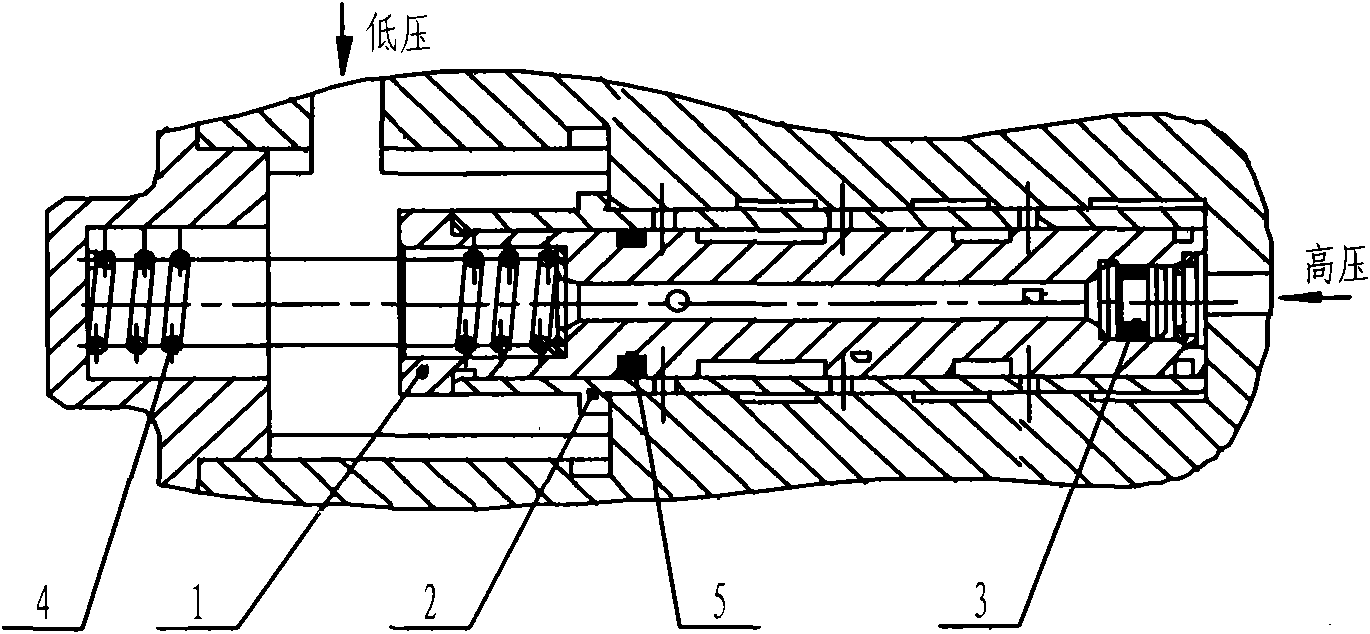

Fuel cut-off valve of reheat fuel control unit of turbofan engine

A technology of turbofan engine and afterburning fuel, which is applied in the direction of engine components, turbine/propulsion fuel delivery system, turbine/propulsion device fuel control, etc. It can solve complex structure, poor changeability of regulator, adjustment and maintenance workload Major and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

