Patents

Literature

49 results about "Fuel control unit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A fuel control unit is a control system for gas turbine engines.

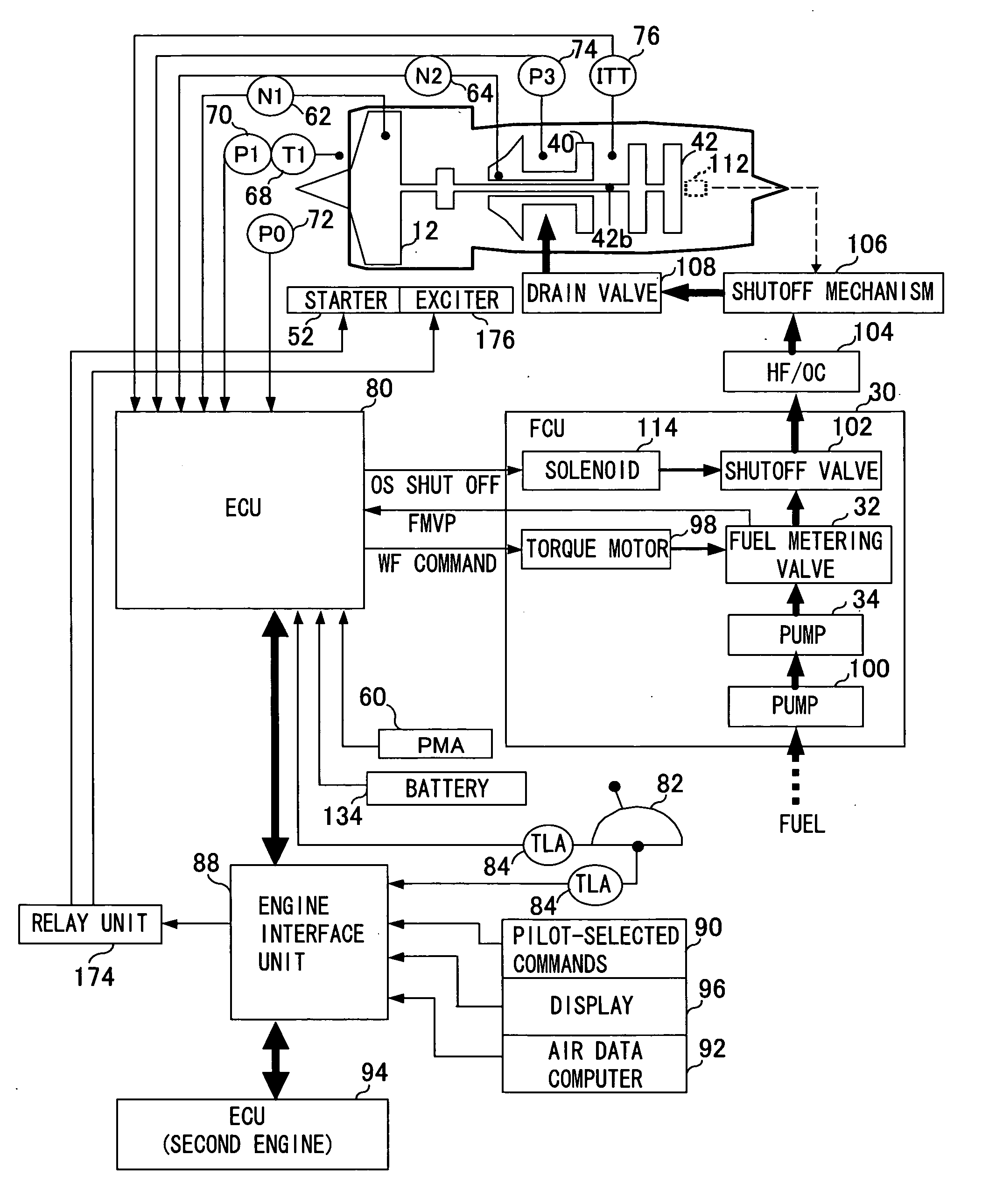

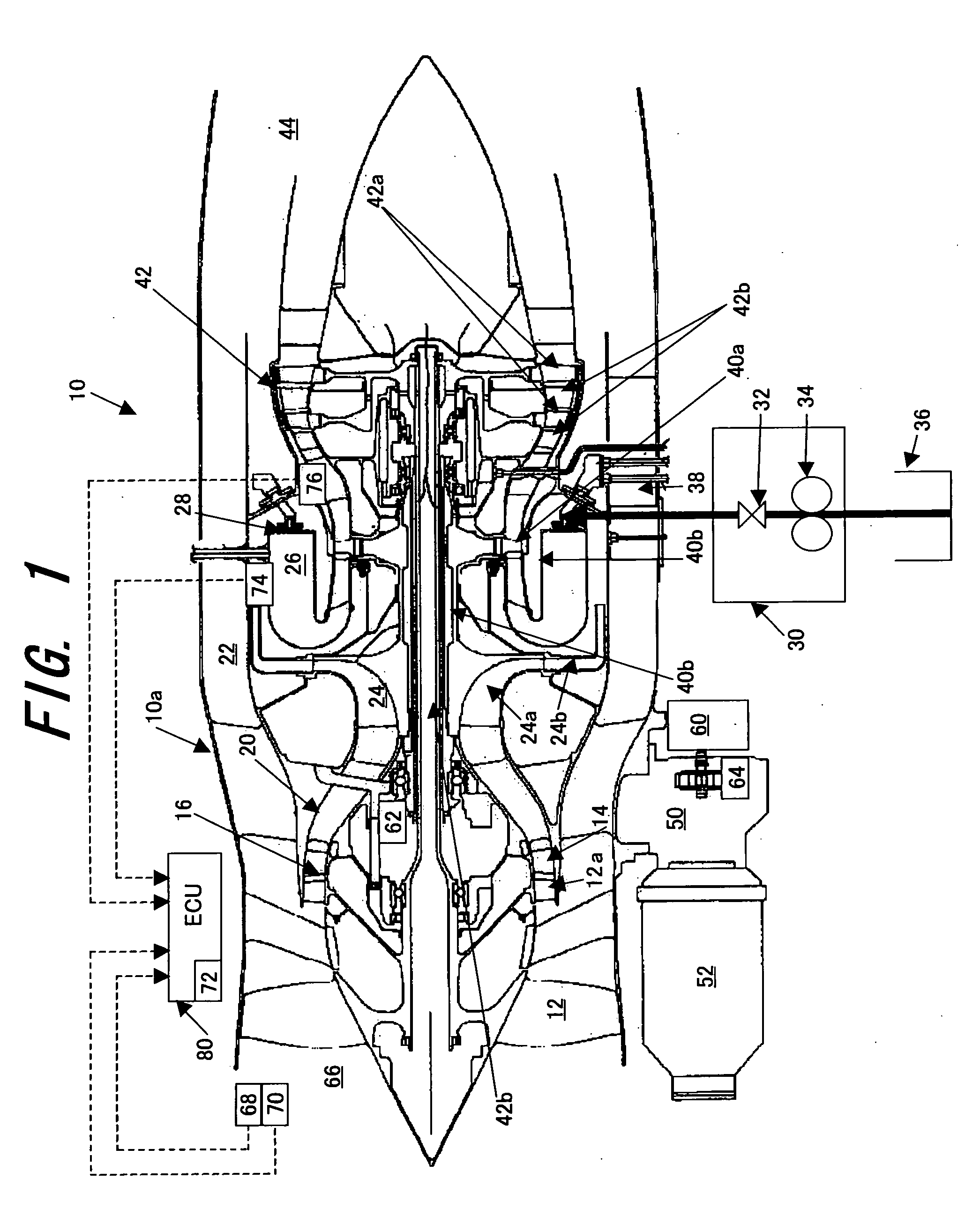

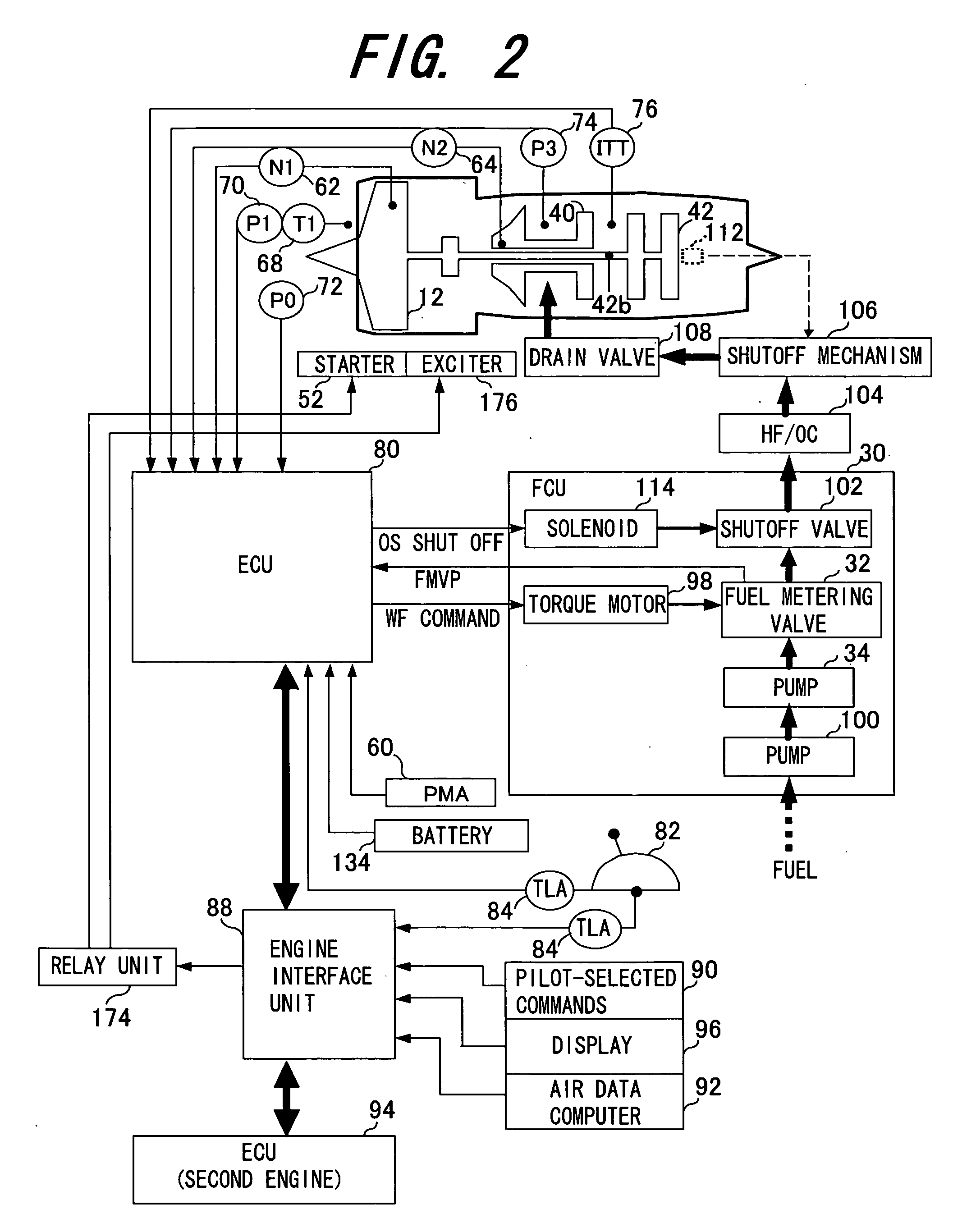

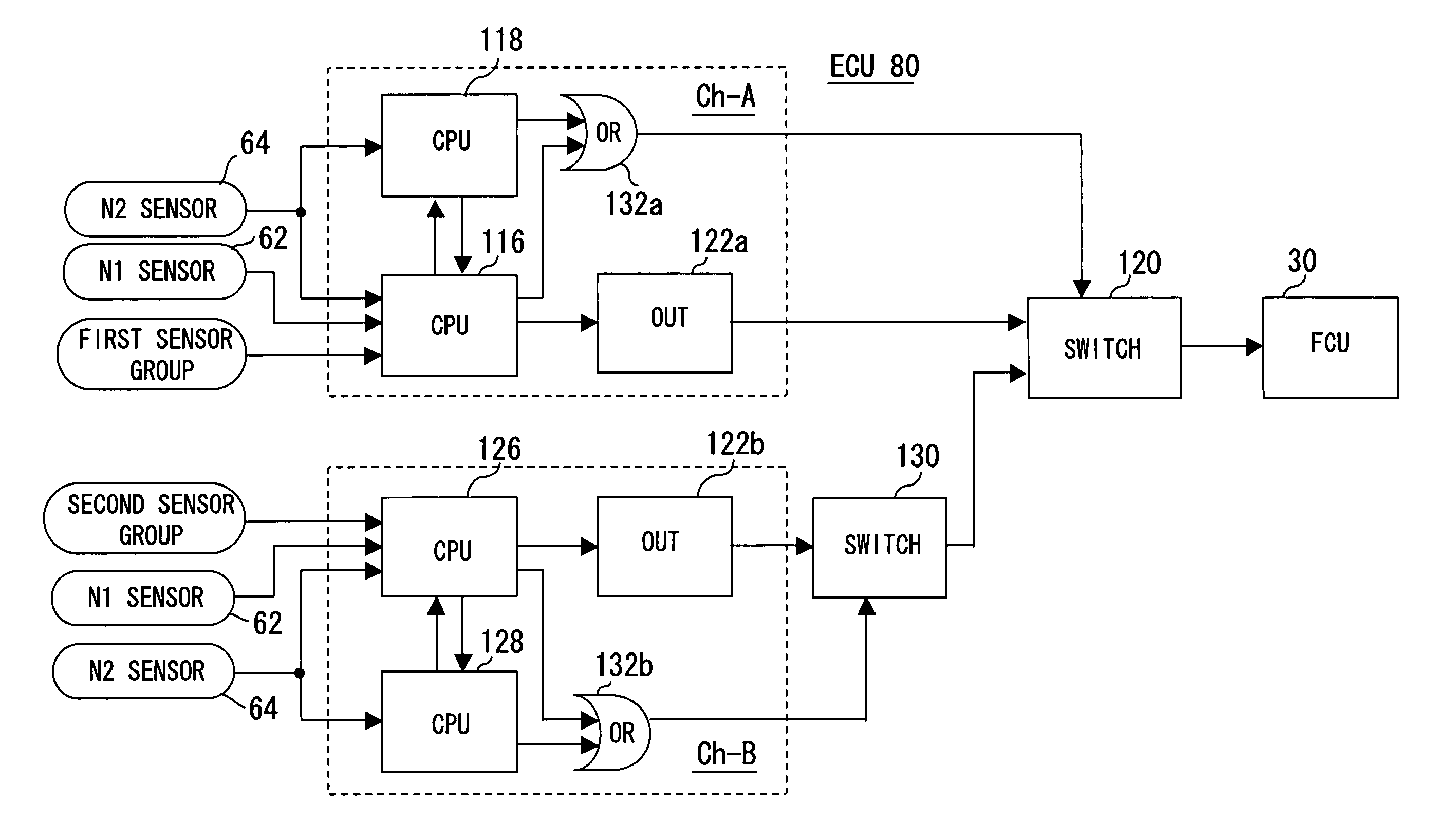

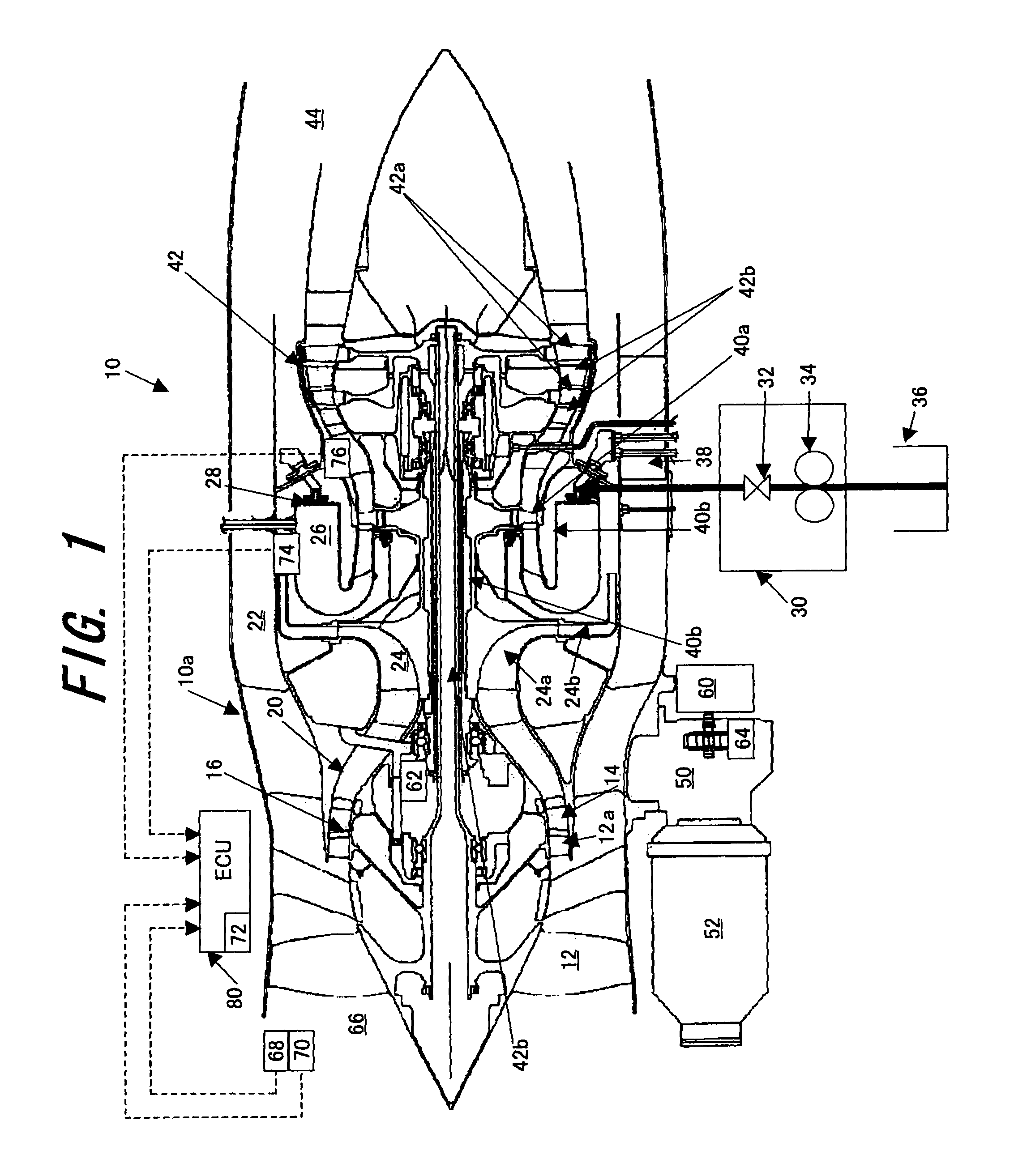

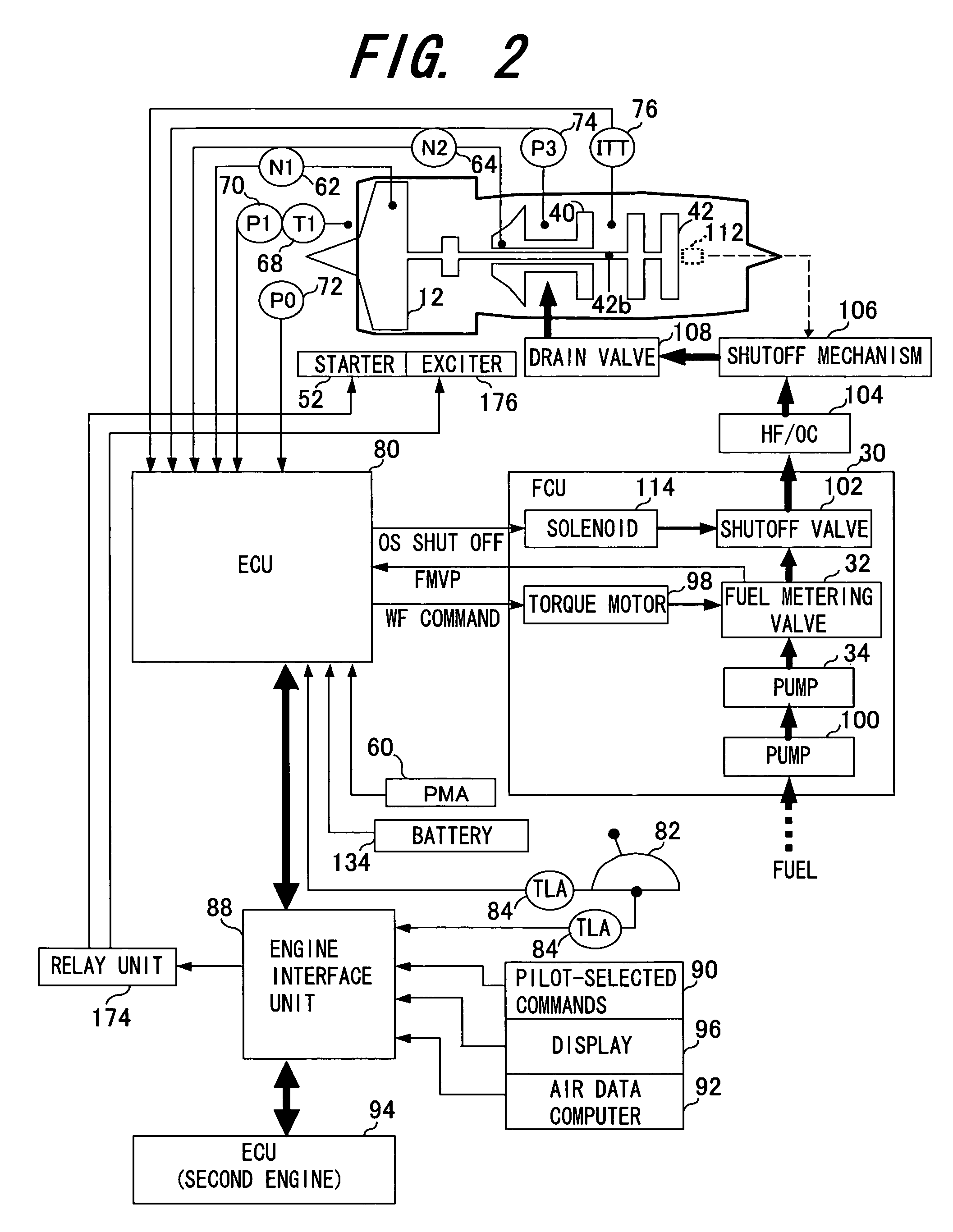

Control system for gas turbine aeroengine

InactiveUS20070055435A1Enhances CPU failure detection accuracyAnalogue computers for vehiclesEngine fuctionsAviationControl system

In a gas turbine aeroengine control system, in Ch-A (first control channel), a first CPU monitors the operation of a second CPU and the second CPU monitors the operation of the first CPU; in Ch-B (second control channel), third and fourth CPUs similarly monitor each other, and when the operation of at least one of the first and second CPUs in Ch-A is found not to be normal, the output sent to an FCU (fuel control unit) is switched from the output of one or the other of the first and second CPUs of Ch-A to the output of one or the other of the third and fourth CPUs of Ch-B, thereby achieving improved CPU failure detection and realizing high redundancy and high reliability.

Owner:HONDA MOTOR CO LTD

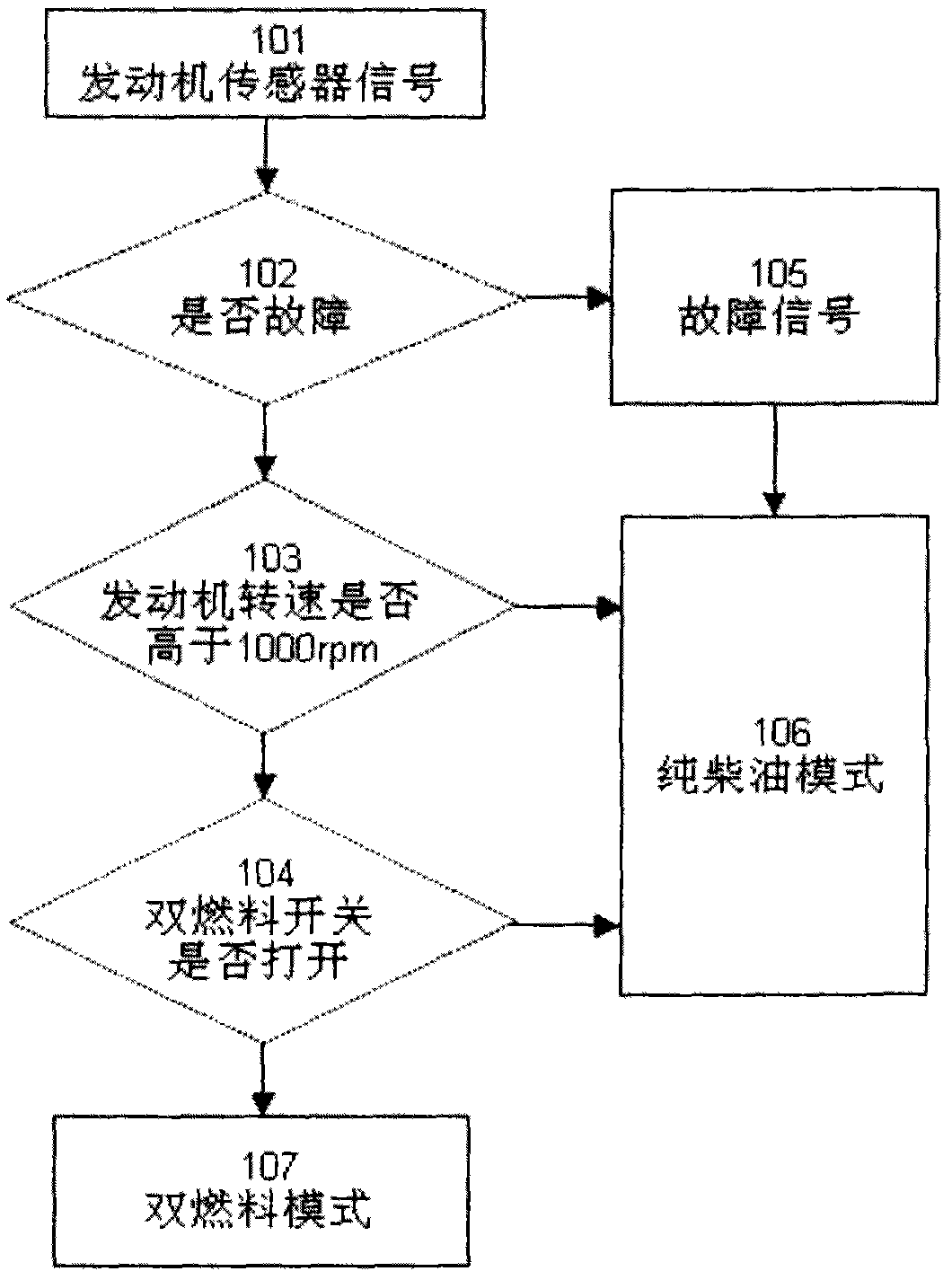

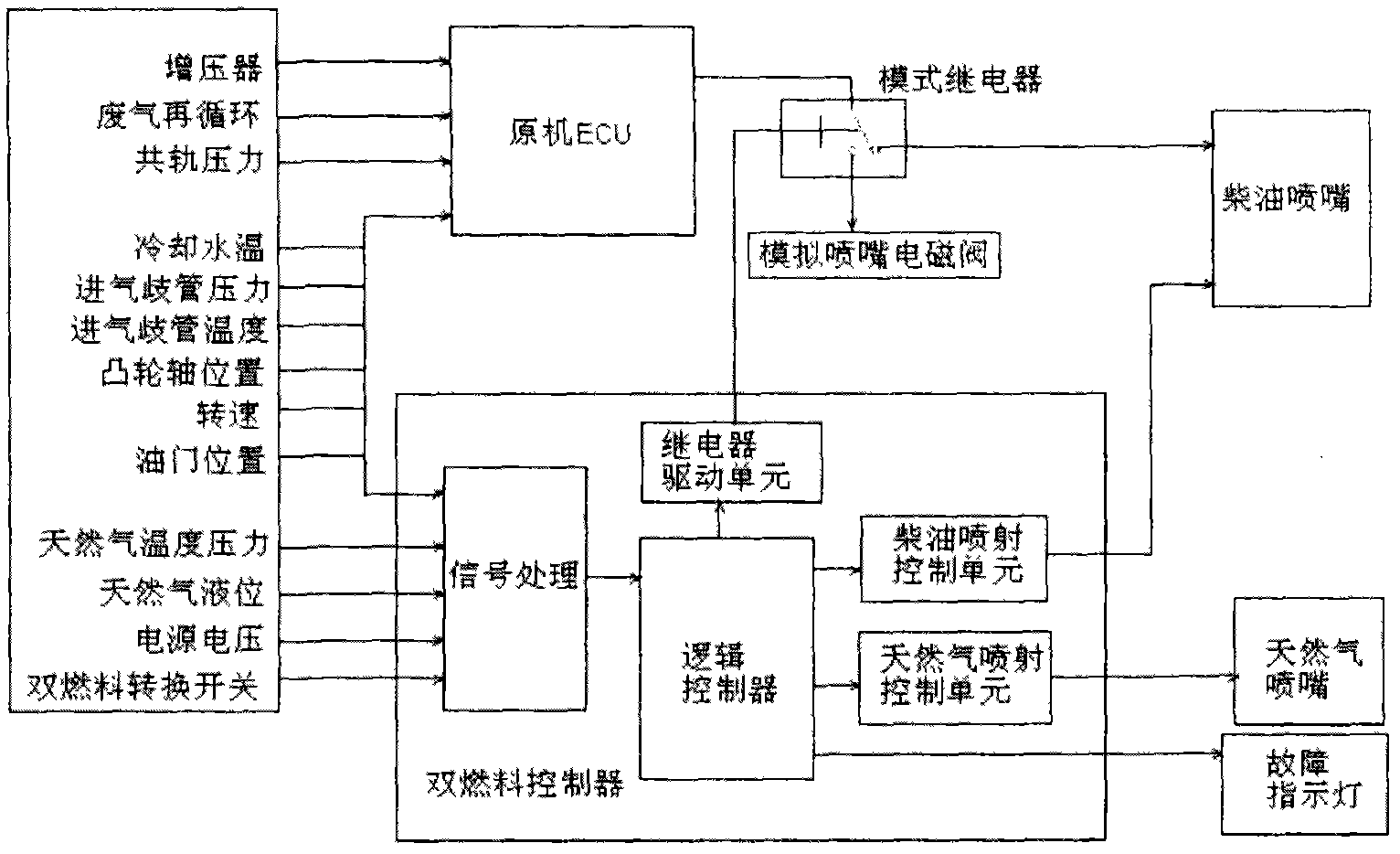

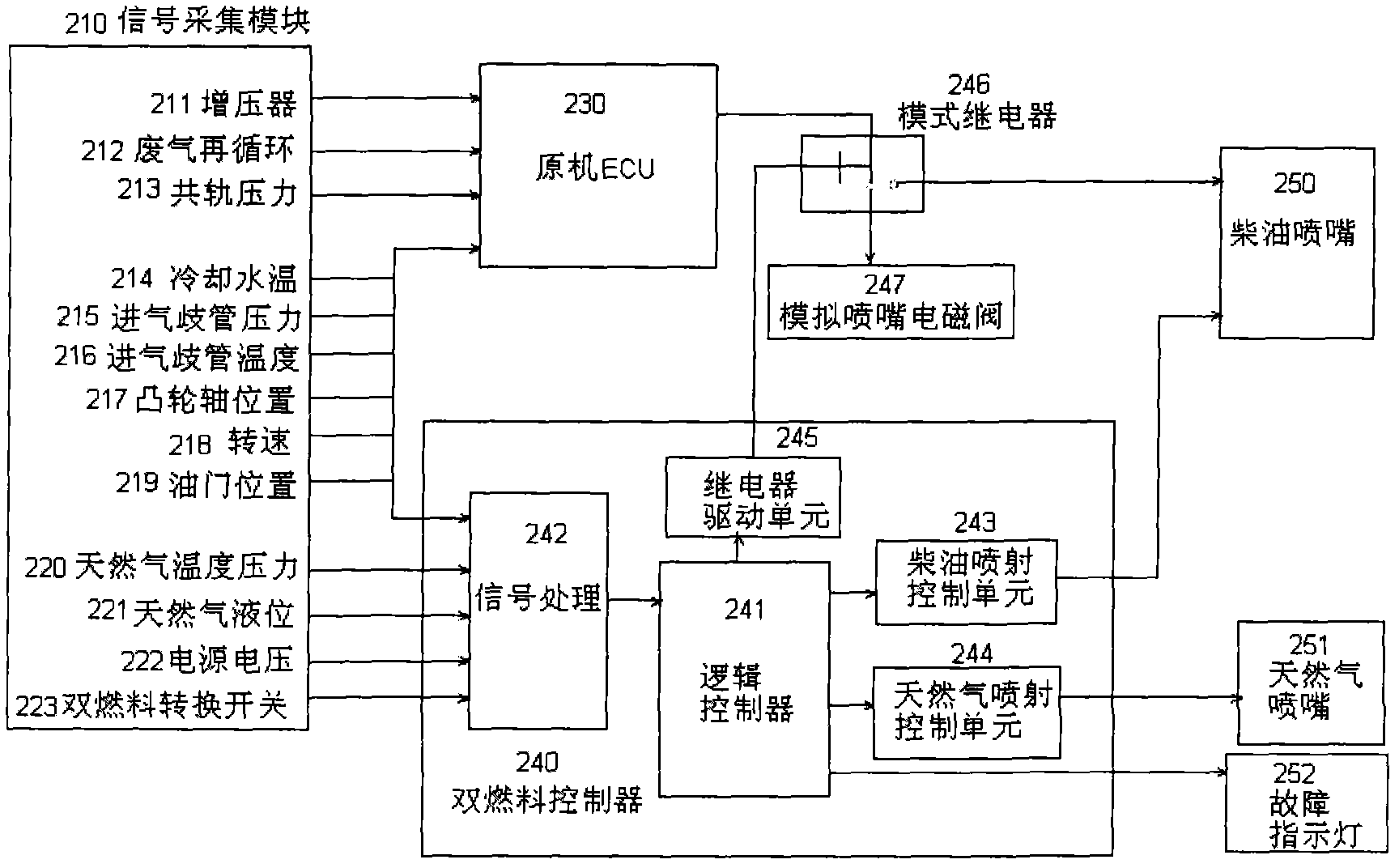

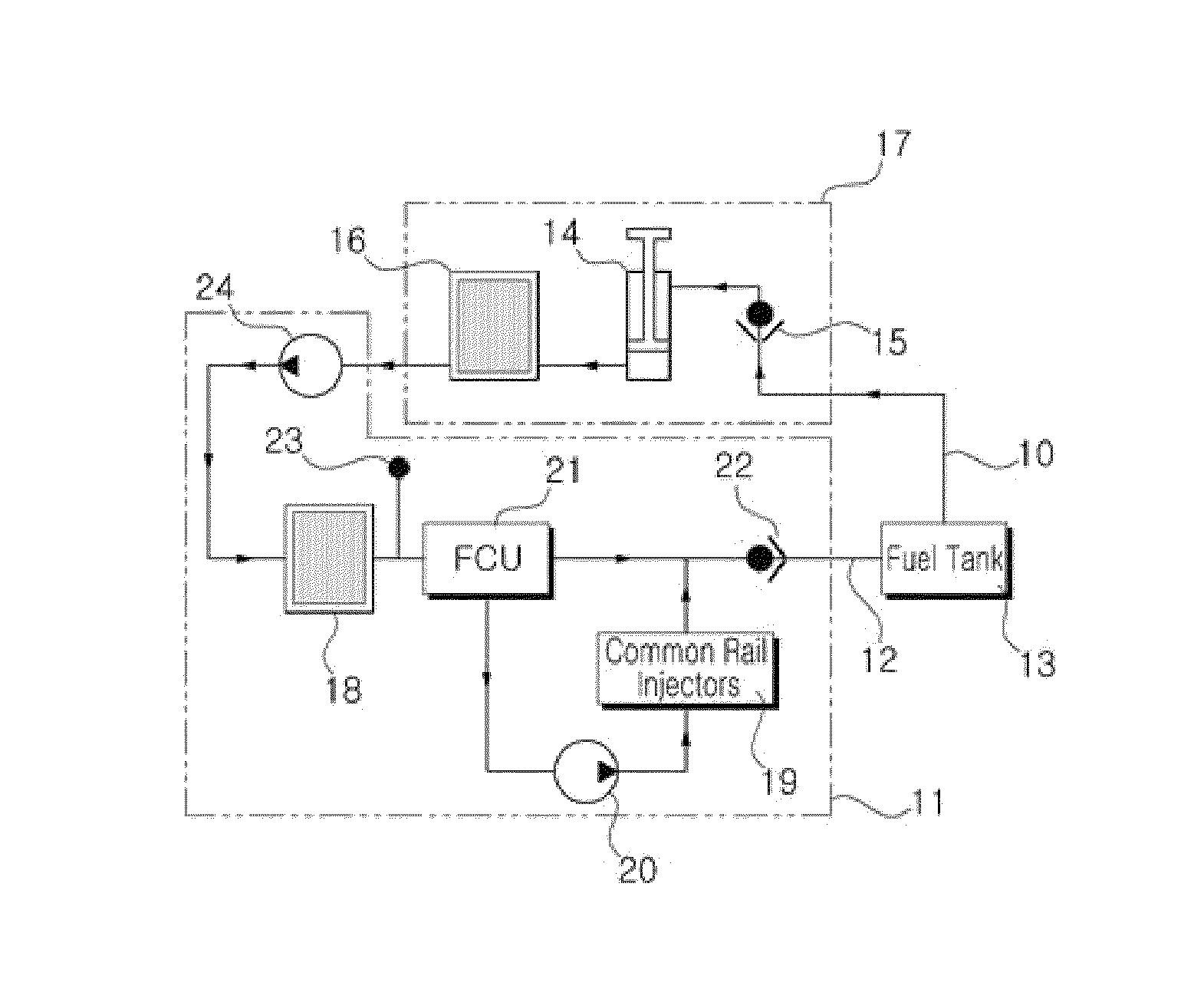

Diesel engine/natural gas dual-fuel engine electric control system

InactiveCN103016168AGuaranteed to workElectrical controlInternal combustion piston enginesFuel control unitControl system

The invention discloses a control method and a control device of a diesel / natural gas dual-fuel engine. The method is characterized in that that on the basis of maintaining an original engine control system, a diesel and gas control unit is added. Signals of all sensors of the original machine are shared by the dual-fuel control system and an electric control system of the original machine. The added dual-fuel control unit can control the injection of the diesel and an additionally-installed gas injection system (including a gas nozzle electromagnetic control, a gas switch valve control, gas liquid level or pressure monitoring and the like), and the added dual-fuel control unit can also process signals which are associated to the gas system. The injection volume and the oil injection moment of the diesel can be precisely controlled according to different working states of a diesel engine, and the injection time and the injection duration of the natural gas can also be controlled. The duel-fuel engine can be enabled to run safely and stably, the fuel consumption can be reduced, and the emission of tail gas can be reduced.

