Solids flow meter for integrated boiler control system

a flow meter and control system technology, applied in combustion control, combustion regulation, fuel supply regulation, etc., can solve the problems of improper combustion in various portions of the combustion system, inability to accurately measure the flow rate of coal through the fuel pipe, so as to achieve more efficient combustion and reduce emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]Disclosed methods and apparatus providing for accurate measurement of fuel flow. The measurements provide for improved control over combustion systems, such as a boiler combustion system, leading to improved efficiency. In general, the teachings herein make use of at least one low-frequency, ultrasonic, non-intrusive solids flow meter. The at least one flow meter may be disposed in a variety of locations, and as an example, may be used to measure flow to each windbox within a boiler combustion system.

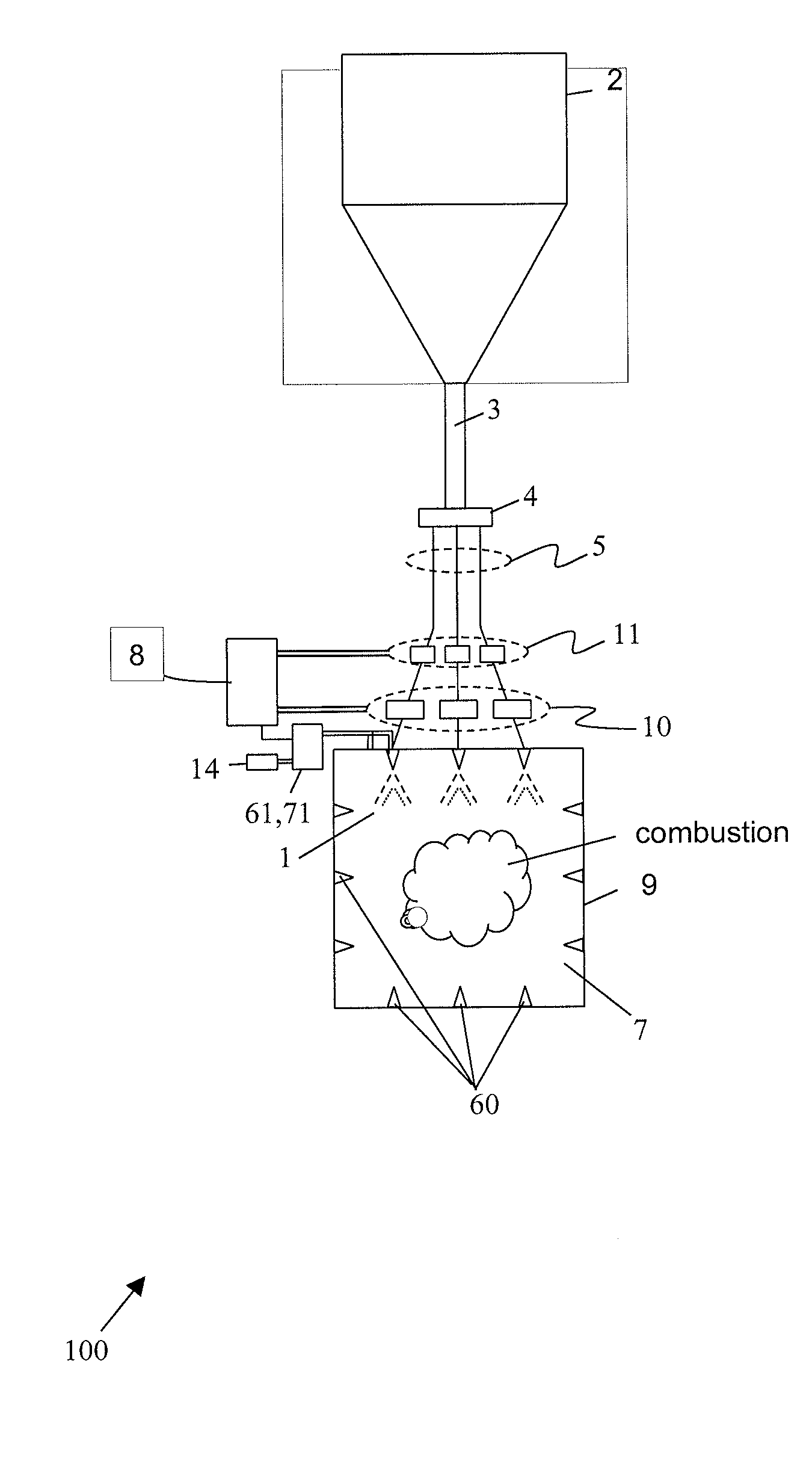

[0020]In FIG. 1, the combustion system shown includes a pulverizer 2 that provides pulverized sold fuel. The solid fuel particles are entrained in a flow of air through a fuel line 3 to a splitter 4.

