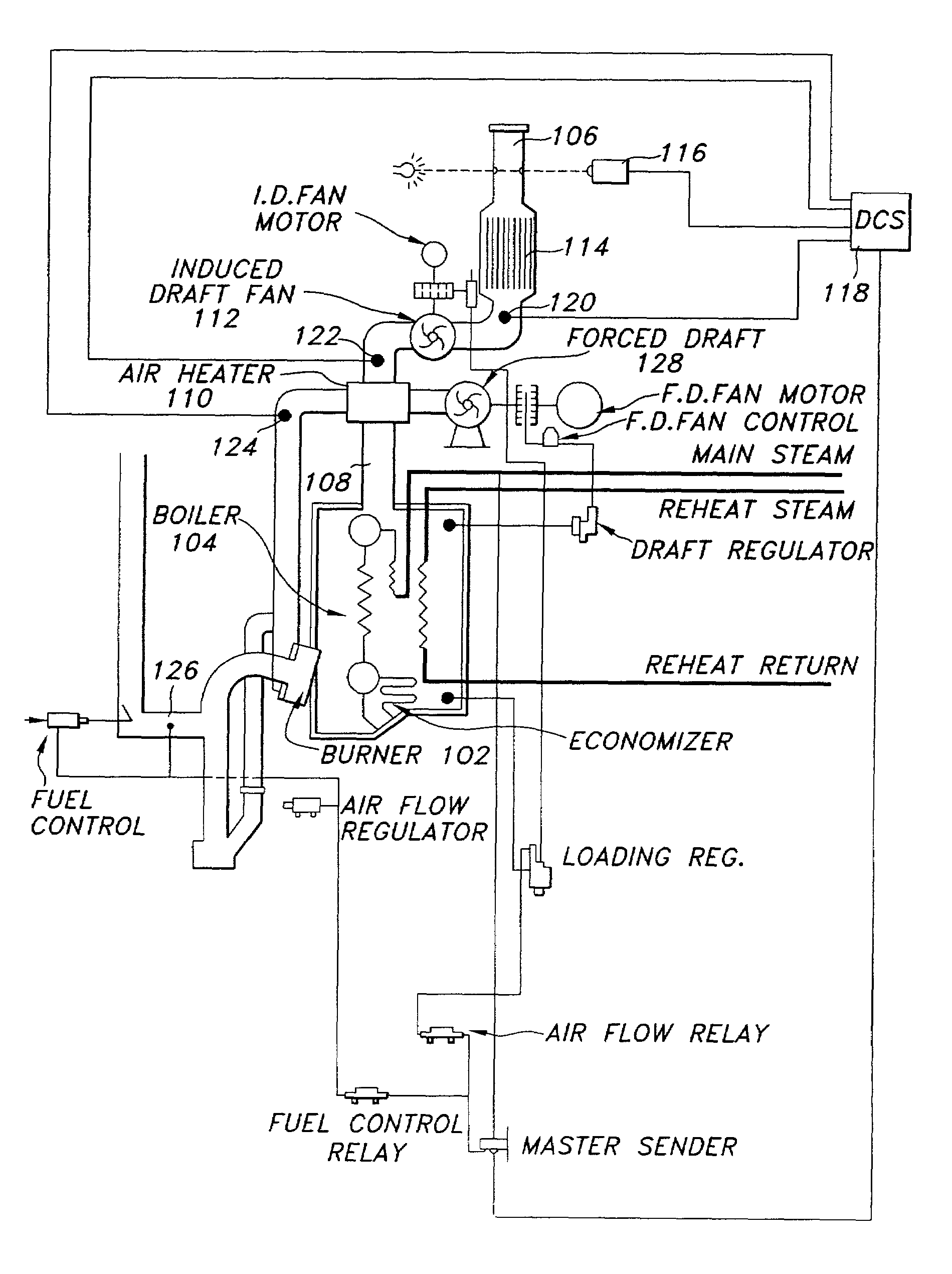

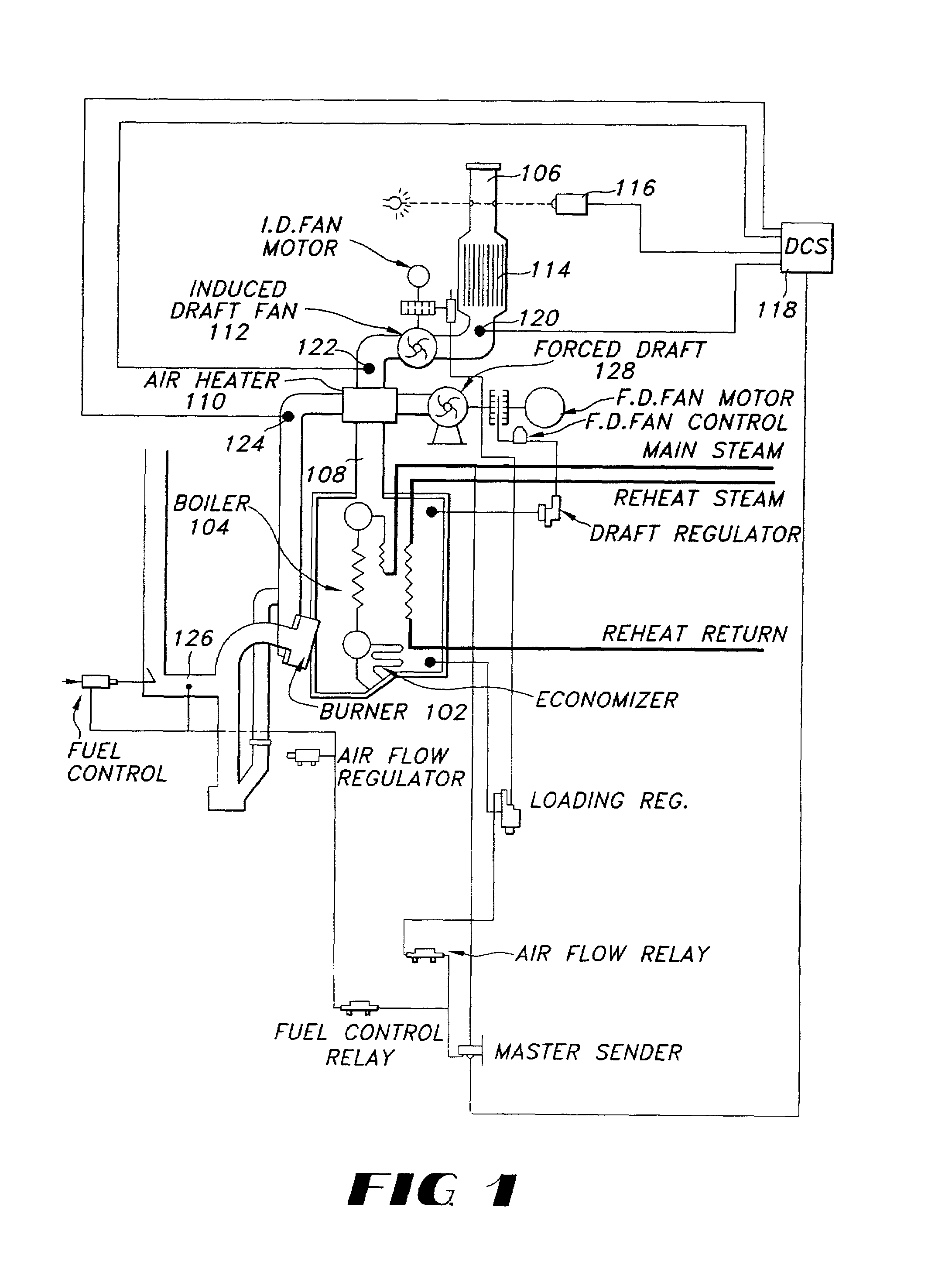

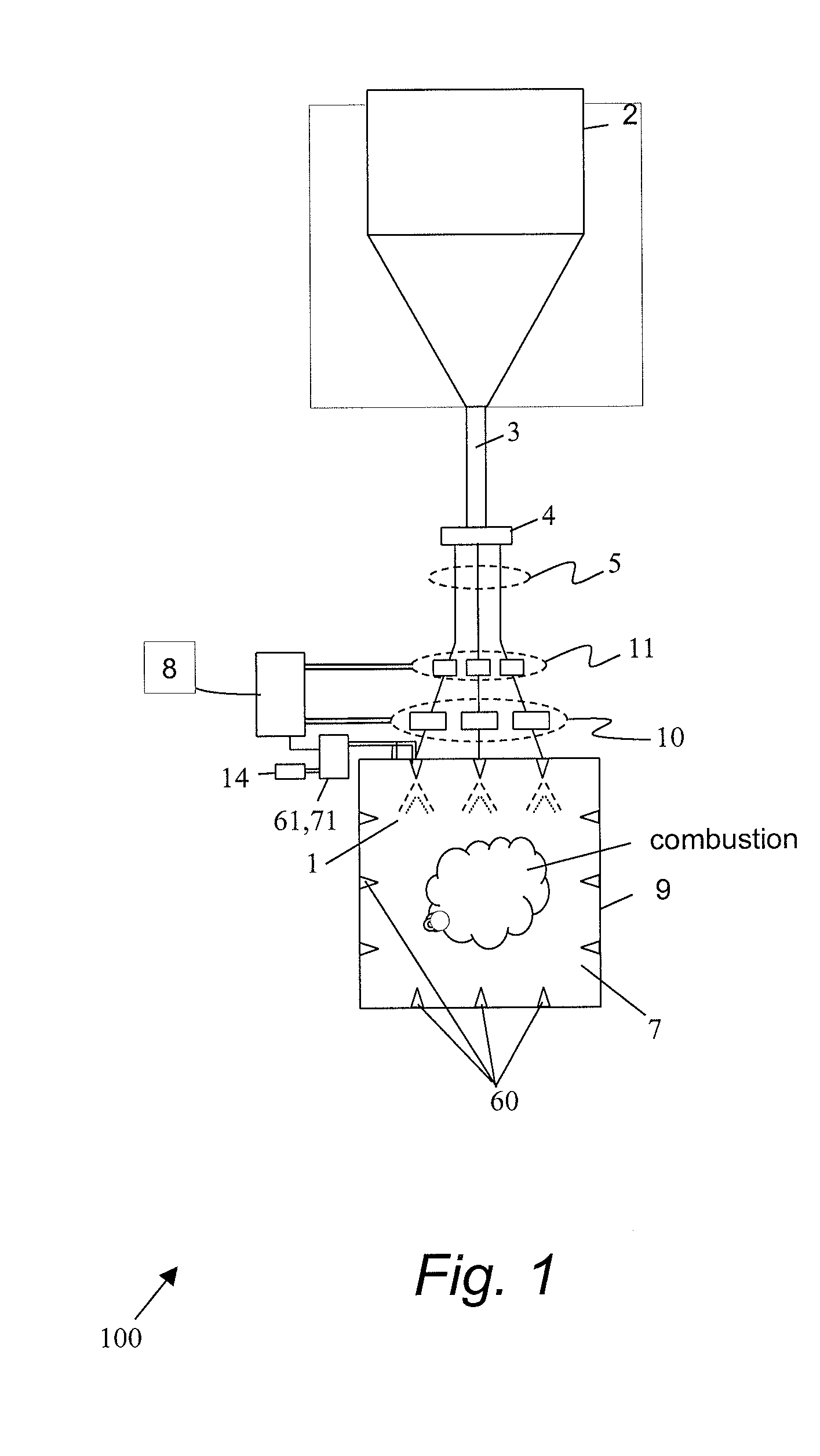

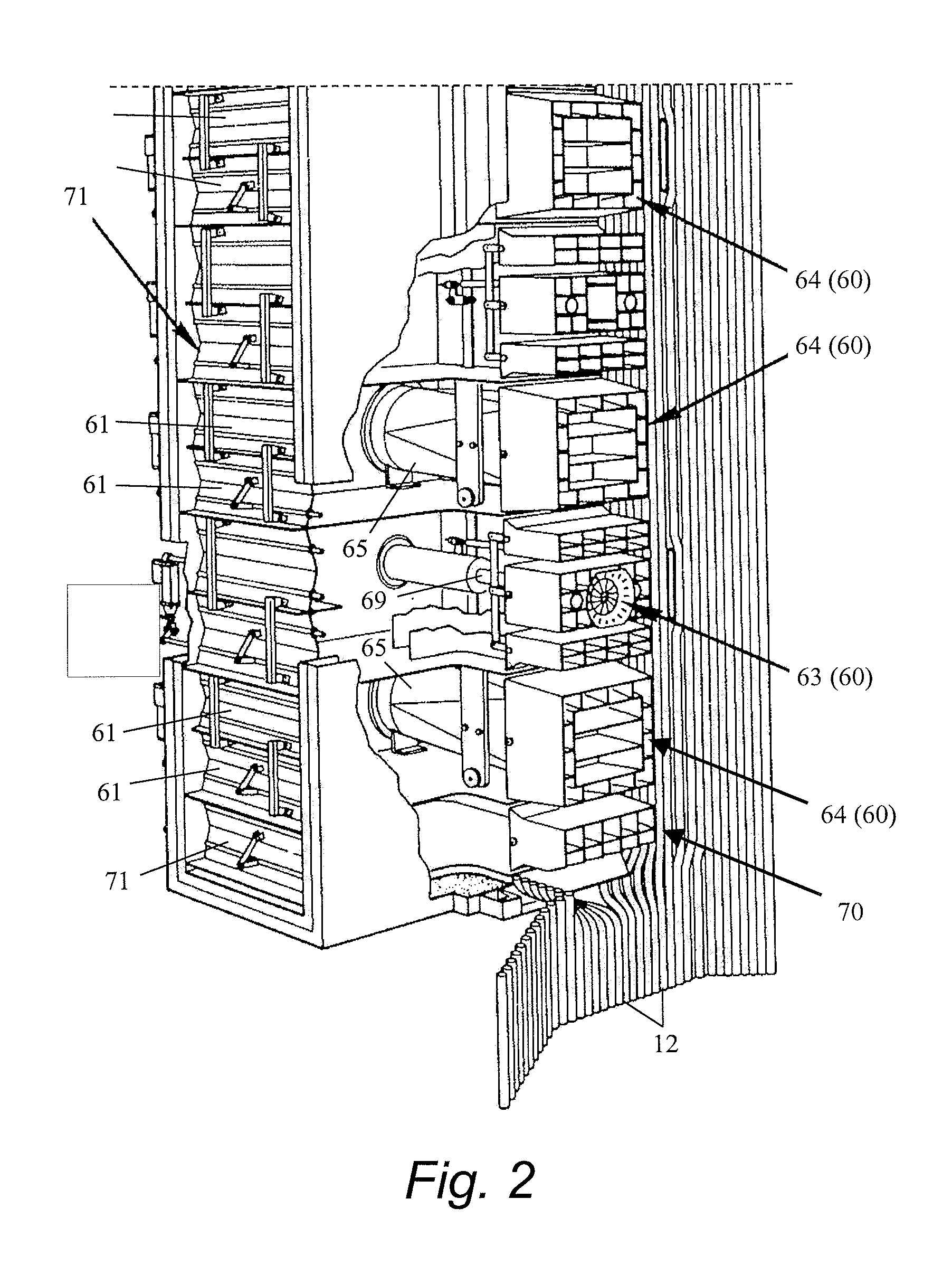

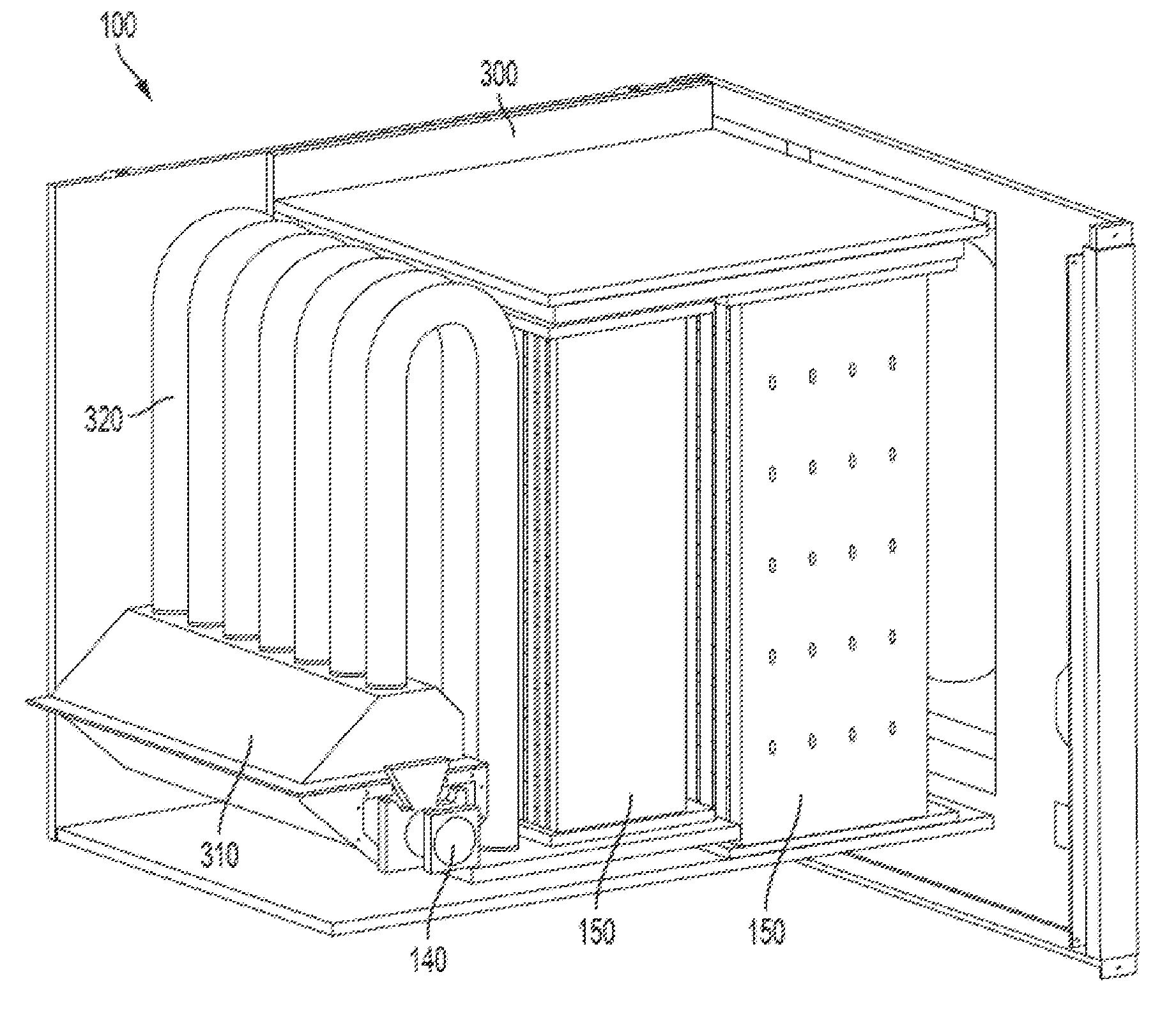

Solids flow meter for integrated boiler control system

InactiveUS20100316964A1Efficient combustionEmission reductionFuel supply regulationAir supply regulationCombustion systemCombustion

A combustion control system [100] for a combustion system [7] having a plurality of fuel pipes [5]. The combustion control system [100] including a plurality of flow meters [10], a controller [8], fuel flow controls [11] and secondary air controls [61,62,72]. Each meter [10] is adapted to monitor flow of fuel within a respective one of the fuel pipes [5] by sensing a pressure field within the fuel pipe [5]. A controller [8] receives the flow information from each of the flow meters [10], to evaluate performance of the combustion system [7]. Controller [8] also providing control information for controlling the flow of secondary air dampers [61,62,71] into the combustion system [7], and optionally controlling the flow of fuel in each fuel pipe [5].