Owner:BEIJING YIKONG LINGBO AUTOMOBILE ELECTRONICS TECH

Control system for gas turbine aeroengine

InactiveUS7840336B2Enhances CPU failure detection accuracyAnalogue computers for vehiclesEngine fuctionsAviationFuel control unit

In a gas turbine aeroengine control system, in Ch-A (first control channel), a first CPU monitors the operation of a second CPU and the second CPU monitors the operation of the first CPU; in Ch-B (second control channel), third and fourth CPUs similarly monitor each other, and when the operation of at least one of the first and second CPUs in Ch-A is found not to be normal, the output sent to an FCU (fuel control unit) is switched from the output of one or the other of the first and second CPUs of Ch-A to the output of one or the other of the third and fourth CPUs of Ch-B, thereby achieving improved CPU failure detection and realizing high redundancy and high reliability.

Owner:HONDA MOTOR CO LTD

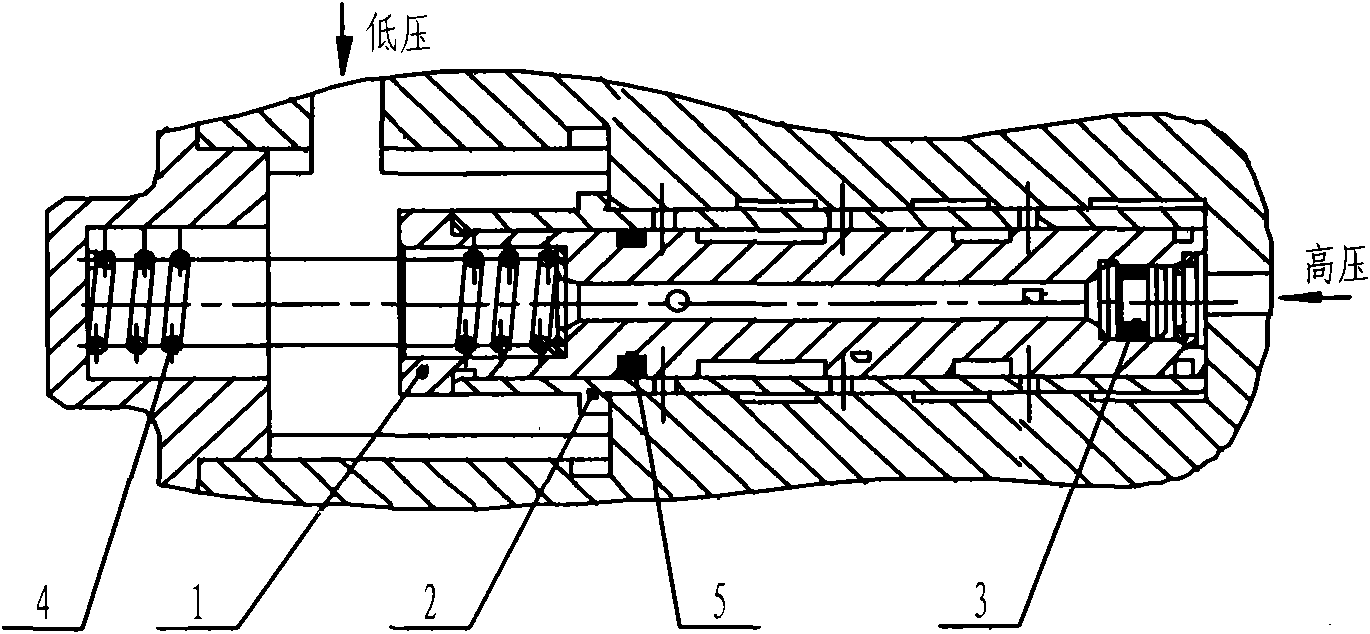

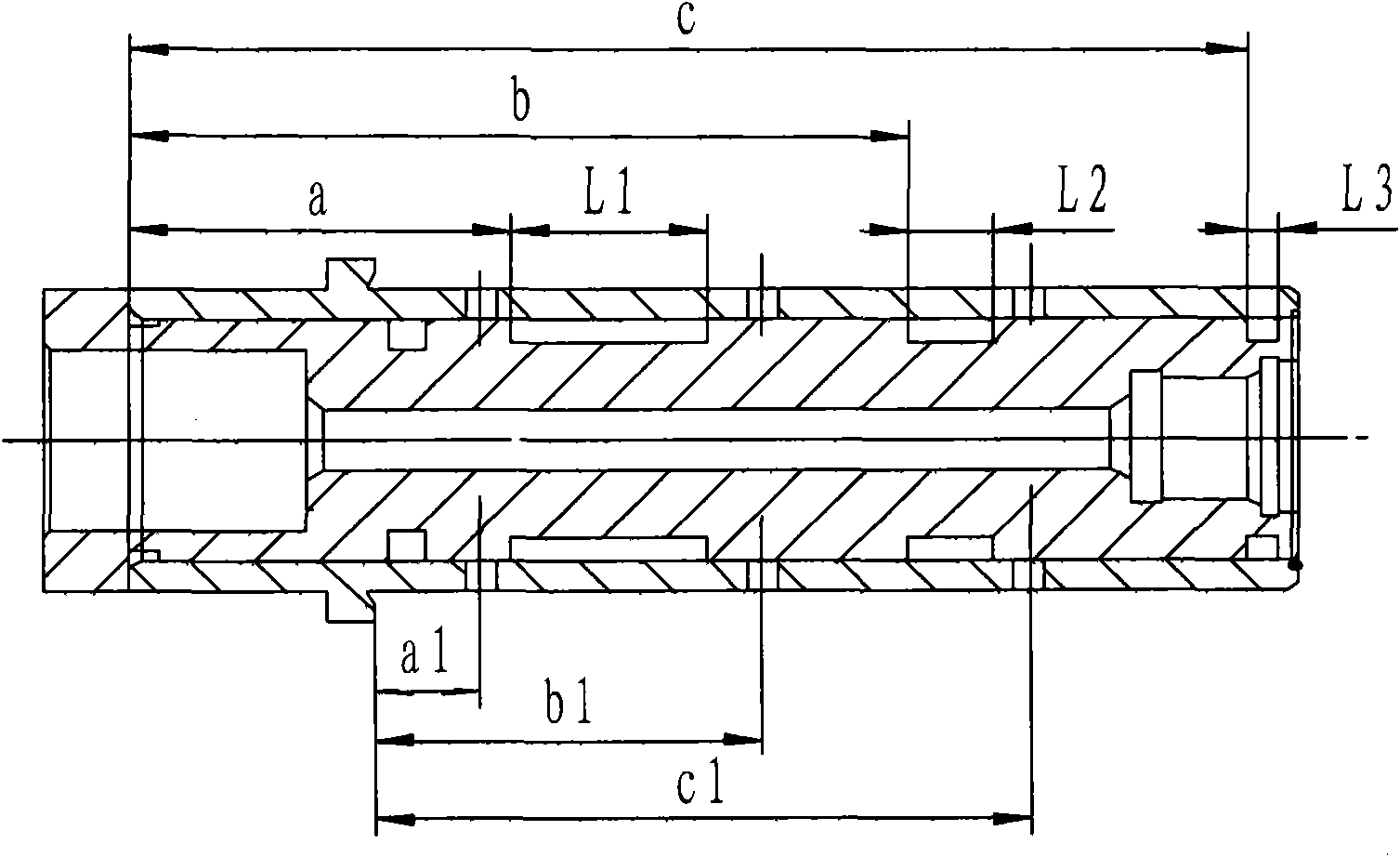

Fuel cut-off valve of reheat fuel control unit of turbofan engine

InactiveCN101684751AContinuous combustion chamberTurbine/propulsion fuel controlInterference fitAviation

The invention provides a fuel cut-off valve which is suitable for aero-engine fuel systems and can delay for a longer time and cut off fuel in sequence. The fuel cut-off valve can control spring forceand the diameter of a flow nipple according to design requirements, thereby achieving functions of lingeringly cutting off reheat bypass, reheat intension and reheat starting oil supply. The fuel cut-off valve of a reheat fuel control unit of a turbofan engine consists of a valve 1, a valve lining 2, a nozzle tip 3, a spring 4 and a sealing rubber cup 5, wherein the valve 1 is arranged in the valve lining 2; the nozzle tip 3 is arranged in a through hole in the middle of the valve 1; the valve 1 is provided with a plurality of through slots; the valve lining 2 is arranged in a shell by interference fit; and the valve lining 2 is provided with oil through holes corresponding to the through slots on the valve 1. The fuel can be respectively led to a control cavity of a metering valve in each area through the oil through holes. The spring 4 is arranged on a spring cavity formed between the top of the valve and the shell, and the airtightness of the spring cavity is ensured by mounting the sealing rubber cup 5 on the valve 1.

Owner:GUIZHOU HONGLIN MACHINERY

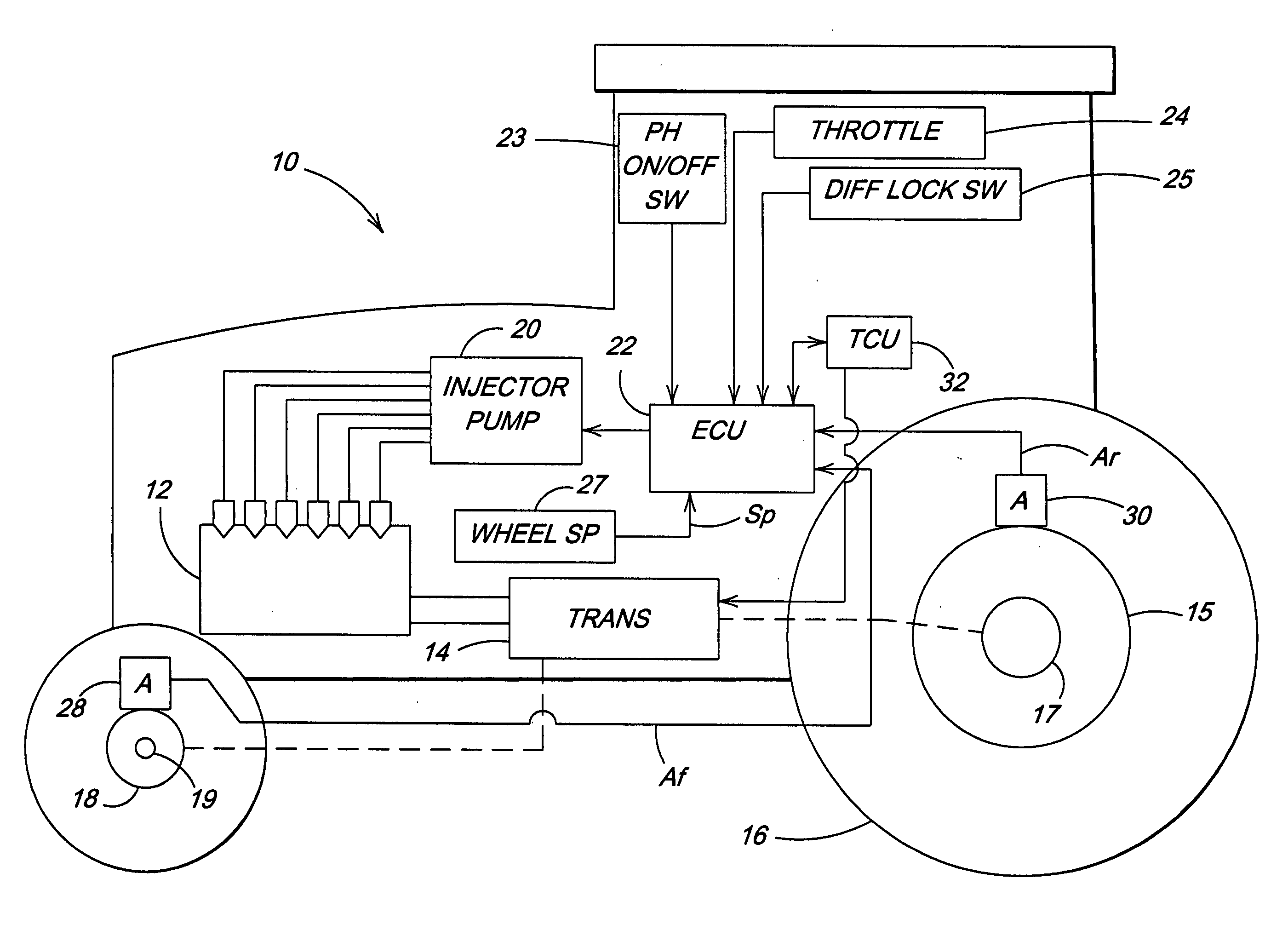

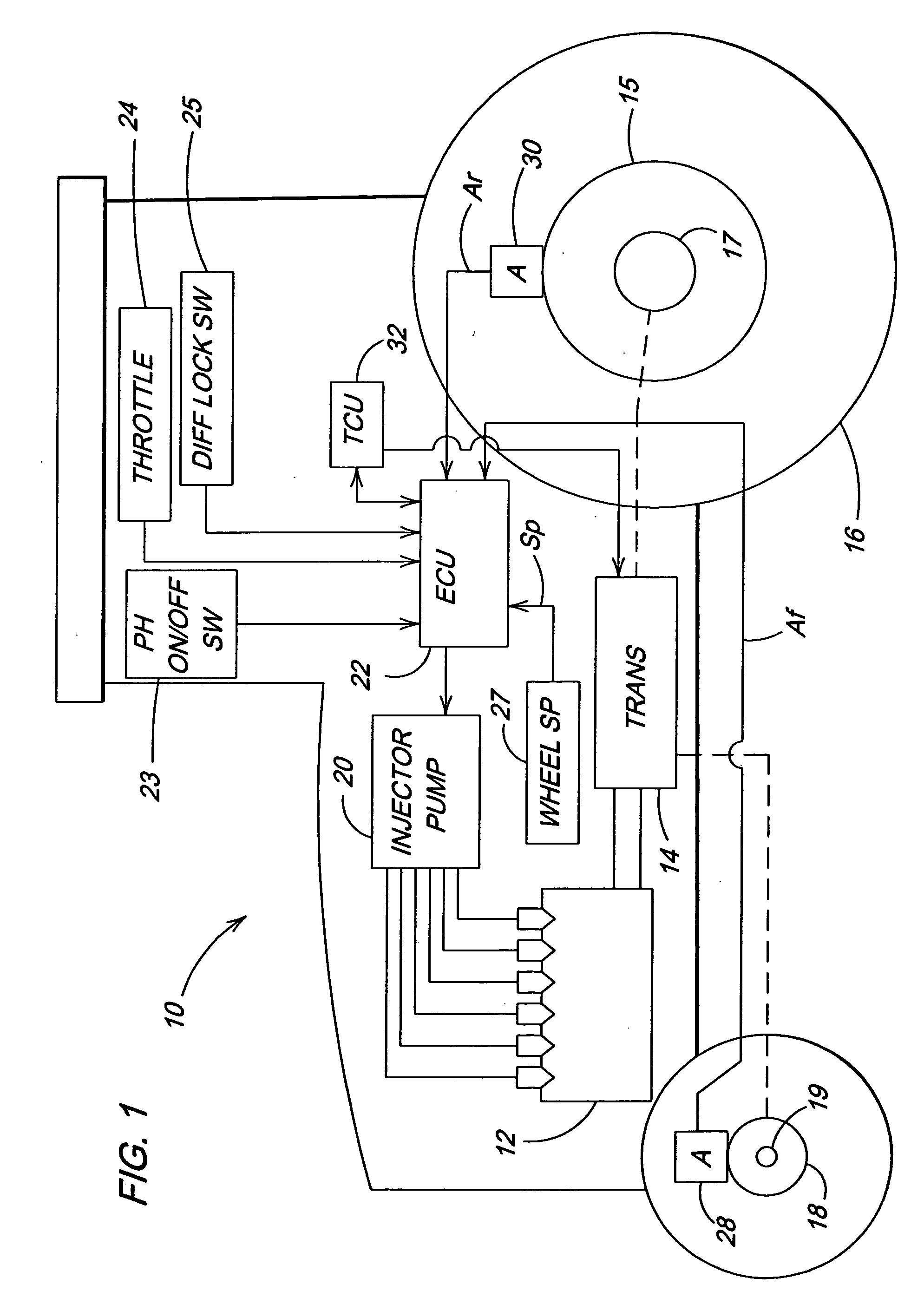

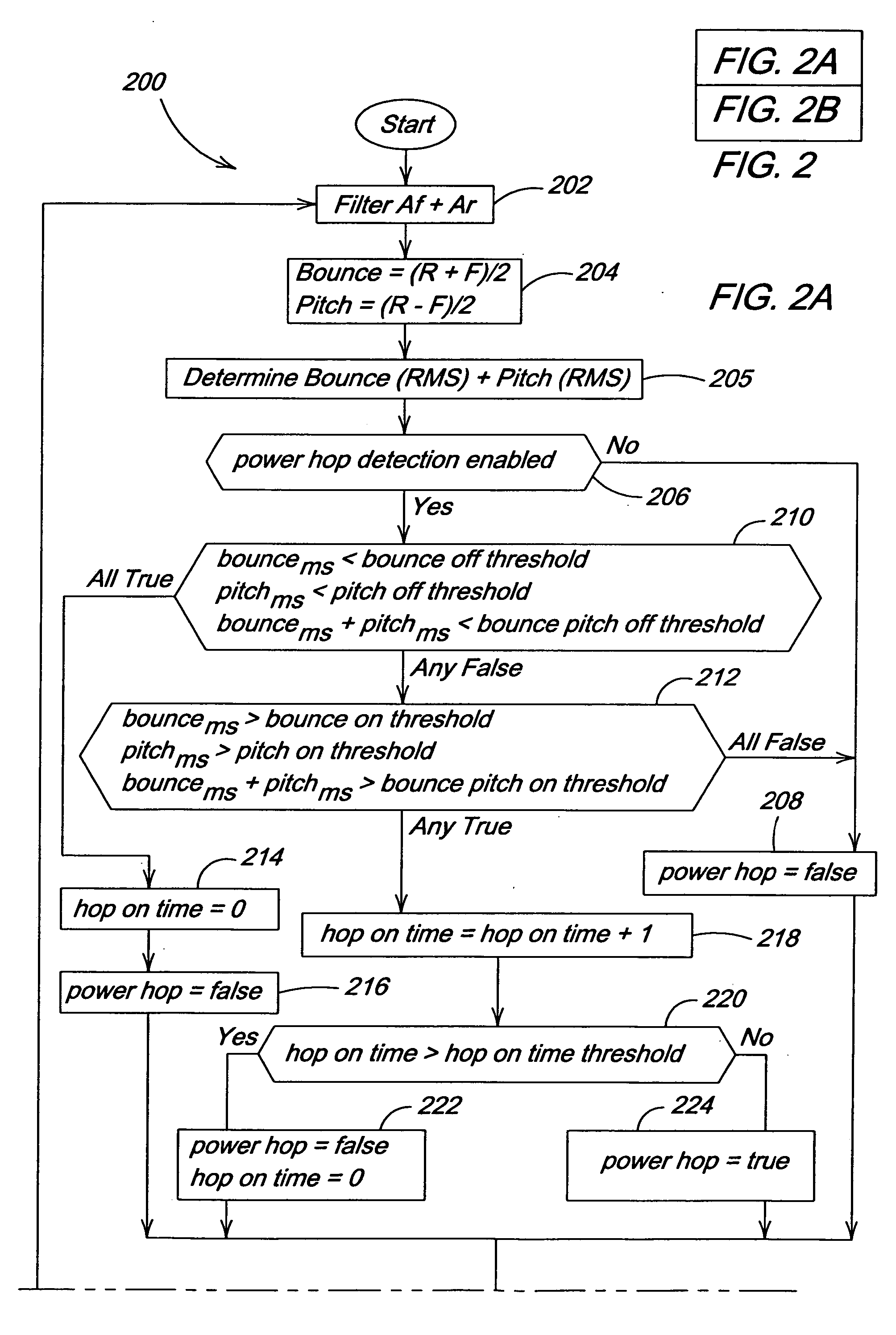

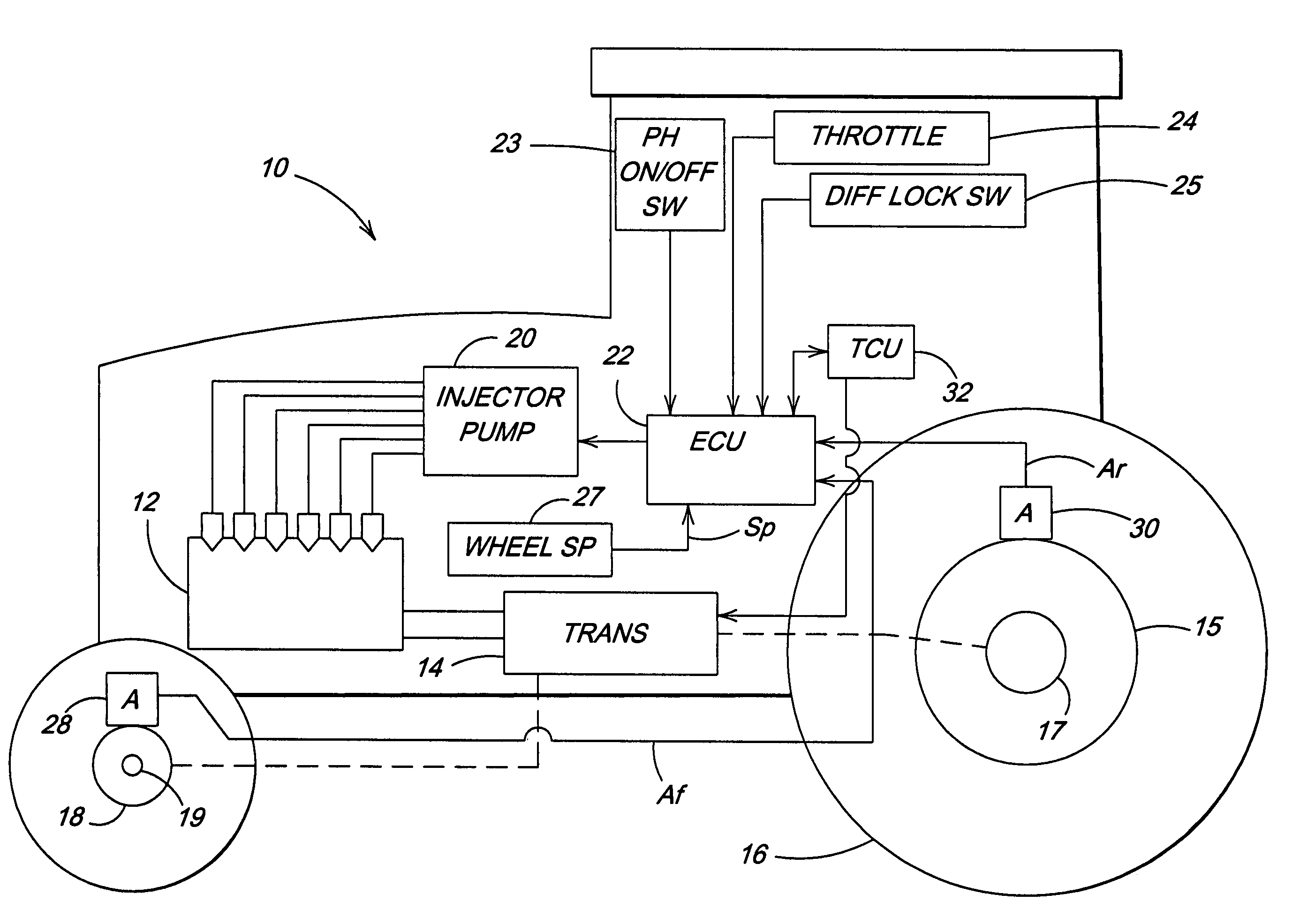

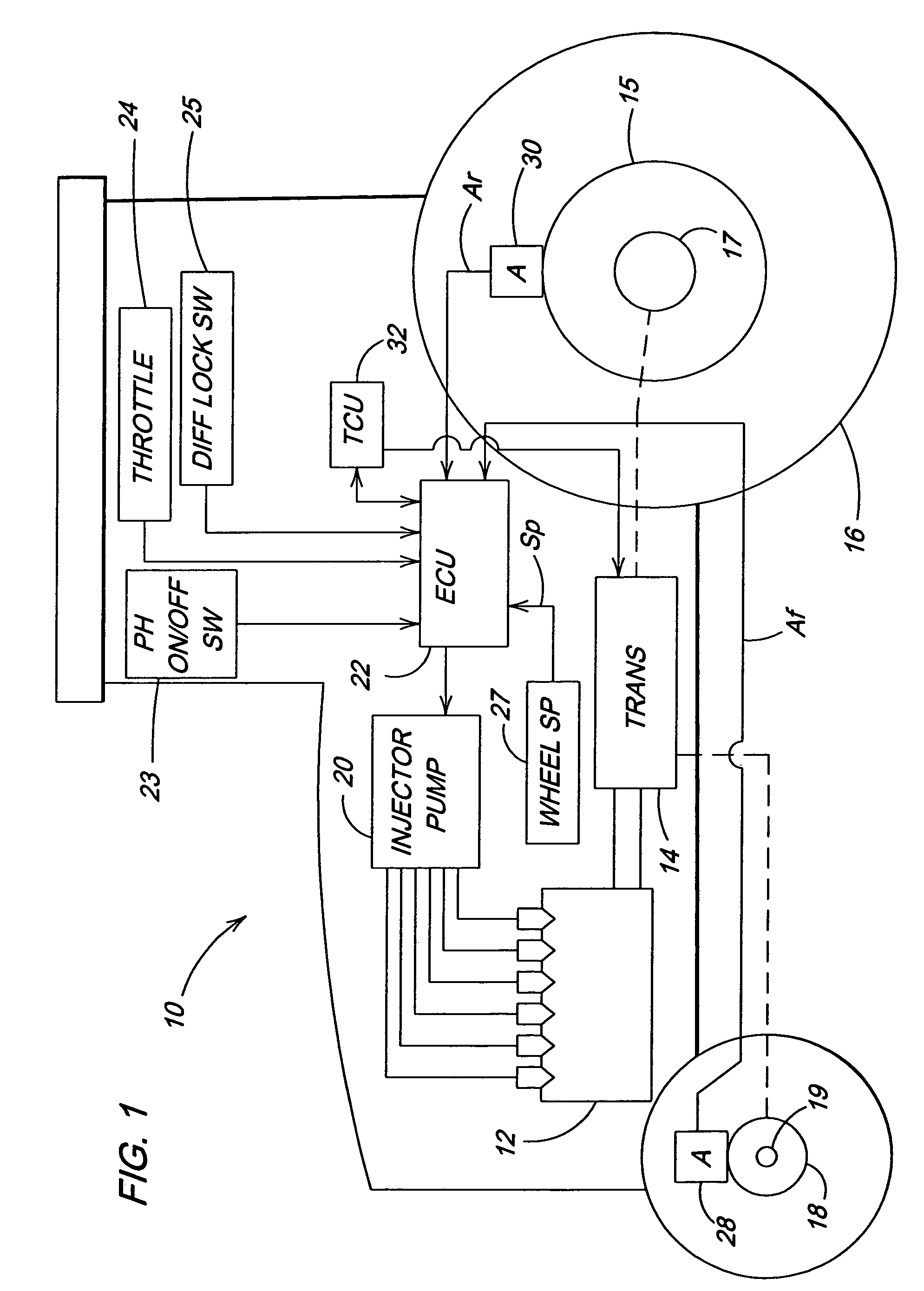

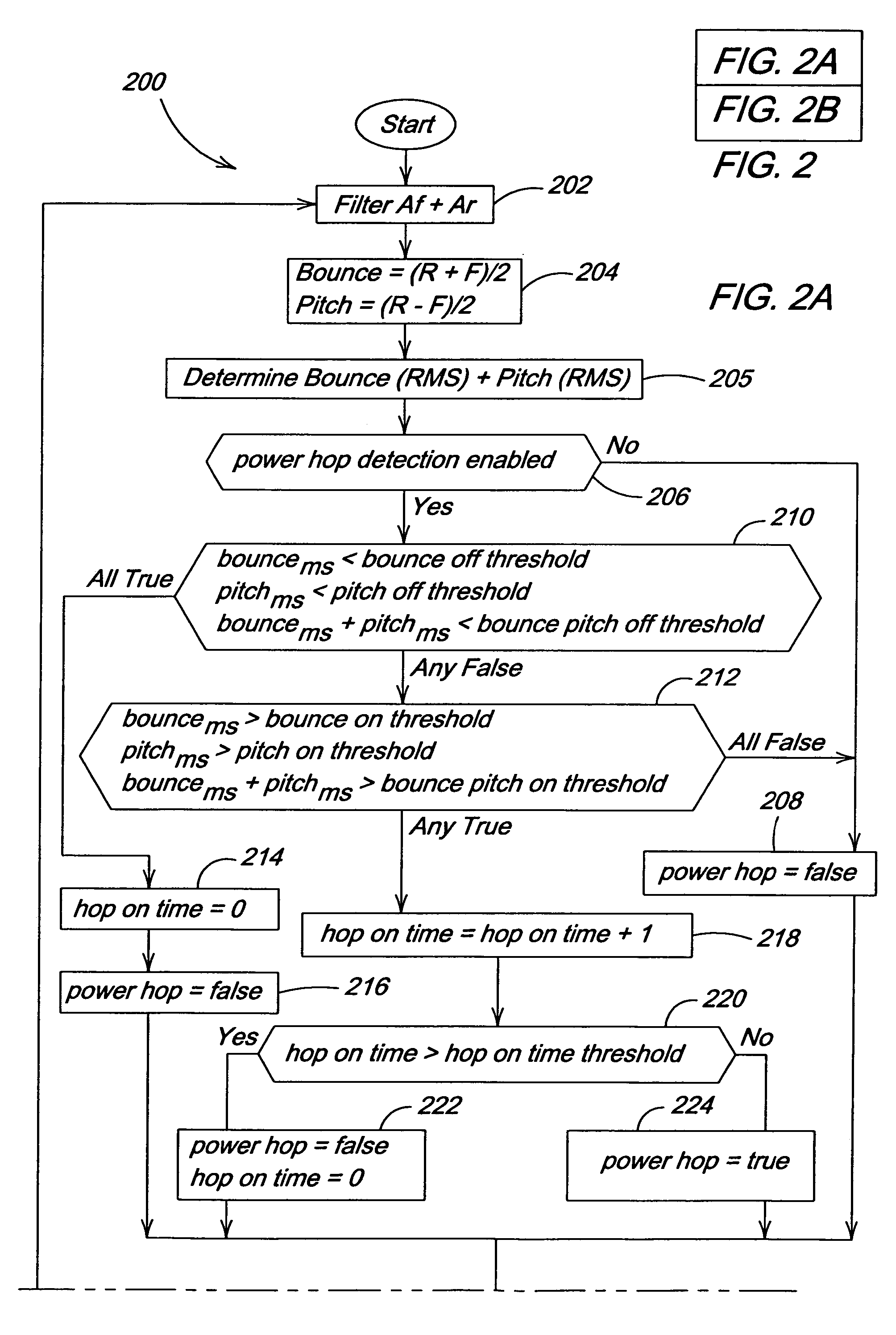

Tractor power hop control system and method

ActiveUS20060009897A1Decrease pitchReduce bouncingElectrical controlAnalogue computers for trafficDrive wheelControl signal

A control system performs a method for controlling pitching and bouncing of a vehicle having an engine driving wheels through a transmission, and having a fuel control unit for supplying a variable amount of fuel to the engine in response to fuel control signals generated by an engine control unit. The method includes, from front and rear acceleration signals, generating vehicle pitch and bounce signals, converting the pitch and bounce signals to RMS pitch and bounce values, generating a fuel offset value as a function of the RMS pitch and bounce values, and modifying fuel delivered to the engine as a function of the fuel offset value. The fuel offset value is operate don by a bi-linear gain function wherein negative values are multiplied by a larger gain and positive values are multiplied by a smaller gain.

