Portable fire pit system

a fire pit and portable technology, applied in the field of portable fire pit systems, can solve the problems of inefficiency of fuel itself, insufficient utilization of fire pit space, and many fire pits without ventilation, and achieve the effect of efficient burning of fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

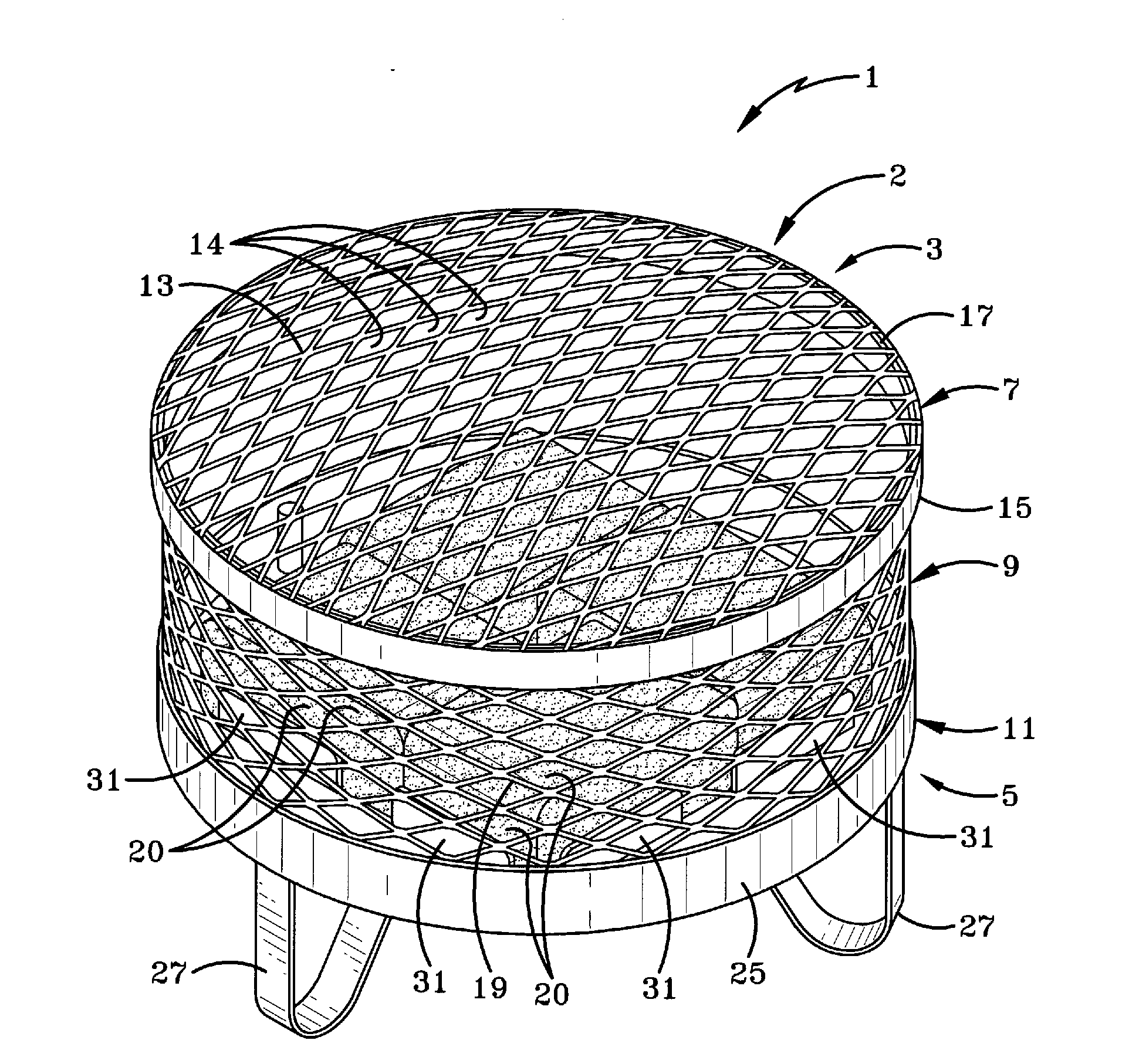

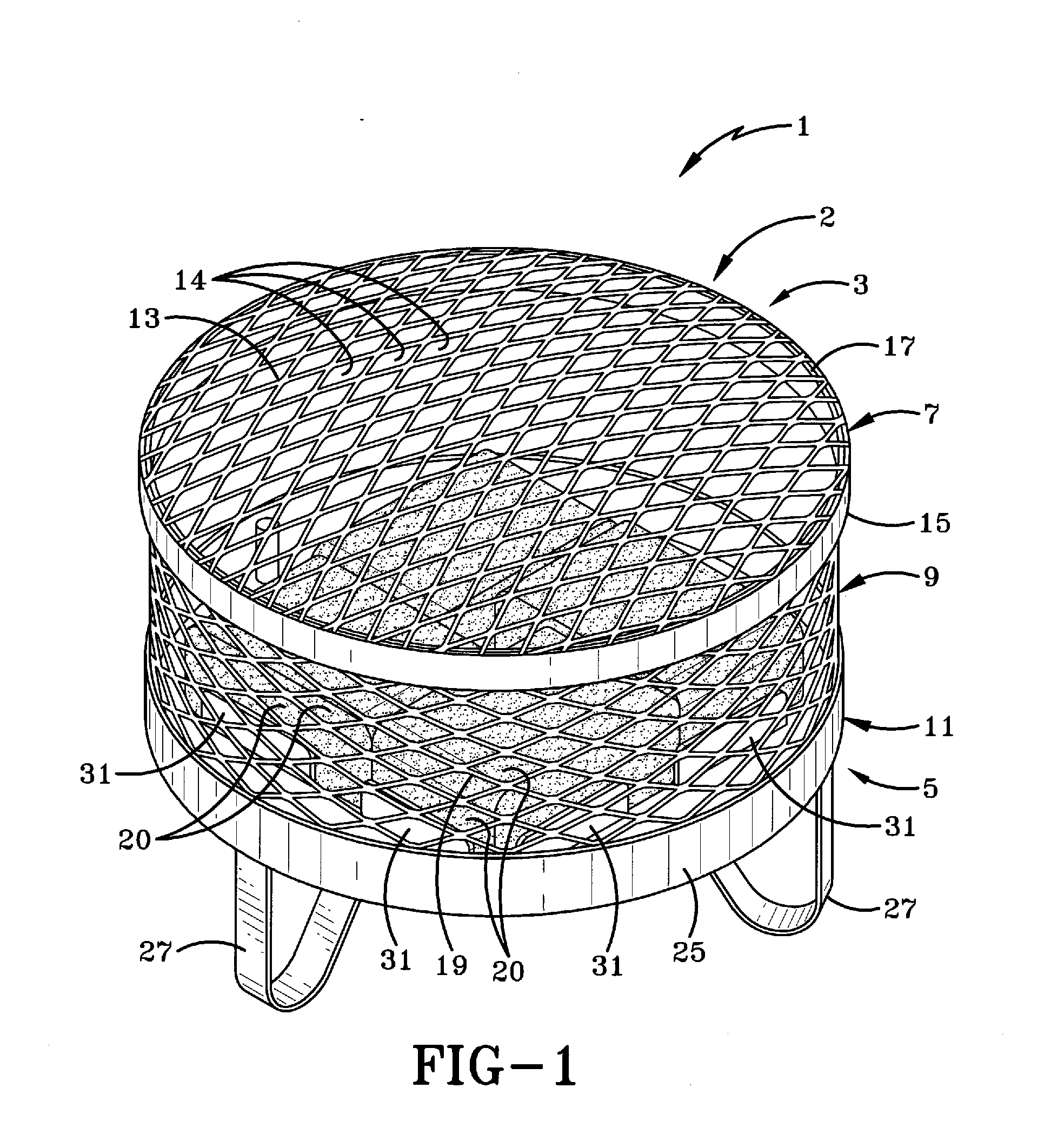

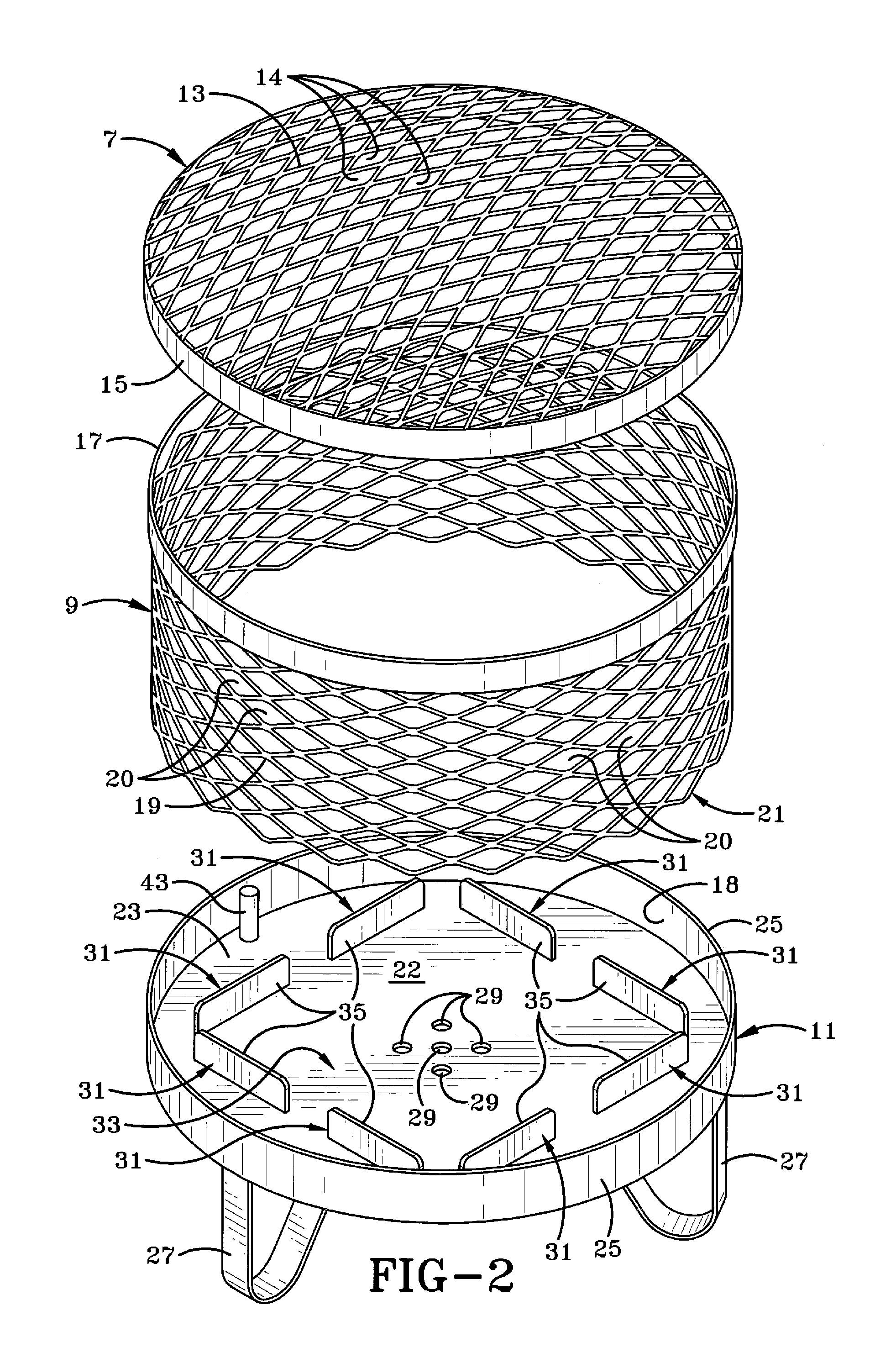

[0021]The portable fire pit system of the present invention is shown in FIGS. 1-11 and is indicated generally at 1. As shown in FIGS. 1 and 2, fire pit system 1 includes a fire pit 2 which extends generally from an upper end 3 to a lower end 5 and includes a lid 7, a spark guard 9, and a base 11. Lid 7 includes a wire mesh portion 13 which defines a plurality of openings 14 and extends from an annular ring 15. Annular ring 15 is sized to removably and snuggly fit around an annular ring 17 having a slightly smaller diameter and disposed on spark guard 9. Spark guard 9 further includes a wire mesh portion 19 extending from annular ring 17 to a lower end 21, and is formed in a generally cylindrical overall shape. Wire mesh portion 19 defines a plurality of openings 20 for allowing air to pass therethrough and to prevent cinders or floating ash from escaping and starting a fire outside the pit.

[0022]Referring to FIGS. 1-3, base 11 includes a plate 23 having an upper surface 22, a lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com