Owner:ALSTOM TECH LTD

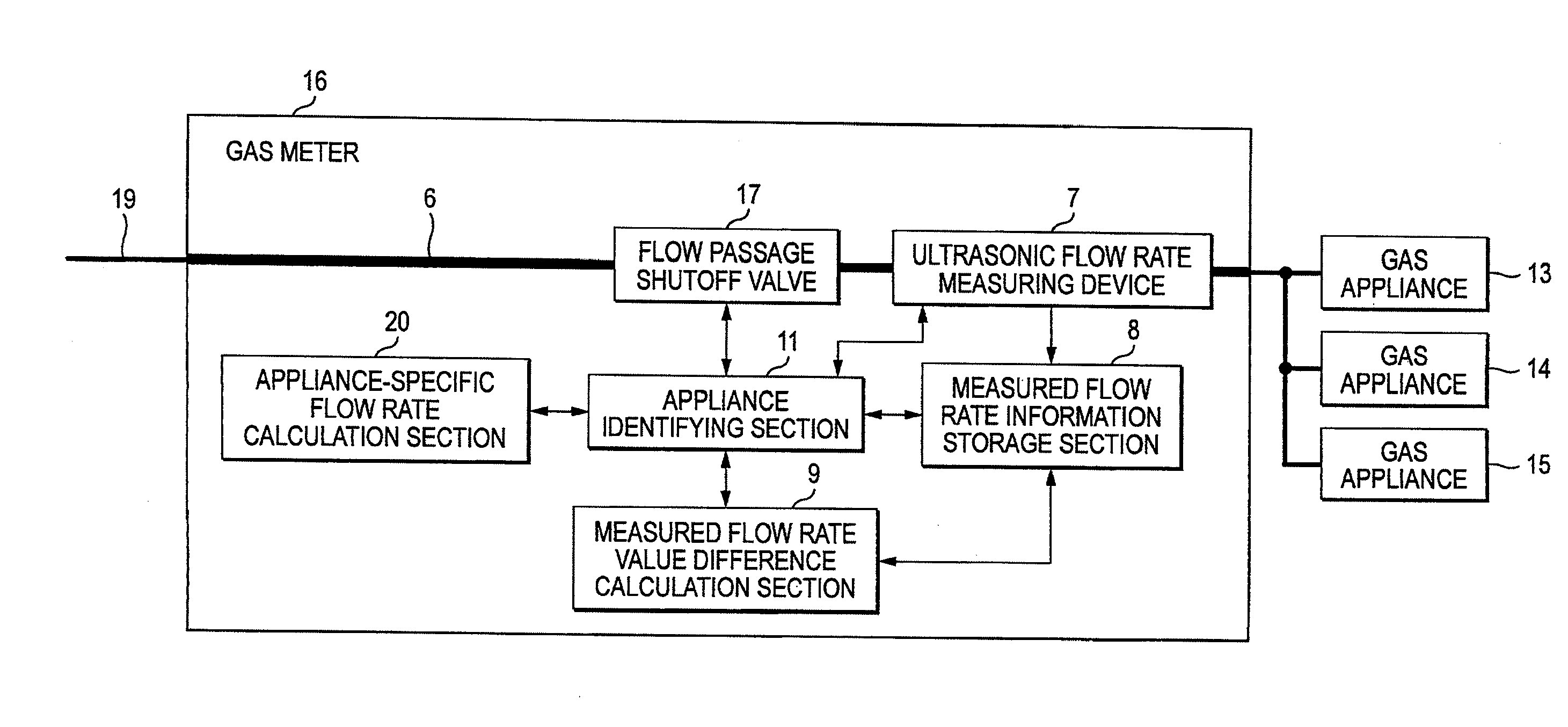

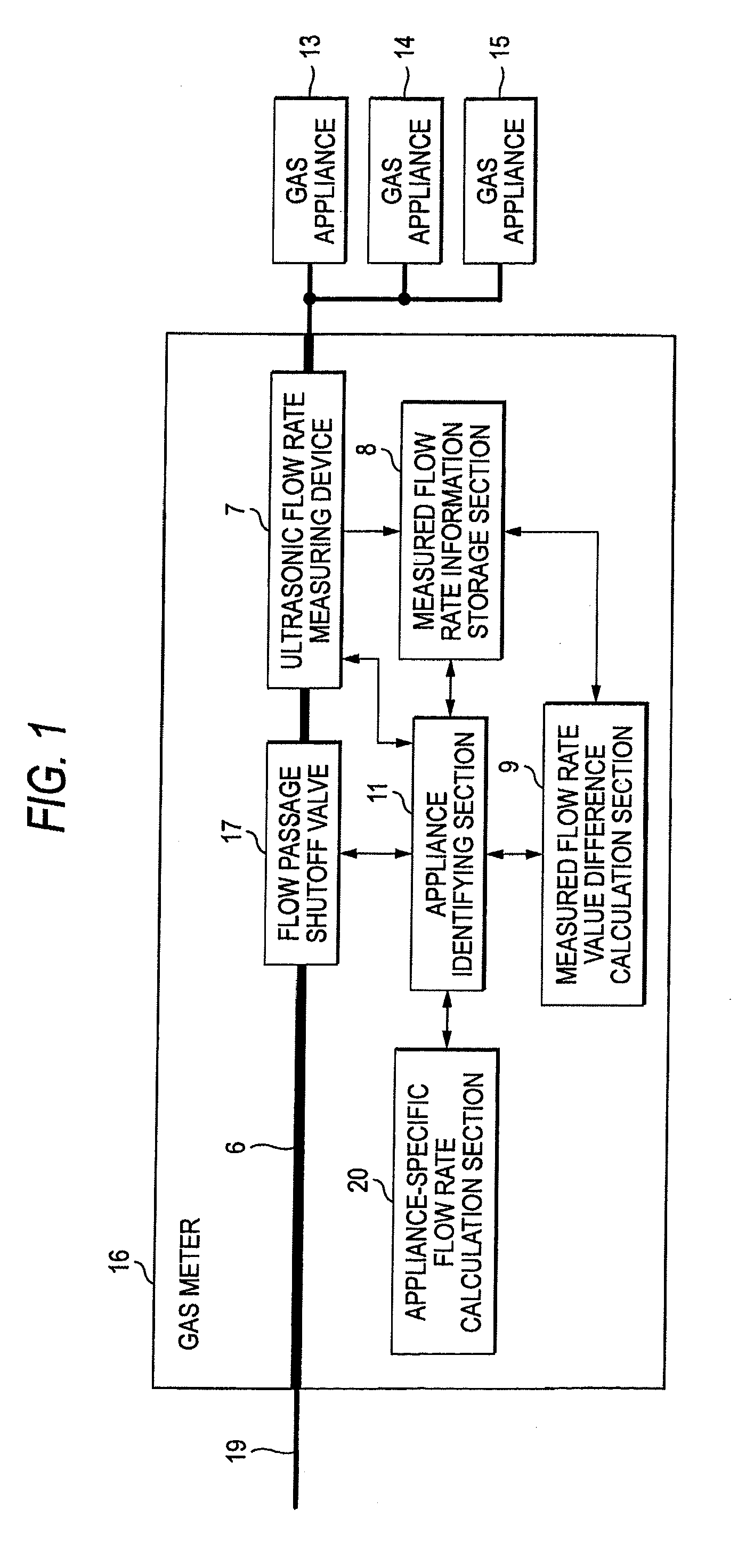

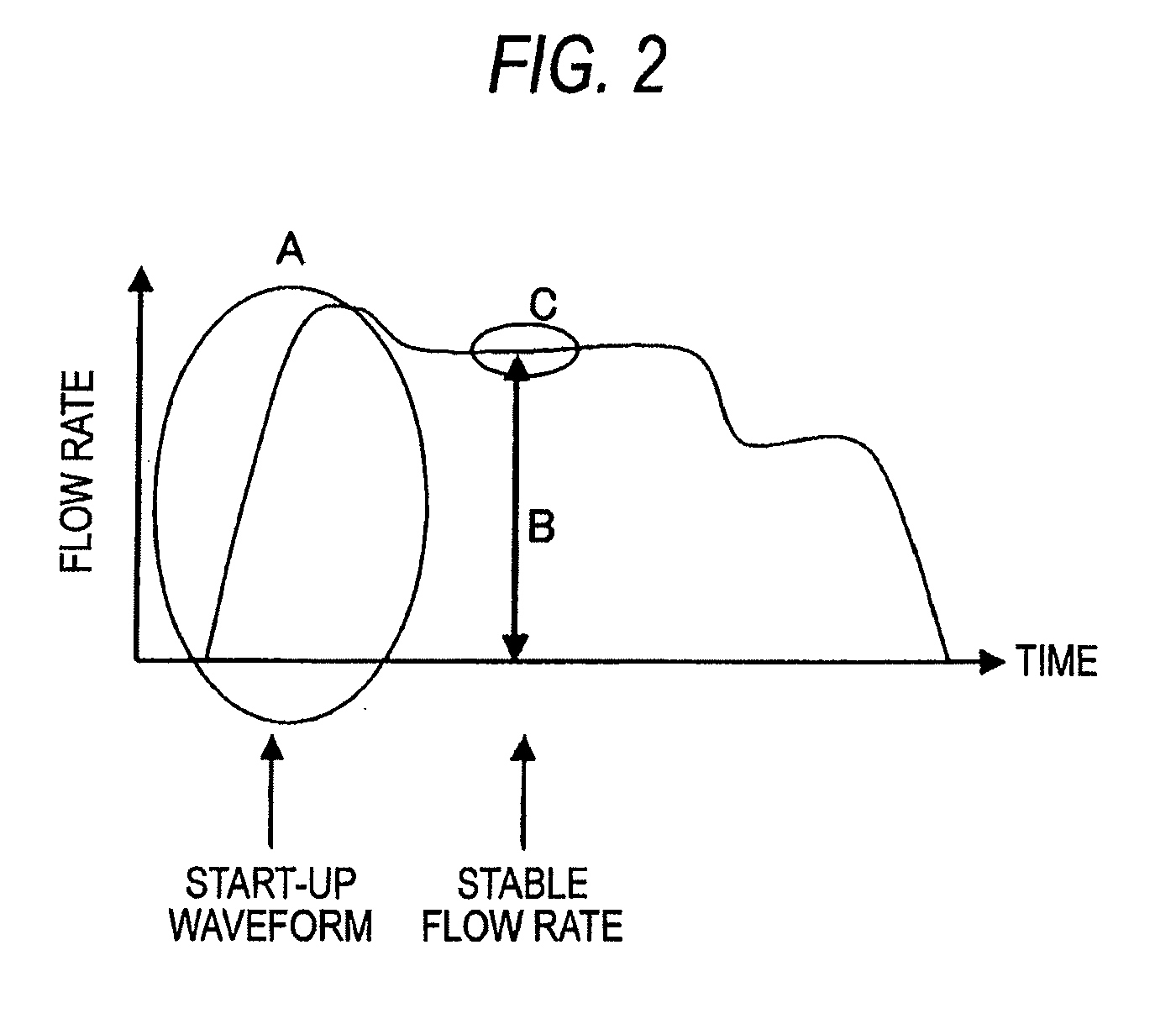

Flow rate measurement apparatus, program thereof, flow rate measurement method, and fluid supply system

InactiveUS20100138167A1Identification of methodFuel supply regulationTesting/calibration apparatusDischarge measurementsEngineering

There is provided a technique for accurately identifying an appliance which uses the fluid from a viewpoint of the range of a change in flow rate value. An ultrasonic flow rate measuring device 7 measures a flow rate value of gas flowing in a flow passage 6 of a gas meter 16, and a measured flow rate information storage section 8 stores a measured flow rate value. A measured flow rate value difference calculation section 9 calculates a measured flow rate value difference within a predetermined period corresponding to an amount of change occurred in a measured flow rate value. An appliance identifying section 11 identifies an appliance which uses the fluid or leakage by determining whether or not the measured flow rate value difference is a predetermined threshold or less.

Owner:PANASONIC CORP

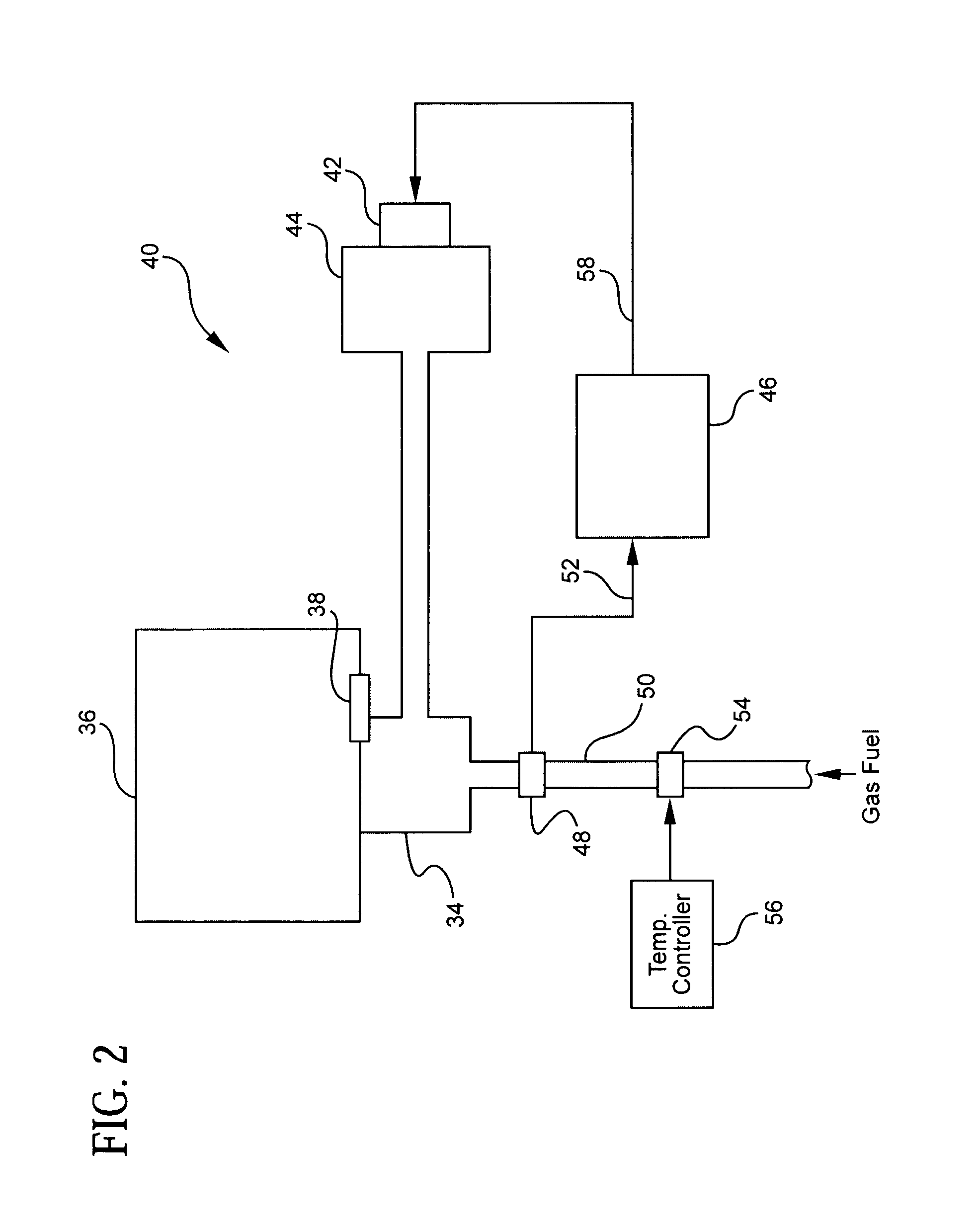