Owner:DEERE & CO

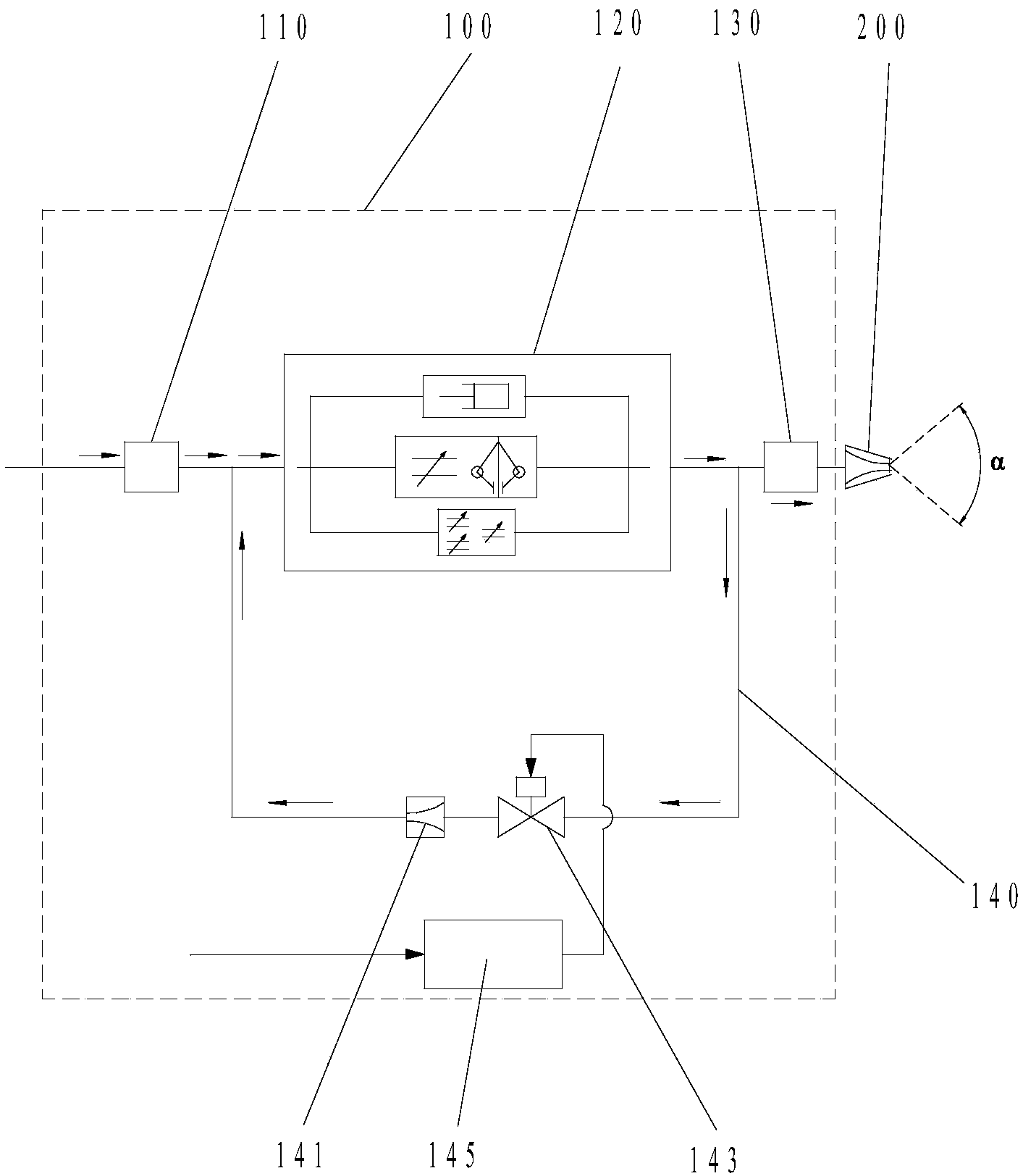

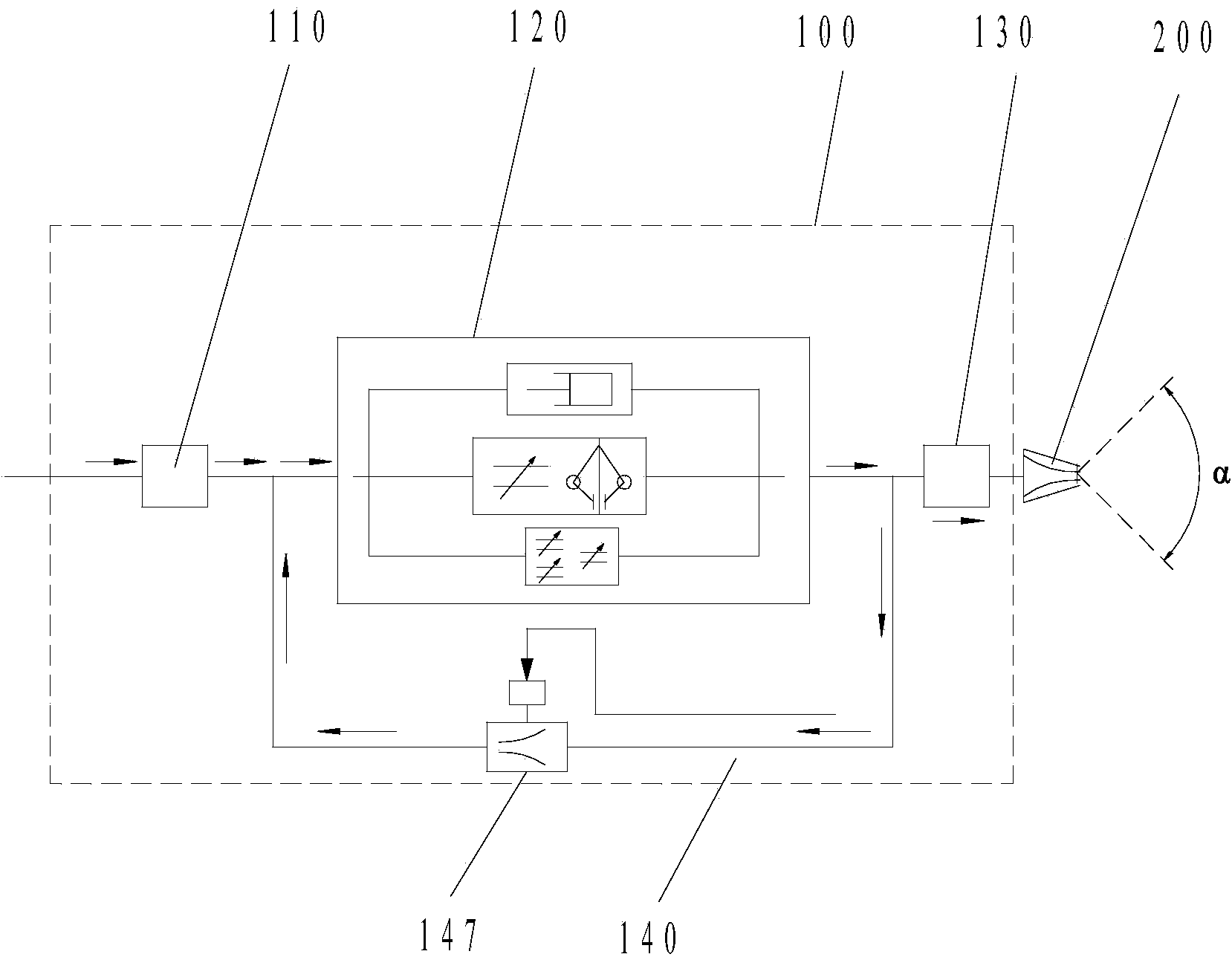

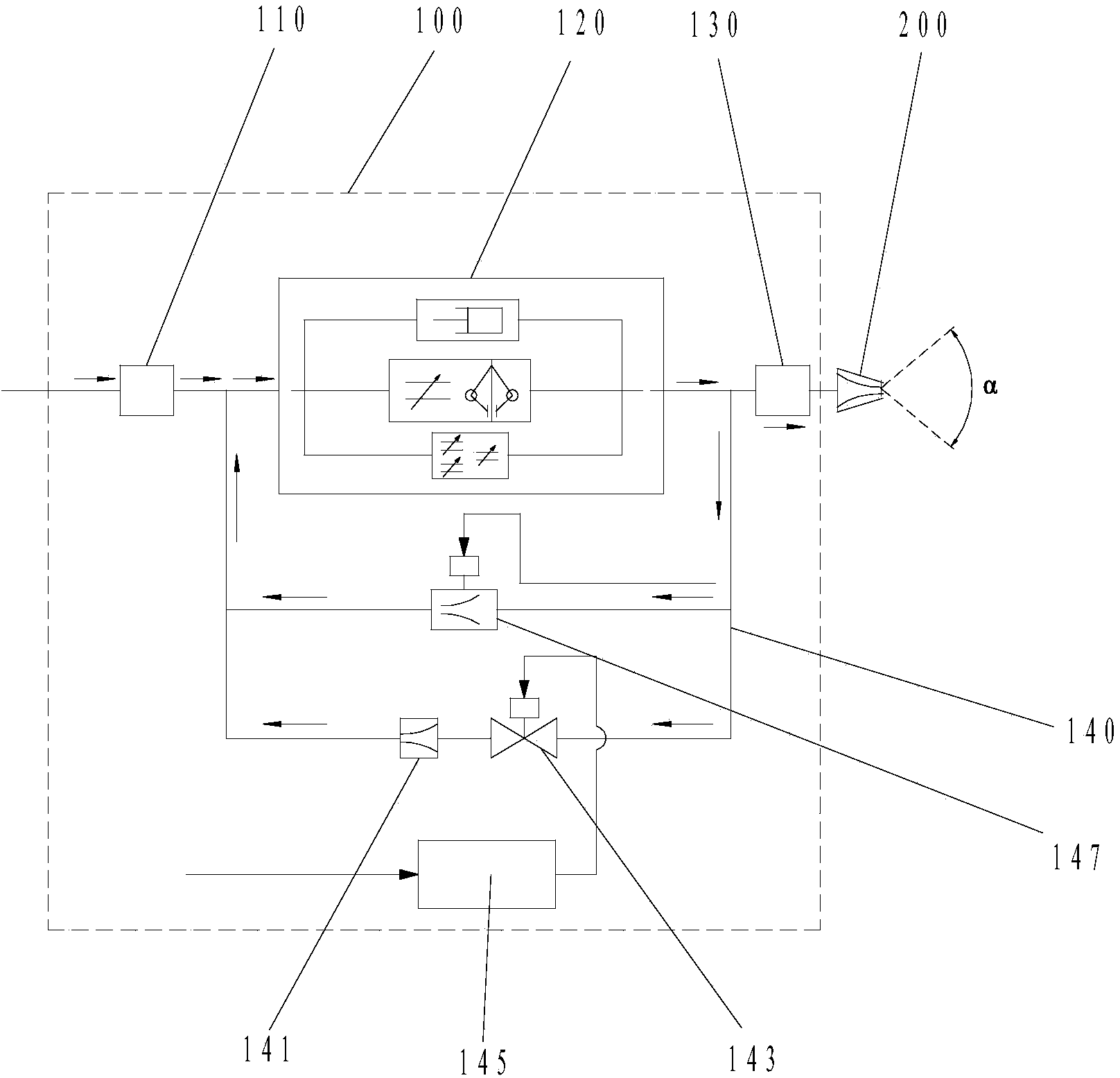

Start fuel supply control method and system for micro gas turbine

ActiveCN103967622ASatisfy oil supplyMeet needsTurbine/propulsion engine ignitionTurbine/propulsion engine startersSpray coneCombustion chamber

The invention discloses a start fuel supply control method and system for a micro gas turbine, and is used for fuel supply control in the start process of the micro gas turbine. The micro gas turbine adopts a centrifugal atomization fuel nozzle, fuel is supplied to the centrifugal atomization fuel nozzle through a fuel control unit, atomized by the centrifugal atomization fuel nozzle, and ignited for combustion in a combustion chamber; the fuel supply requirements of the micro gas turbine in plain and plateau application scenarios can be met through adjusting the flow amount and / or a spray cone angle of the centrifugal atomization fuel nozzle. According to the method and system, under the condition of not changing technical parameters of the fuel supply control unit, the flow pressure characteristics of the fuel nozzle can be changed, the start fuel flow can be reduced, the gas-fuel ratio of ignition start can be increased, the fuel pressure in front of the nozzle can be increased, the atomization performance is enhanced, and the plateau ignition start performance is enhanced, and thus the fuel supply characteristic requirements of the micro gas turbine in high altitude application can be met and the operation field range of the micro gas turbine is widened.

Owner:CHINA AVIATION POWER MACHINE INST

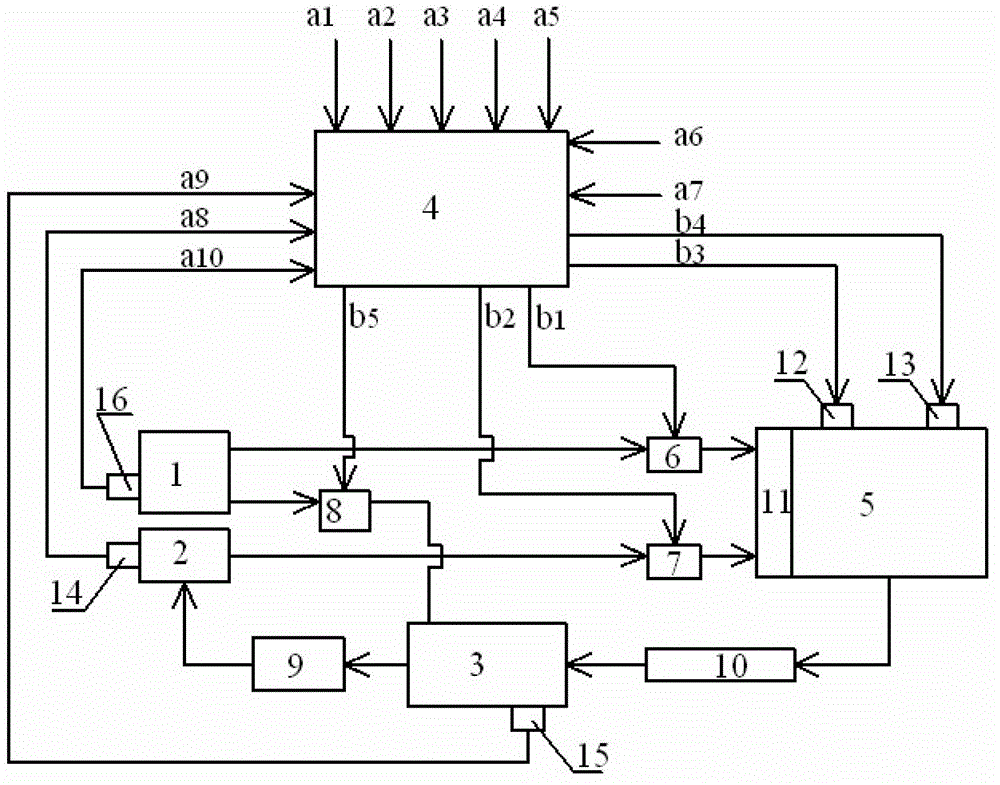

Control method for power system of dimethyl ether/hydrogen internal combustion engine

ActiveCN102748143AImprove the combustion processImprove emission effectNon-fuel substance addition to fuelInternal combustion piston enginesAlternative fuelsControl signal

The invention provides a power system of a dimethyl ether / hydrogen internal combustion engine and a control method for the power system of the dimethyl ether / hydrogen internal combustion engine, belonging to the fields of energy saving and the use of alternative fuels of the internal combustion engine. The power system comprises a dimethyl ether gas supply device and a hydrogen gas supply device, wherein dimethyl ether is reformed to produce hydrogen by the waste heat of the tail gas. The power system also comprises a dimethyl ether tank and a hydrogen tank, a tail gas waste heat reforming device, a blended fuel control unit and a dimethyl ether reformer controller, and input signals such as a crank angle signal, a cooling water temperature signal, a gas inlet temperature and pressure signal, and output signals such as a dimethyl ether jetting signal and a hydrogen jetting signal, an igniting module signal, an idle speed motor control signal, and a tail gas waste heat reforming device control signal. According to the invention, the discharging performance and the combustion performance of a spark ignition engine can be improved and increased due to dimethyl ether and hydrogen, and hydrogen is produced by reforming dimethyl ether, so that the use cost can be reduced, and the compensation of hydrogen can be realized. The device is simple in design structure, easy to install, and lower in cost, and the system is further good in adaptability and expansibility, wide in market prospect, and better in economic benefit.

Owner:BEIJING UNIV OF TECH

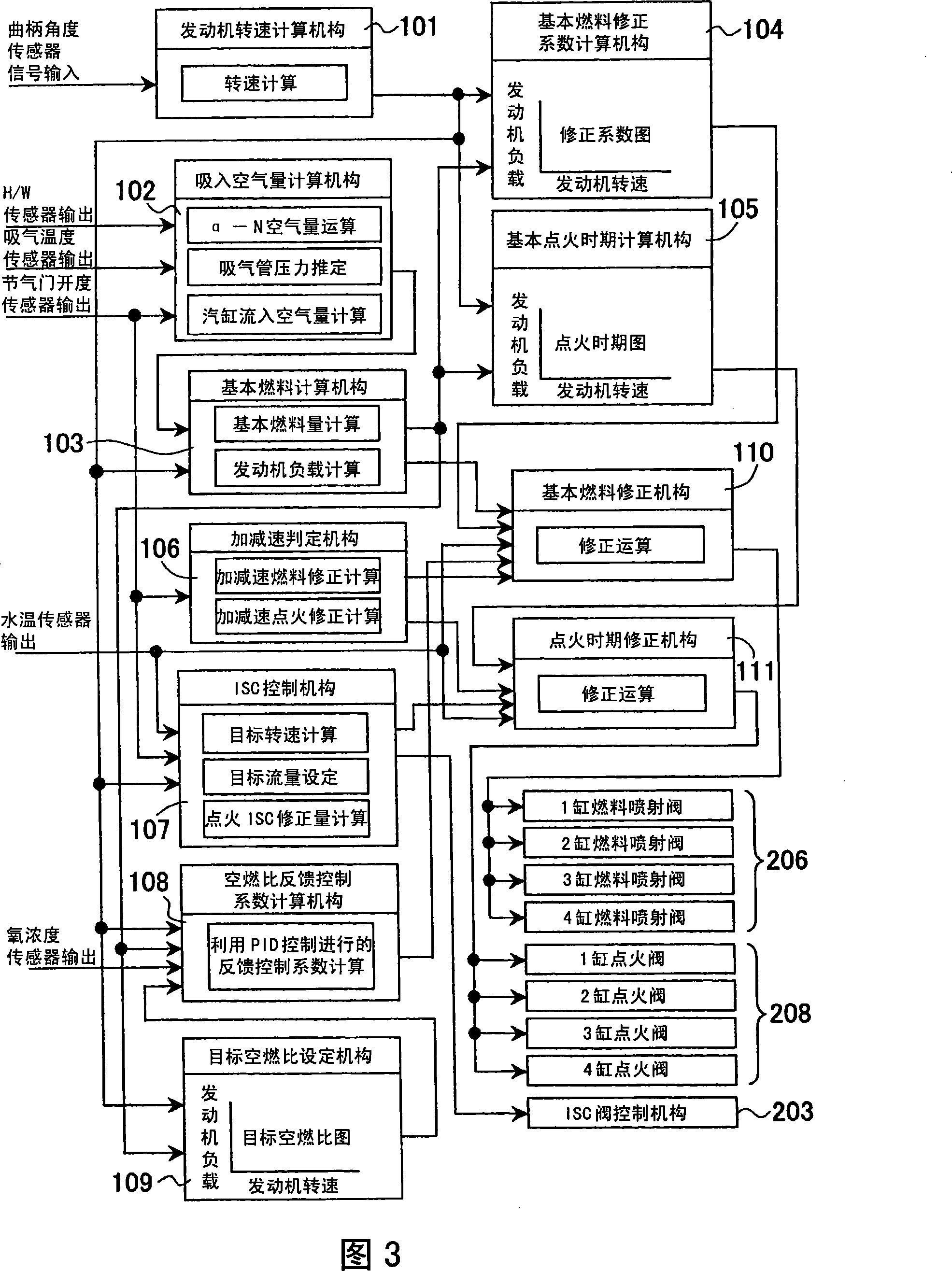

Air amount computing unit and fuel control unit of internal combustion engine

InactiveCN101187341ASmooth connectionNo change in air-fuel ratioElectrical controlMachines/enginesFuel control unitInternal combustion engine

An air volume computing device for an internal combustion engine, comprising: an air volume detecting mechanism for detecting the air volume passing through an intake throttle portion of the internal combustion engine; and an air volume for obtaining a calculated value of the air volume passing through the intake throttle portion based on the throttle opening degree Calculation mechanism; use the difference between the current value of the air volume passing through the intake throttle part and the previous filtering value to filter, and remove the air volume filled in the intake manifold to obtain the air volume flowing into the cylinder of the internal combustion engine mechanism; the first filter based on the air volume detected by the air volume detection mechanism; the second filter based on the calculated value of the air volume obtained by the air volume calculation mechanism; selected when the internal combustion engine is stable The input value of the first filter and the last output value, the selected mechanism for selecting the input value and the last output value of the second filter at the transition of the internal combustion engine; the input of the selected value selected by the selected mechanism The third filter uses the output of the third filter as the amount of air flowing into the cylinder.

Owner:HITACHI LTD

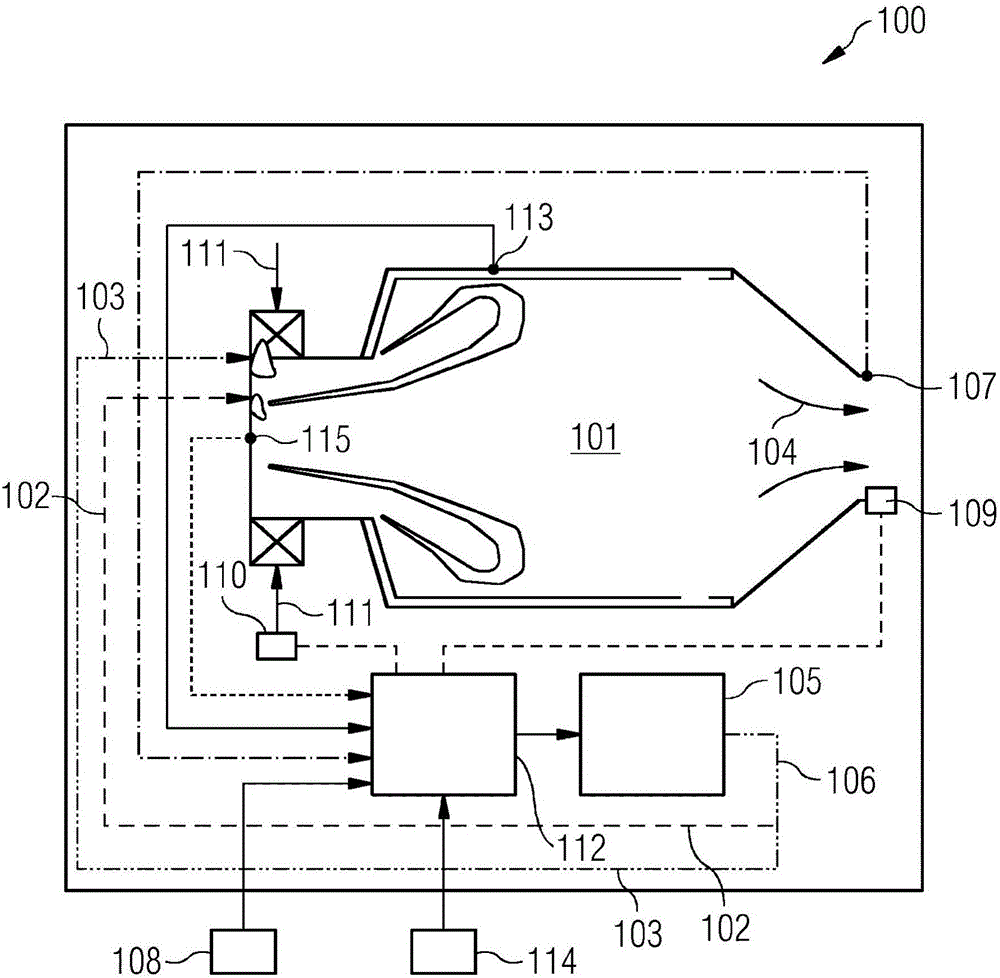

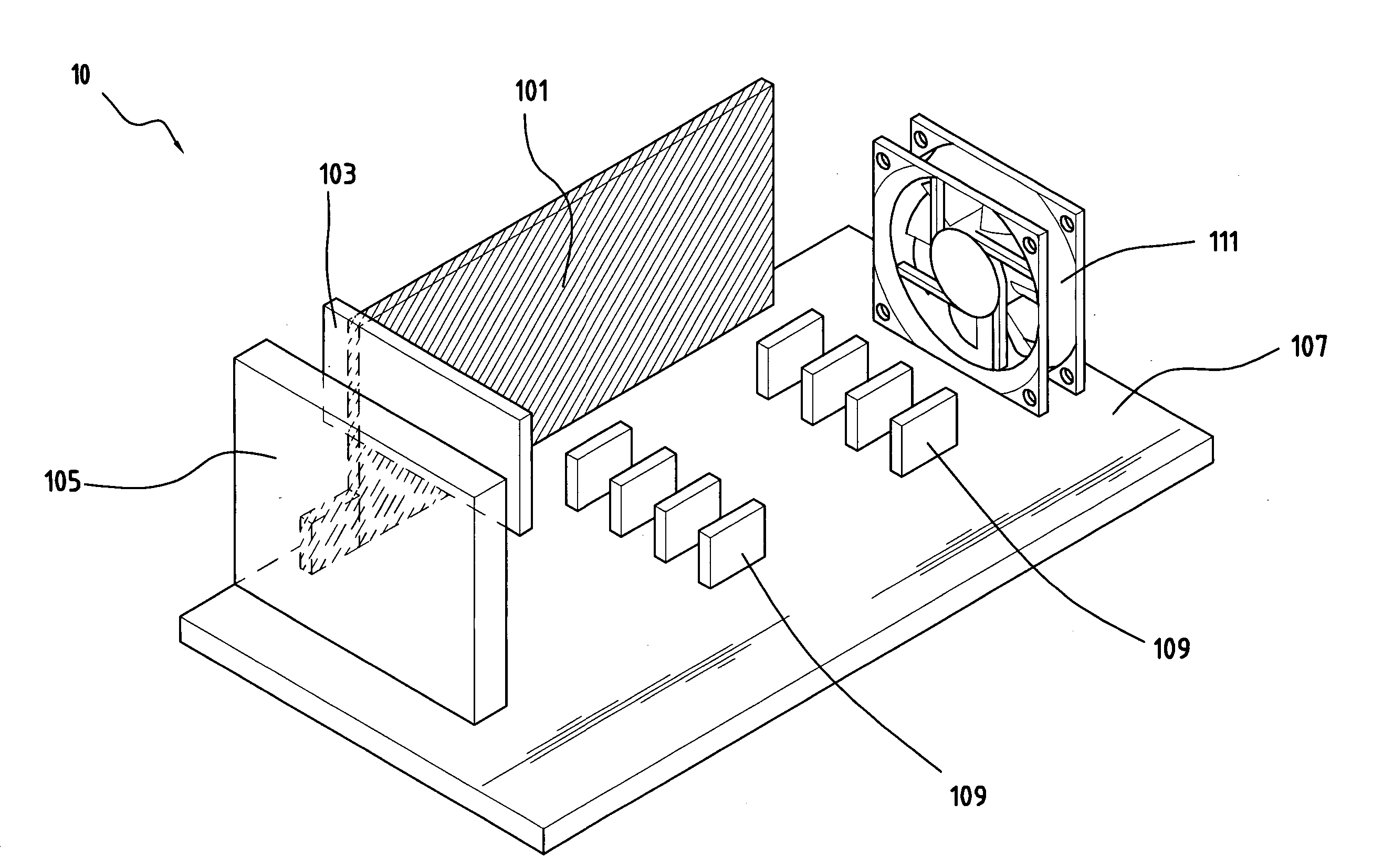

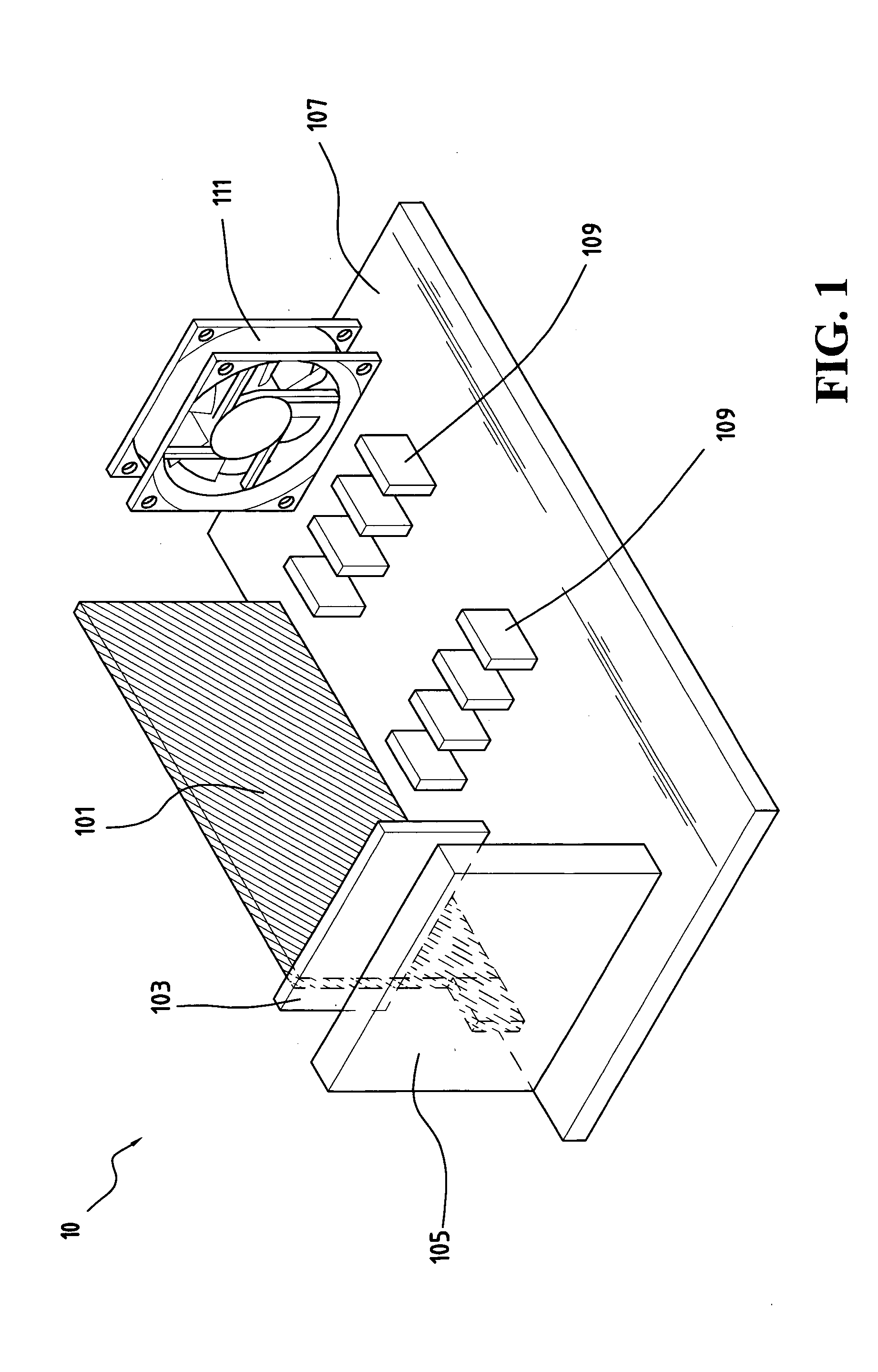

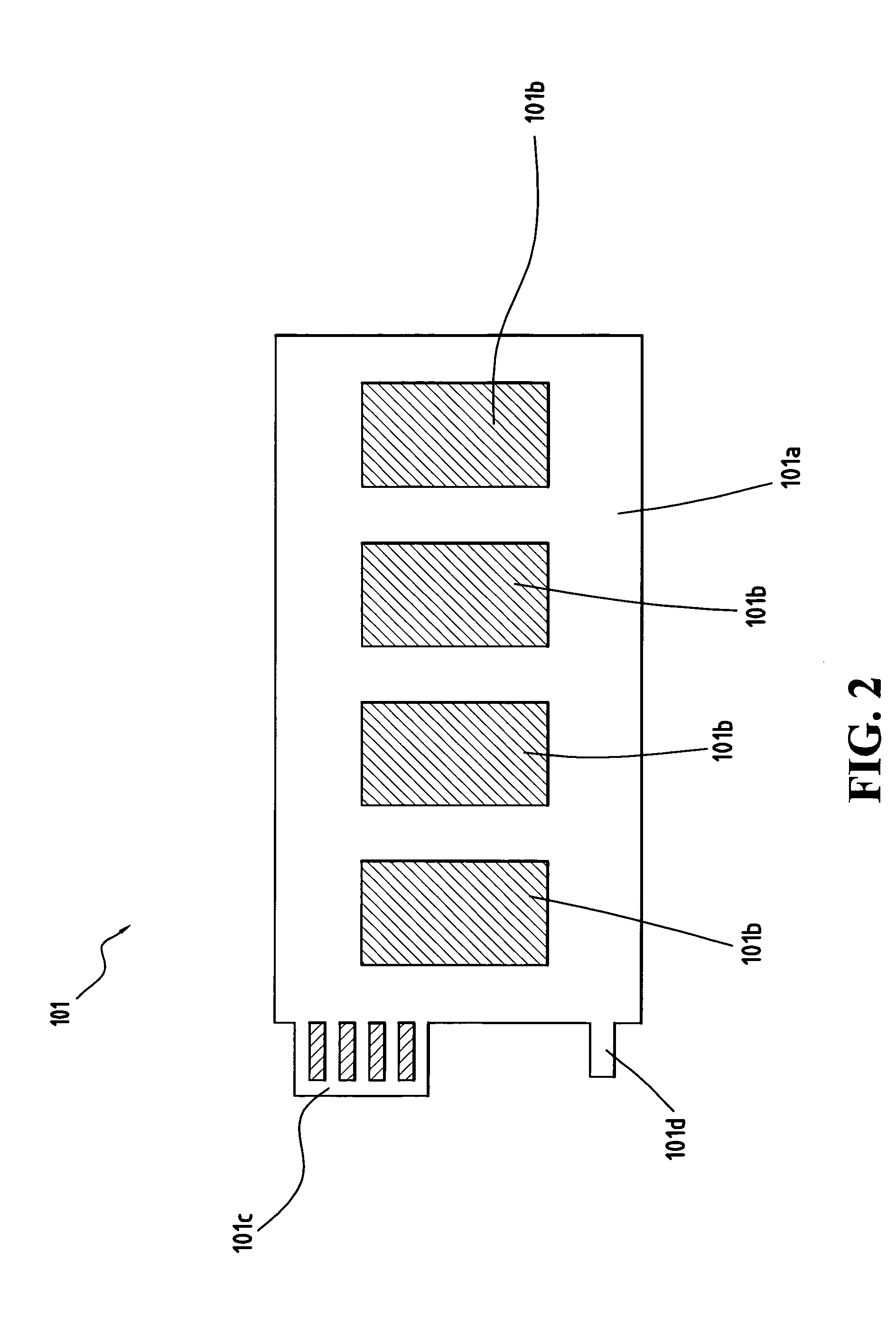

Intelligent control method with predictive emissions monitoring ability

InactiveCN105745497AReduce the temperatureReliable emissionsContinuous combustion chamberGas turbine plantsCombustion chamberCombustor

The present invention relates to a combustor system (100) for a gas turbine engine. The combustor system (100) comprises a combustion chamber (101) into which a pilot fuel (102) and a main fuel (103) is injectable and flammable, wherein an exhaust gas (104) generated by the burned pilot fuel (102) and the burned main fuel (103) is exhaustible out of the combustion chamber (101). A control unit (112) is coupled to a fuel control unit (105) for adjusting the pilot fuel (102) ratio. The control unit (112) is adapted for determining a predicted pollutant concentration of the exhaust gas (104) on the basis of a temperature signal, a fuel signal, a mass flow signal and a fuel split ratio.