[0021]The pulverized solid fuel is passed through a plurality of fuel pipes 5. The splitter 4 may be a riffling distributor that adjusts the flow through each of the fuel pipes 5.

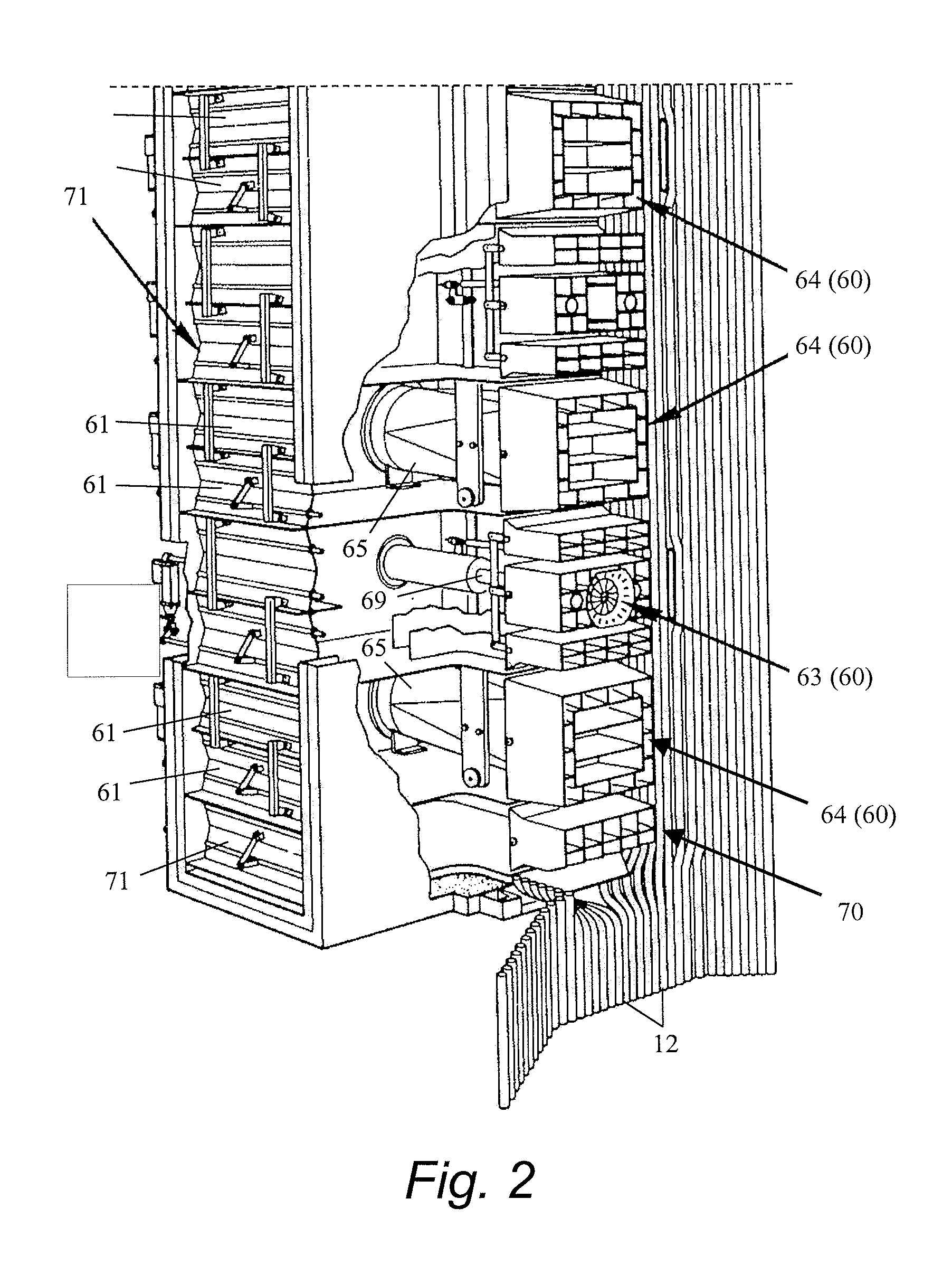

[0022]The fuel then flows through a plurality of fuel nozzles 60. The fuel nozzles 60 are disposed on an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com