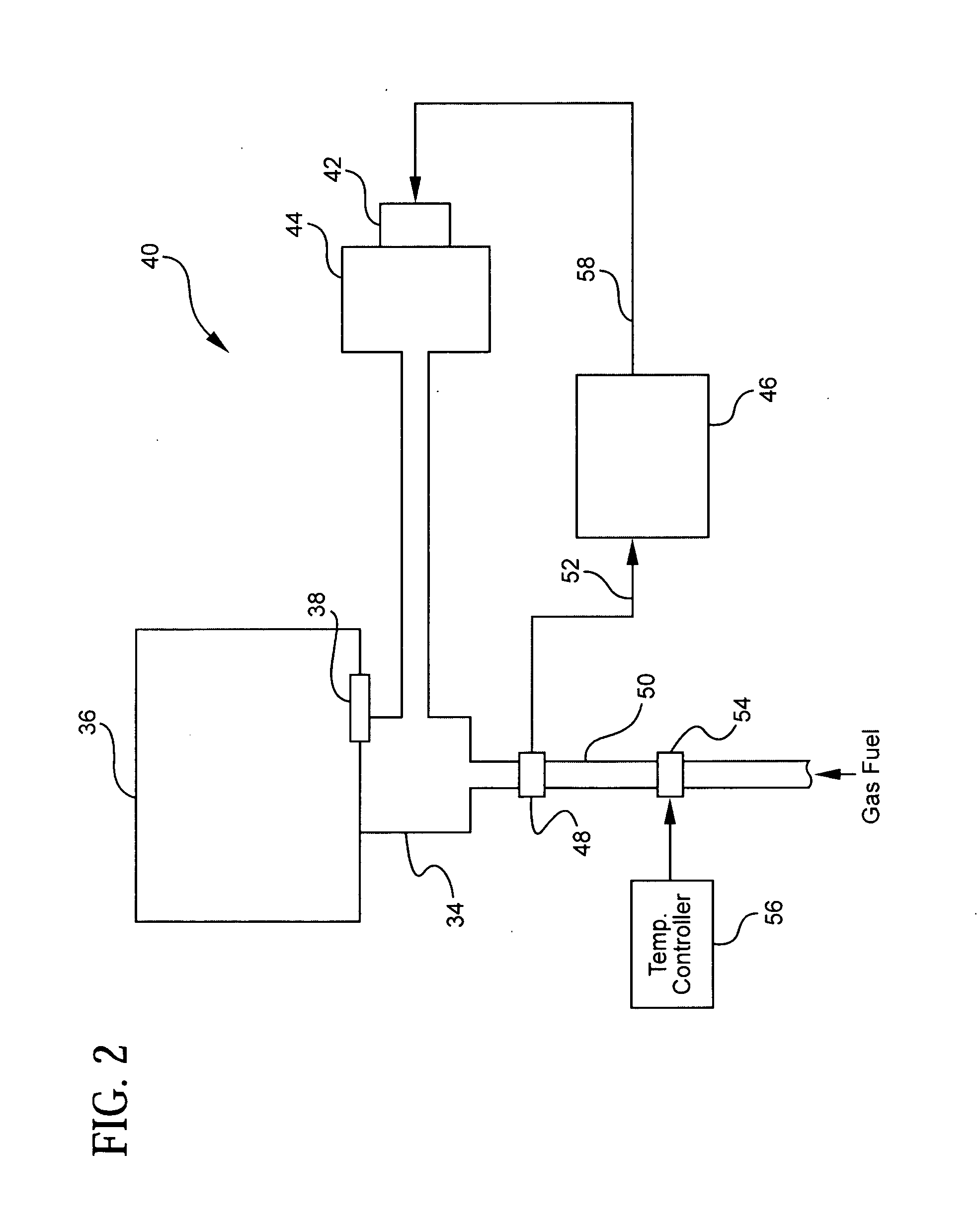

System and method for combustion-air modulation of a gas-fired heating system

InactiveUS7802984B2Improve thermal efficiencyBurn fasterFuel supply regulationAir supply regulationMotor speedEngineering

A system and method for providing a gas-fired heating system with improved thermal efficiency includes modulating a quantity of combustion air flow to a combustion mixture in response to a measured change in fuel-gas pressure using a DC (e.g., brushless) motor to drive a combustion air blower. A pressure transducer in a manifold transporting fuel-gas into the combustion mixture outputs a signal proportional to the measured pressure to the motor. The motor speed and thus the resultant quantity of combustion air flow are modulated in proportion to the quantity of fuel-gas to the mixture. Accordingly, a constant fuel-gas to combustion air ratio is maintained. The system and method may further provide for adjusting the output signal to accommodate measured intake air temperature, and / or measured atmospheric pressure in order to maintain a constant, good thermal efficiency (preferably ≧80%) regardless of air temperature and altitude at the system's installation location.