Owner:SIEMENS AG

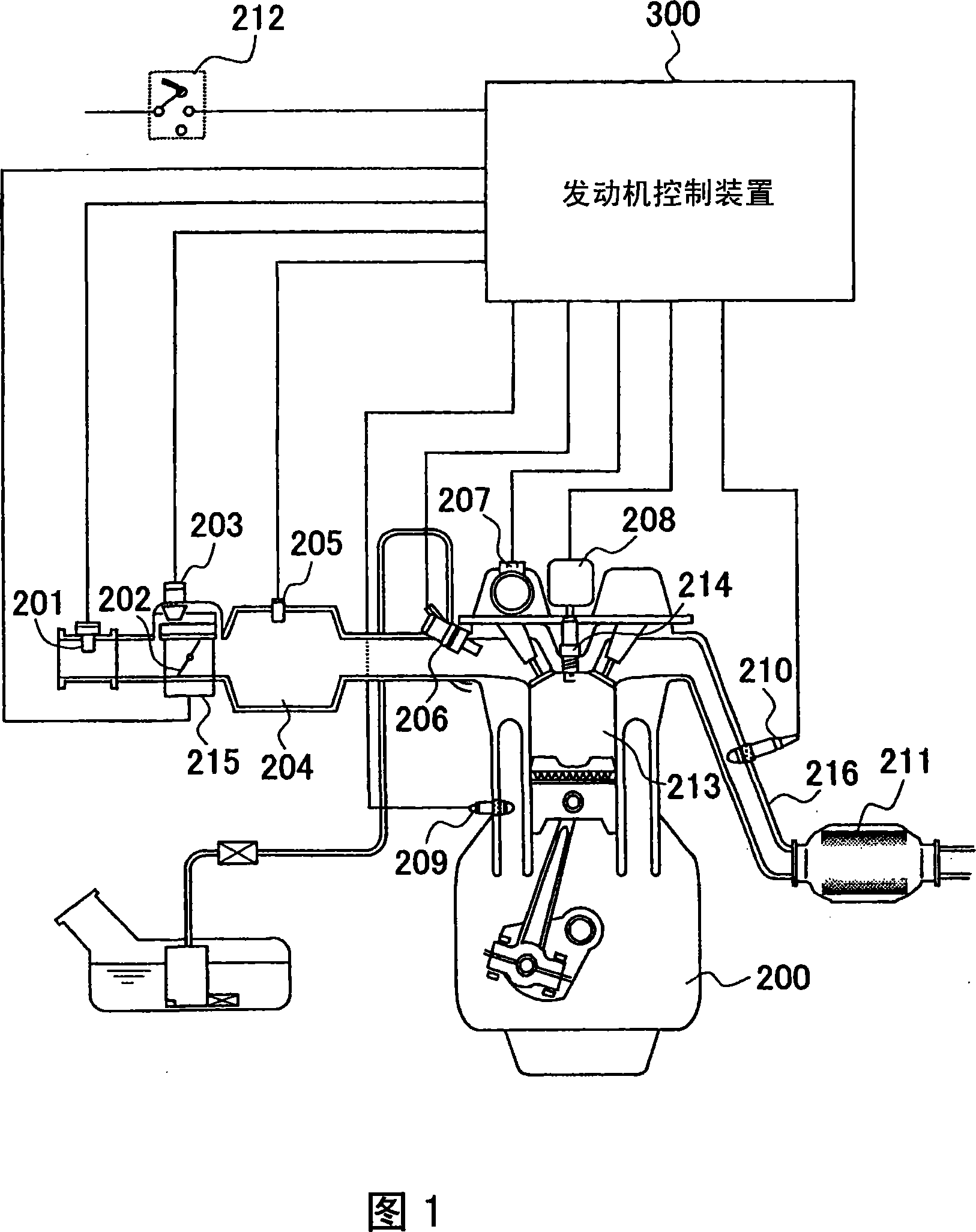

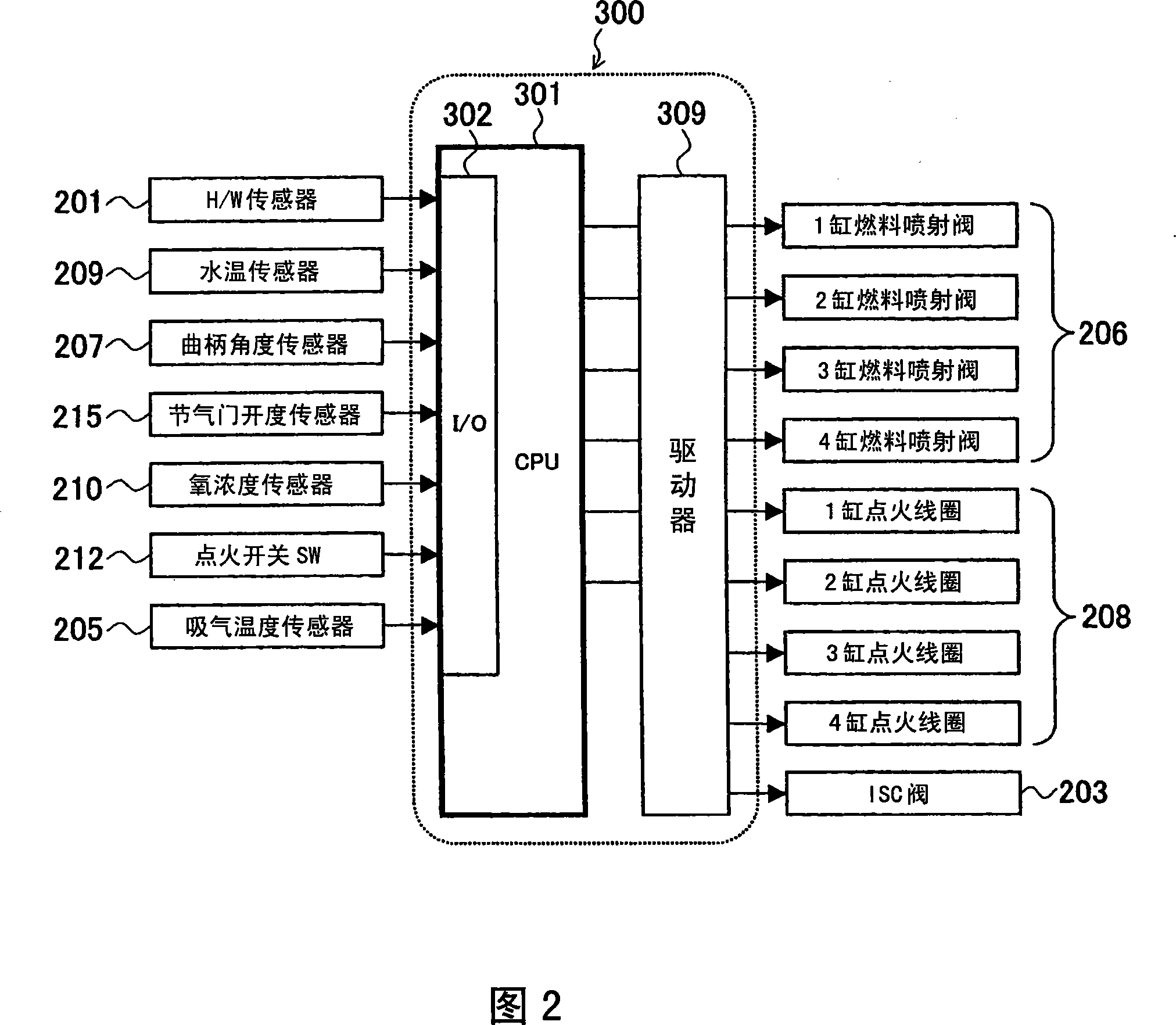

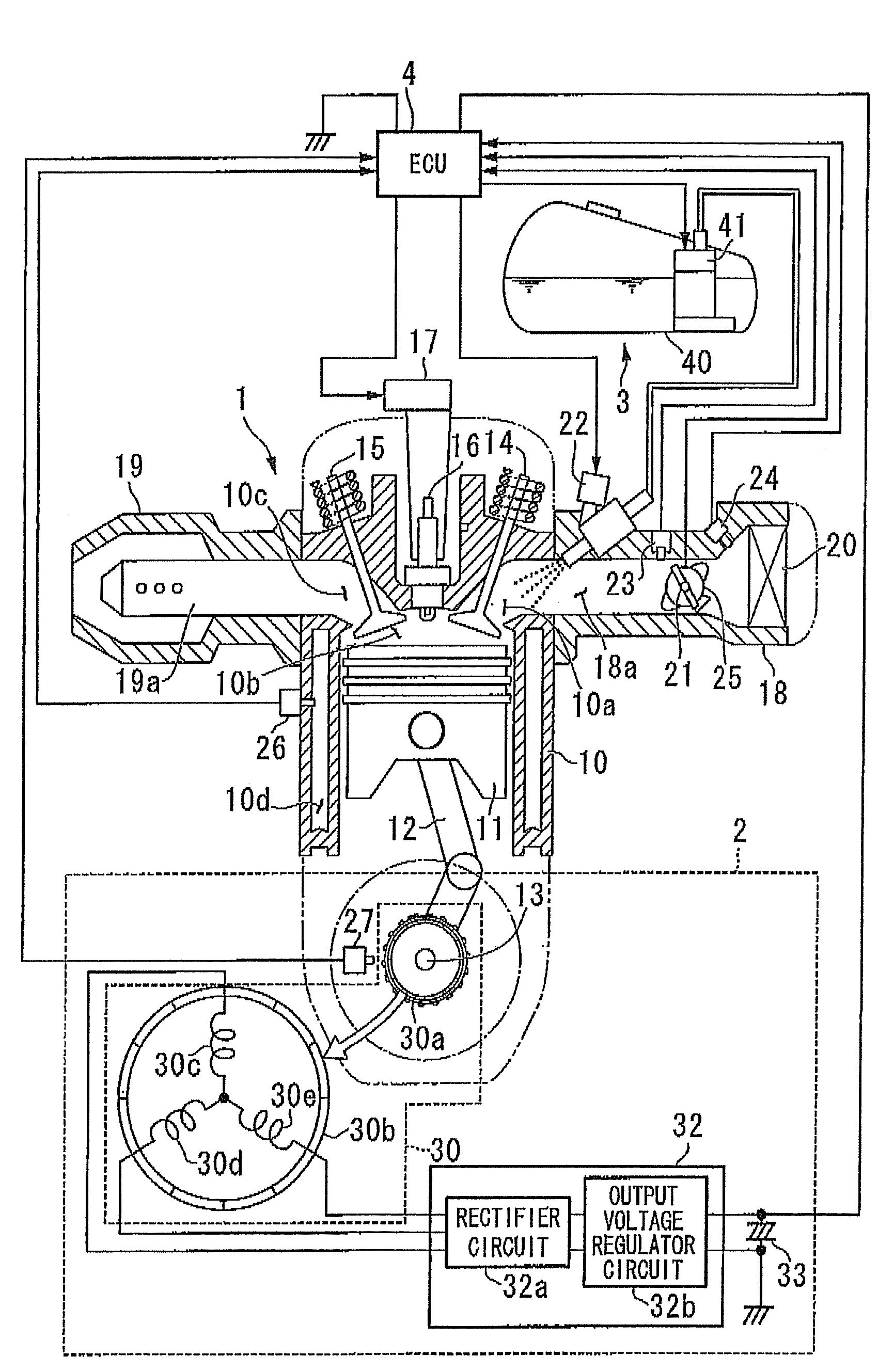

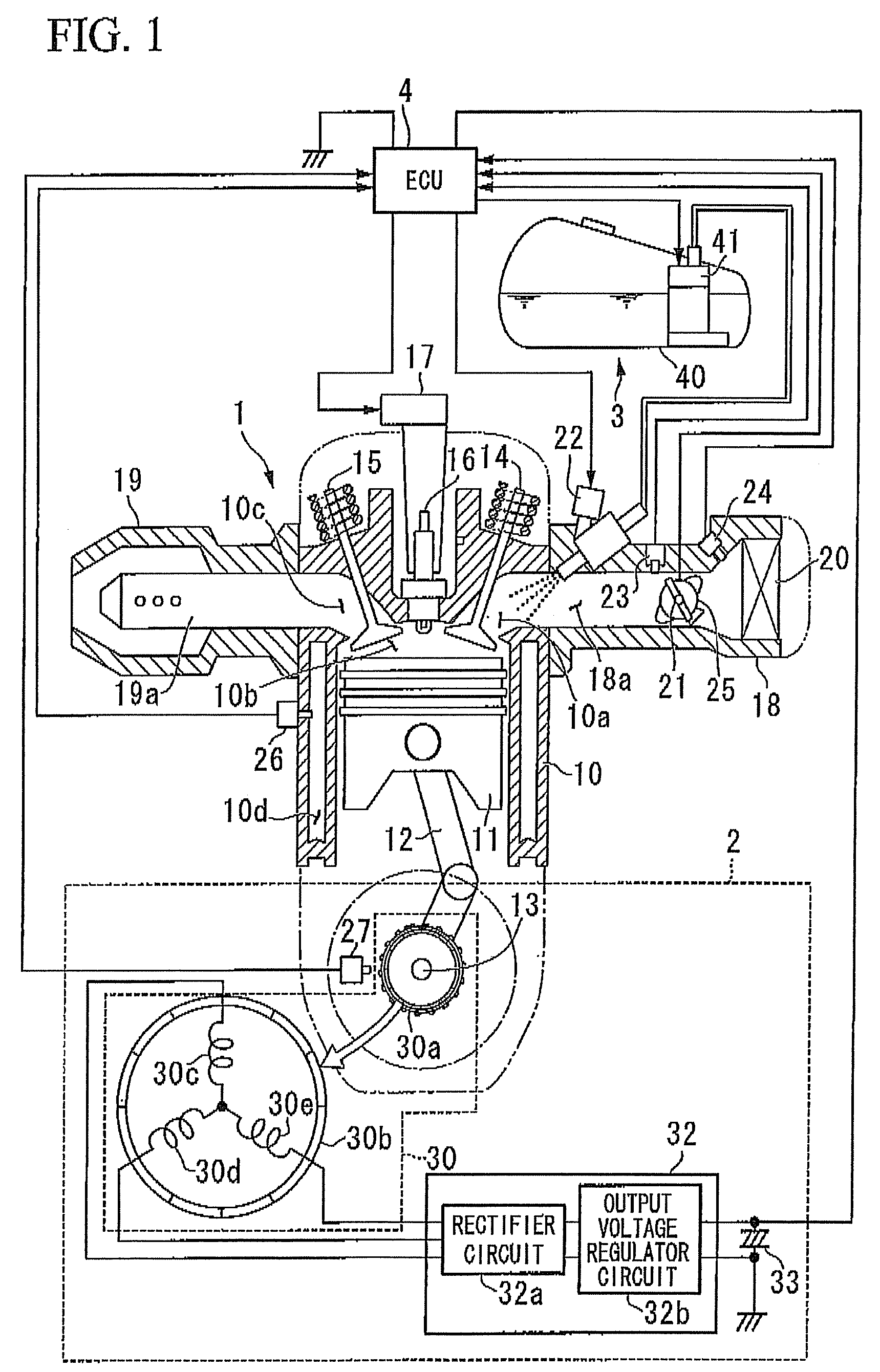

Control apparatus for internal combustion engine

InactiveUS7930092B2Avoid stopPower supply voltage can be preventedAnalogue computers for vehiclesElectrical controlExternal combustion engineFuel control unit

A control apparatus for an internal combustion engine, includes: a fuel injection unit; an ignition unit; a crank angle detection unit; a fuel pump; a booster unit; an ignition discharge unit; and a control unit that controls the fuel injection unit, the ignition unit, and the fuel pump, that ascertains ignition timings based on crank signals output from the crank angle detection unit, and that performs a startup control sequence that is made up of fuel injection processing, voltage boosting processing, ignition processing, and fuel supply processing.

Owner:HITACHI ASTEMO LTD

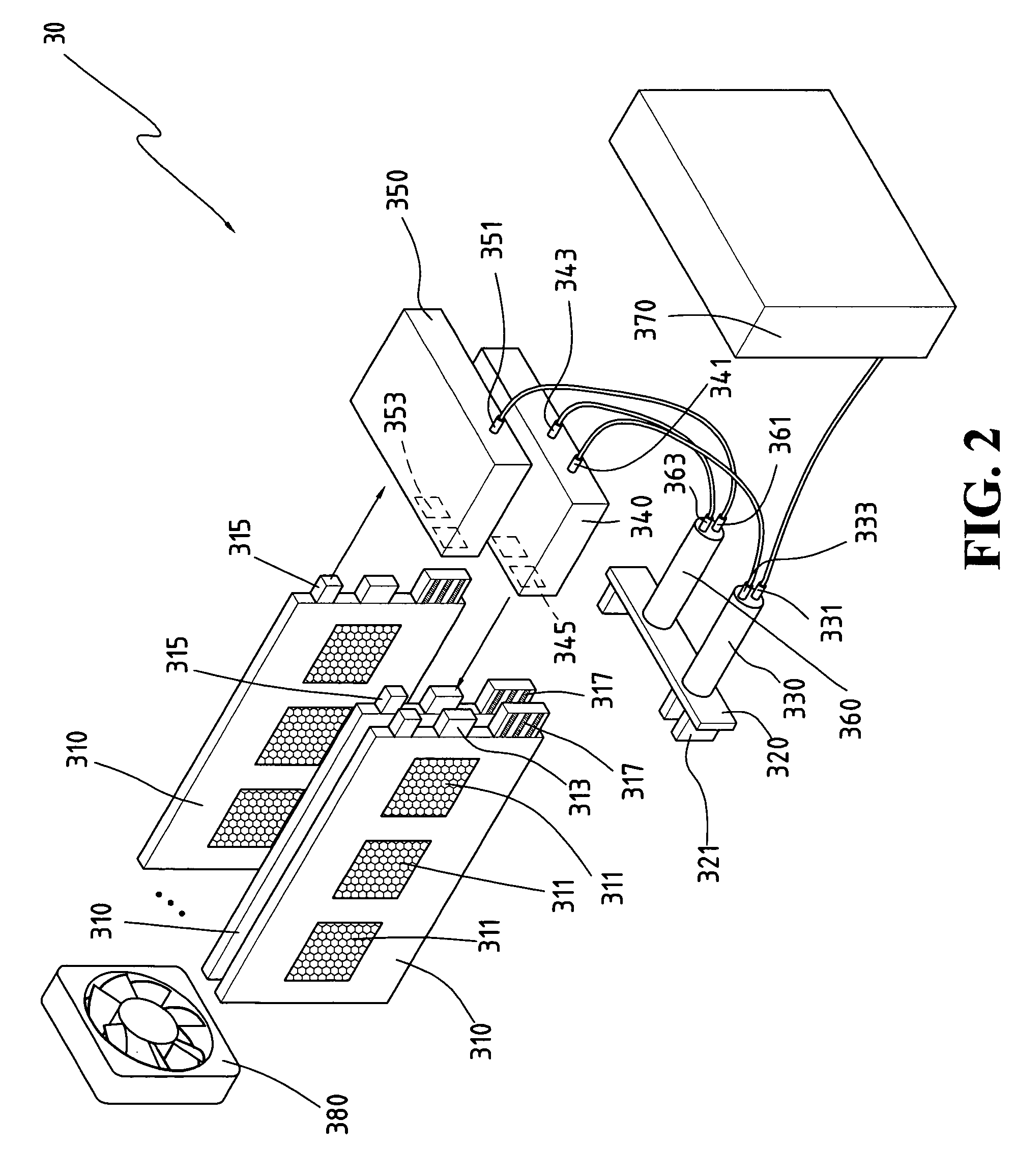

Semi-active full cell apparatus

The present invention is related to a semi-active fuel cell apparatus, mainly comprising plural fuel cell boards, gas cycling supply unit, fuel replenishing unit, fuel cycling unit, first fuel control unit and second fuel control unit. By way of connecting these constituent elements, the anode fuel is capable of being supplied to the fuel cell boards by cycling means; the gas cathode fuel is capable of being supplied to the fuel cell boards. Meanwhile, the gas cycling supply unit is also used for heat dissipation.

Owner:ANTIG TECH CO LTD

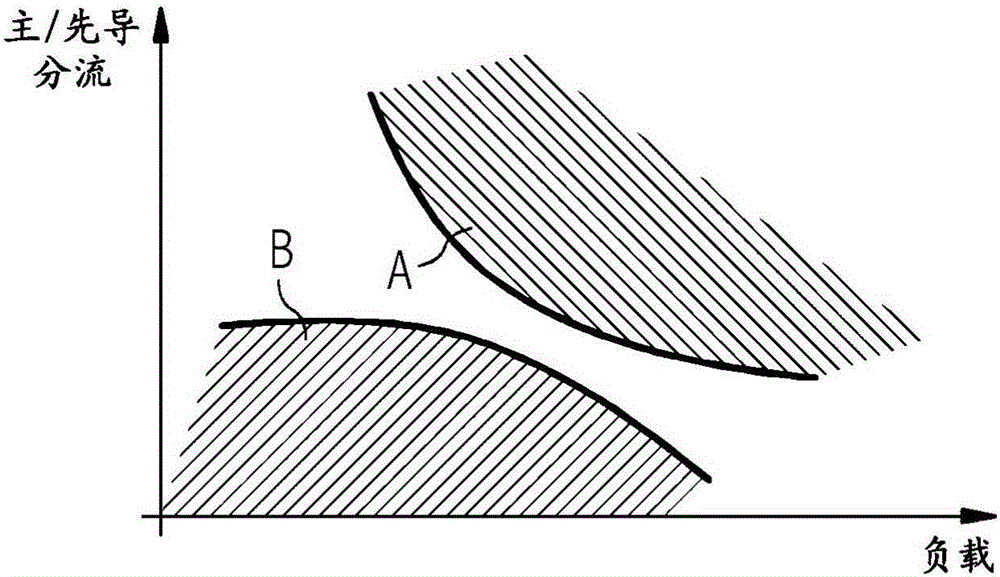

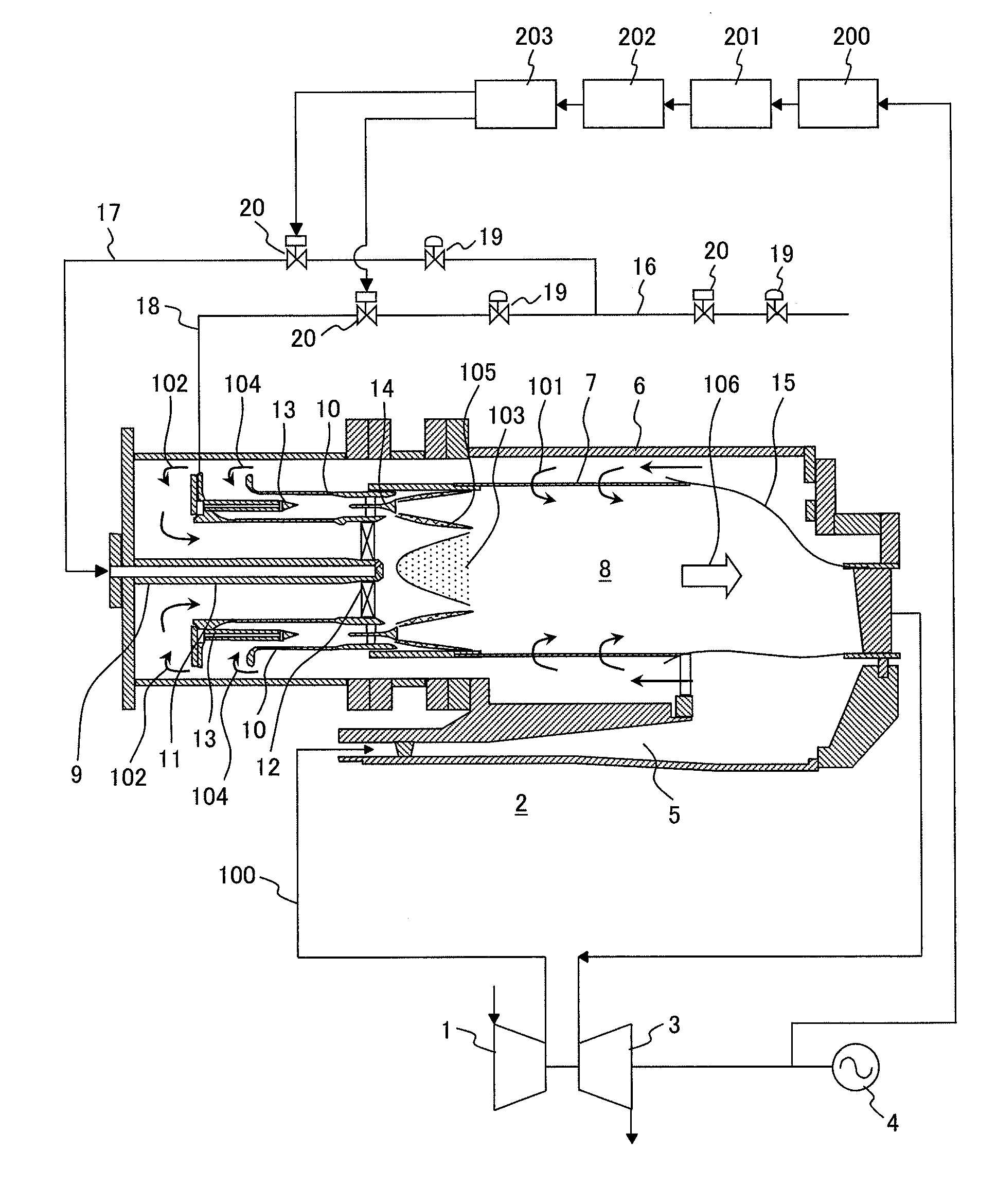

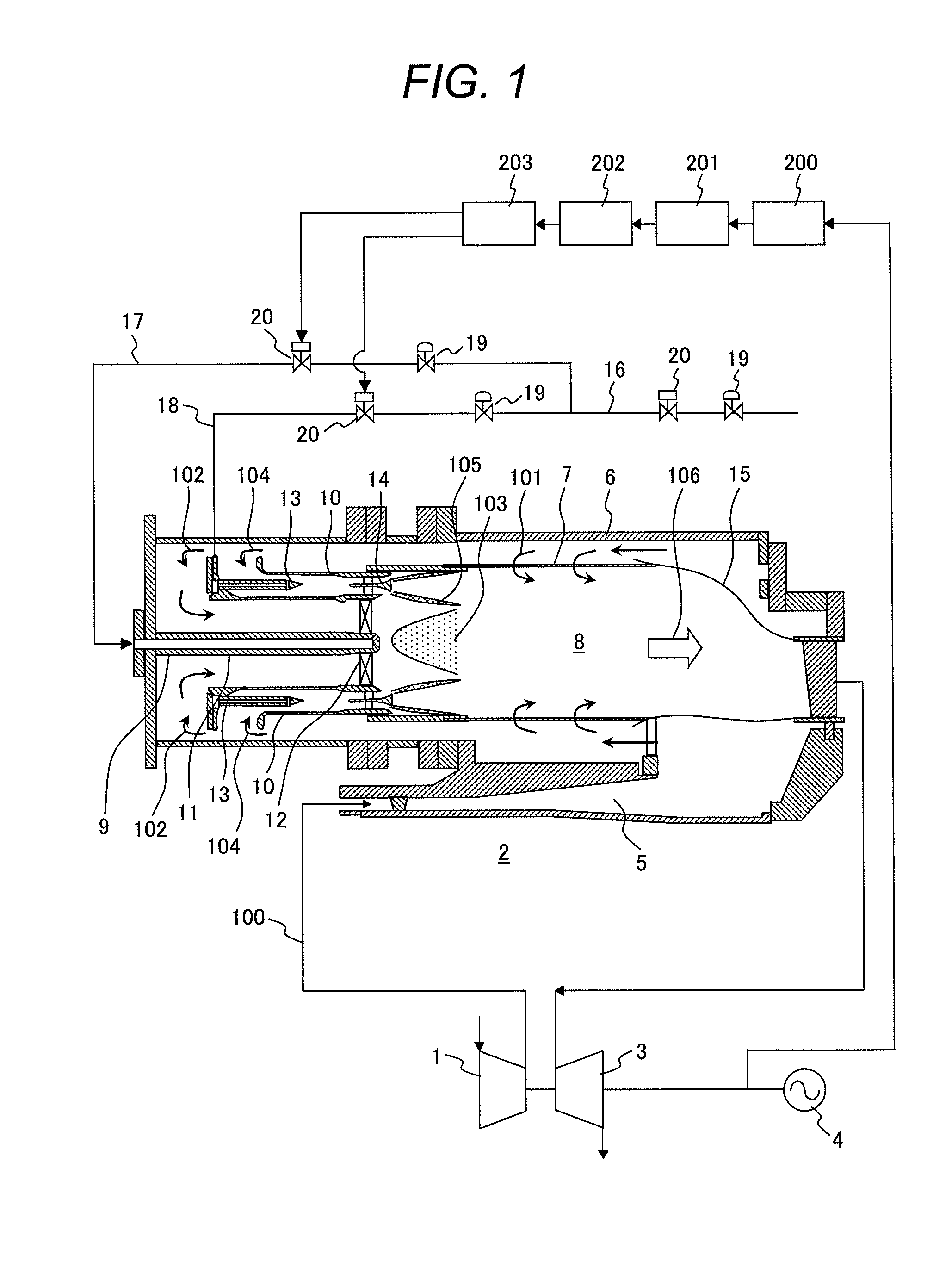

Method and Apparatus for Controlling Gas Turbine Combustor

InactiveUS20120055161A1Reduce nitrogen oxide emissionsLower emission rateFuel supply regulationContinuous combustion chamberCombustion chamberCombustor

An apparatus for controlling a gas turbine combustor having a diffusion combustion burner and a premix combustion burner comprising: a rotating speed detector for detecting a rotating speed of gas turbine, a recorder for recording the detected value of the rotating speed of gas turbine detected by the rotating speed detector, an arithmetic unit for calculating a change with time of the rotating speed of gas turbine in accordance with details of the detected value of the rotating speed of gas turbine recorded in the recorder, and a fuel control unit for judging a starting situation of reduction in the rotating speed of gas turbine on the basis of the change with time of the rotating speed of gas turbine calculated by the arithmetic unit and controlling respectively a fuel flow rate for the diffusion combustion burner to be fed to the diffusion combustion burner installed in the gas turbine combustor and a fuel flow rate for the premix combustion to be fed to the premix combustion burner.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

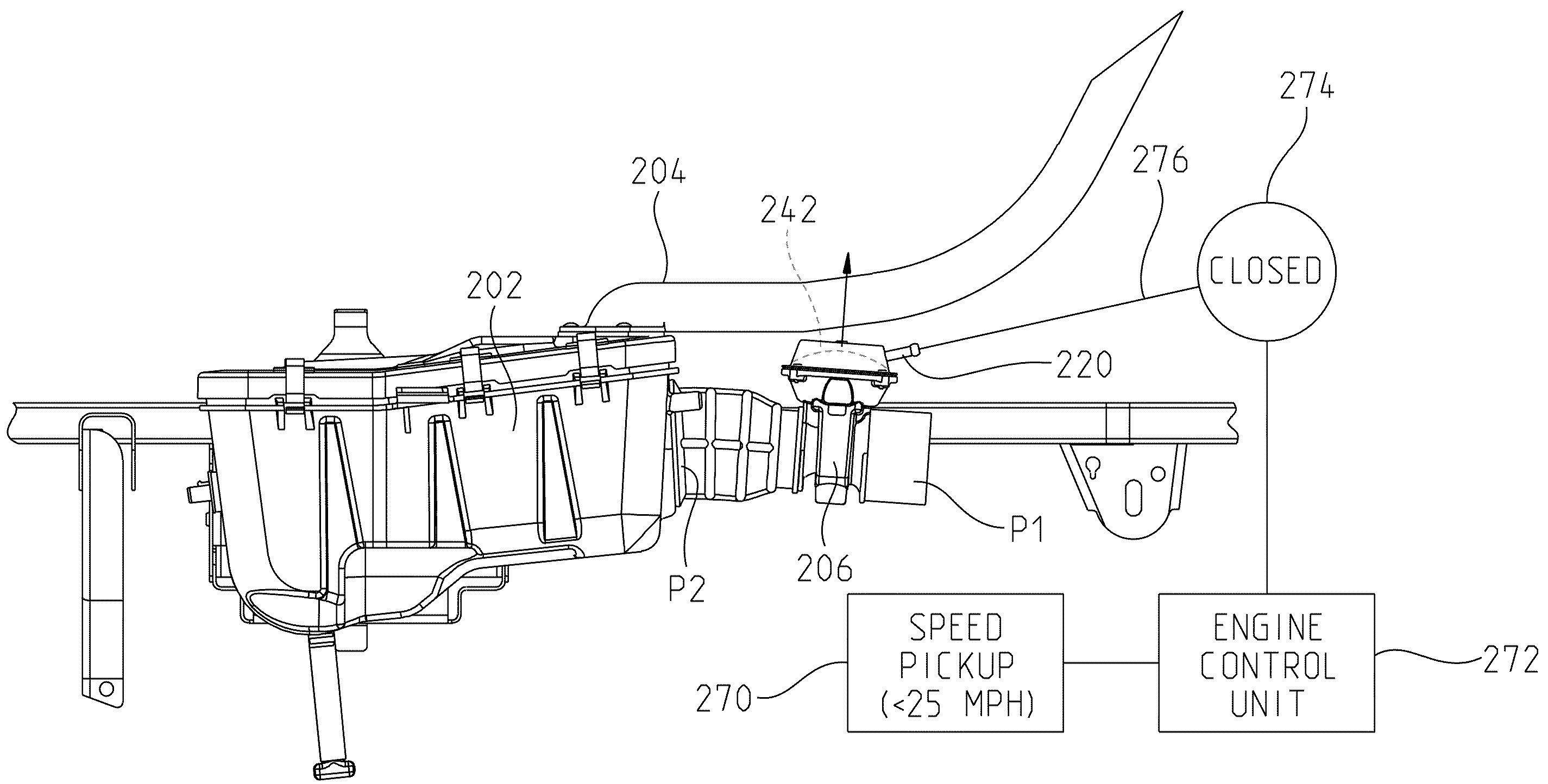

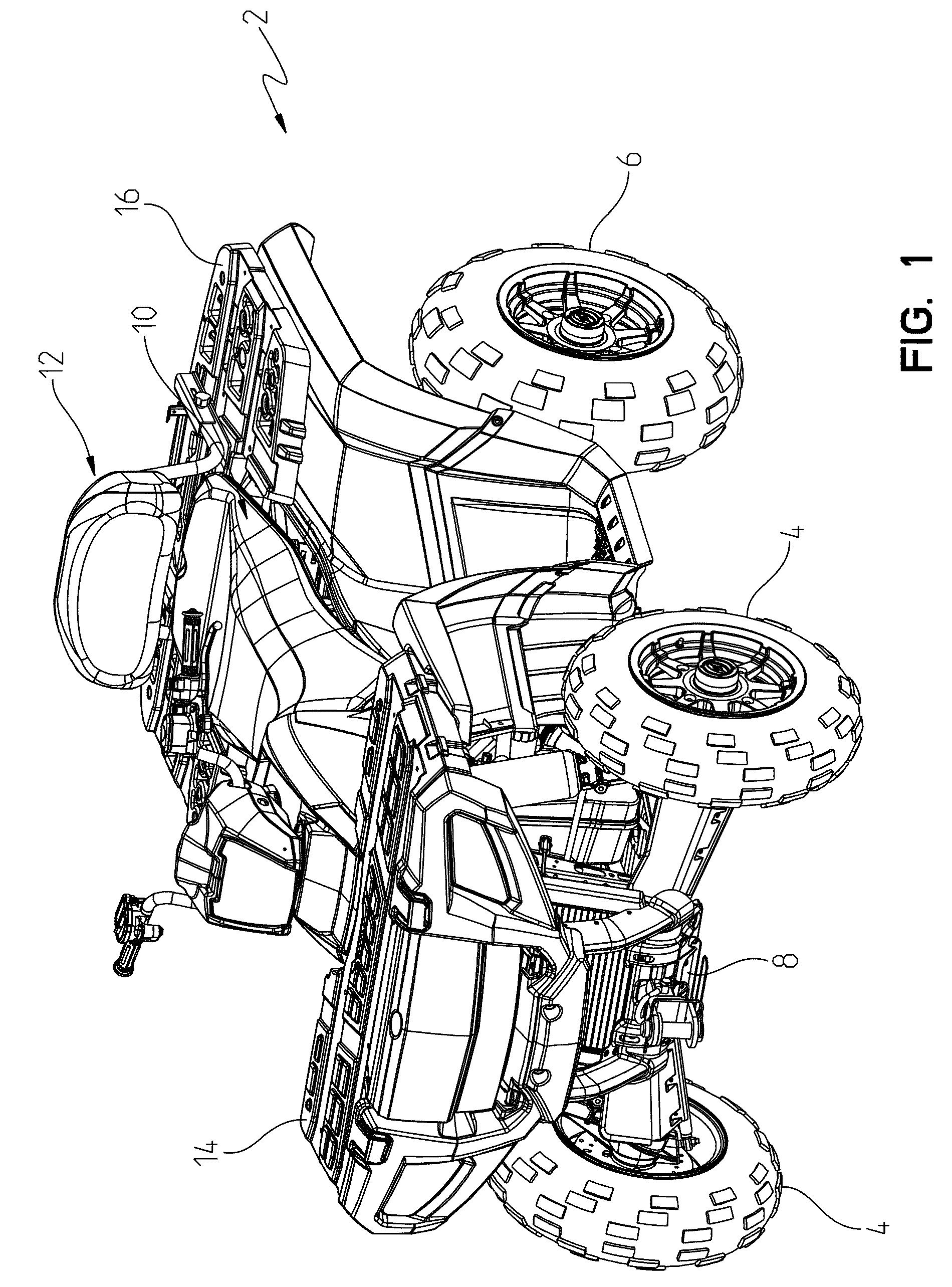

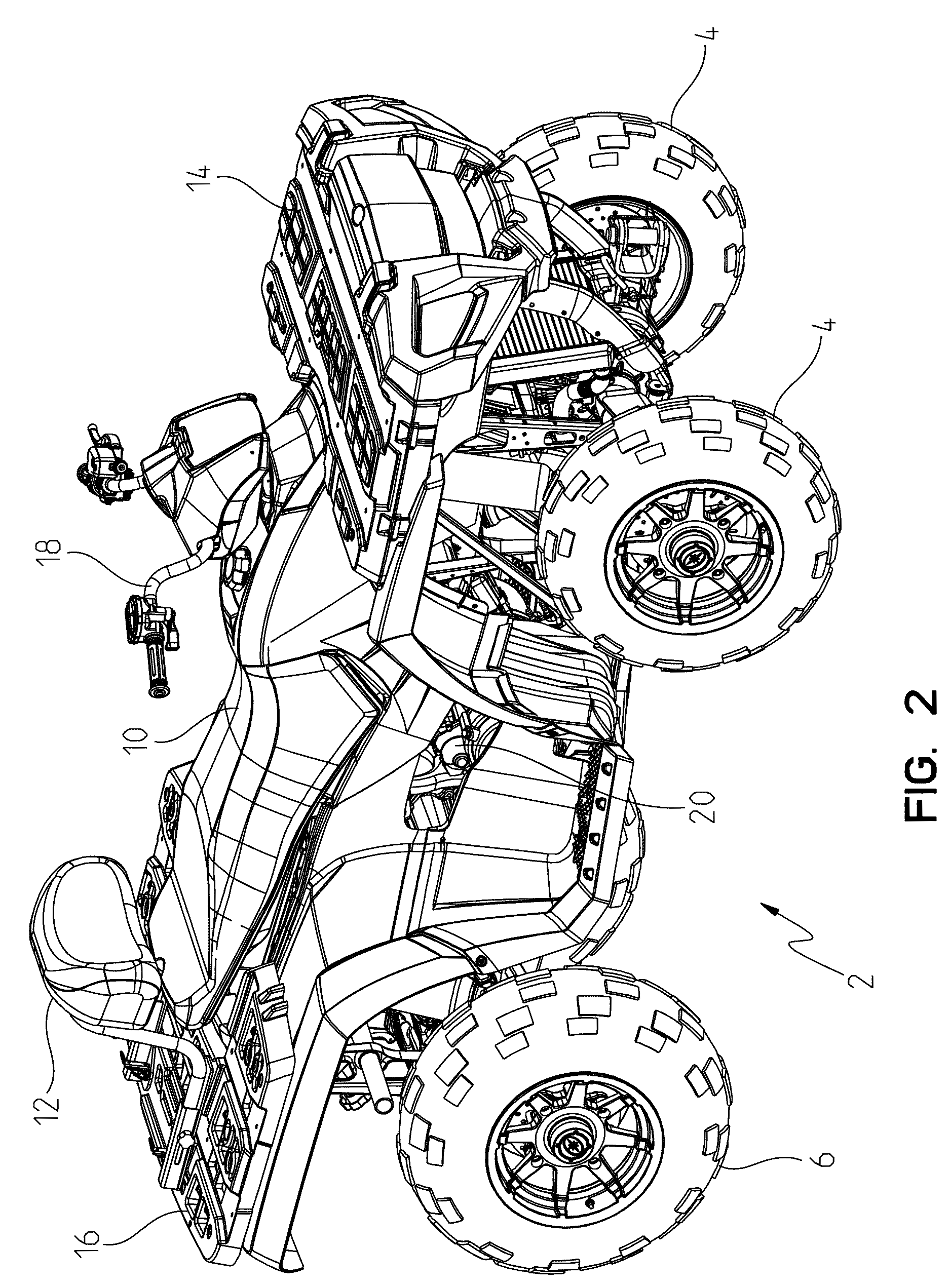

Vehicle having speed control unit

ActiveUS20100023233A1Analogue computers for trafficCombustion-air/fuel-air treatmentFuel control unitEngineering

A tractor is disclosed as a four-wheel drive vehicle with a movable seat back, with a seat height adjustment and with a varying load capability.