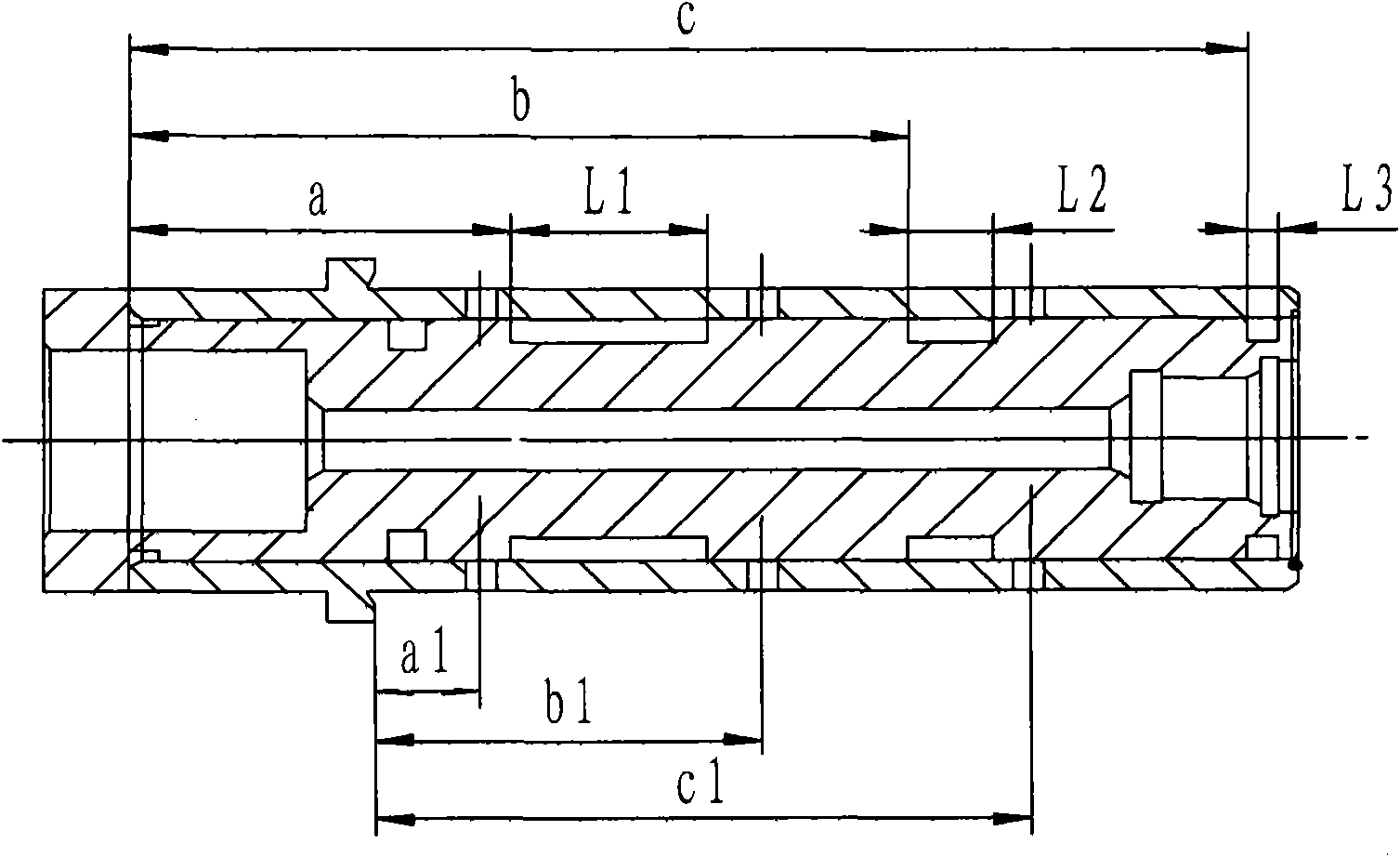

[0014] refer to figure 2 , according to the actual principle of the present invention, it is determined that there are 3 communication grooves with different positions and lengths on the fuel cut-off valve 1, which respectively correspond to the fuel control points of the afterburner external culvert, afterburner connotation, and afterburner start, and at the same time set the bushing 2 a1=7±0.1mm, b1=25±0.1mm, c1=43±0.1mm; according to the above size of the bushing 2, a=25±0.1mm of the valve 1 is determined, and the moving speed of the valve is determined to be 4.7mm / Seconds, in order to meet the cut-off from the afterburner connotation to the afterburner connotation, the total working time is controlled at 1.5 seconds to 3 seconds, and the time from cutting off the afterburner I area to completely cutting off the afterburner I area is guaranteed to be within Within 0.5 seconds, b=51±0.1mm and c=73±0.1mm of valve 1 can be obtained. According to the total moving distance of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com