Owner:REZNOR

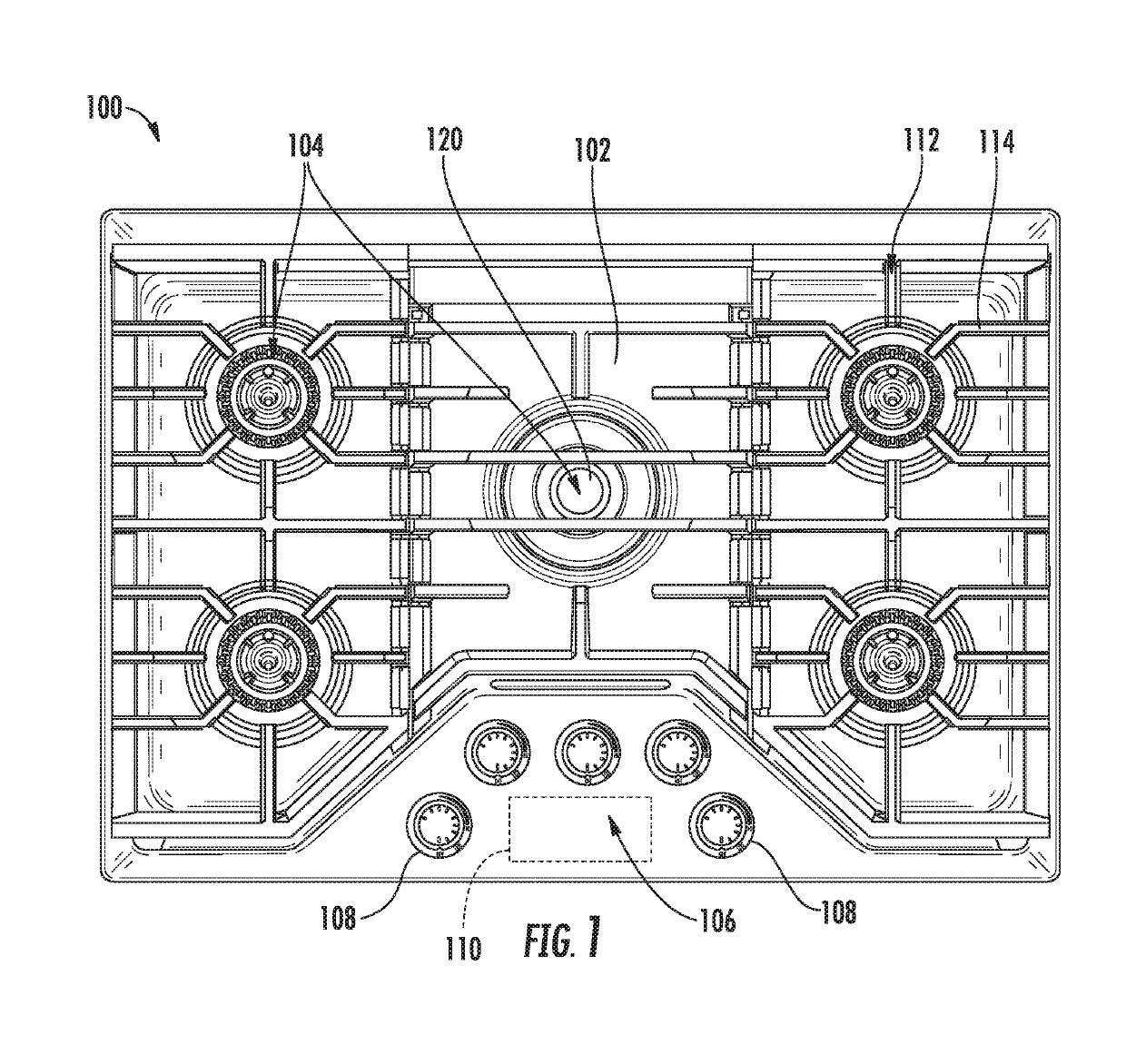

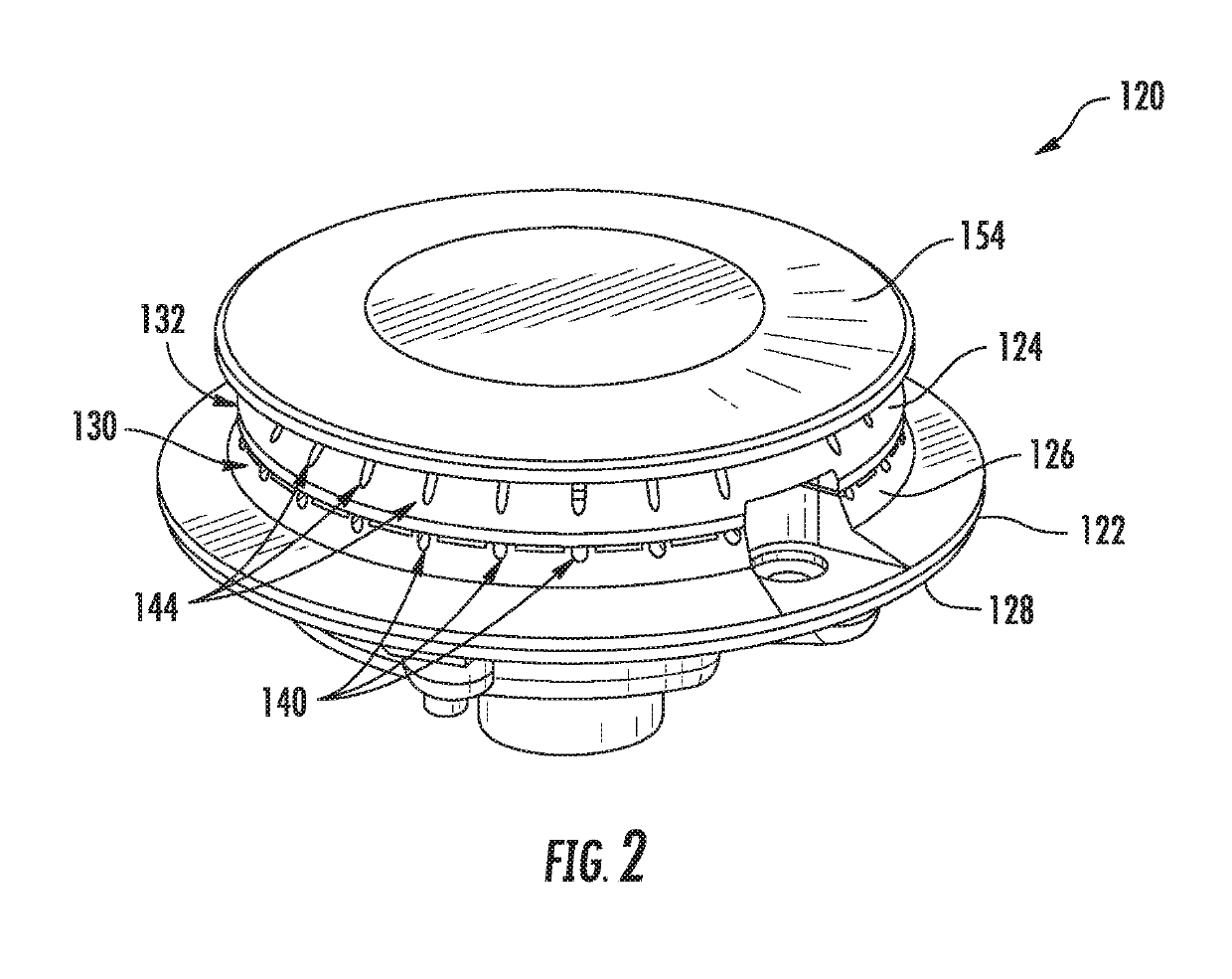

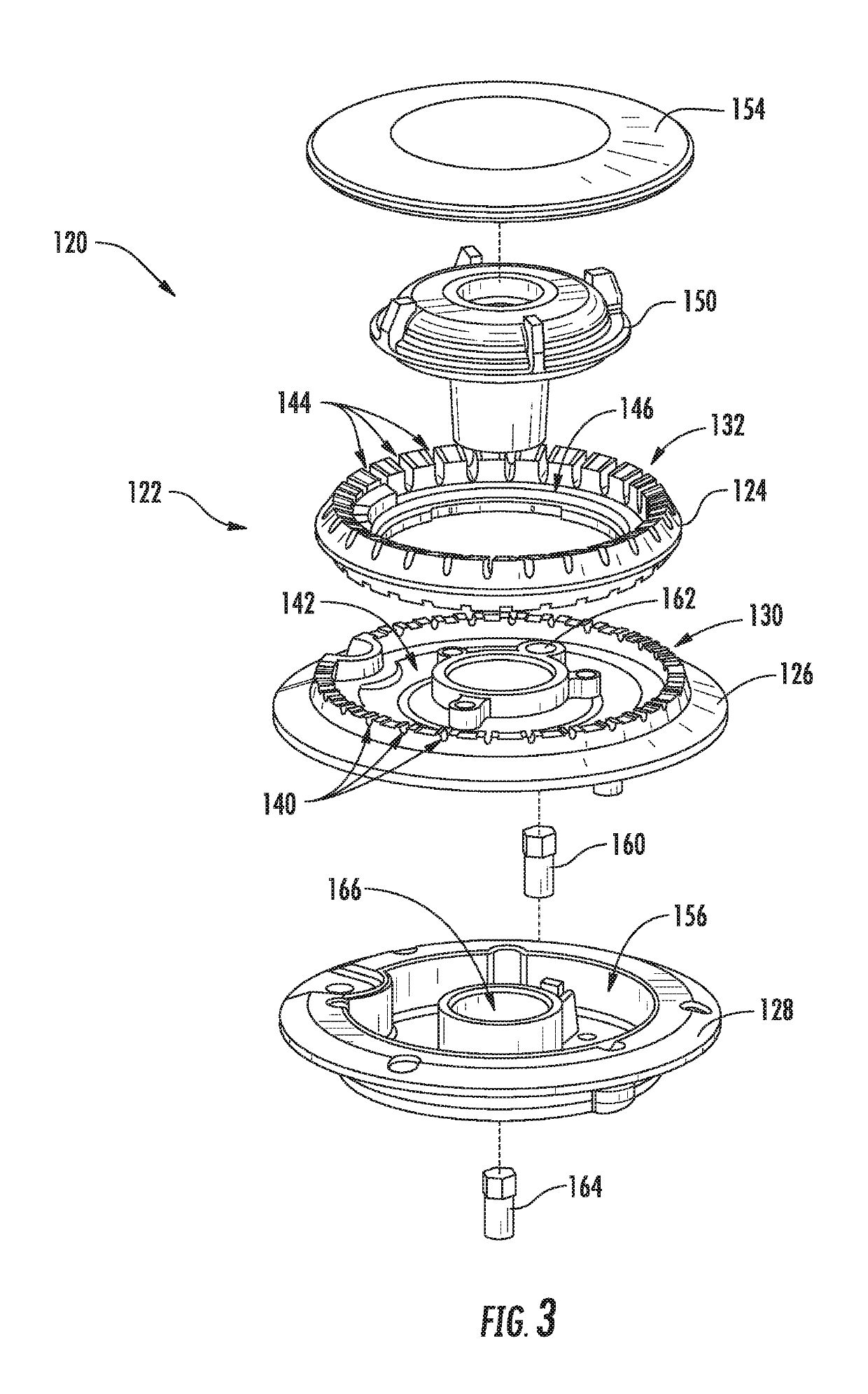

Fuel supply system for a gas burner assembly

ActiveUS20190120496A1Gaseous fuel feeder/distributionDomestic stoves or rangesControl valvesFuel supply

A fuel supply system for a gas burner assembly is provided. The gas burner assembly includes an inner burner stage positioned concentrically within an outer burner stage. The fuel supply system includes a fuel supply for providing a primary flow of fuel through a primary fuel conduit and a single outlet control valve operably coupled to the primary fuel conduit. A first and second fuel supply conduit split off of the primary fuel conduit and are fluidly coupled with the outer burner stage and the inner burner stage, respectively. A shutoff valve is operably coupled to one of the first fuel supply conduit and the second fuel supply conduit and is configured for closing when a flow rate of fuel through the shutoff valve drops below a predetermined flow rate.