Owner:POLARIS IND INC

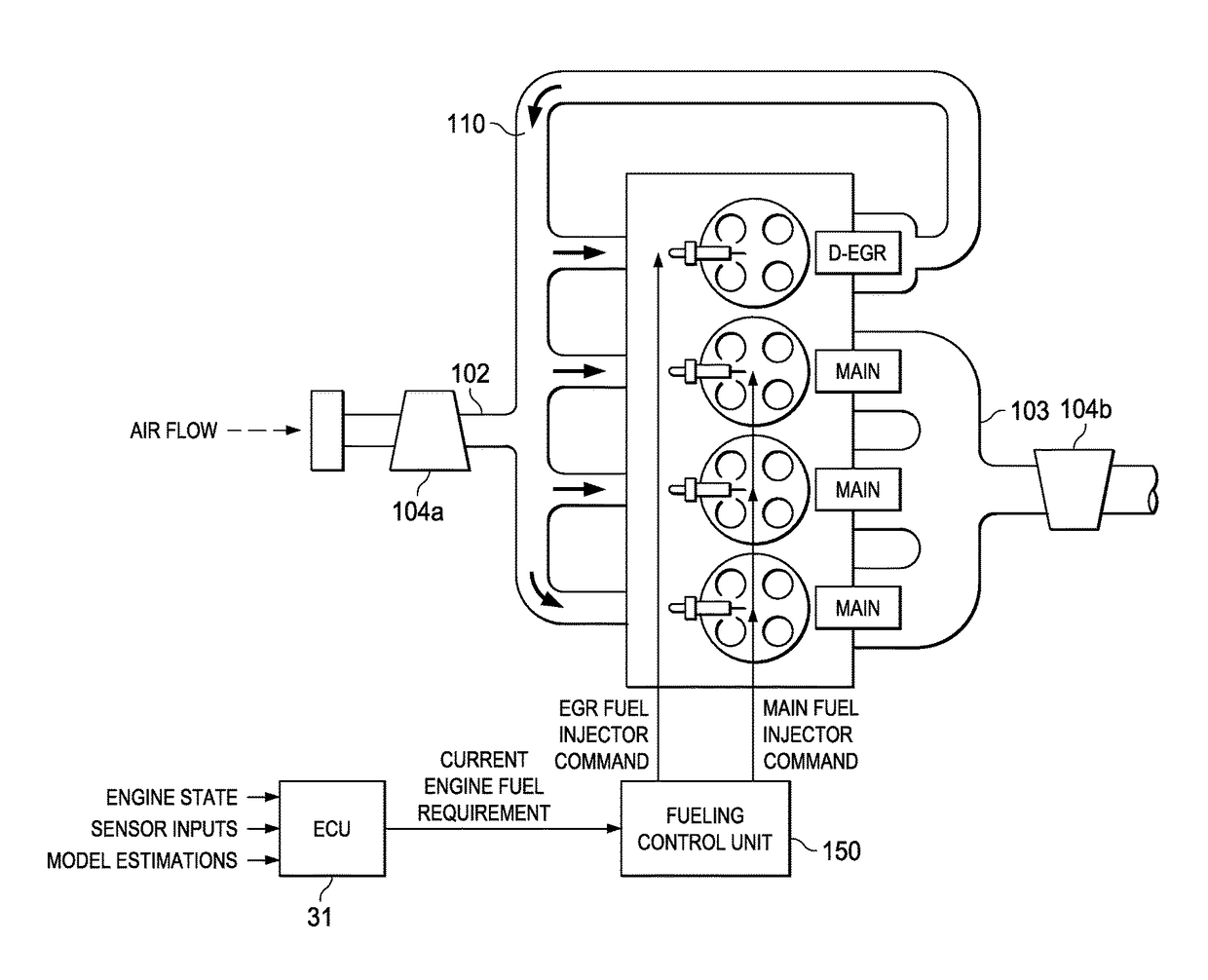

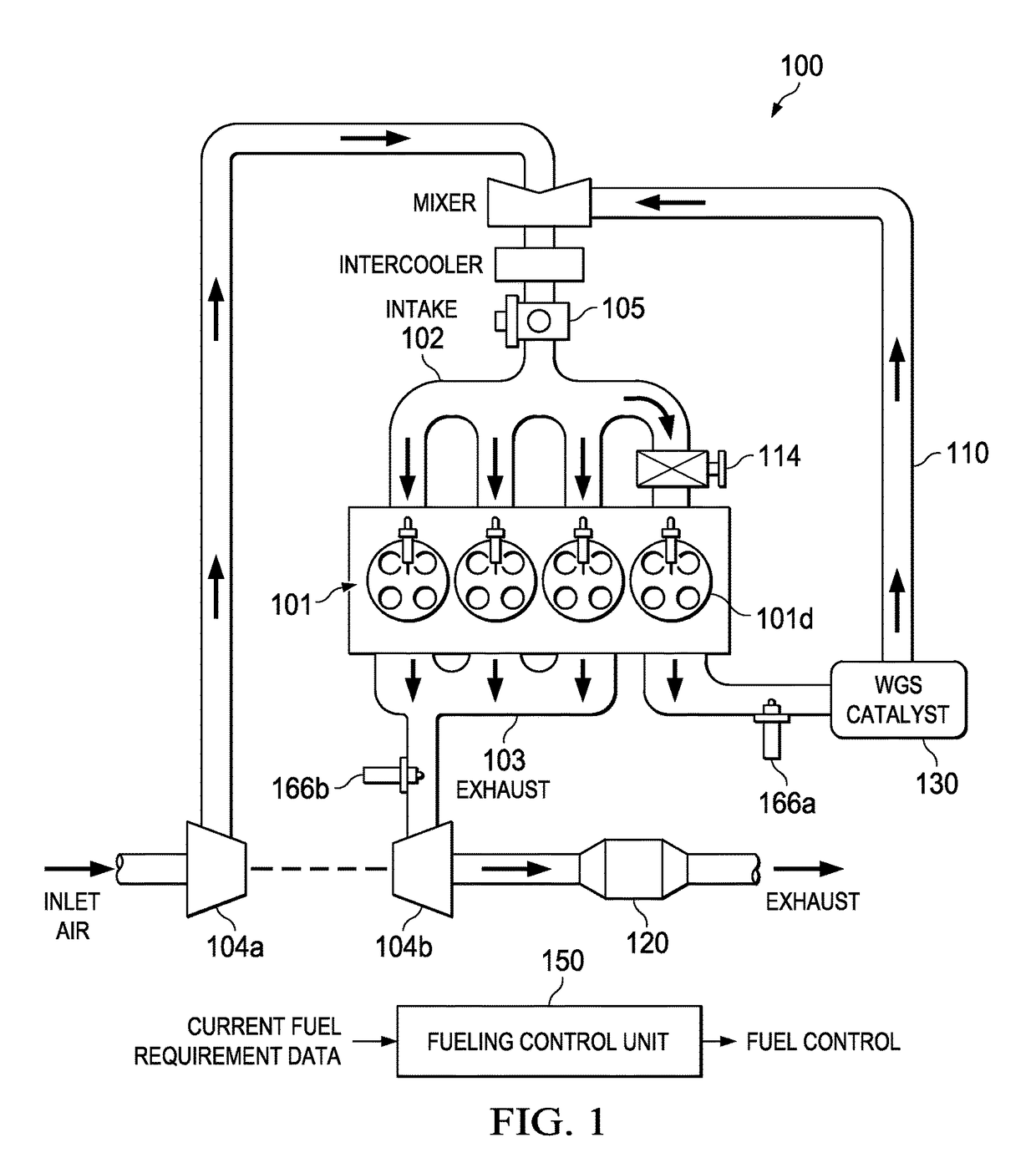

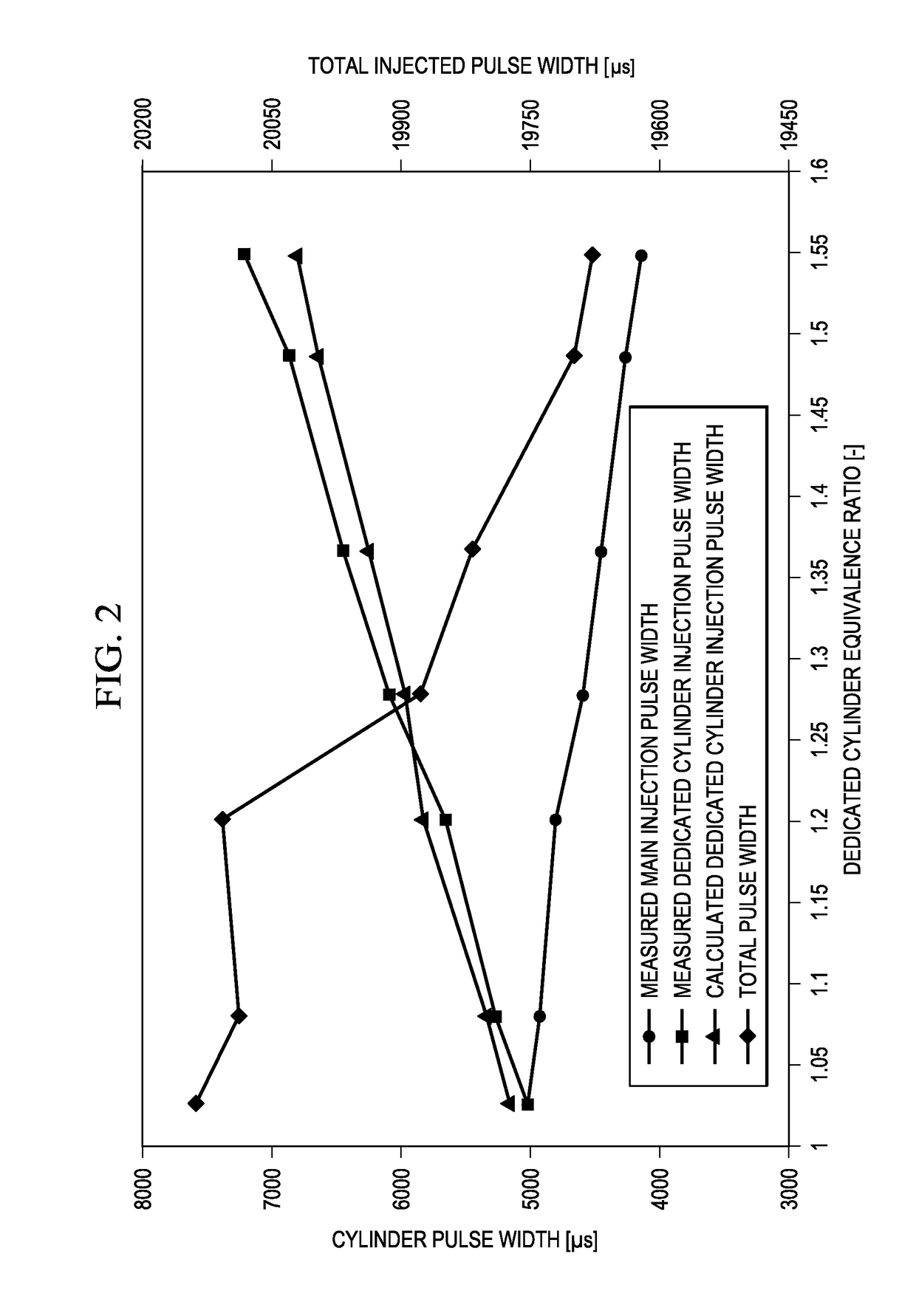

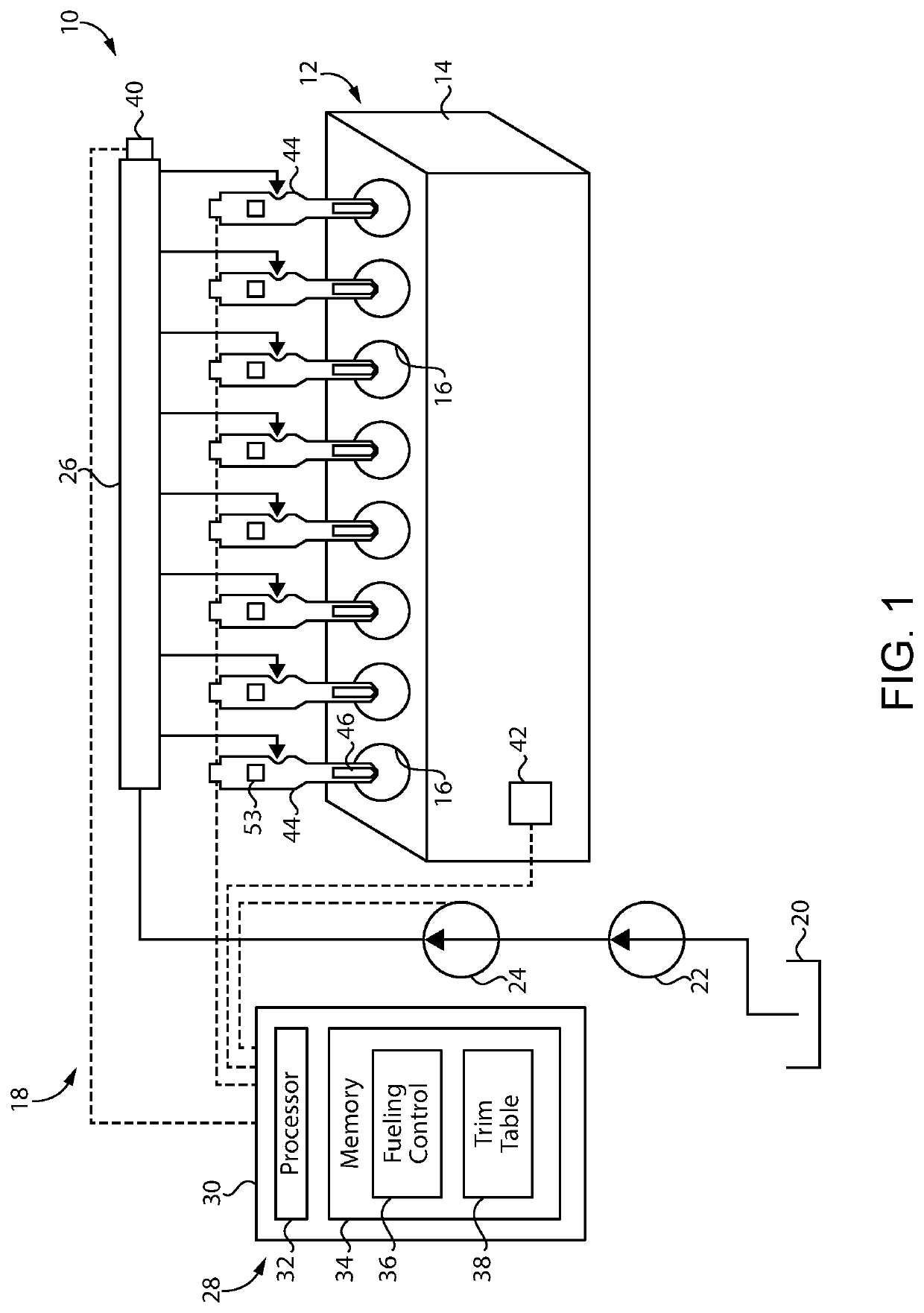

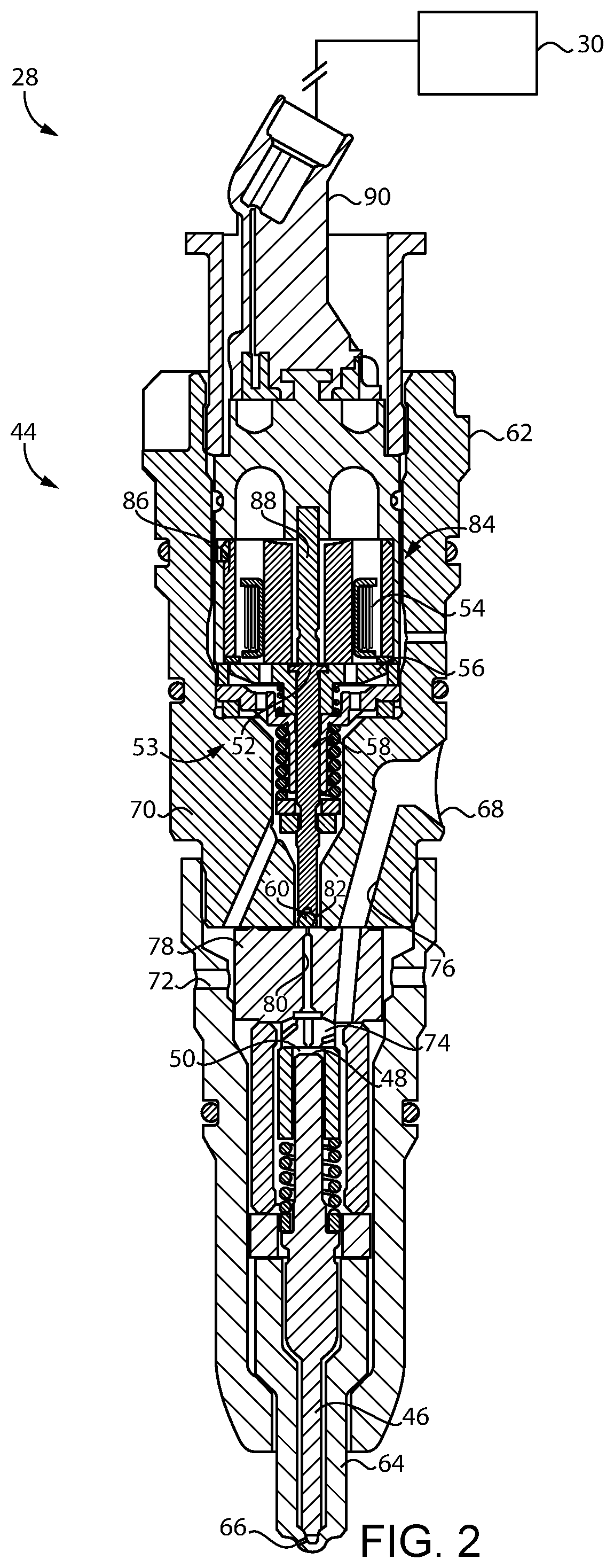

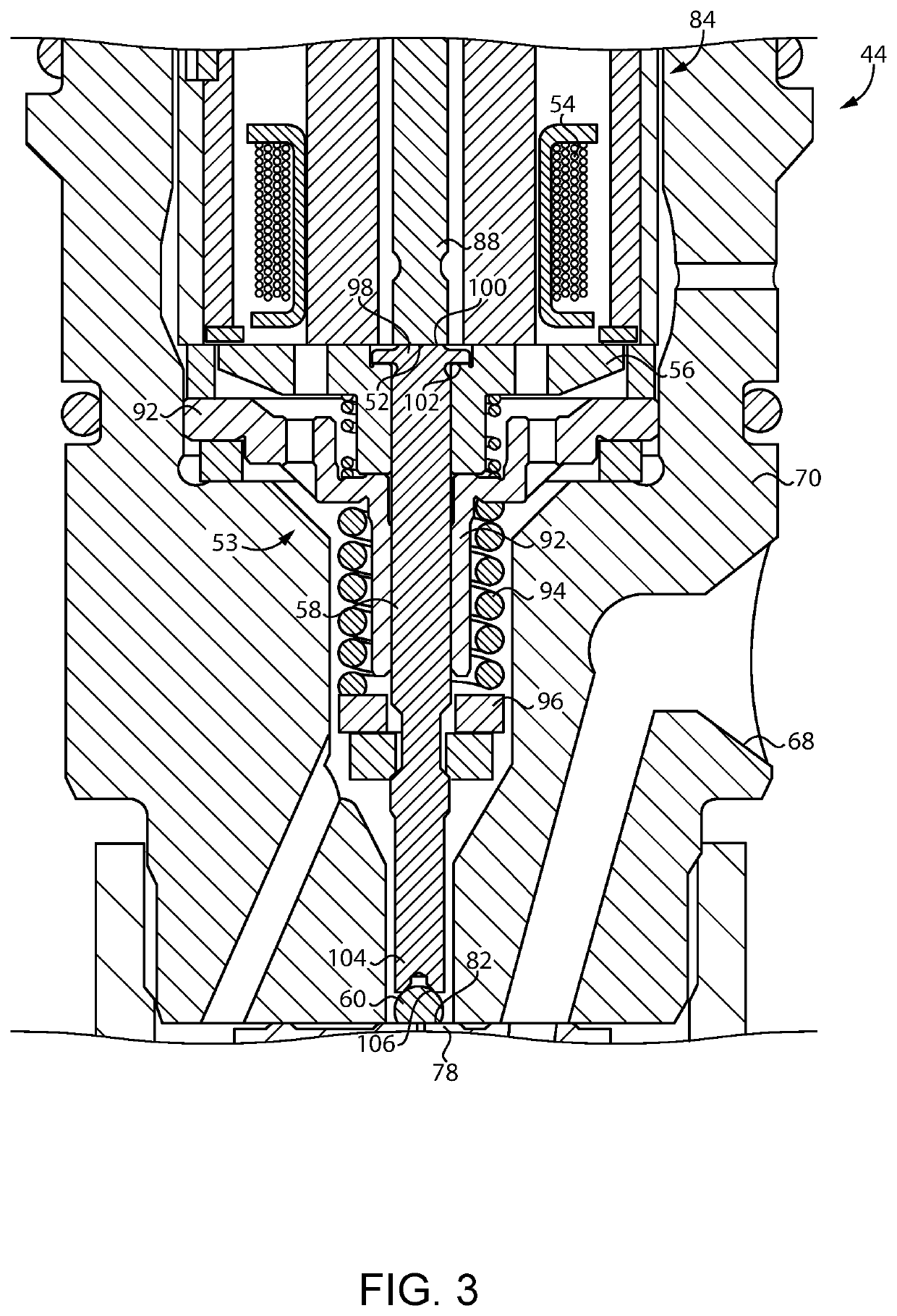

Engine fuel control for internal combustion engine having dedicated EGR

ActiveUS9650976B2Electrical controlInternal combustion piston enginesControl signalFuel control unit

A method of controlling the amount of fuel delivered to an engine having at least one dedicated EGR cylinder. The method is typically performed on an engine cycle-by-cycle basis. A fueling control unit receives, from the engine's main control unit, fueling requirement data representing a current fueling requirement suitable for the main cylinders. The fueling control unit then calculates a current amount of fuel to be delivered to the dedicated EGR cylinder as a function of the number of dedicated EGR cylinders, the number of main cylinders, the current equivalence ratio for the dedicated EGR cylinder, and the fueling requirement data. With the amounts of fuel for both the dedicated EGR cylinder and the main cylinders now having been determined, the fueling control unit generates appropriate control signals to the cylinder fuel delivery mechanisms.

Owner:SOUTHWEST RES INST

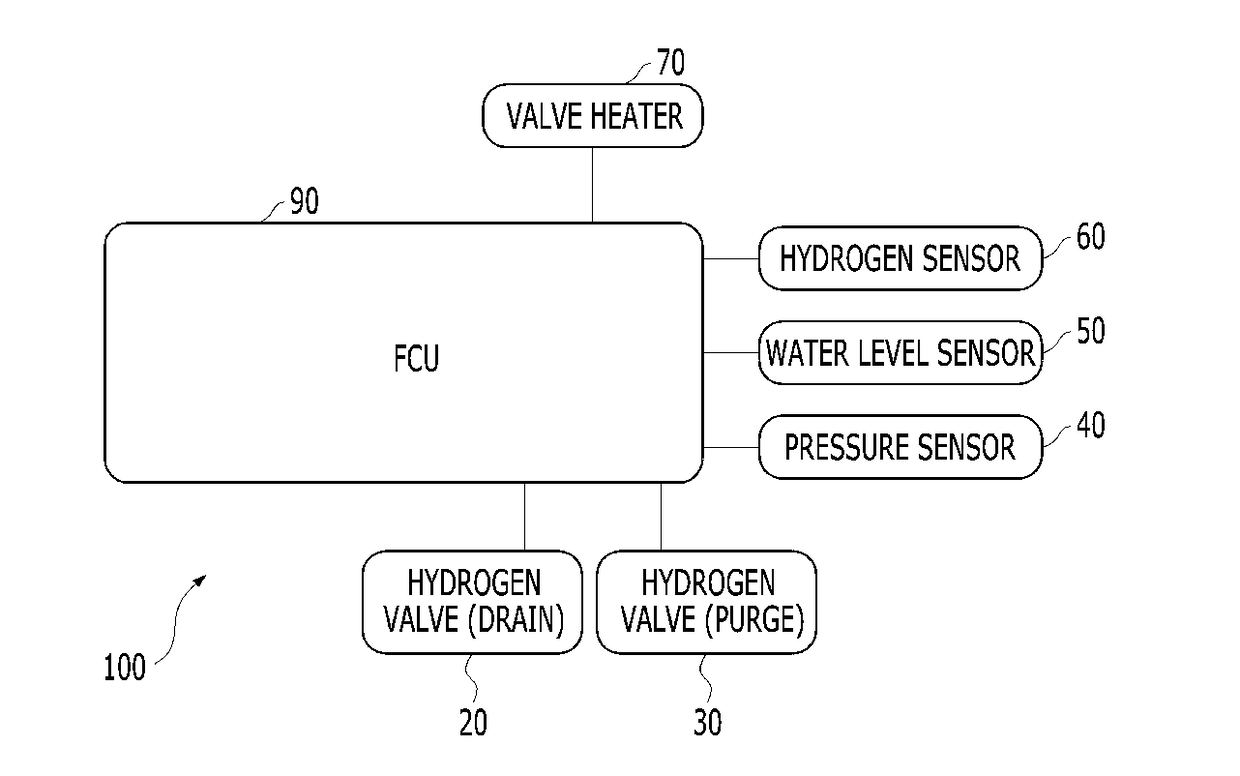

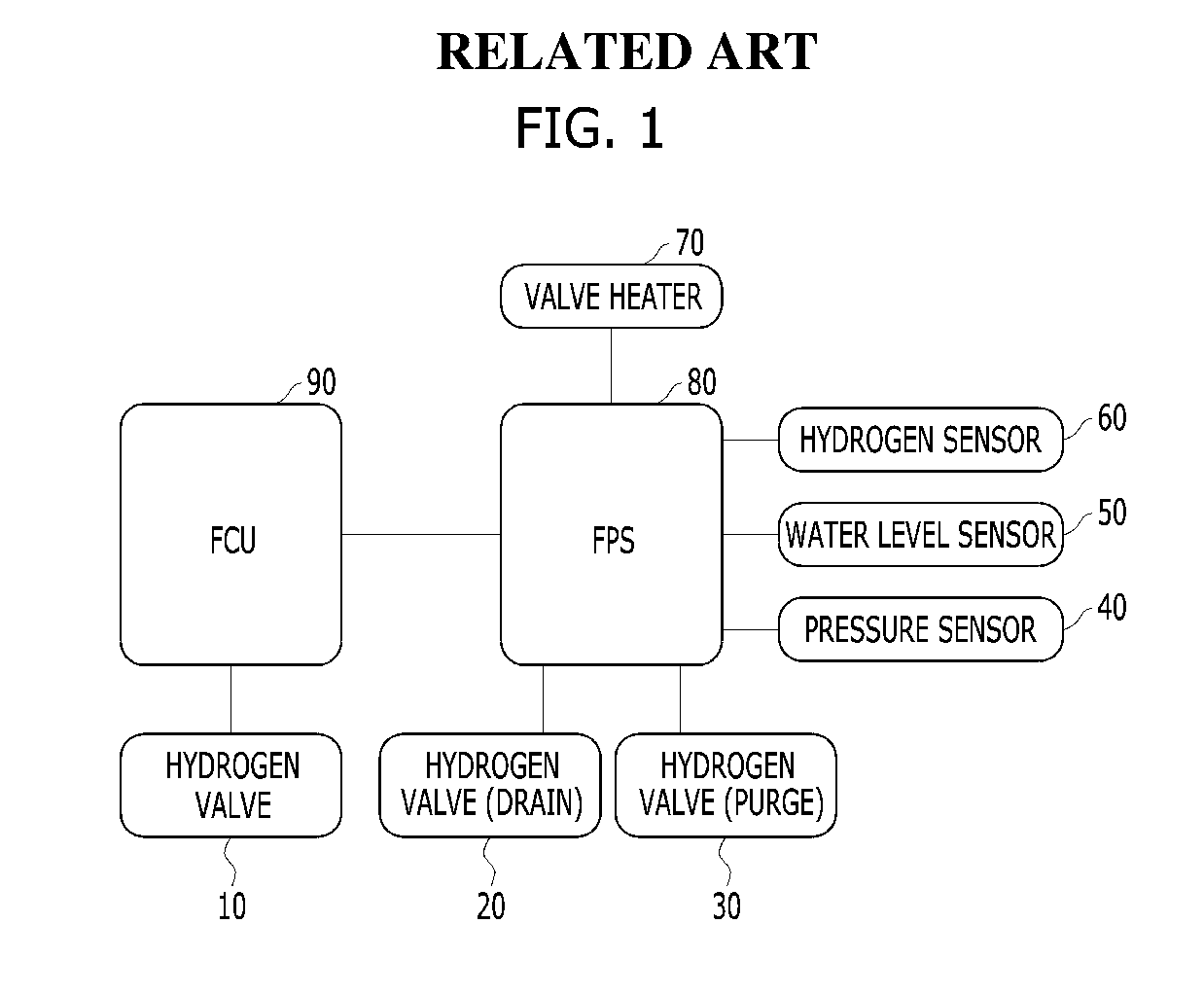

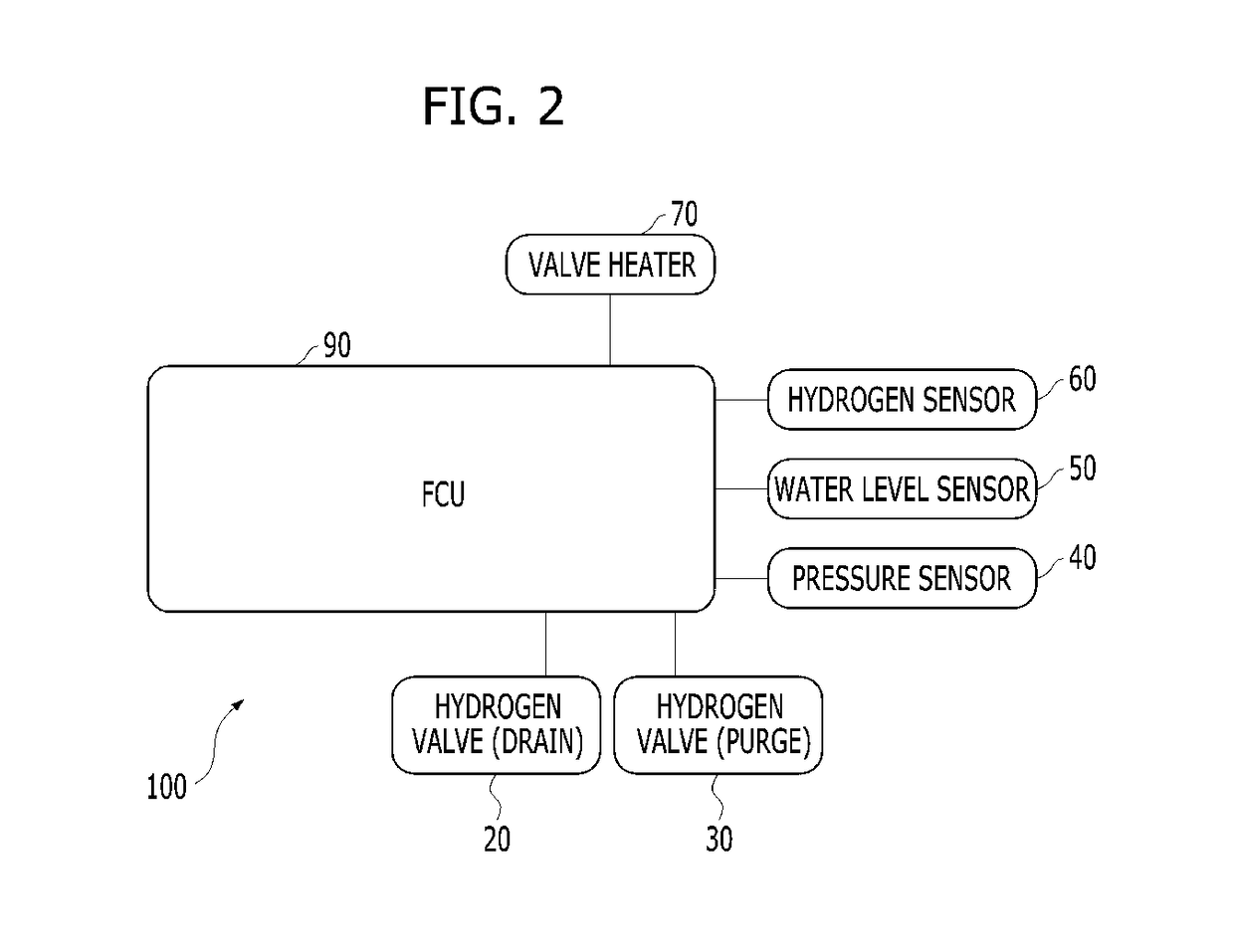

Integrated fuel cell control system and operating method thereof

An integrated fuel cell control system is provided. The integrated fuel cell control system includes at least one sensor, at least one hydrogen on / off valve, and a fuel control unit (FCU). The FCU is configured to directly operate the at least one sensor and the at least one hydrogen on / off valve in real time and to determine a supply pressure of hydrogen supplied to a fuel cell. Thereby, noise between controllers may be removed and costs may be reduced.

