Liquefied petroleum gas (LPG) buffer release tank and control system

A control system and buffer tank technology, applied in the direction of fixed-capacity gas storage tanks, container discharge methods, non-pressure vessels, etc., can solve problems such as splashing, incomplete vaporization, damage to ships and crews, etc., to avoid excessive backlog, Effects of improving safety and strengthening safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

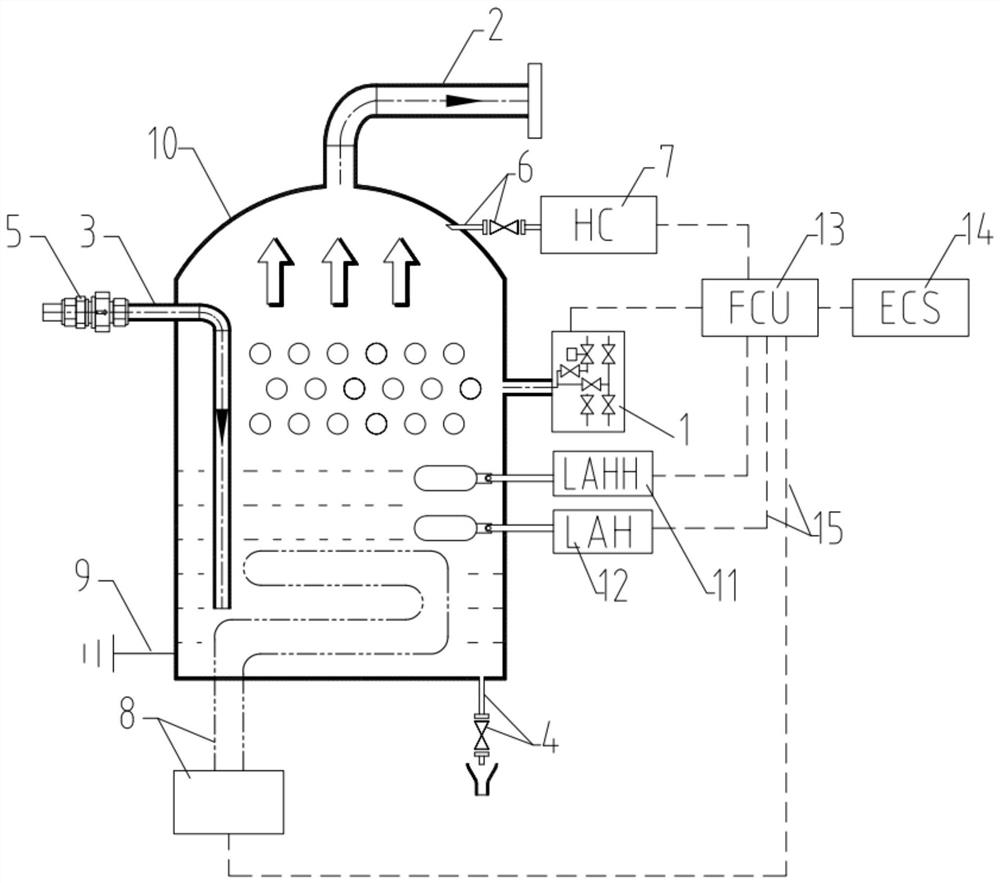

[0028] see figure 1 , an LPG buffer release tank and control system, divided into a buffer release tank part and an LPG control part, the buffer release tank part includes a release valve group 1 and a tank body 10, the release valve group 1 and the tank body 10 of the buffer release tank For communication, the highest part of the dome of the tank body 10 of the buffer release tank is fixedly installed with a discharge pipe 2, and the discharge port of the discharge pipe 2 is connected to the venting mast on the LPG ship, and one side of the tank body 10 is fixedly installed There is a nitrogen blow-off pipe 3, and a check valve 5 is fixedly installed on the nitrogen blow-off pipe 3;

[0029] The LPG control part includes a fuel control unit 13, a host control unit 14 and multiple sets of control signal lines 15, and the fuel control unit 13 and the host control unit 14 are respectively used for emergency response to the release valve group 1 and the control host of the LPG sh...