Owner:HAIER US APPLIANCE SOLUTIONS INC

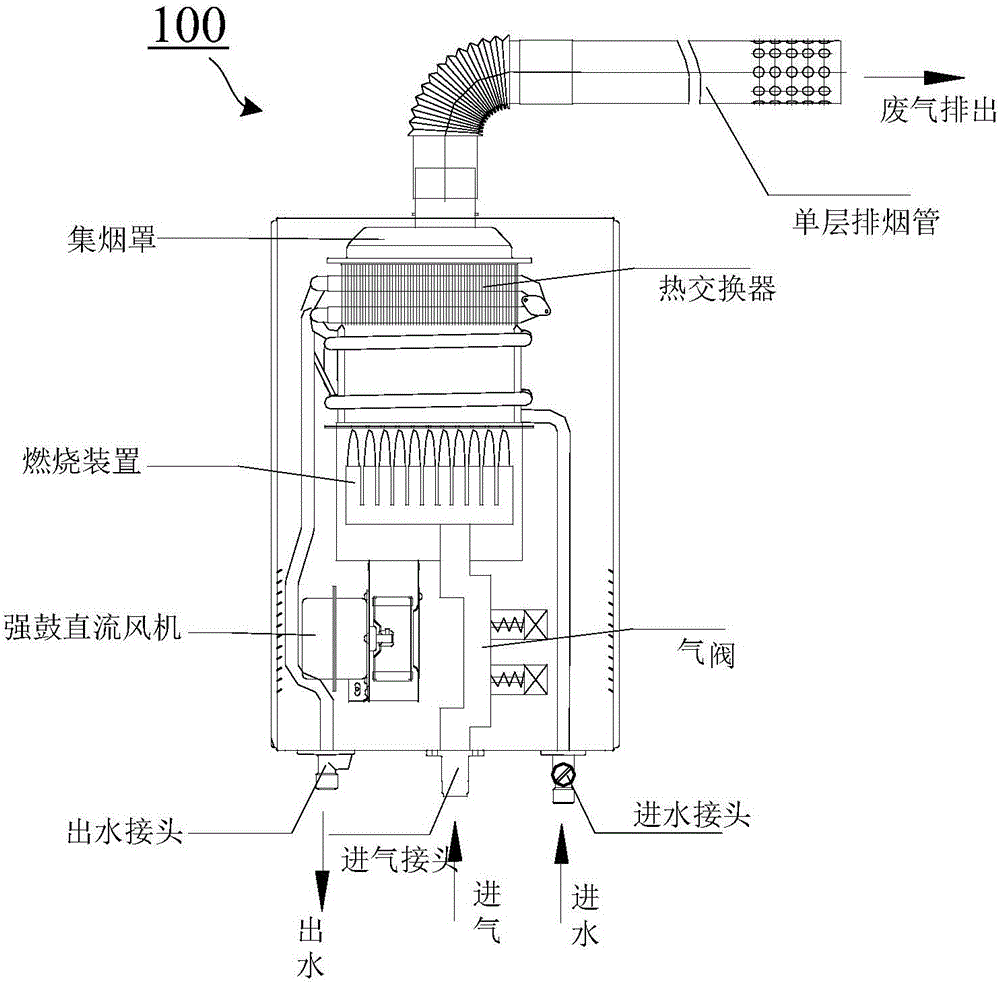

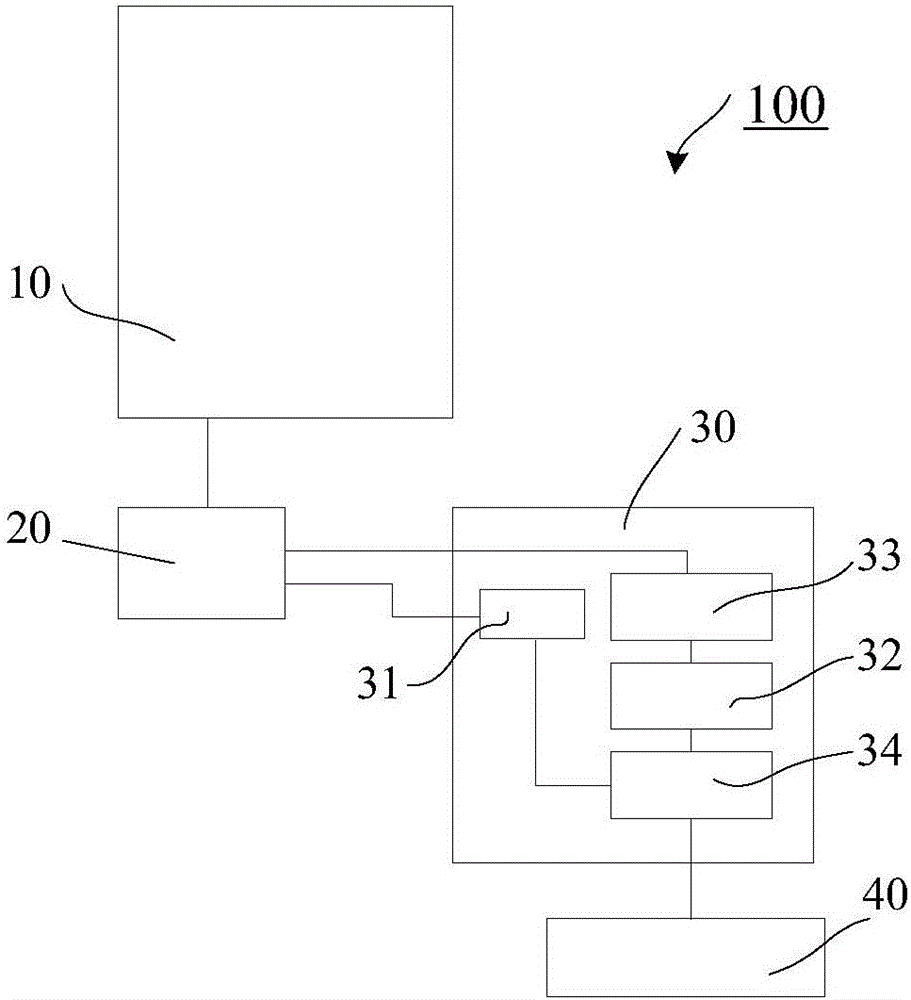

Gas water heater and exhaust controlling method thereof

ActiveCN105757998AStable currentGuaranteed air supplyFluid heatersCombustion regulation systemsCombustion chamberControl signal

The invention discloses a gas water heater. The gas water heater comprises a combustion chamber, a fan, a constant-current regulating module and a control module, wherein the fan is used for conveying air to the combustion chamber and discharging the combustion tail gas in the combustion chamber out of the chamber; the constant current regulating module is used for collecting current signals of the fan and regulating the fan to run in constant current according to the current signals and control signals of the fan; and the control module is used for outputting the control signals of the fan to control the fan. The gas water heater has the advantages that when the exhaust is not smooth, the normal air supply in the combustion chamber can be guaranteed to carry out normal combustion and guarantee the safety. The invention also discloses an exhaust controlling method of the gas water heater.

Owner:WUHU MIDEA KITCHEN & BATH APPLIANCES MFG CO LTD

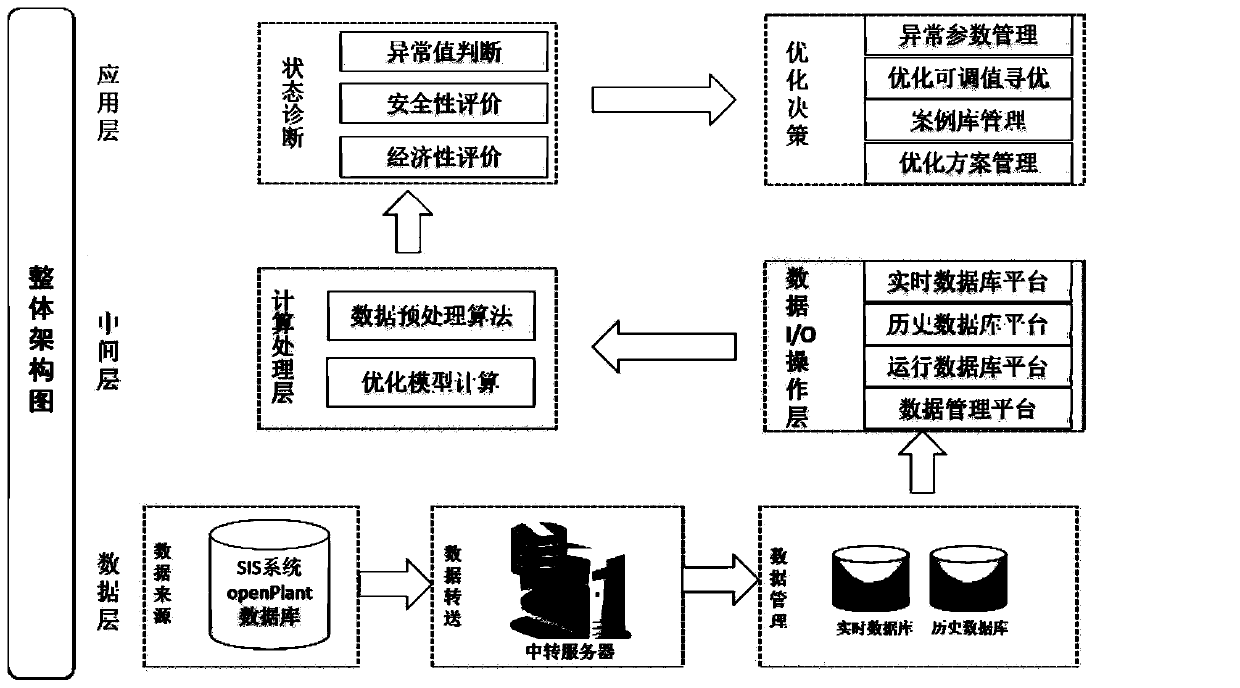

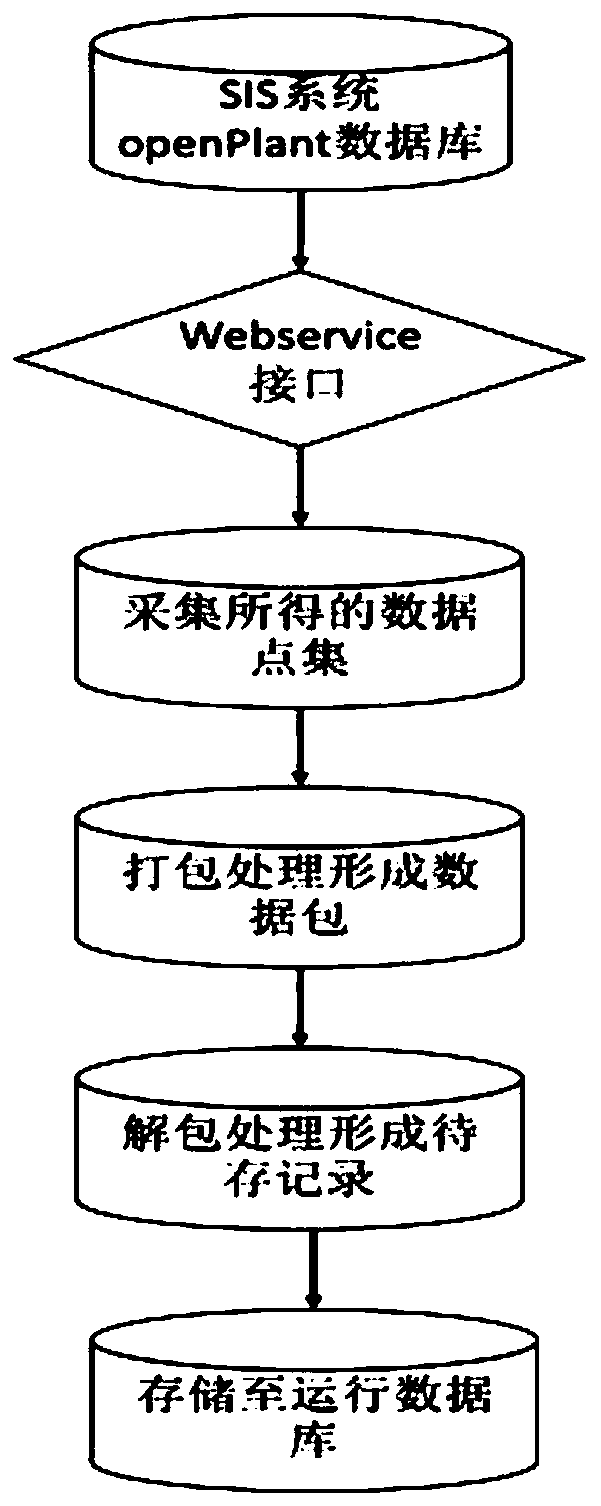

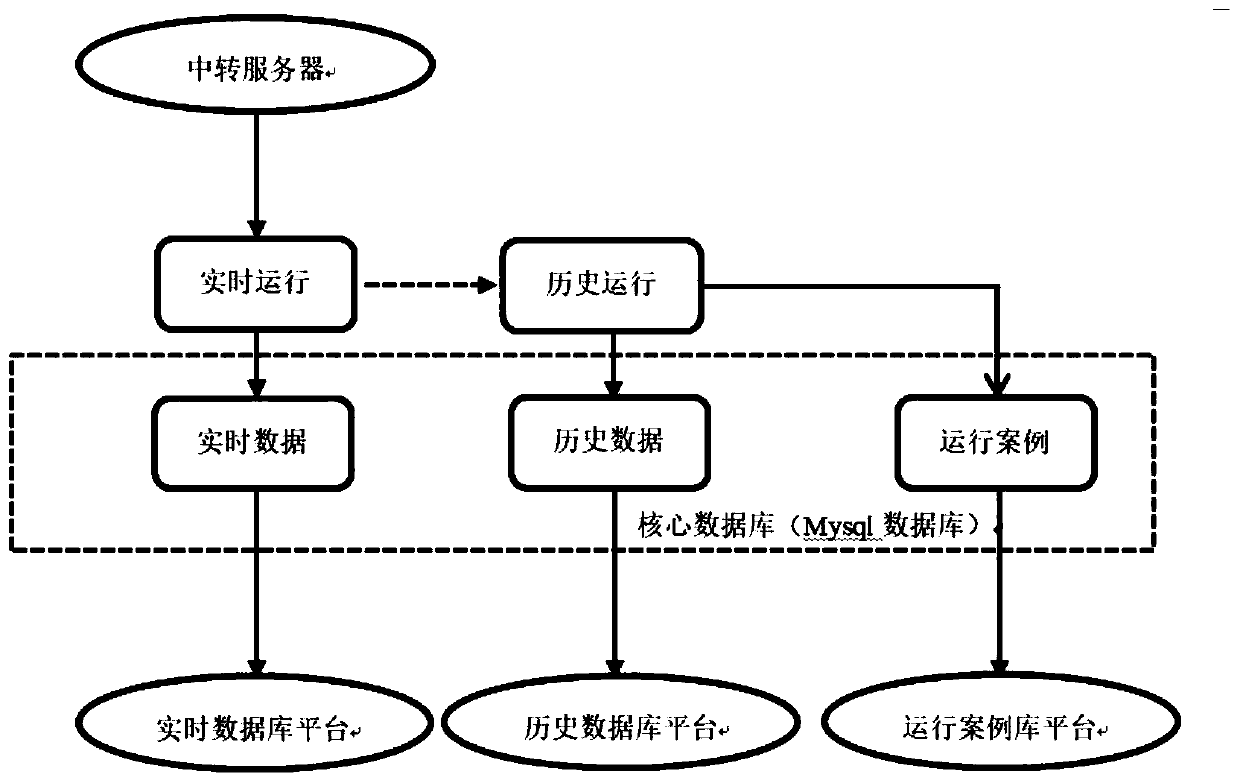

Boiler combustion optimization system, method and device based on data driving and intelligent algorithm

ActiveCN110397951AAchieve real-time operation optimizationSolve problems such as difficulty in operating within the optimal operating curve rangeCombustion regulation systemsReal-time dataCombustion

The invention discloses a boiler combustion optimization system, method and device based on data driving and intelligent algorithm. The optimization system comprises a data management system, an intelligent optimization system and a display system, wherein an optimal operation mode of each working condition is obtained by carrying out data mining on a large amount of historical operation data, andan optimal case knowledge base containing boiler operation characteristics and laws is built. Operation real-time data of a boiler are optimized through the intelligent optimization system, a combustion optimization instruction is obtained, transmitted to the display system for display, and fed back to a control system. According to the system, method and device, existing data resources are fullyutilized, the optimal adjustment of the combustion instruction is realized, and the technical problems that the boiler is likely to operate in a non-optimal operation curve range in an existing control system can be solved.