Owner:HYUNDAI MOTOR CO LTD

Tractor power hop control system and method

ActiveUS7313472B2Decrease pitchReduce bouncingElectrical controlAnalogue computers for trafficDrive wheelControl signal

A control system performs a method for controlling pitching and bouncing of a vehicle having an engine driving wheels through a transmission, and having a fuel control unit for supplying a variable amount of fuel to the engine in response to fuel control signals generated by an engine control unit. The method includes, from front and rear acceleration signals, generating vehicle pitch and bounce signals, converting the pitch and bounce signals to RMS pitch and bounce values, generating a fuel offset value as a function of the RMS pitch and bounce values, and modifying fuel delivered to the engine as a function of the fuel offset value. The fuel offset value is operate don by a bi-linear gain function wherein negative values are multiplied by a larger gain and positive values are multiplied by a smaller gain.

Owner:DEERE & CO

Assembly structure of clustering fuel cell

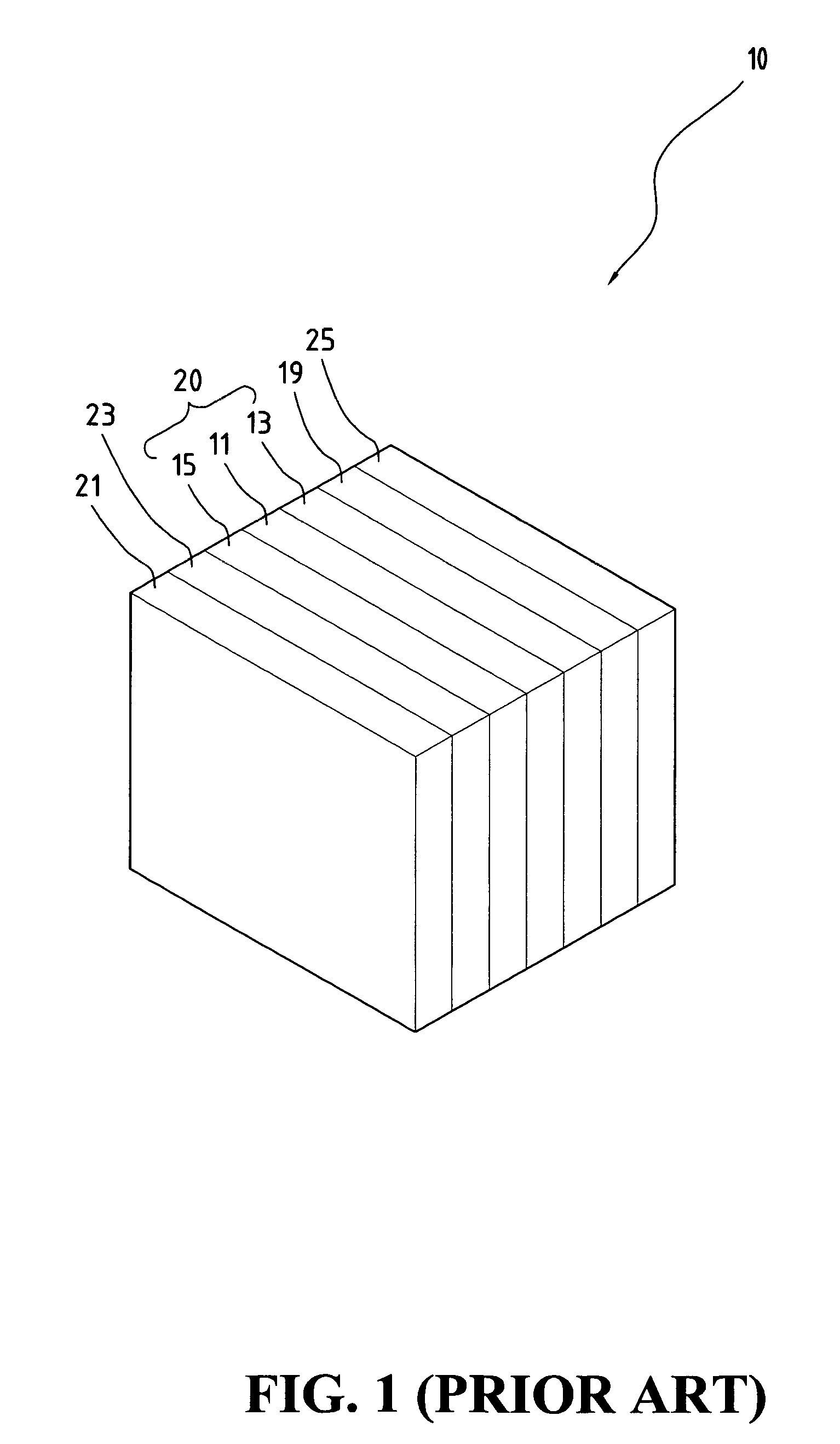

InactiveUS20060228614A1Convenient lightingThin and short and small and high power outputFuel cells groupingFuel cell auxillariesFuel cellsFuel control unit

The present utility is related to an assembly structure of clustering fuel cell, comprising the fuel cell, electrical plug board and fuel control unit. The fuel cell has a PCB substrate, at least more than one membrane electrode assembly (MEA), fuel injecting inlet and electrically connecting part. The electrical plug board includes at least more than one electrical connector; each electrical connector is used to plug into the electrically connecting part of each fuel cell. The fuel control unit includes at least more than one fuel output outlet, wherein each fuel output outlet contacts with the fuel injecting inlet of each fuel cell.

Owner:ANTIG TECH CO LTD

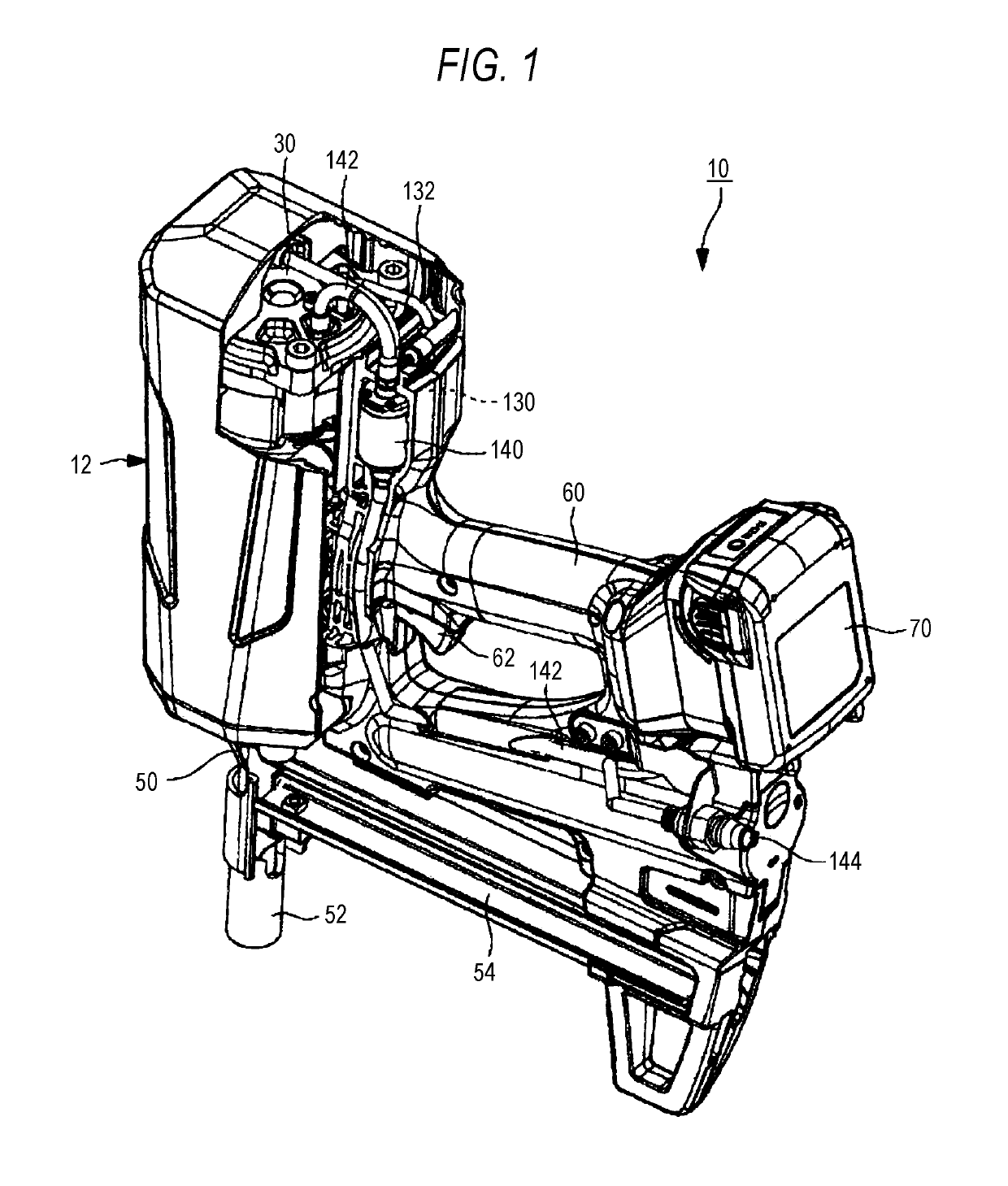

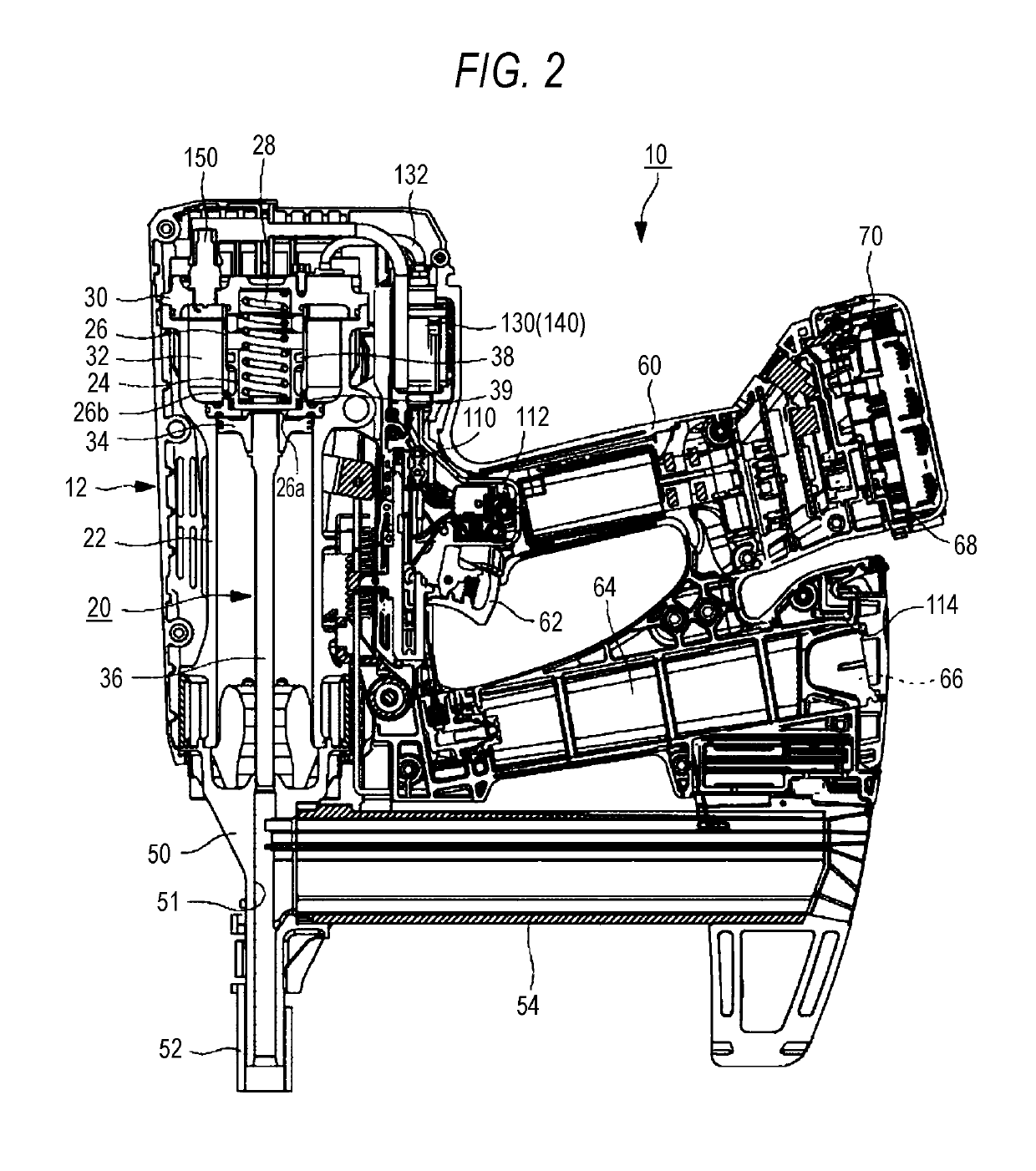

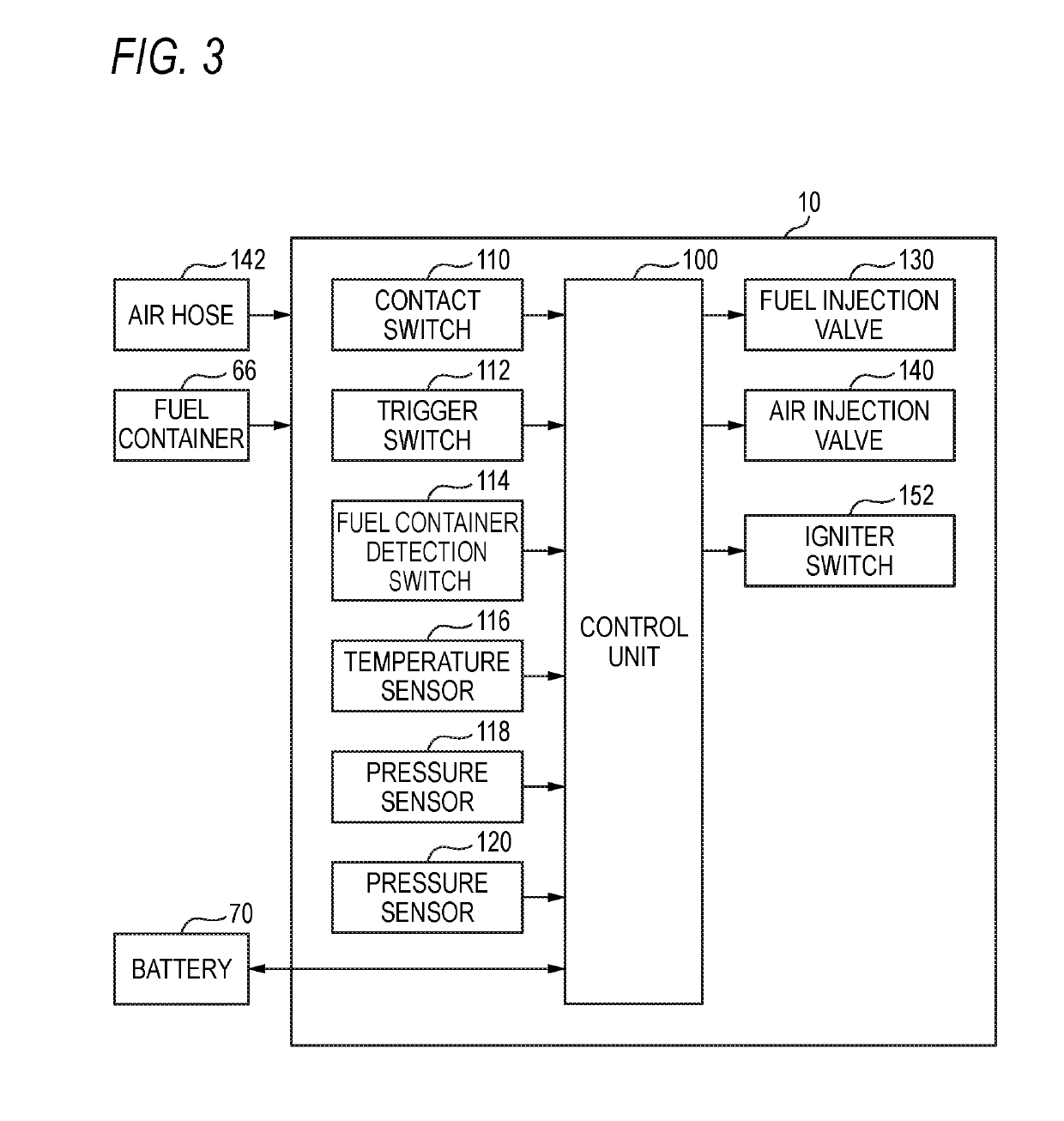

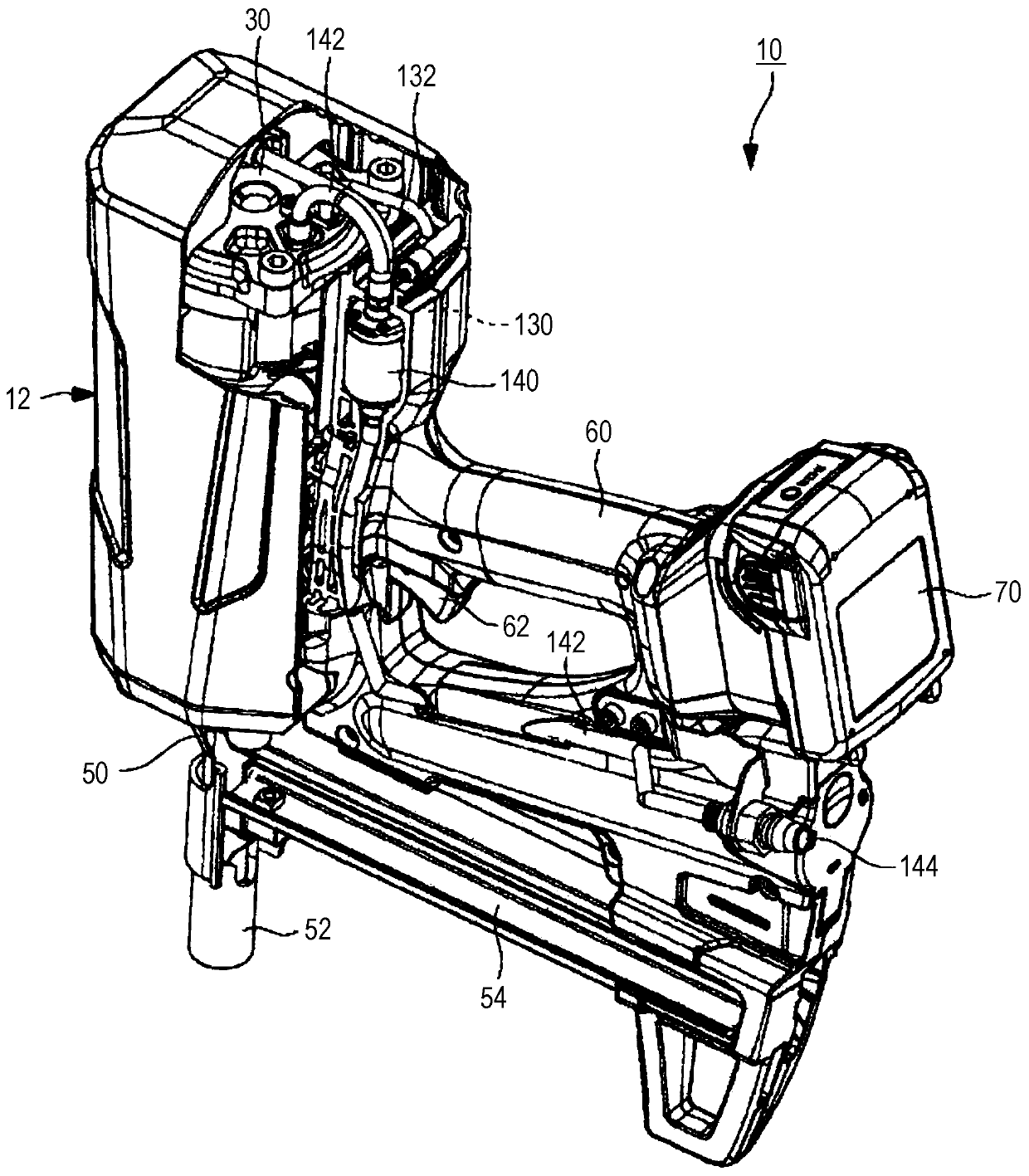

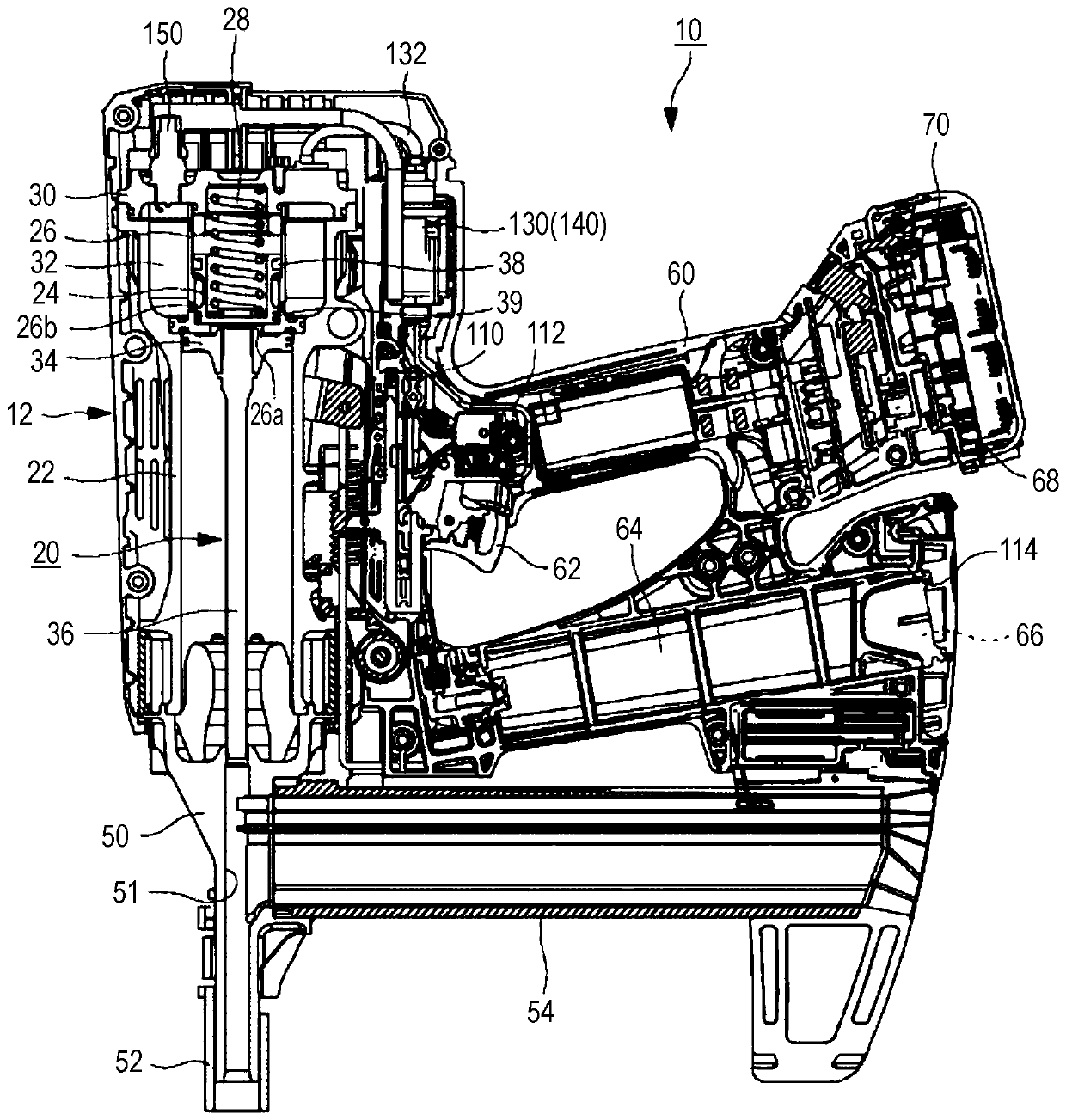

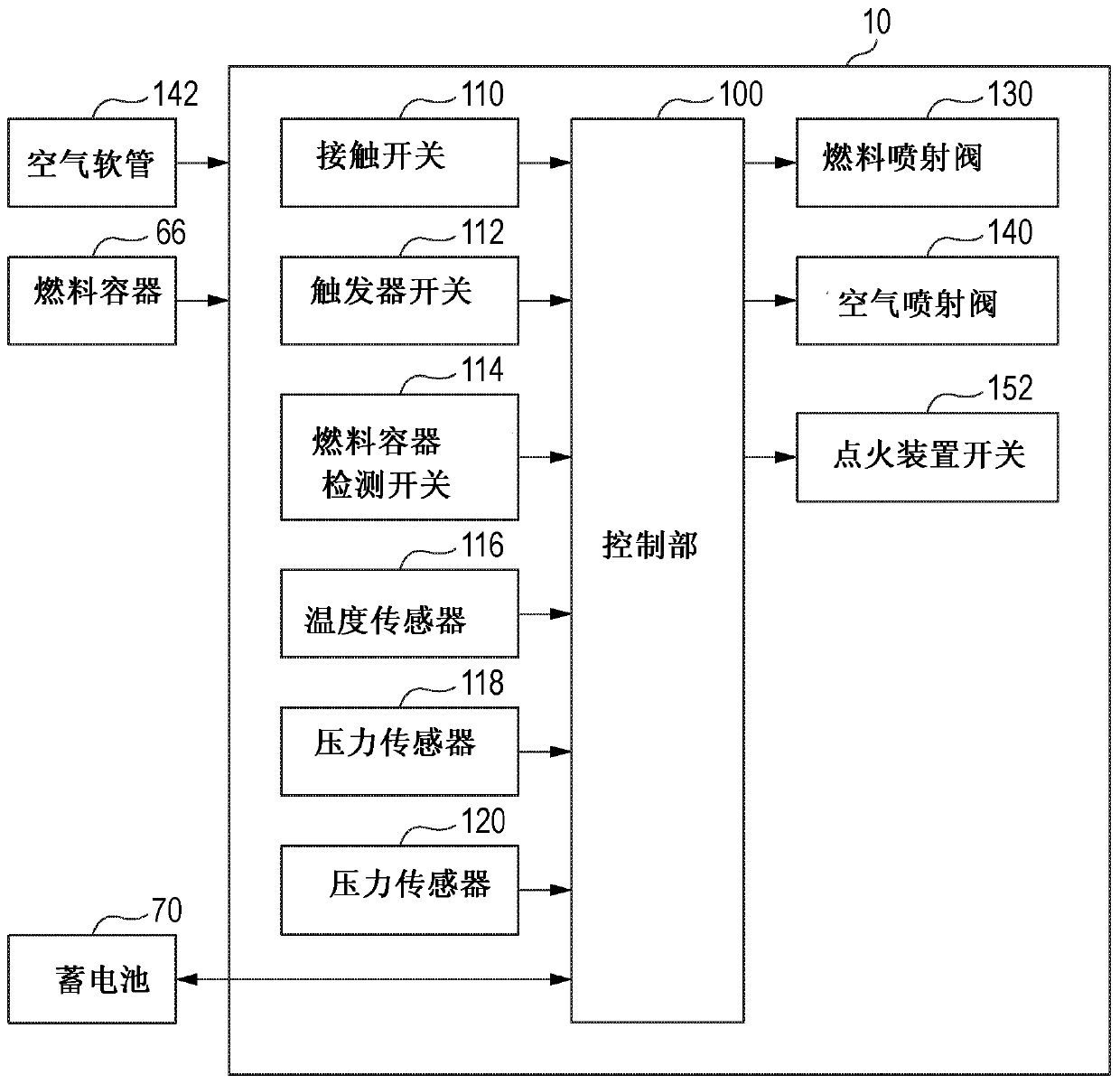

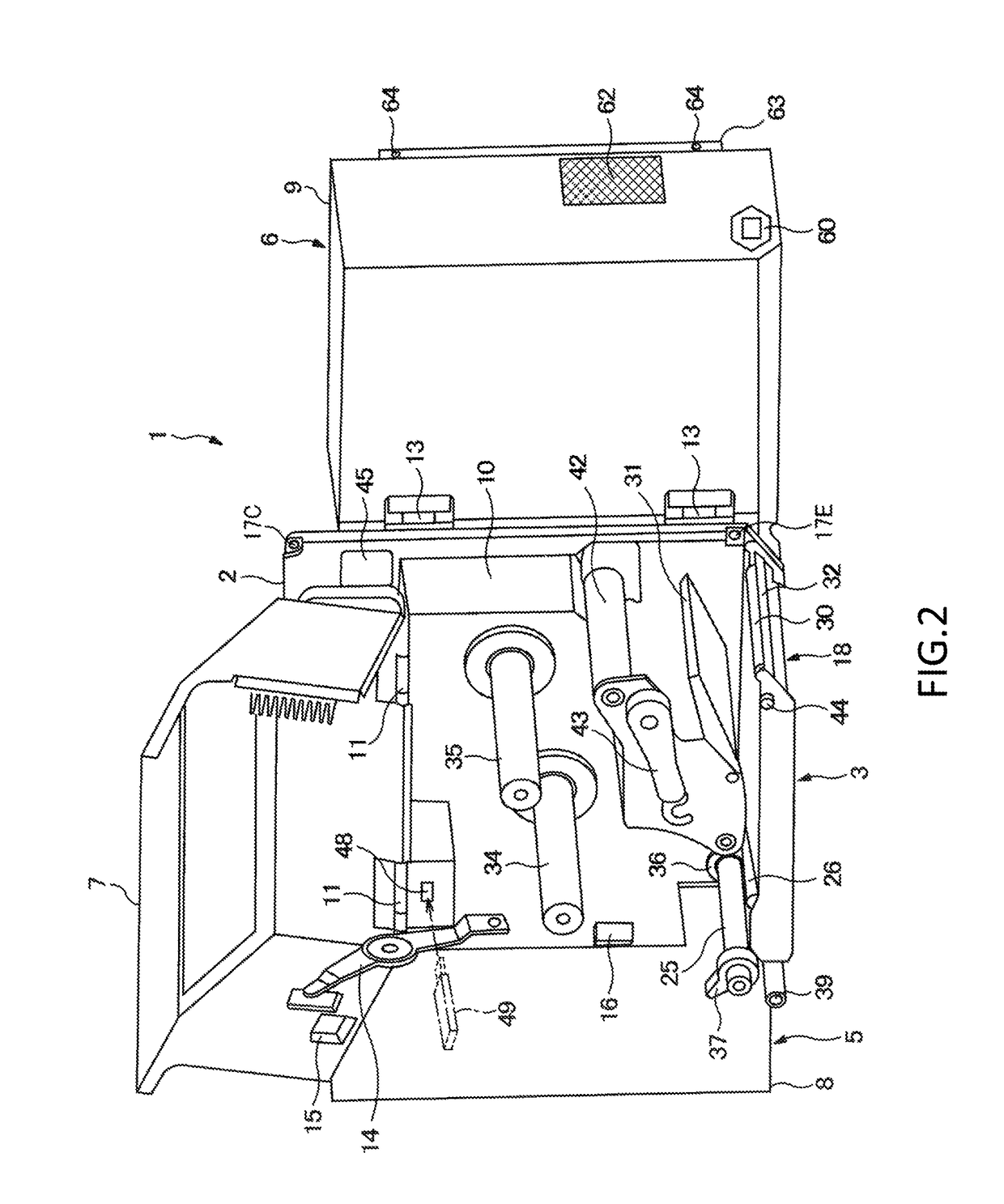

Driving tool

InactiveUS20190224831A1Prevent return failureGuaranteed uptimePortable percussive toolsMachines/enginesCombustion chamberFuel control unit

A driving tool includes a combustion chamber, a cylinder, a valve and a control unit. Fuel and compressed air are supplied into the combustion chamber. The cylinder is configured to movably store a piston which is driven by combustion pressure at a time of igniting a mixture of the fuel and the compressed air filled in the combustion chamber. The valve is configured to open and close a passage through which the compressed air is supplied into the combustion chamber. The control unit is configured to control the valve to supply the compressed air into the combustion chamber when the control unit determines that a return of the piston is completed.