Embodiment 2

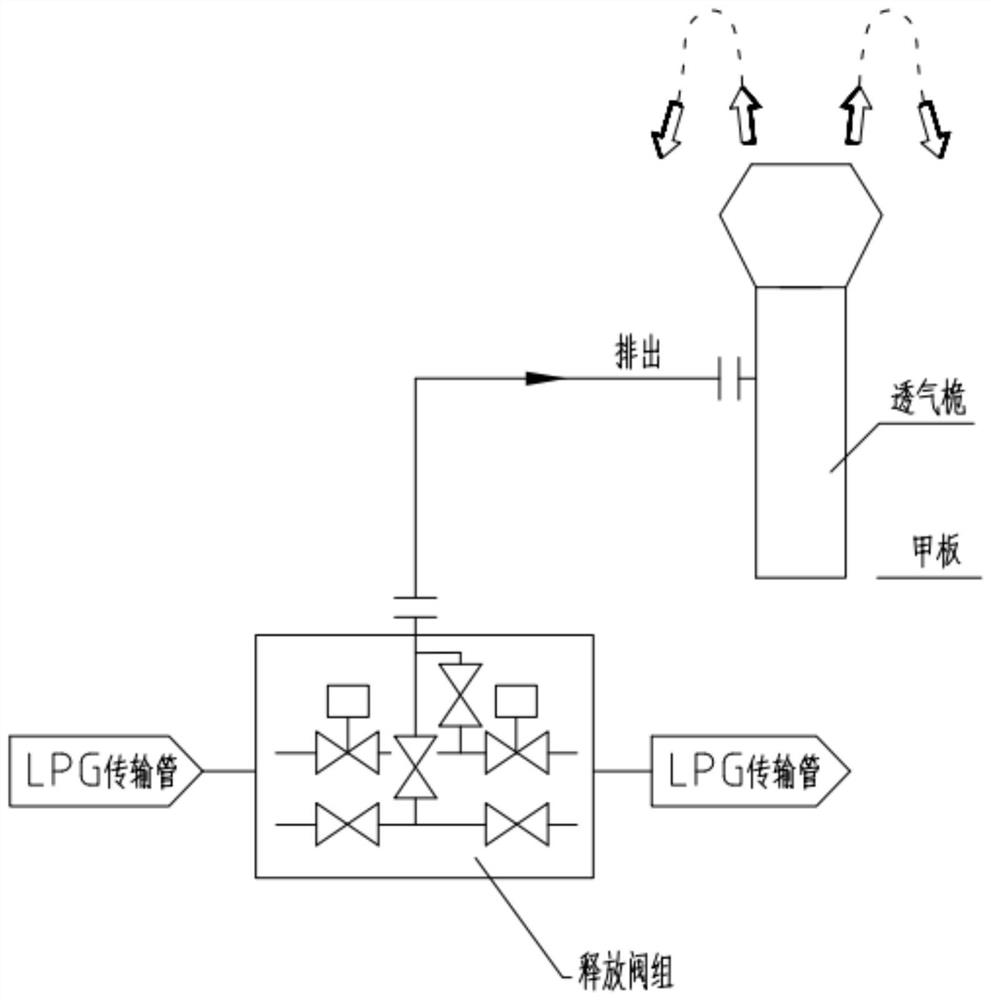

[0038] see figure 2, the common safety release line is directly released from the release valve group to the venting mast, which is used when the LPG power transmission pipe needs to be released urgently, resulting in incomplete vaporization during release, and it is easy to splash the residual LPG liquid through the venting mast, which will cause Injury to the ship and crew; and without HC (hydrocarbon) content detection and nitrogen blow-off, there is no way to know the explosive mixture in the vented mast, and there is no way to clean it up. Using the LPG buffer release tank and control system described in Embodiment 1, during emergency release, the release valve group 1 is opened, LPG enters the tank body 10 of the buffer tank, and the outlet of the tank body 10 of the buffer tank is at normal pressure After the LPG enters, it is vaporized under normal pressure, and part of the liquid drops to the bottom of the tank body 10 without enough time to vaporize. After the LPG v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com