Owner:GUANGZHOU DEV GRP CO LTD +2

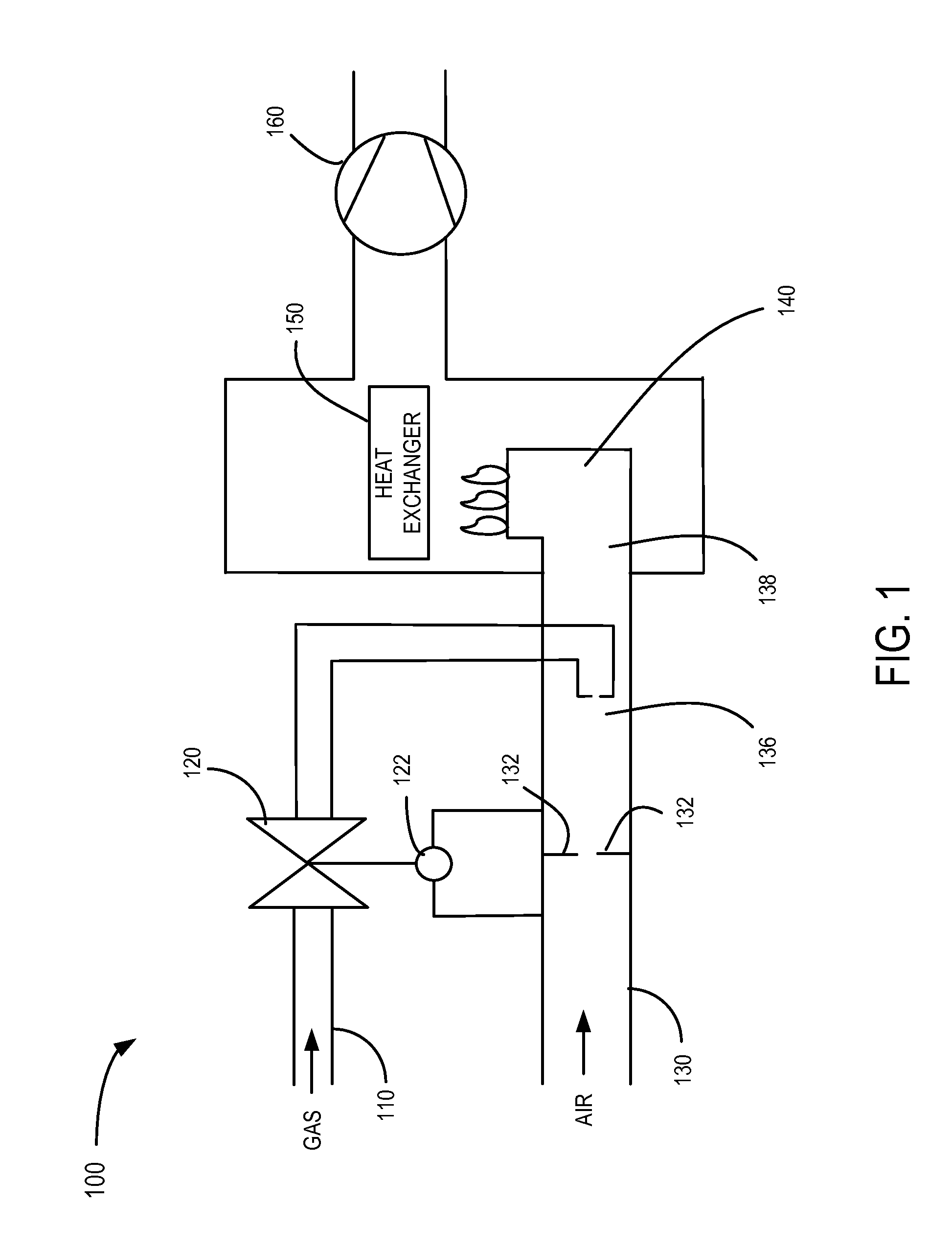

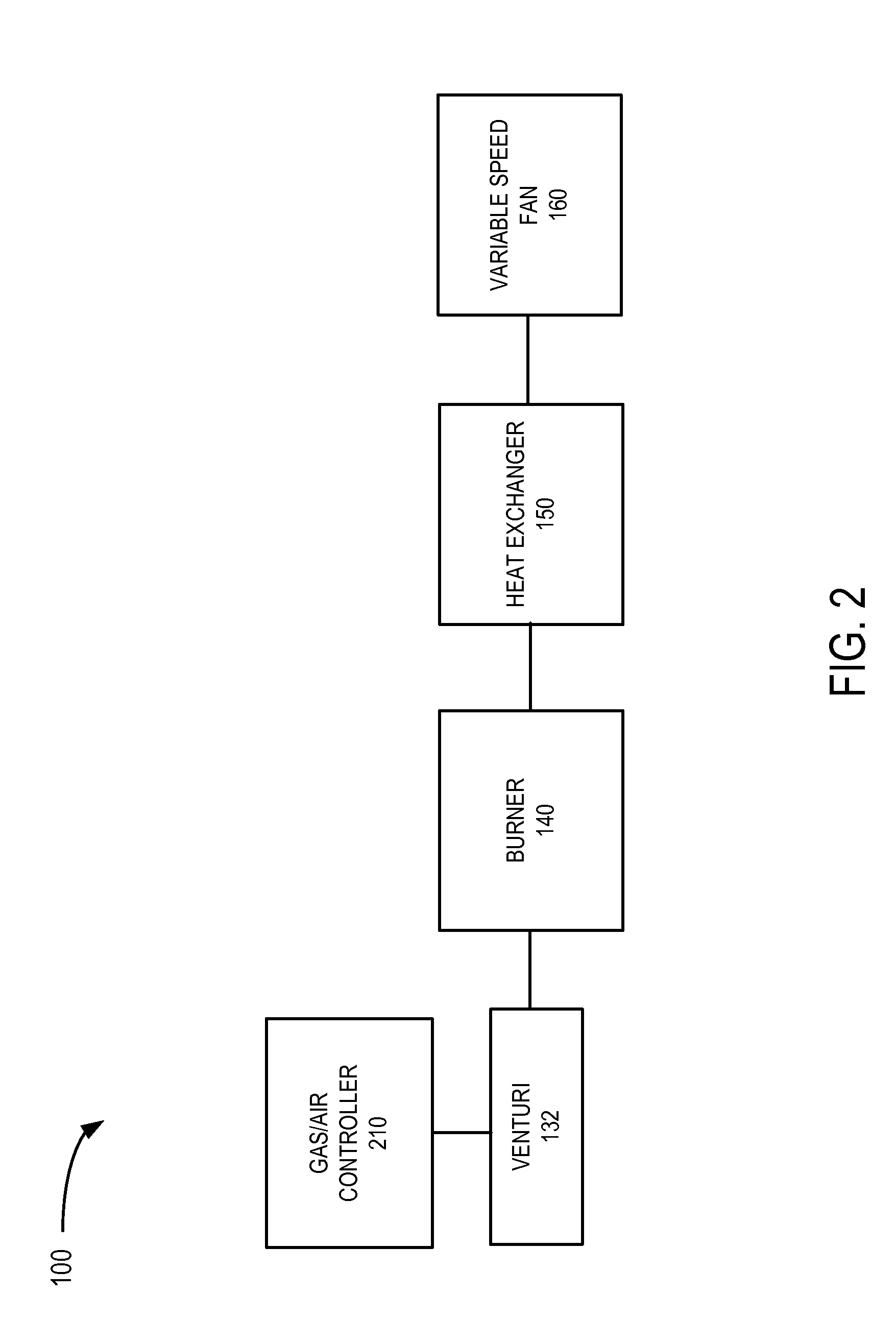

Premix air heater

A gas-fired heater includes a gas supply line, an air supply line, a valve coupled to the gas supply line and a controller coupled to the valve. The controller is configured to control the valve to control a gas-air mixture. The gas-fired heater also includes a burner configured to receive the gas-air mixture and burn the gas-air mixture, and a heat exchanger coupled to the burner. The heat exchanger is configured to perform a heat exchange process and output heated air. The gas-fired heater further includes a combustion fan located downstream of the heat exchanger, the combustion fan being configured to pull or draw flue gases through the heat exchanger.

Owner:REZNOR

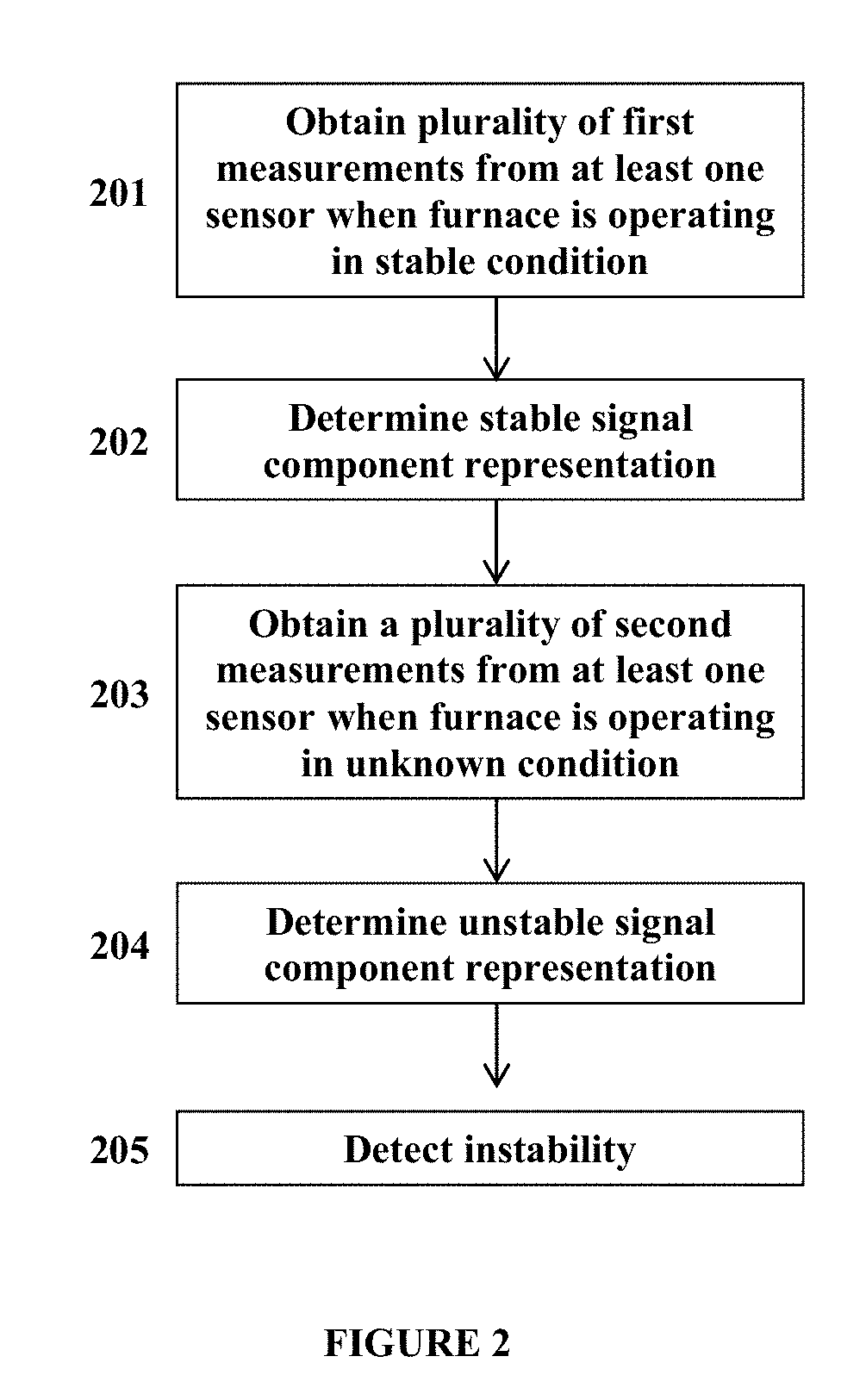

Methods and systems for monitoring burner flame conditions in a furnace

InactiveUS20170219208A1Pulsating combustionSubsonic/sonic/ultrasonic wave measurementFrequency spectrumCombustor

Systems and methods for using at least one sensor for monitoring a condition in a furnace are disclosed. The at least one sensor can be an optical fiber acoustic sensor. The at least one sensor can be coupled to at least one processor that can be configured to receive at least one measurement from the sensor, convert the at least one measurement into a digital format, and determine a condition associated with at least one burner based at least in part on the digital format. The digital format can be, for example, a sound waveform or a frequency spectrum.