Owner:MAX CO LTD

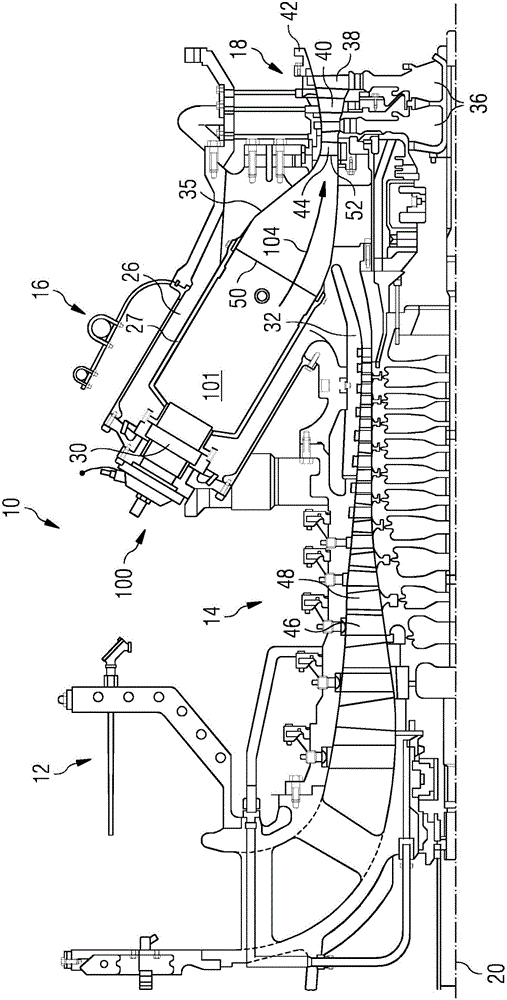

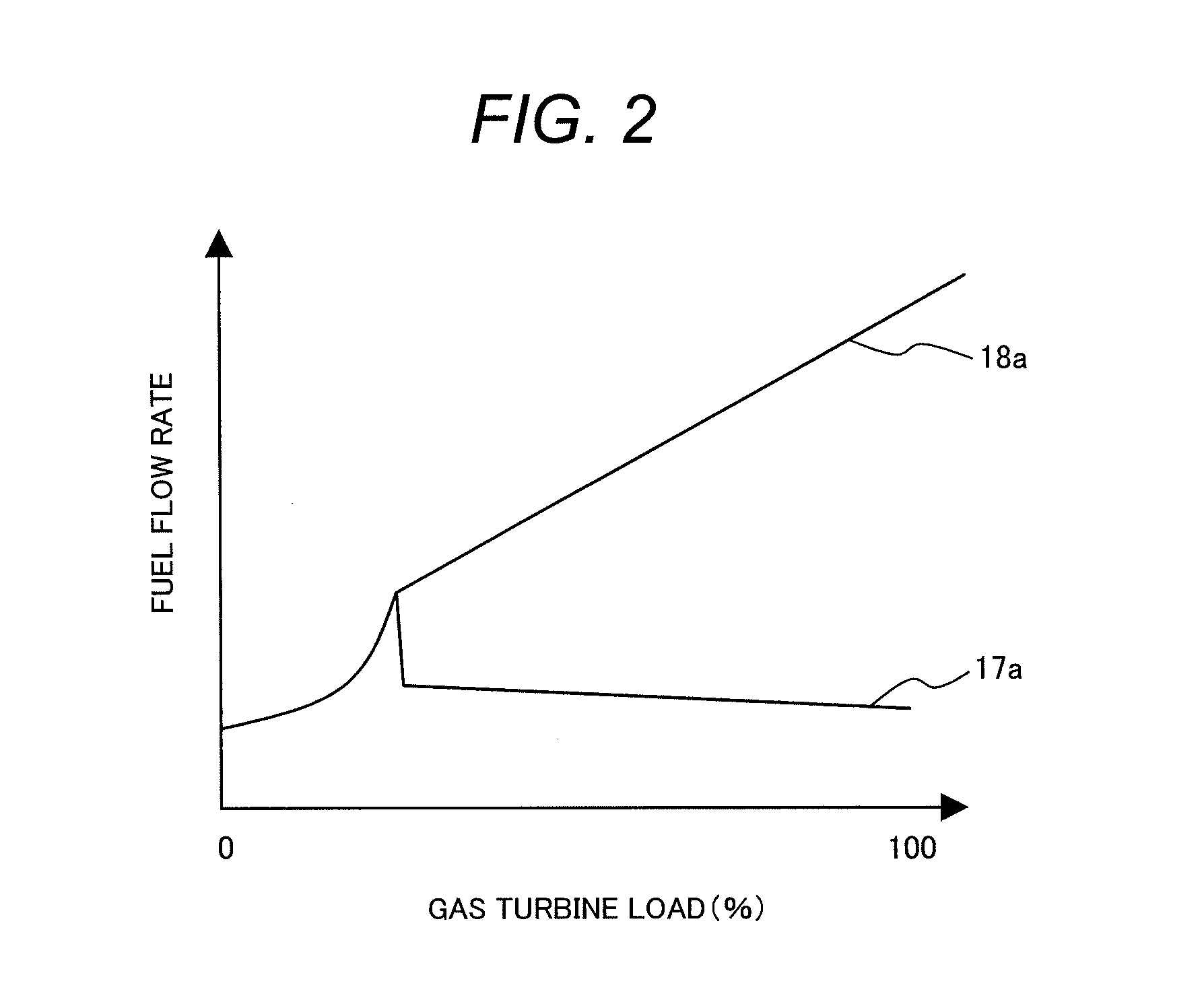

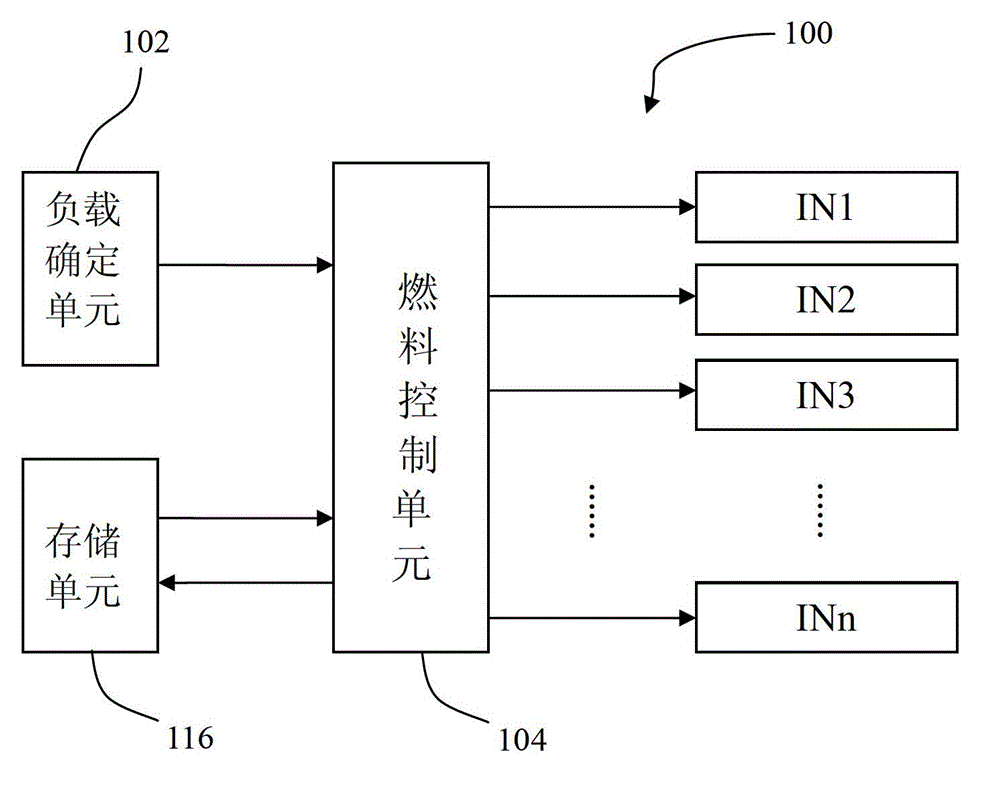

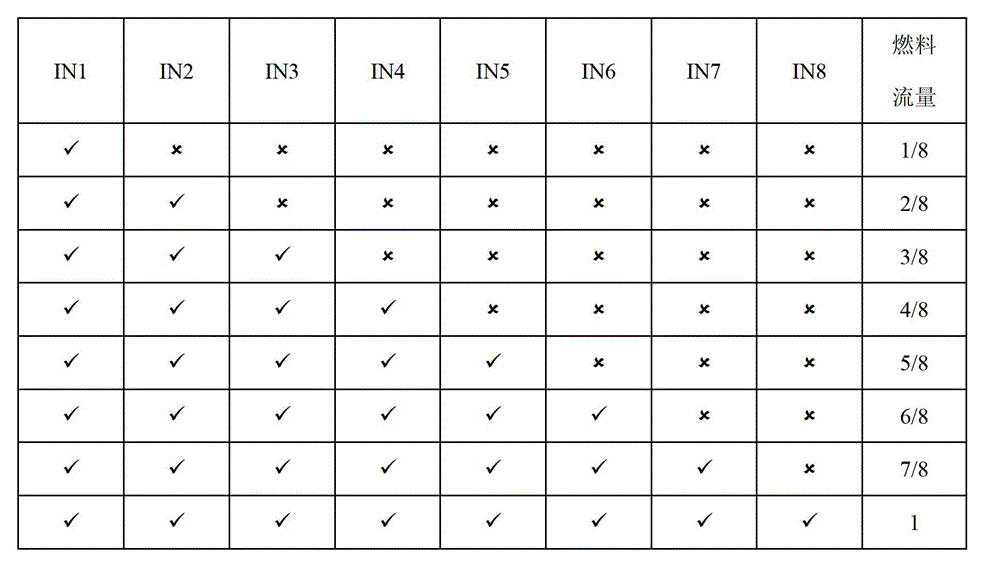

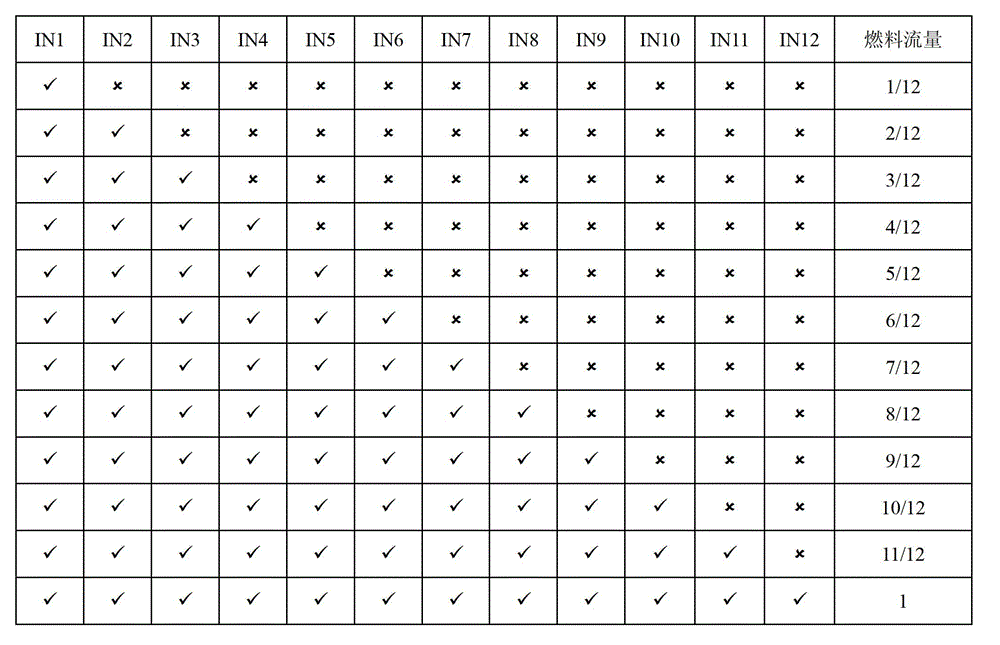

Fuel control system of gas turbine

ActiveCN102748137AMaximum combustion efficiencyImprove combustion efficiencyTurbine/propulsion fuel controlCombustion systemCombustion

The invention provides a fuel control system of a gas turbine. The fuel control system mainly comprises a load determining unit and a fuel control unit. The load determining unit is used for determining load information of the gas turbine, and the fuel control unit is used for receiving the determined load information and controlling fuel nozzles of the gas turbine to be opened or closed selectively according to the received load information, so that the sum of rated flow of the opened fuel nozzles is matched with the determined load information. Regardless of a high-load condition or a low-load condition, the flow of each opened fuel nozzle can be lower than the rated flow of the opened fuel nozzle all along during working, so that the combustion efficiency of each fuel nozzle can keep the highest, and a total combustion system keeps the highest combustion efficiency basically.

Owner:SHENZHEN WISDOM ENERGY TECH CO

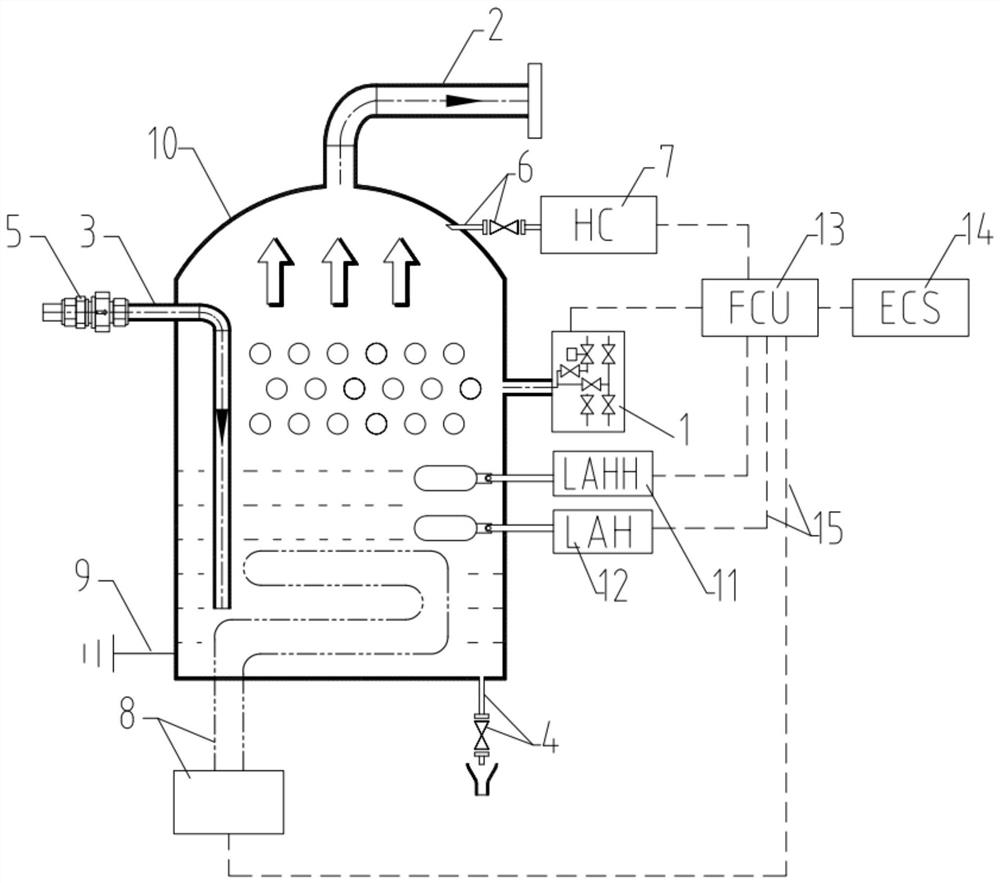

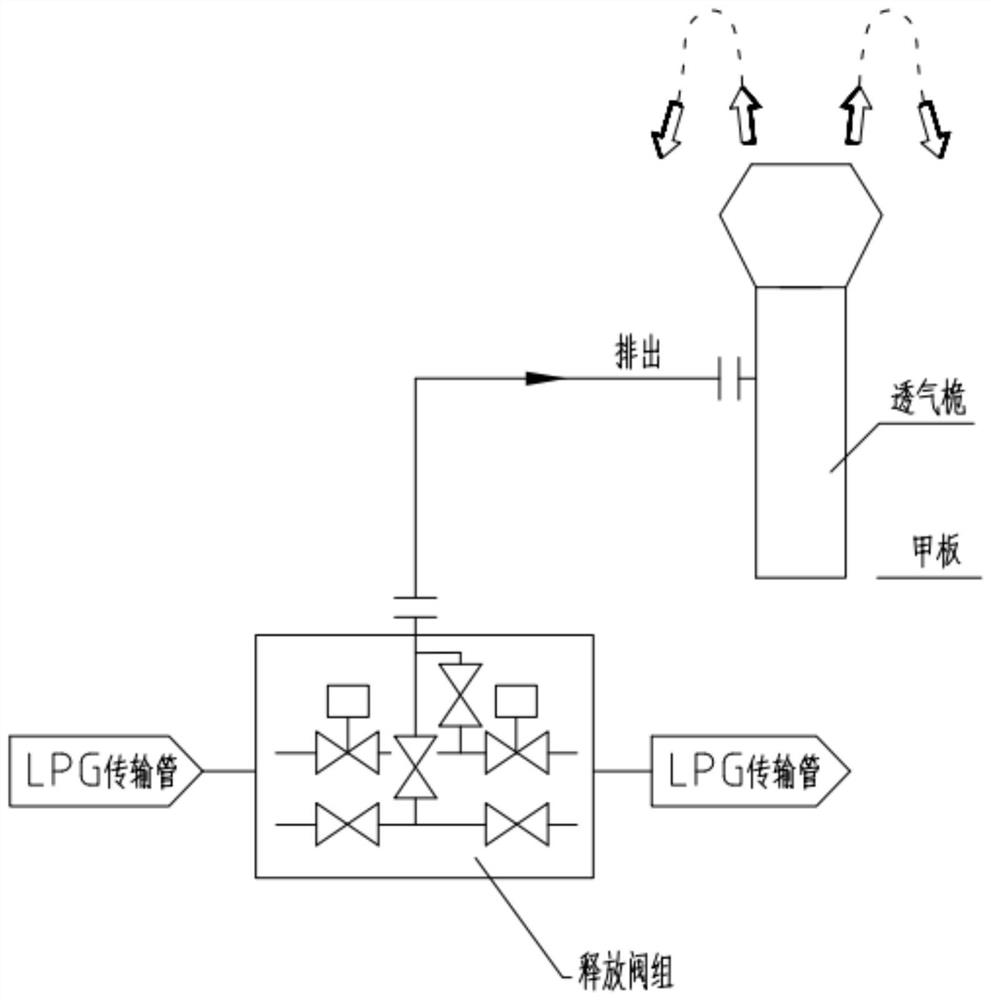

Liquefied petroleum gas (LPG) buffer release tank and control system

PendingCN113236961AAvoid harmReal-time monitoring of concentrationContainer filling methodsNon-pressured vesselsAutomatic controlFuel control unit

The invention discloses a liquefied petroleum gas (LPG) buffer release tank and a control system, and belongs to the technical field of ship LPG power pipeline safety control. The LPG buffer release tank is divided into a buffer release tank part and an LPG control part, wherein the buffer release tank part comprises a release valve group and a tank body, the release valve group communicates with the tank body of the buffer release tank, a discharge pipe is fixedly mounted at the highest position of the top of the tank body of the buffer release tank, a discharge port of the discharge pipe communicates with a ventilation mast on an LPG ship, a nitrogen blow-off pipe is fixedly mounted on one side of the tank body, and a one-way valve is fixedly mounted on the nitrogen blow-off pipe. According to the LPG buffer release tank and the control system, the buffer tank is arranged, liquid left when LPG is not completely vaporized is collected, the released LPG is vaporized through the buffer release tank and then discharged to the ventilation mast to be discharged, the situation that the ship and sailors are hurt by liquid splashing is avoided, related equipment is displayed and remotely controlled through a fuel control unit, and multifunctional remote automatic control of the buffer tank is realized.

Owner:CHINA MERCHANTS HEAVY IND SHENZHEN

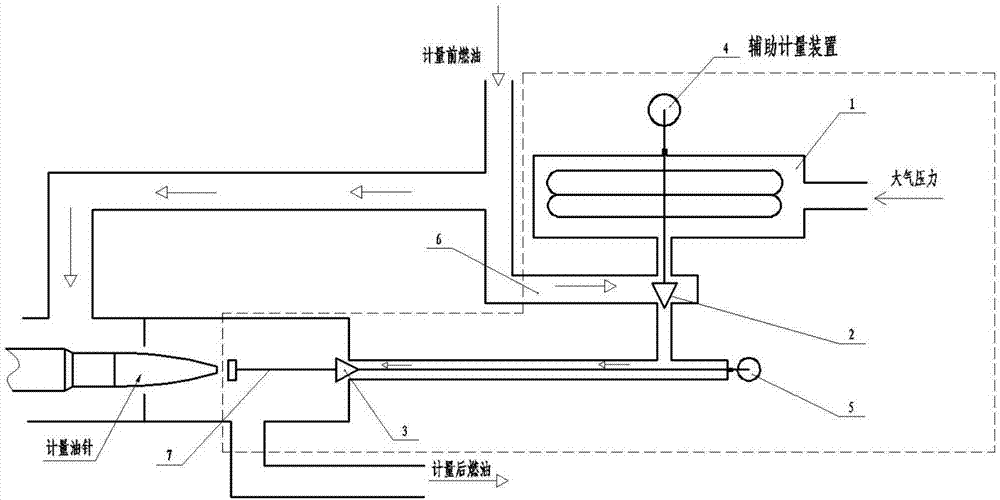

Engine mechanical hydraulic fuel flow auxiliary metering adjusting device

ActiveCN107061021AFuel flow restrictionFeel atmospheric pressure in real timeGas turbine plantsTurbine/propulsion fuel controlAtmospheric airFuel control unit

The invention belongs to the engine fuel technology and particularly relates to an engine mechanical hydraulic fuel flow auxiliary metering adjusting device. The engine mechanical hydraulic fuel flow auxiliary metering adjusting device comprises an air pressure sensor (1), a first metering valve (2), a second metering valve (3) and an auxiliary fuel way (6). According to the engine mechanical hydraulic fuel flow auxiliary metering adjusting device, an automatic auxiliary metering device sensing the air state of the outside atmosphere is added to assist in metering of fuel flow of a fuel regulator, and thus the fuel metering precision of the engine mechanical hydraulic type fuel regulator can be improved effectively. Meanwhile, two adjusting screws can both achieve metering adjustment, the high-altitude adaptability of a mechanical hydraulic type fuel control unit is improved, the minimum fuel quantity of engine fuel is ensured, and large practical application value is achieved.

Owner:BEIJING HANGKE ENGINE CONTROL SYST SCI & TECH

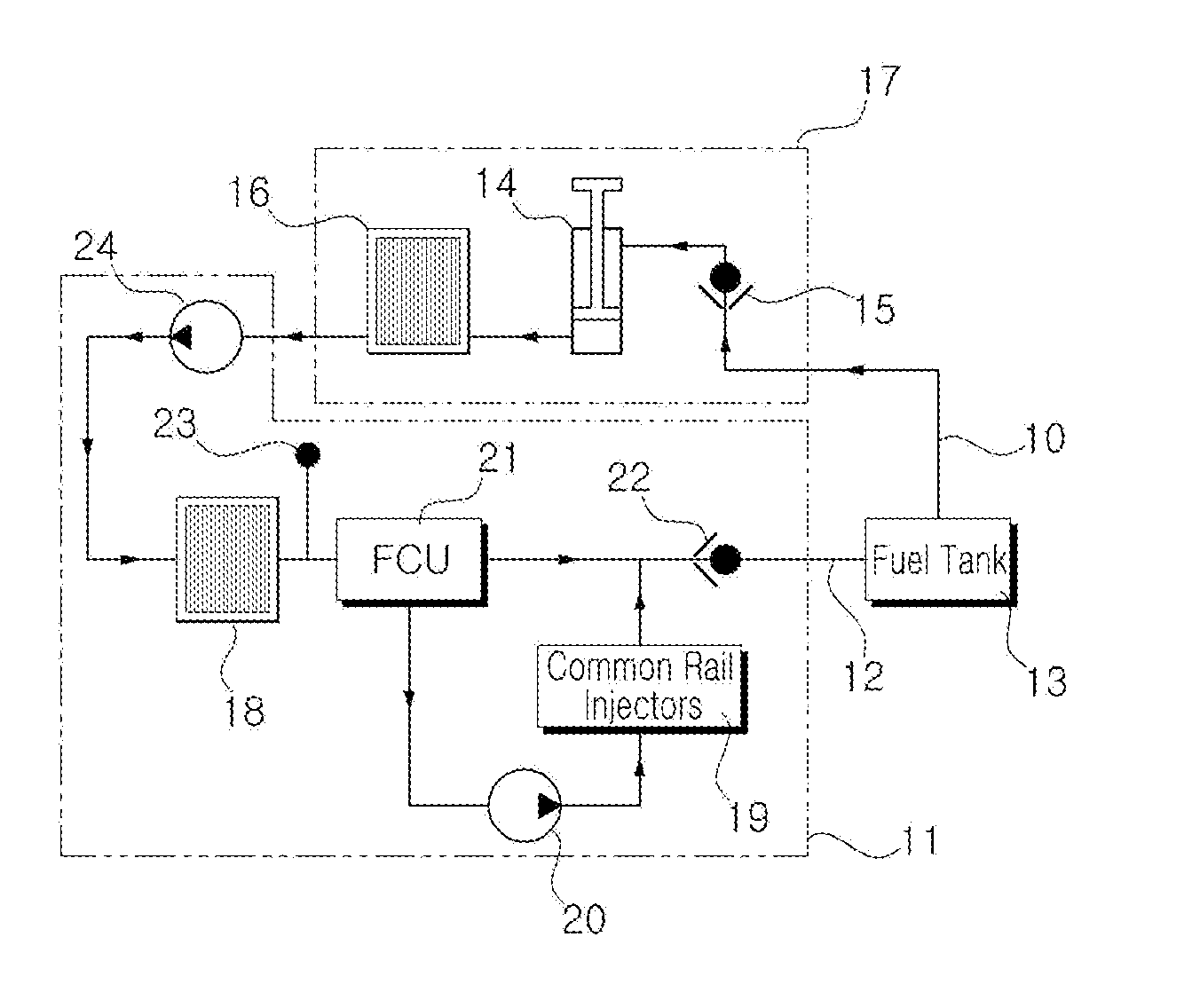

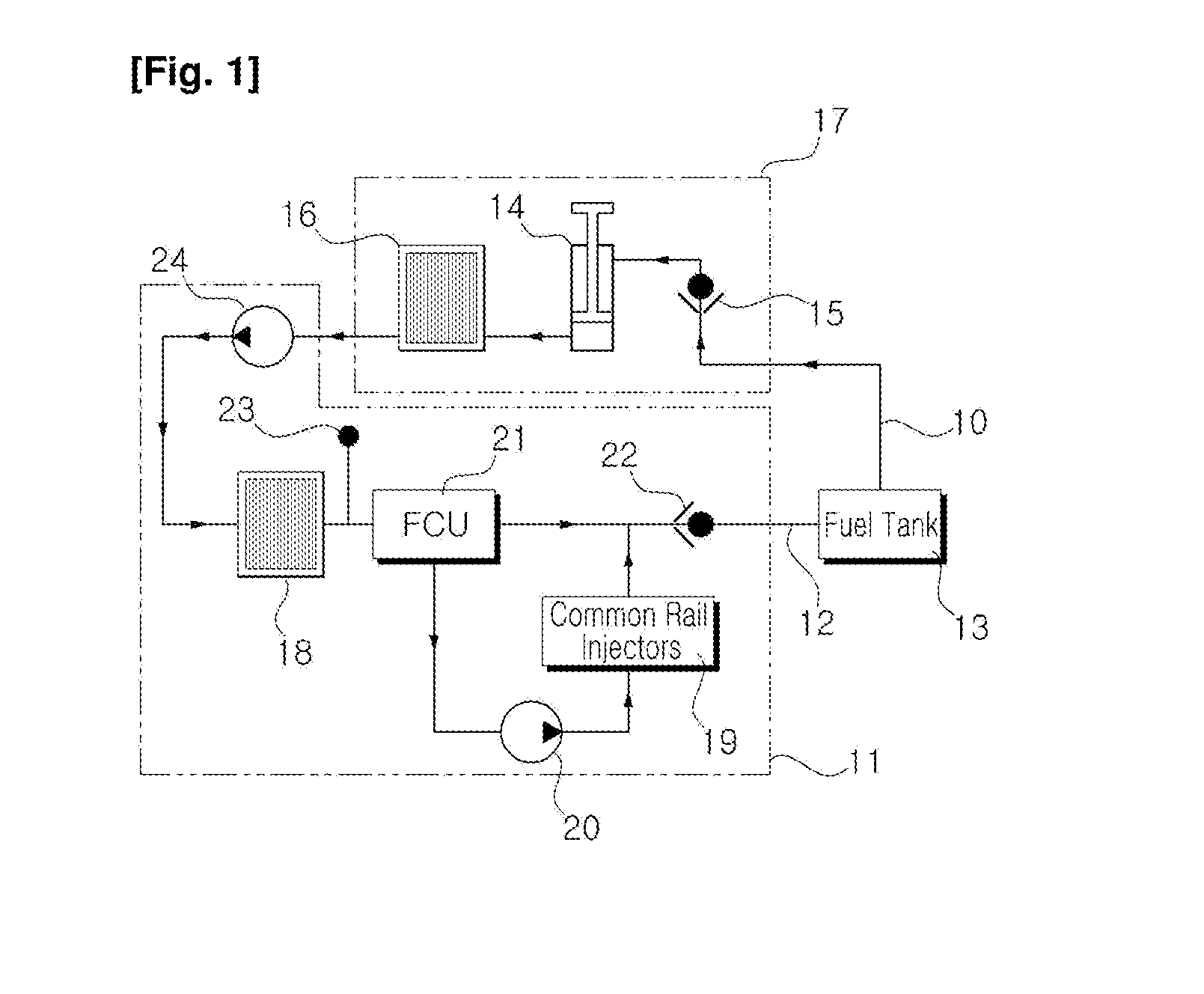

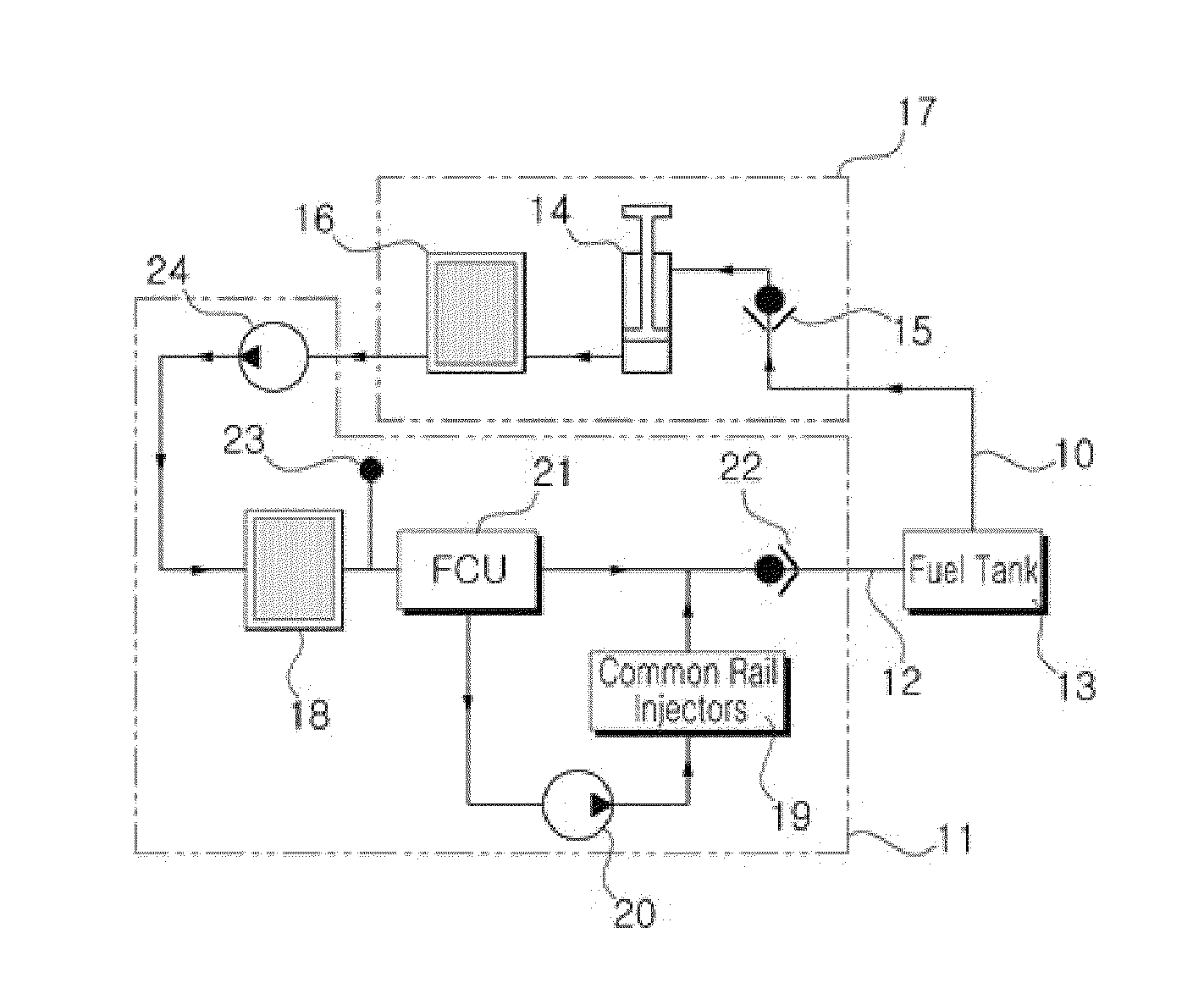

Fuel system for an excavator

ActiveUS20140165968A1Prevent internal leakageImprove startup performanceCombustion-air/fuel-air treatmentLow pressure fuel injectionStopped workCombustion chamber

A fuel system is disclosed which is adapted to improve engine ignition properties by ensuring that, when the engine ignition is turned off, residual fuel left over in the engine area after use is not returned to the fuel tank but instead remains in a common rail injector area. The fuel system for an excavator according to the present invention comprises: a fuel tank having a fuel supply line for discharging fuel and a return line for returning residual fuel after combustion in the engine area; a water-fraction separator which is provided downstream of the fuel tank, removes the water fraction contained in the fuel that is sucked in, and consists of a hand pump that is linked to the fuel supply line and of a first filter that is linked to the hand pump and filters out extraneous material in the fuel; an injection pump which is provided downstream of the water-fraction separator and which provides an injector with a high pressure supply of the fuel, from which the extraneous material has been filtered out on passing through the first filter and a second filter linked thereto, such that said fuel is sprayed into an engine combustion chamber; a fuel control unit which is respectively linked to the second filter and the injection pump and controls the injection pump so as to control the volume of fuel supplied to the injector; and a check valve which is provided in the return line and ensures that, when the equipment is made to stop working because the engine ignition is turned off, residual fuel left over in the engine area after use is not returned to the fuel tank along the return line but instead remains in the injector area.

Owner:VOLVO CONSTR EQUIP

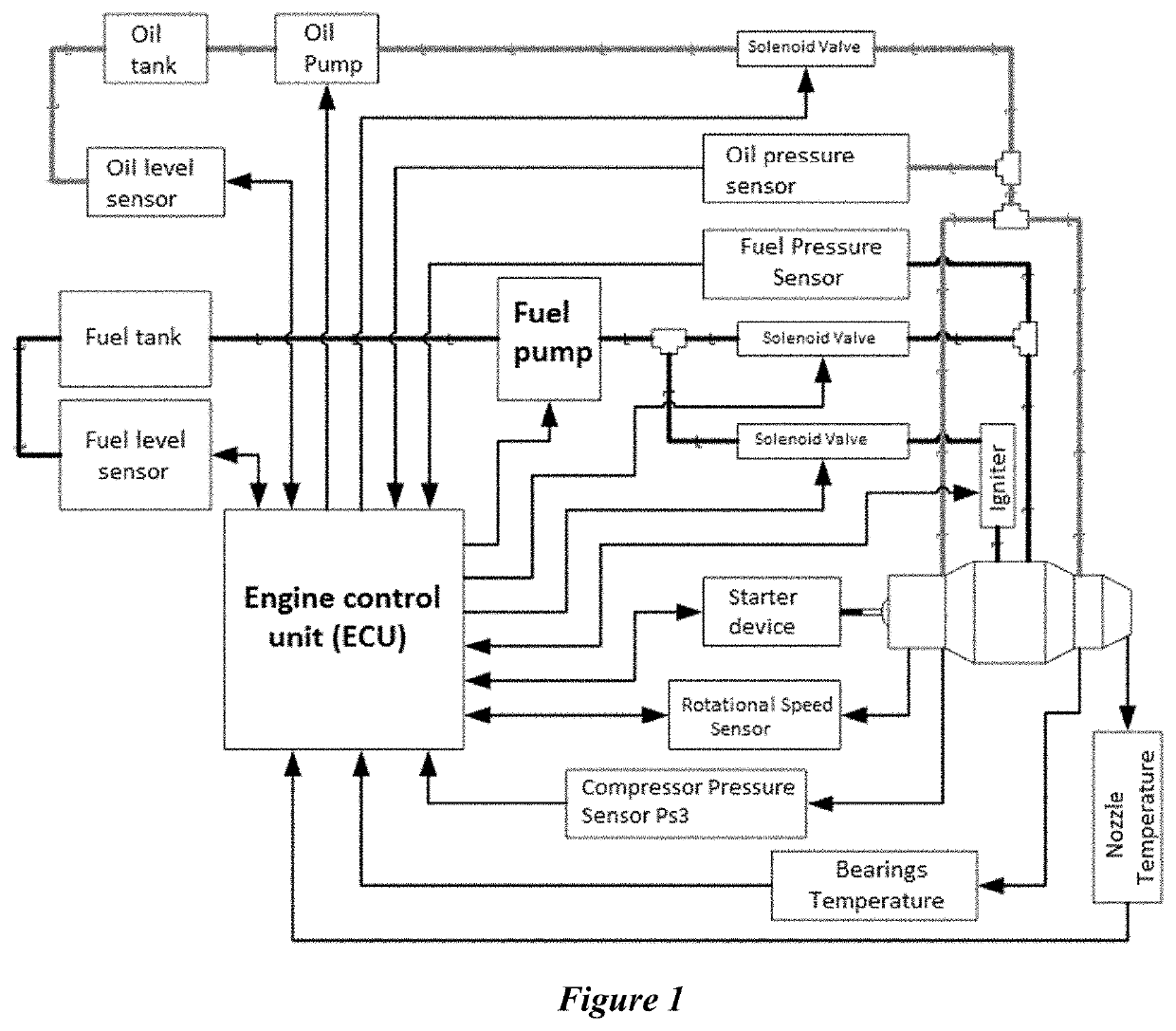

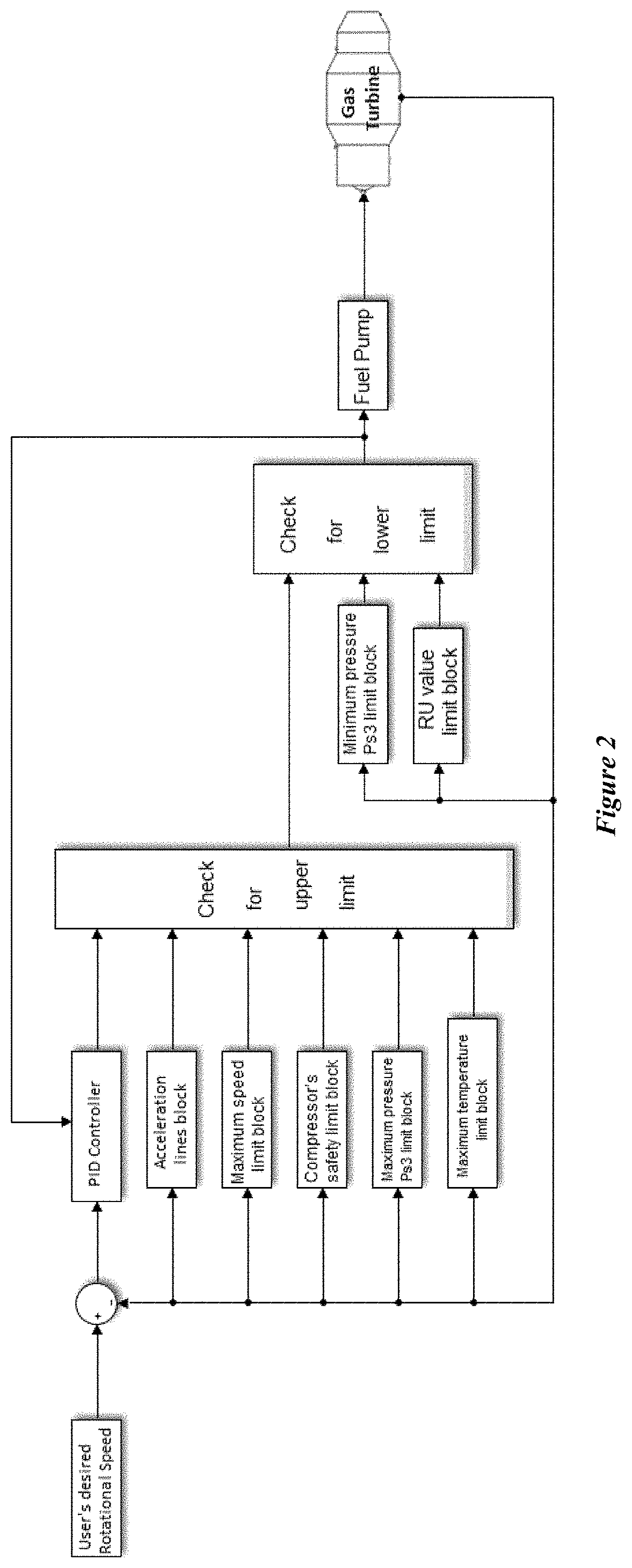

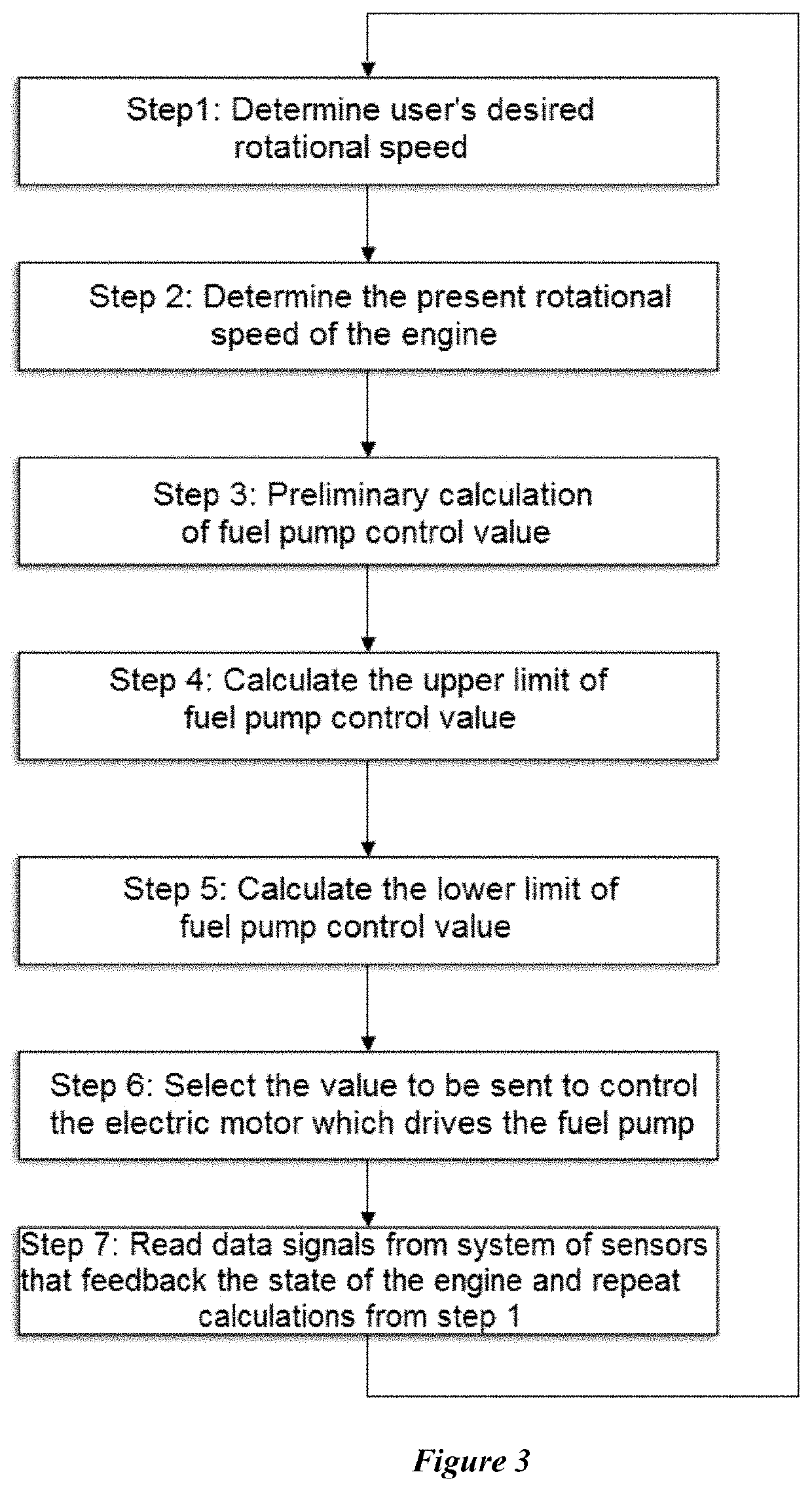

System and method for gas turbine engine control

InactiveUS20200340409A1Guaranteed uptimeAcceptable accuracyEngine fuctionsTurbine/propulsion fuel controlControl signalControl cell

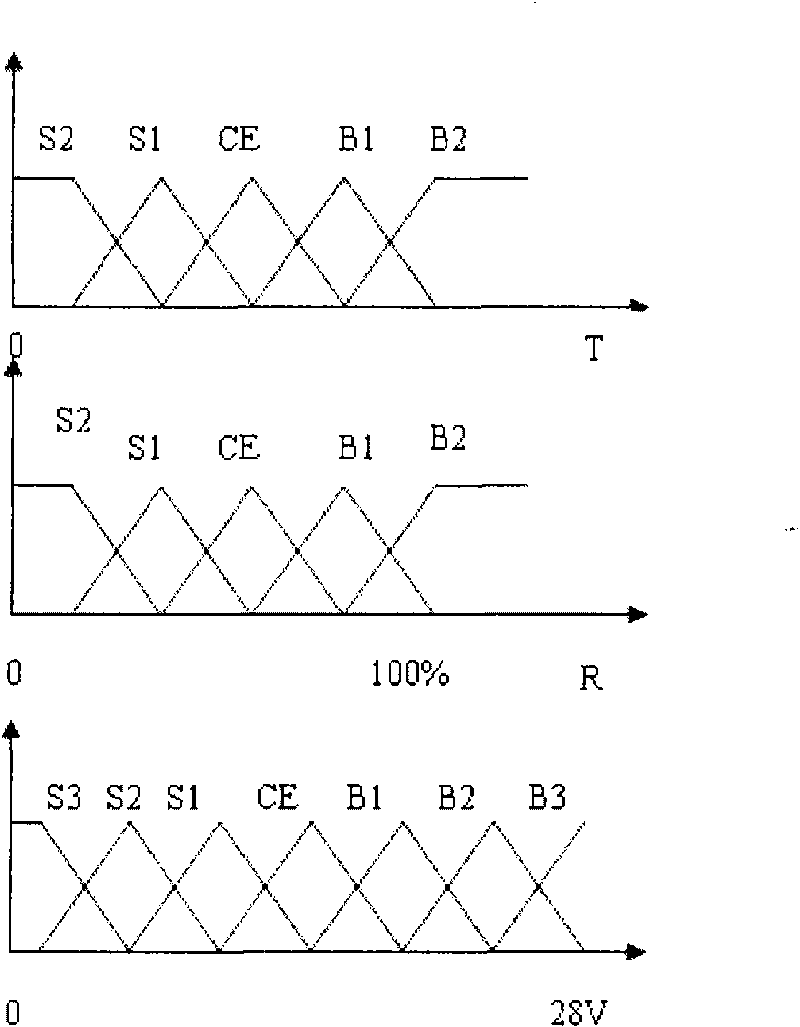

A system and method for controlling gas turbine engines with maximum thrust of less than 500 kgf. The control system includes electronic control unit (“ECU”), sensors and actuators. To ensure the requirement of compactness, physical control system simplicity but maintain stability and accurate operation for the engine, the control system does not include components such as Fuel Control Unit (“FCU”), alternator and corresponding rectifier circuits. A sensor, instead of alternator's wave form signal, is used to detect the rotational speed of the engine. Voltage regulation into the electric motor driving the fuel pump controls fuel flow, instead of the FCU. The control method consists of upper and lower limits computation calculation blocks of the control signal, and PID control algorithm block with coefficients designed to be suitable for the engine operating ranges. Control is implemented through a 7-step calculation process. Piecewise linearization modeling and tuning PID coefficients is also presented.

Owner:VIETTEL GRP

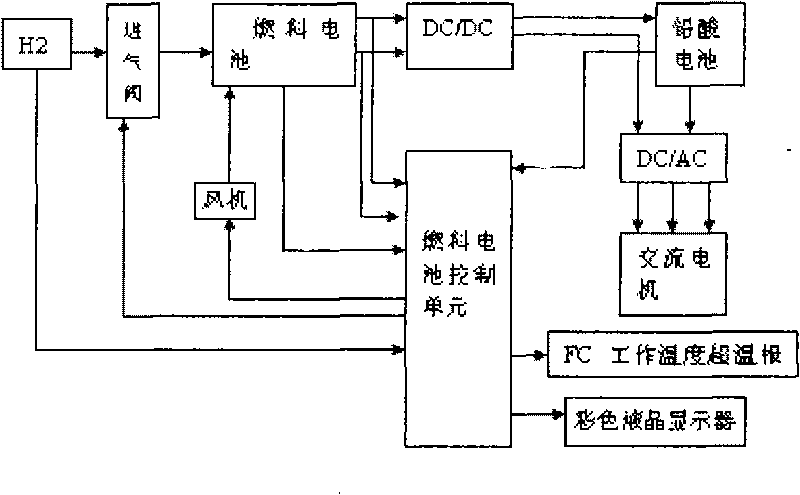

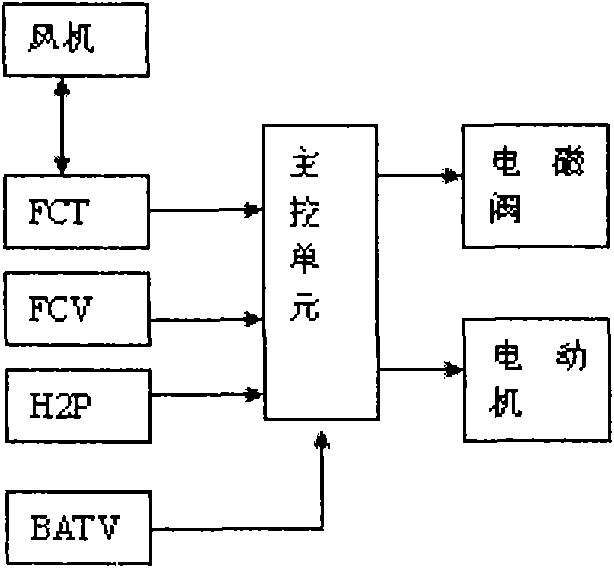

Hybrid power supply control system

InactiveCN101752886ASafe and reliable workGuaranteed uptimeBatteries circuit arrangementsFuel cell controlFuel cellsLiquid-crystal display

The invention relates to the industrial control field, in particular to a hybrid power supply control system. The invention provides a hybrid power supply control system with high energy / weight ratio. The invention is characterized in that the output end of H2 is respectively connected with the input ends of a fuel cell control unit and an air inlet valve, the output end of the air inlet valve is connected with the input end of the fuel cell, the output end of the fuel cell is respectively connected with the input end of a DC / DC converter and the input end of the fuel control unit, the output end of the DC / DC converter is respectively connected with the input ends of a lead-acid cell and an DC / AC, the output end of the lead-acid cell is respectively connected with the input ends of the DC / AC and the fuel cell control unit, the output end of the DC / AC is connected with the input end of an AC dynamo, the output end of the fuel cell control unit is respectively connected with the input ends of a color LCD, a fan, an FC and the air inlet valve, and the output end of the fan is connected with the other input end of the fuel cell.

Owner:杨小帆

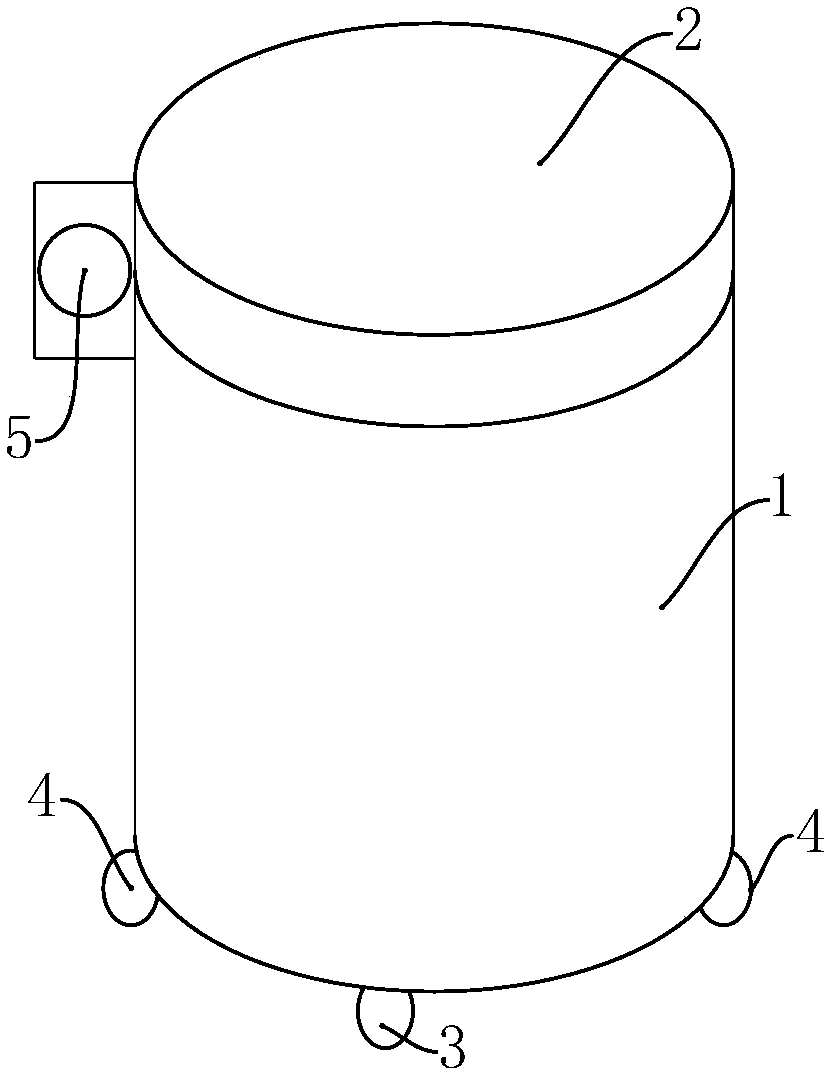

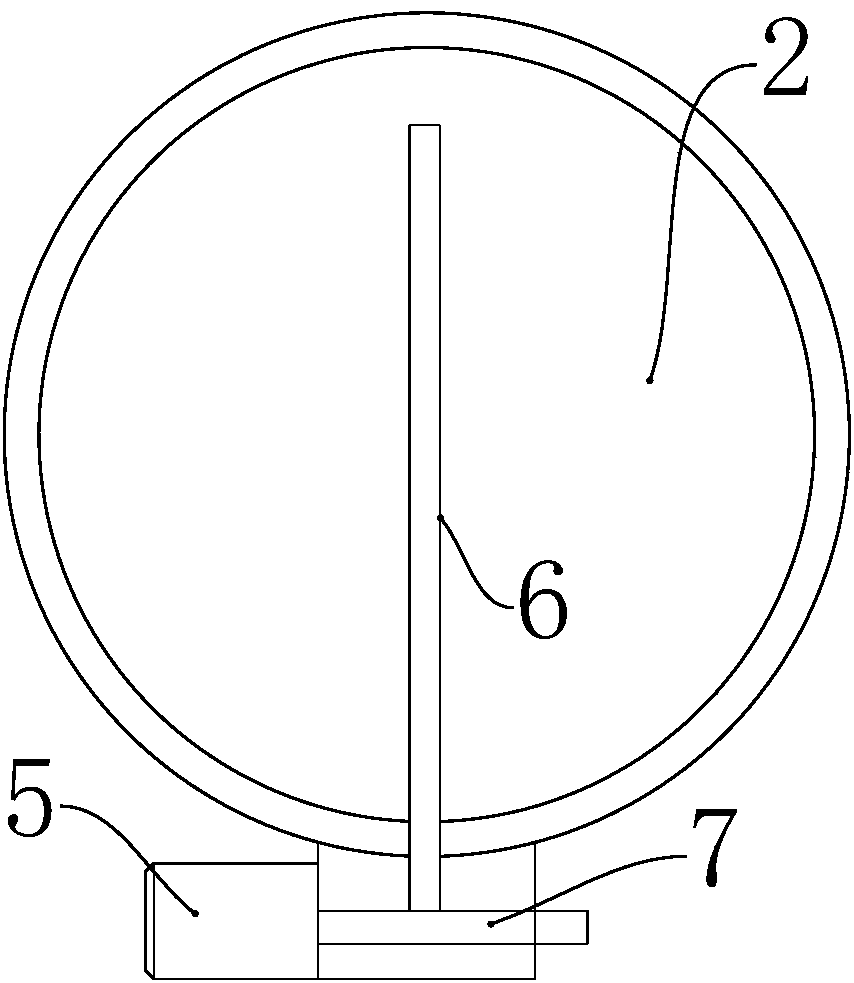

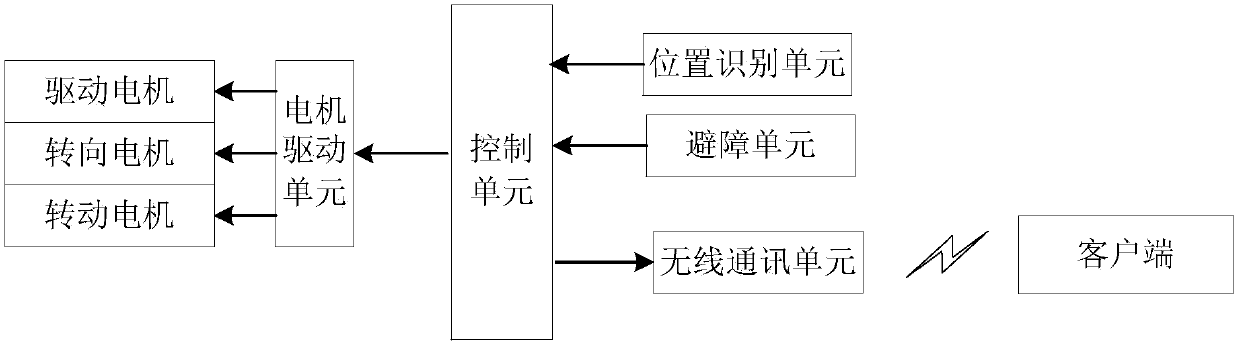

Intelligent office garbage recycling bin

The invention discloses an intelligent office garbage recycling bin. The intelligent office garbage recycling bin comprises a bin body and a bin cover; the bin body is connected with the bin cover through a hinge; an automatic uncovering mechanism is arranged between the bin body and the bin cover; a driving wheel and steering wheels are arranged at the bottom of the bin body; a power supply, a controller, a driving motor and a steering motor are arranged on the bin body; the controller comprises a control unit, a motor driving unit, a position identification unit, an obstacle avoidance unit and a wireless communication unit; a personnel client can be in wireless connection with the controller through the wireless communication unit; the motor driving unit is connected with the control unit; the obstacle avoidance unit is connected with the control unit; the obstacle avoidance unit identifies the position of an obstacle by adopting a diffuse reflection type photoelectric identificationswitch and feeds the position into the control unit; and the control unit controls the motors to avoid the obstacle. The intelligent office garbage recycling bin can avoid the obstacle automaticallyin a movement process; the intelligence degree is high; and the intelligent office garbage recycling bin is suitable to be used in a plurality of indoor places, such as an office and a meeting room.

Owner:成都华普尔科技有限公司

Driving tool

InactiveCN110053001APrevent poor resetAchieve stabilizationPortable percussive toolsMachines/enginesCombustion chamberFuel control unit

Owner:MAX CO LTD

Fuel system for an excavator

ActiveUS9388779B2Improve startup performanceRelieve stressLow pressure fuel injectionSoil-shifting machines/dredgersForeign matterCombustion chamber

A fuel system is disclosed which is adapted to improve engine ignition properties by ensuring that, when the engine ignition is turned off, residual fuel left over in the engine area after use is not returned to the fuel tank but instead remains in a common rail injector area. The fuel system for an excavator according to the present invention comprises: a fuel tank having a fuel supply line for discharging fuel and a return line for returning residual fuel after combustion in the engine area; a water-fraction separator which is provided downstream of the fuel tank, removes the water fraction contained in the fuel that is sucked in, and consists of a hand pump that is linked to the fuel supply line and of a first filter that is linked to the hand pump and filters out extraneous material in the fuel; an injection pump which is provided downstream of the water-fraction separator and which provides an injector with a high pressure supply of the fuel, from which the extraneous material has been filtered out on passing through the first filter and a second filter linked thereto, such that said fuel is sprayed into an engine combustion chamber; a fuel control unit which is respectively linked to the second filter and the injection pump and controls the injection pump so as to control the volume of fuel supplied to the injector; and a check valve which is provided in the return line and ensures that, when the equipment is made to stop working because the engine ignition is turned off, residual fuel left over in the engine area after use is not returned to the fuel tank along the return line but instead remains in the injector area.

Owner:VOLVO CONSTR EQUIP AB

Fuel system for retarded armature lifting speed and fuel system operating method

ActiveUS11300068B1Limit bouncingElectrical controlFuel injection apparatusFuel control unitInternal combustion engine

A fuel system for an internal combustion engine includes a fuel injector, and a fueling control unit electrically connected to a solenoid in the fuel injector. The fueling control unit energizes the solenoid with a lift current pulse to lift an armature, then energizes the solenoid with a separate capture current pulse to capture the armature at a lifted position. The solenoid is deenergized a dwell time while the armature is in flight toward the lifted position. Armature lifting speed is retarded based on the deenergizing of the solenoid so as to limit bouncing of a valve pin in the fuel injector against a stop. The techniques assist in linearizing a fuel delivery curve.

Owner:CATERPILLAR INC

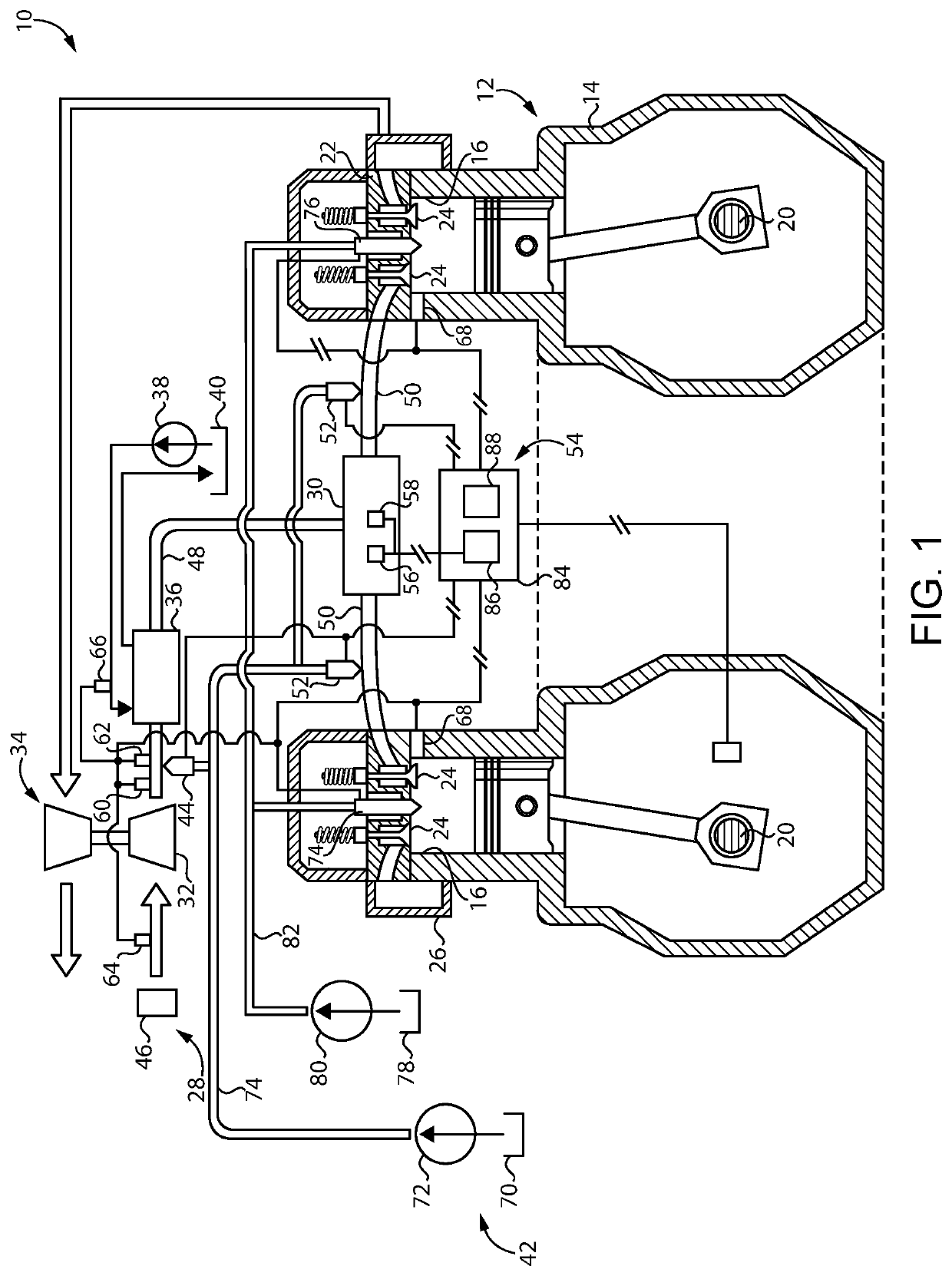

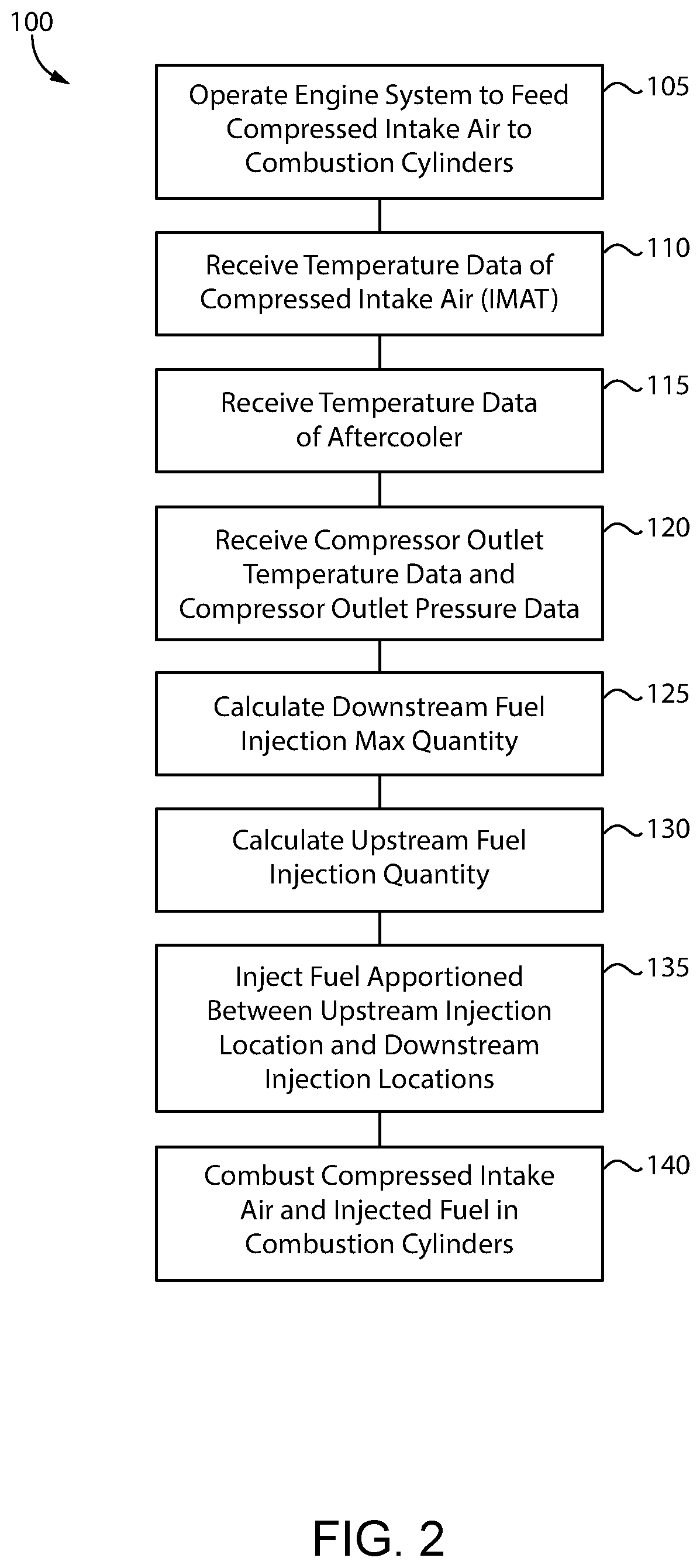

Engine system operating strategy apportioning fuel injection between upstream and downstream injection locations

Operating an engine includes injecting a liquid alcohol fuel such as methanol into a stream of compressed intake air at an upstream injection location, and injecting the liquid fuel at a plurality of downstream injection locations into a plurality of streams of the compressed intake air from an intake manifold to combustion cylinders in the engine. A fueling control unit apportions a total injected quantity of the liquid fuel between the upstream injection location and the plurality of downstream injection locations based on a temperature parameter of the compressed intake air. The compressed intake air is combusted with the liquid fuel and a compression ignition pilot fuel in the plurality of combustion cylinders.

Owner:CATERPILLAR INC

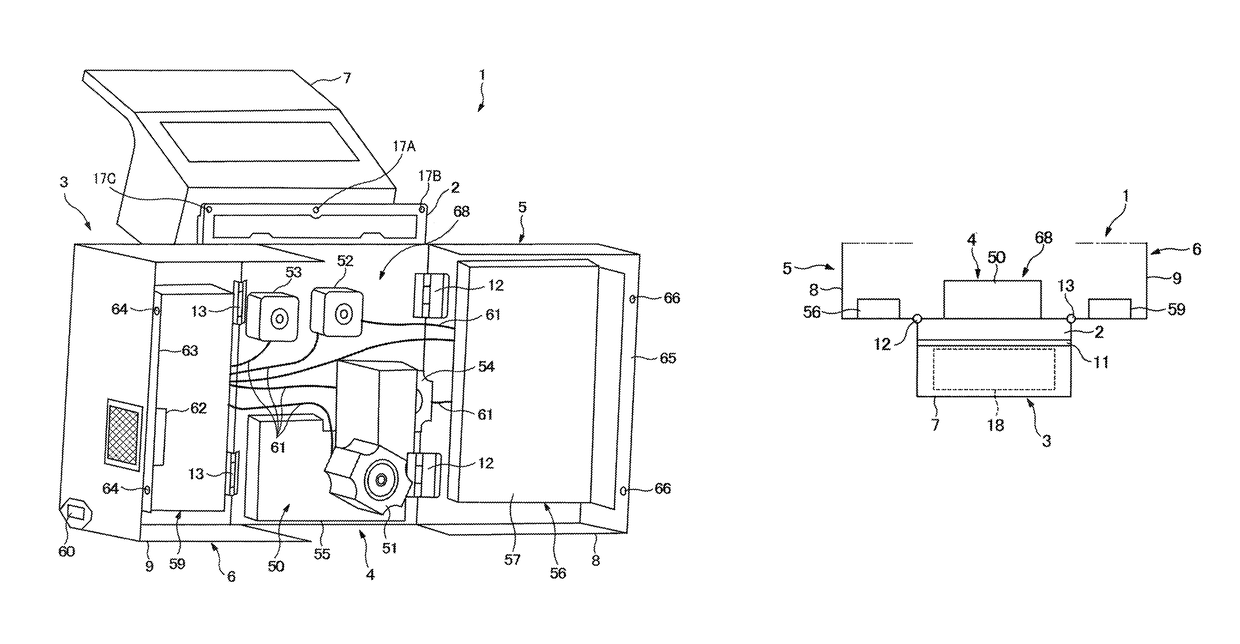

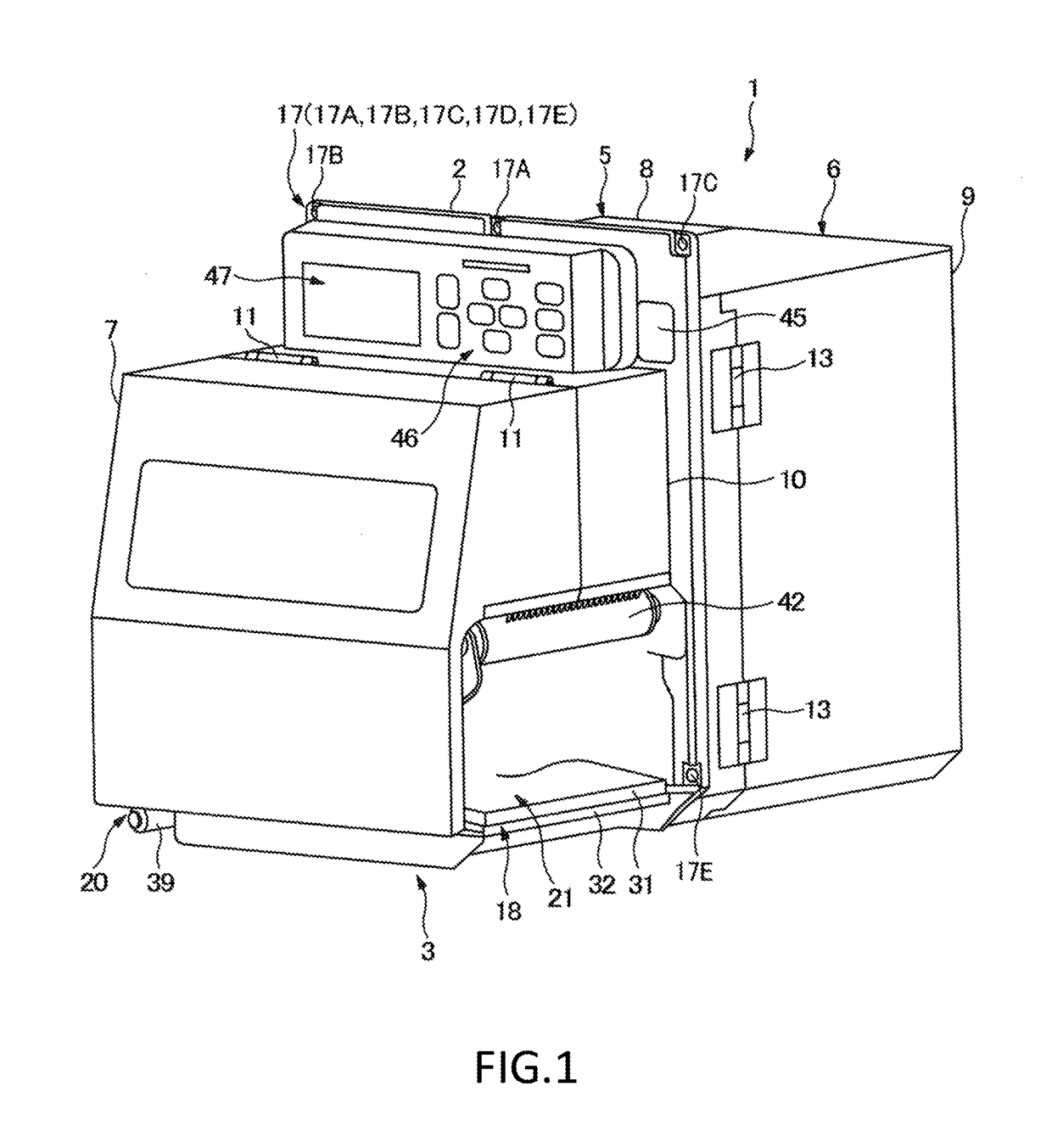

Printer apparatus

ActiveUS9969196B2Improve workabilityEasy to assembleTypewritersOther printing apparatusFuel control unitEngineering

A printer apparatus has a main unit, a print unit, a driving unit, a control unit, and a power unit. The print unit is provided on one side surface of the main unit. The driving unit is provided on another side surface of the main unit. The control unit and the power unit are installed openably and closably to the main unit such that the driving portion, the control portion, and the power supply portion are exposable to the outside.

Owner:SATO HLDG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com