Owner:EXXON RES & ENG CO

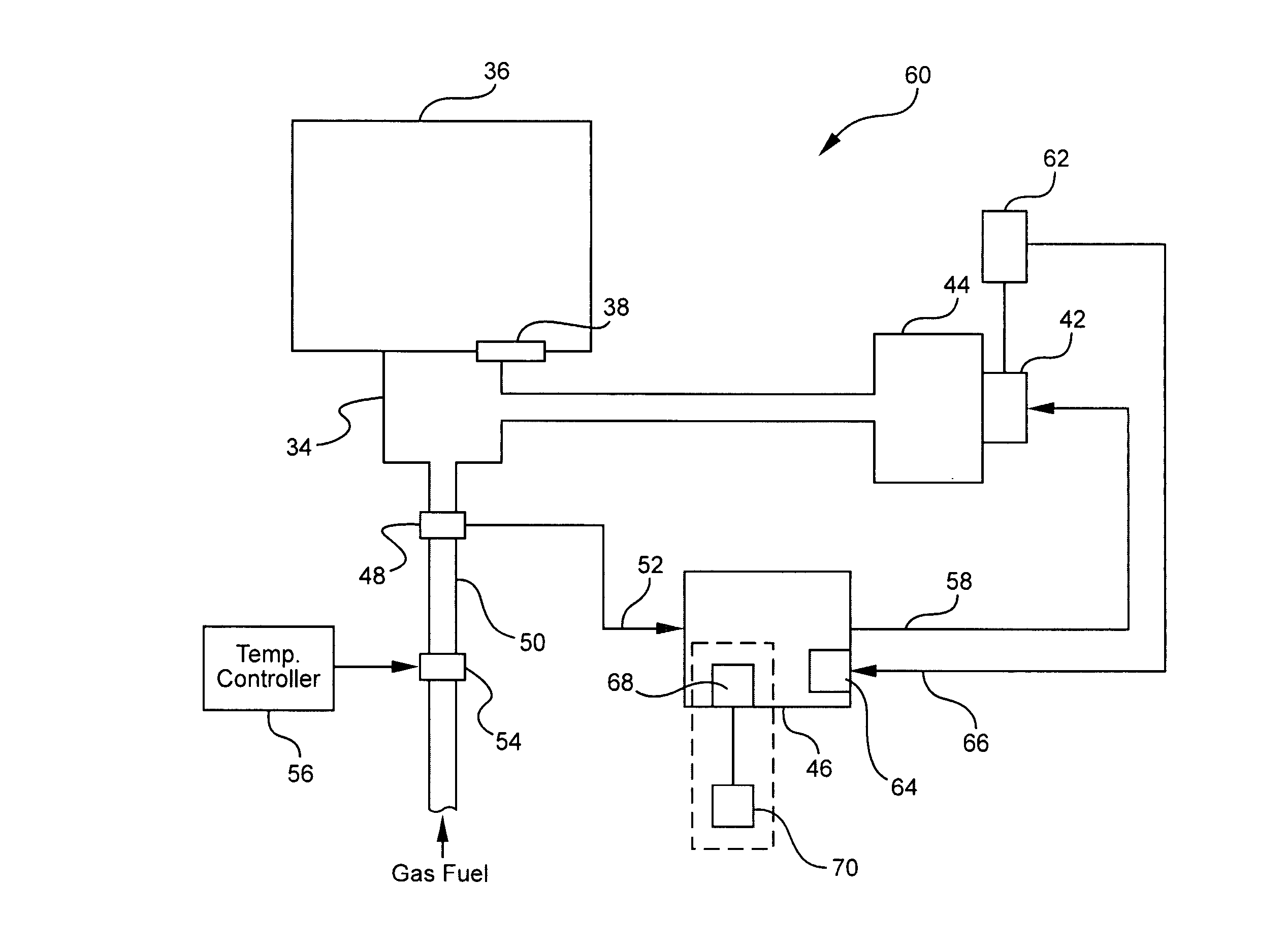

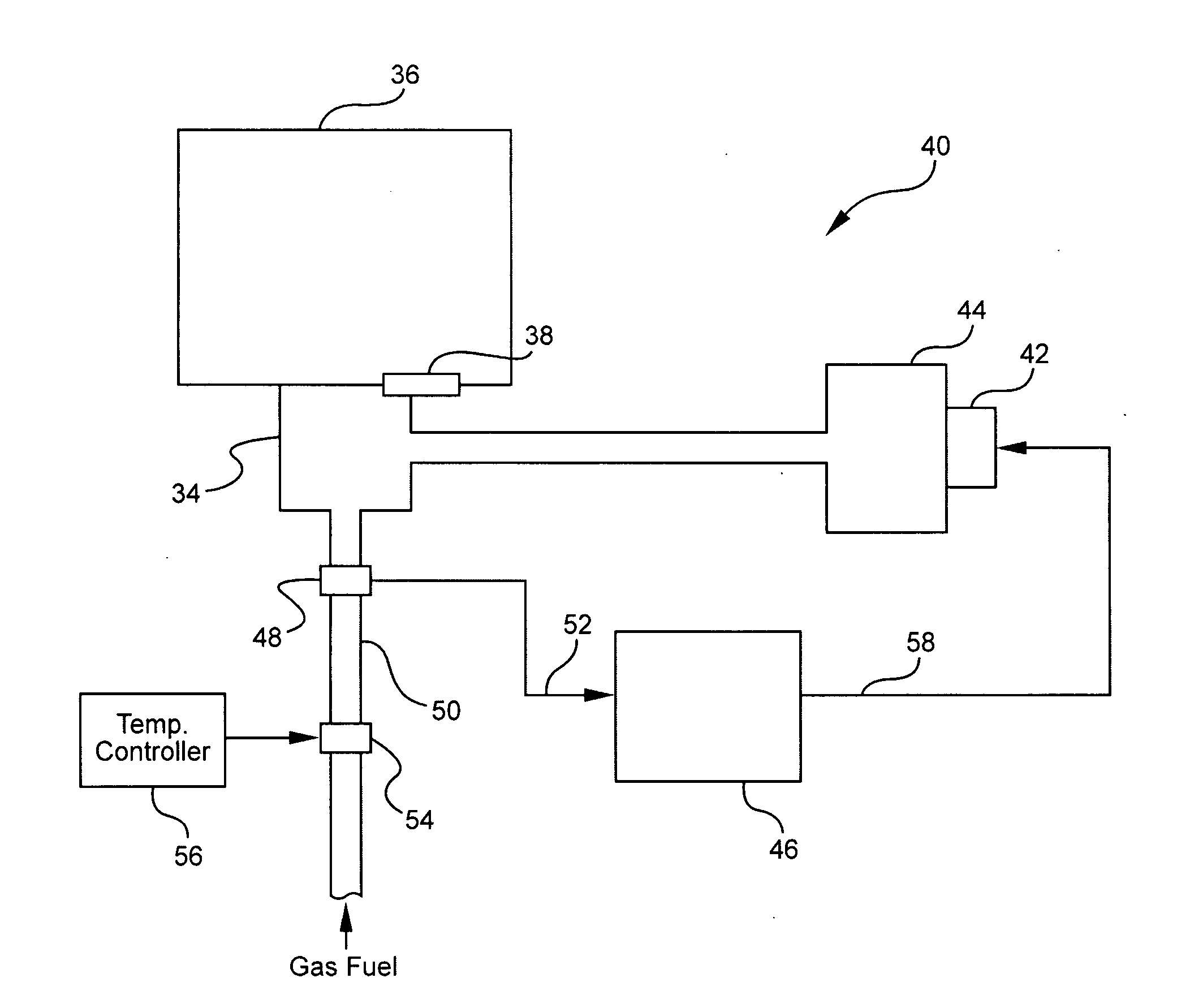

System and method for combustion-air modulation of a gas-fired heating system

InactiveUS20070238057A1Improve combustion qualityImprove thermal efficiencyFuel supply regulationAir supply regulationMotor speedEngineering

A system and method for providing a gas-fired heating system with improved thermal efficiency includes modulating a quantity of combustion air flow to a combustion mixture in response to a measured change in fuel-gas pressure using a DC (e.g., brushless) motor to drive a combustion air blower. A pressure transducer in a manifold transporting fuel-gas into the combustion mixture outputs a signal proportional to the measured pressure to the motor. The motor speed and thus the resultant quantity of combustion air flow are modulated in proportion to the quantity of fuel-gas to the mixture. Accordingly, a constant fuel-gas to combustion air ratio is maintained. The system and method may further provide for adjusting the output signal to accommodate measured intake air temperature, and / or measured atmospheric pressure in order to maintain a constant, good thermal efficiency (preferably ≦80%) regardless of air temperature and altitude at the system's installation location.

Owner:REZNOR

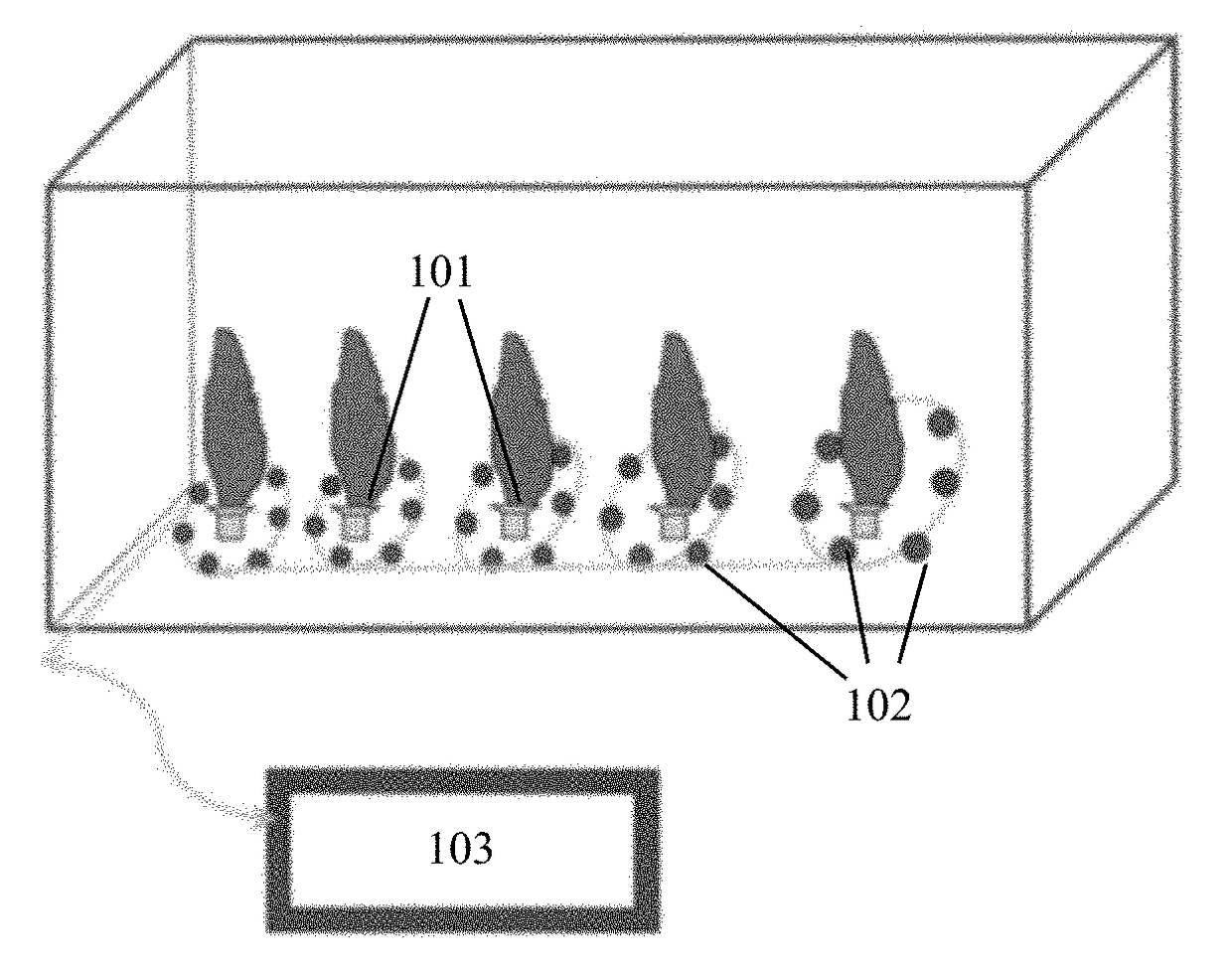

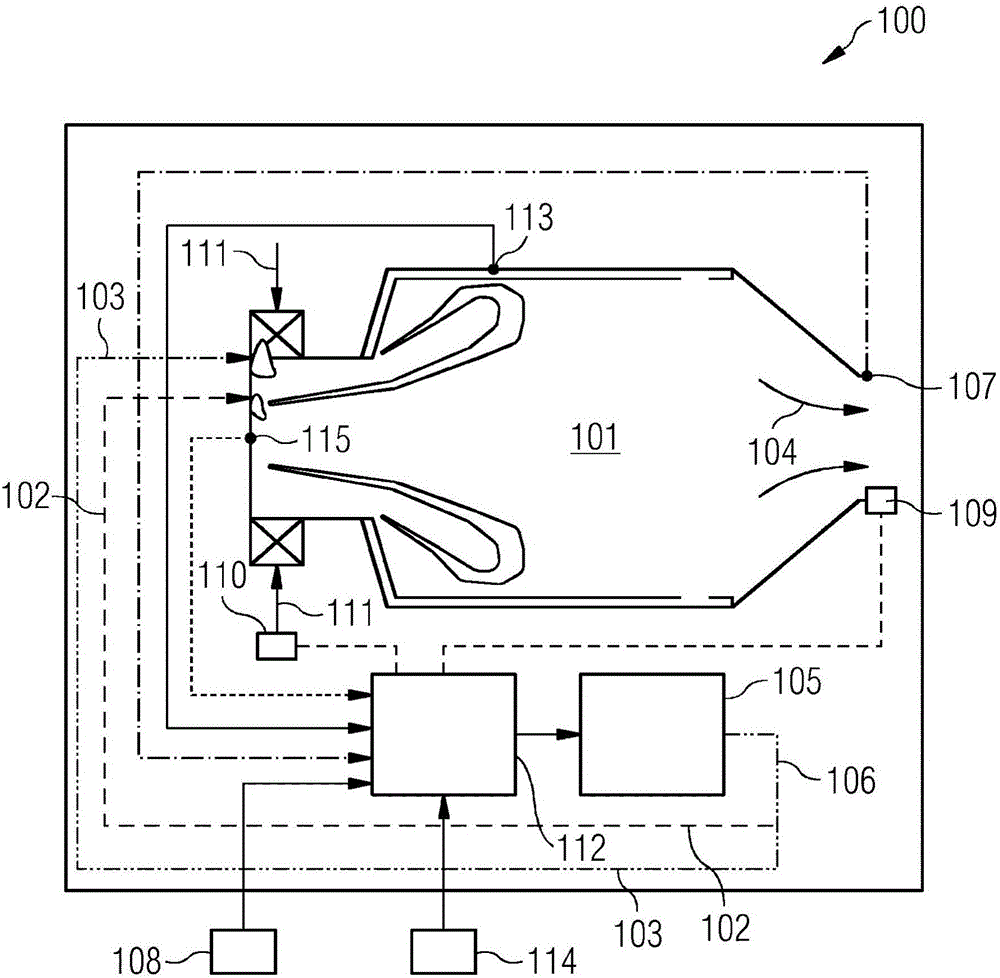

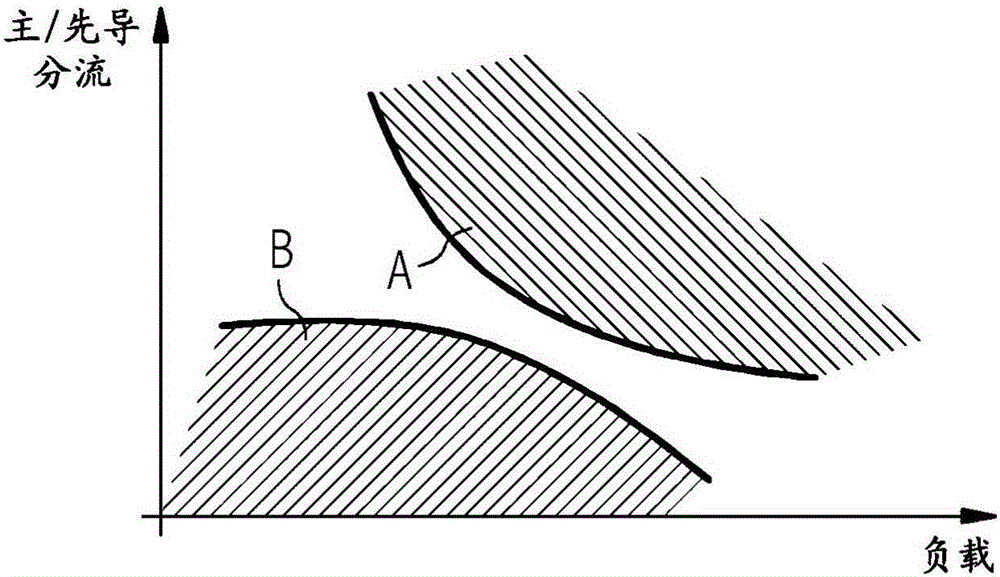

Intelligent control method with predictive emissions monitoring ability

InactiveCN105745497AReduce the temperatureReliable emissionsContinuous combustion chamberGas turbine plantsCombustion chamberCombustor

The present invention relates to a combustor system (100) for a gas turbine engine. The combustor system (100) comprises a combustion chamber (101) into which a pilot fuel (102) and a main fuel (103) is injectable and flammable, wherein an exhaust gas (104) generated by the burned pilot fuel (102) and the burned main fuel (103) is exhaustible out of the combustion chamber (101). A control unit (112) is coupled to a fuel control unit (105) for adjusting the pilot fuel (102) ratio. The control unit (112) is adapted for determining a predicted pollutant concentration of the exhaust gas (104) on the basis of a temperature signal, a fuel signal, a mass flow signal and a fuel split ratio.

Owner:SIEMENS AG

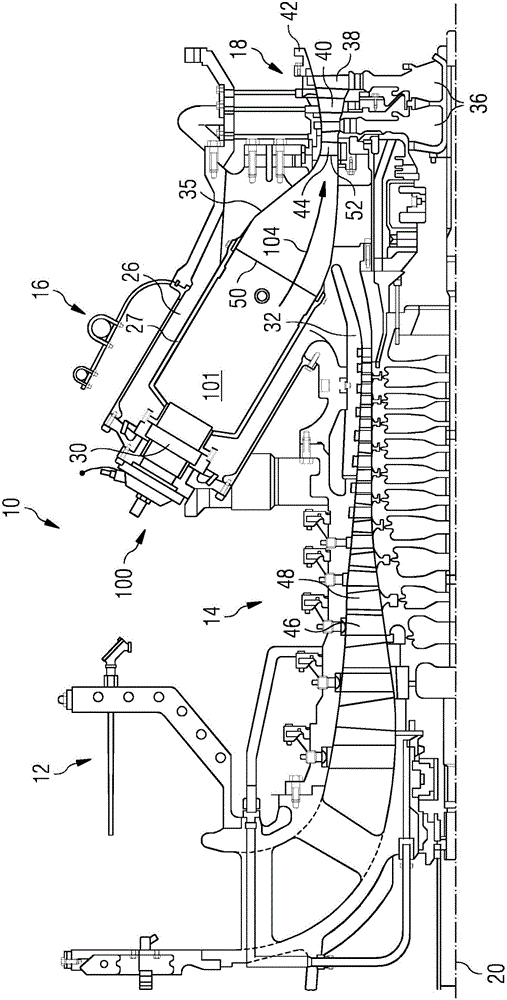

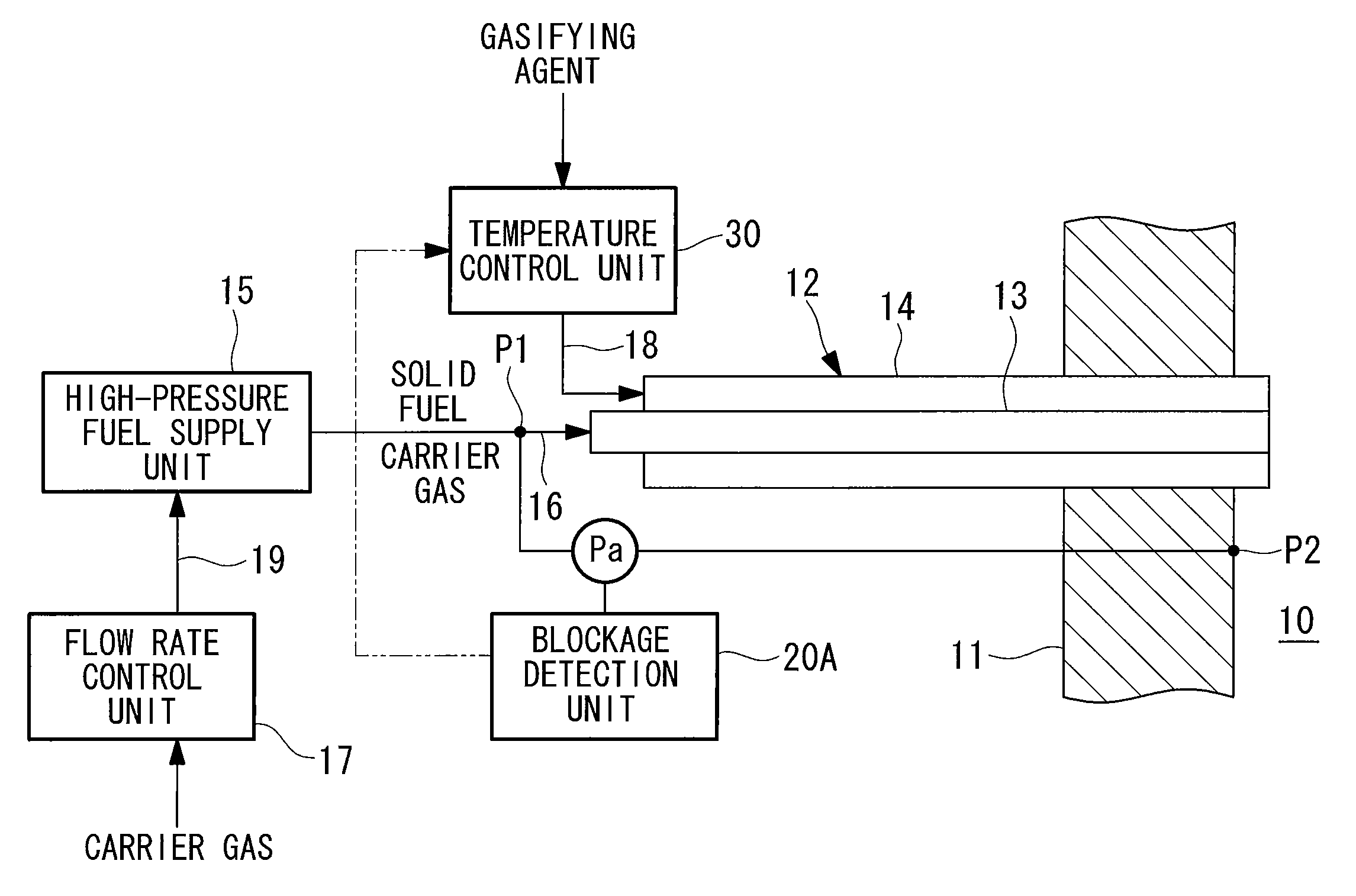

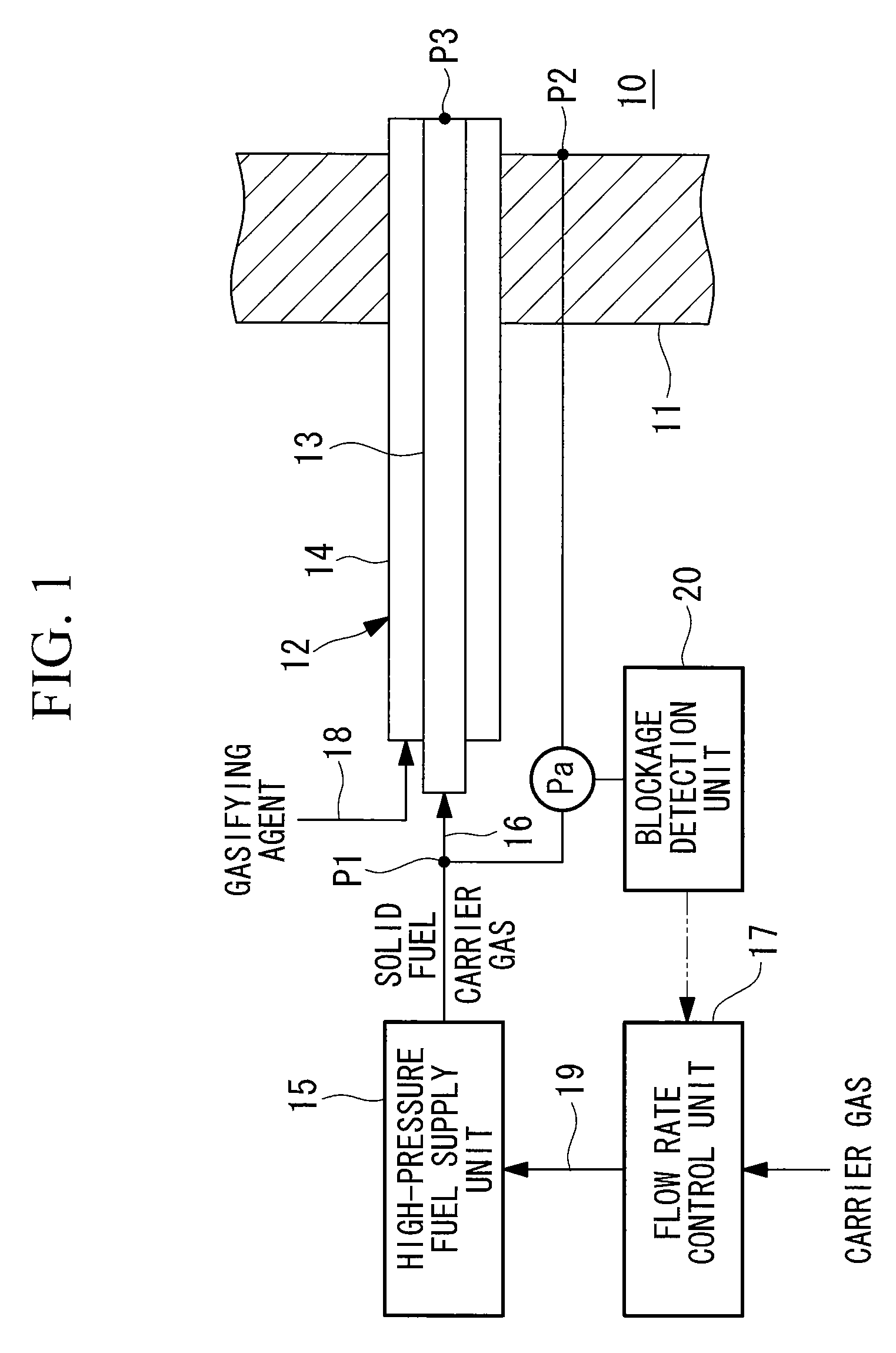

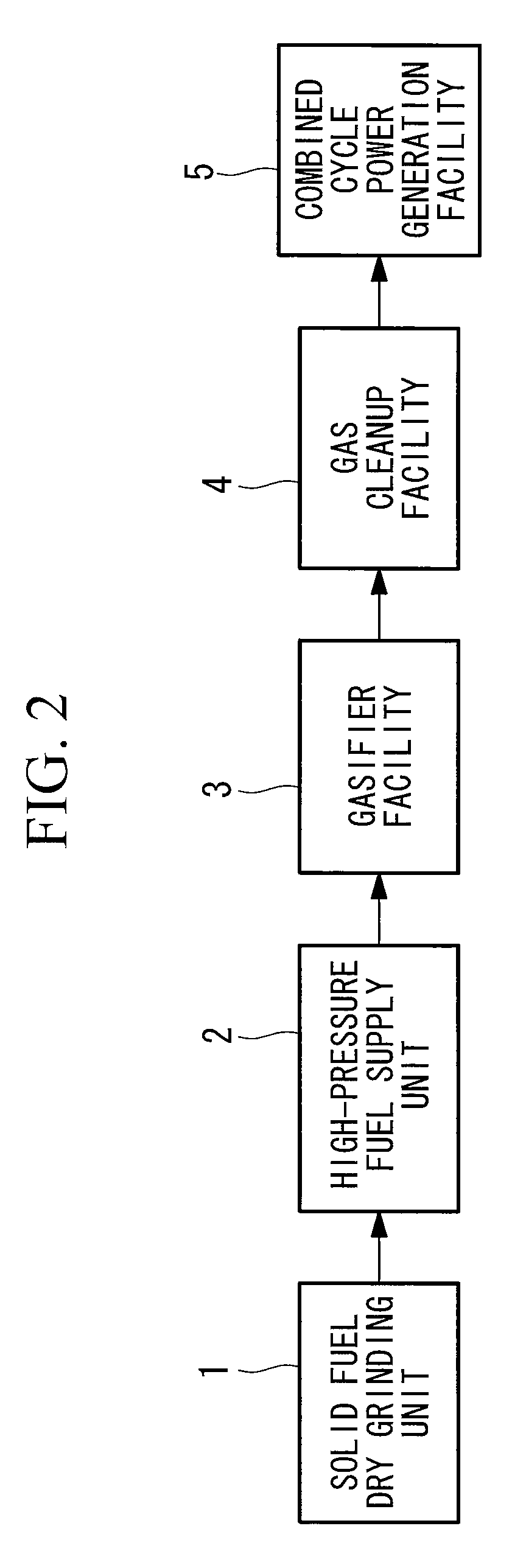

Burner for highly caking coal, and gasifier

ActiveUS8667912B2Guaranteed uptimeSuppress and prevent temperature increaseCombustion using gaseous and pulverulent fuelFuel supply regulationCombustorSolid fuel

In a burner for highly caking coal in which a solid fuel channel that is attached penetrating through a surrounding wall of a gasifier for gasifying a highly caking solid fuel that has been pulverized into particles and that supplies the solid fuel into the gasifier by gas flow transportation, and a gasifying agent channel that supplies a gasifying agent into the gasifier are provided, a blockage detection unit that detects a blockage situation of the solid fuel channel is provided, and a process for reducing the temperature of the solid fuel is performed when the blockage detection unit detects a predetermined blockage situation.

Owner:MITSUBISHI POWER LTD

Start flow measurement

ActiveUS7841184B2Analogue computers for vehiclesAnalogue computers for trafficPressure differenceGas turbines

Owner:PRATT & WHITNEY CANADA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com