Patents

Literature

56 results about "Compressor station" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A compressor station is a facility which helps the transportation process of natural gas from one location to another. Natural gas, while being transported through a gas pipeline, needs to be constantly pressurized at intervals of 40 to 100 miles. Siting is dependent on terrain, and the number of gas wells in the vicinity. Frequent elevation changes and a greater number of gas wells will require more compressor stations.

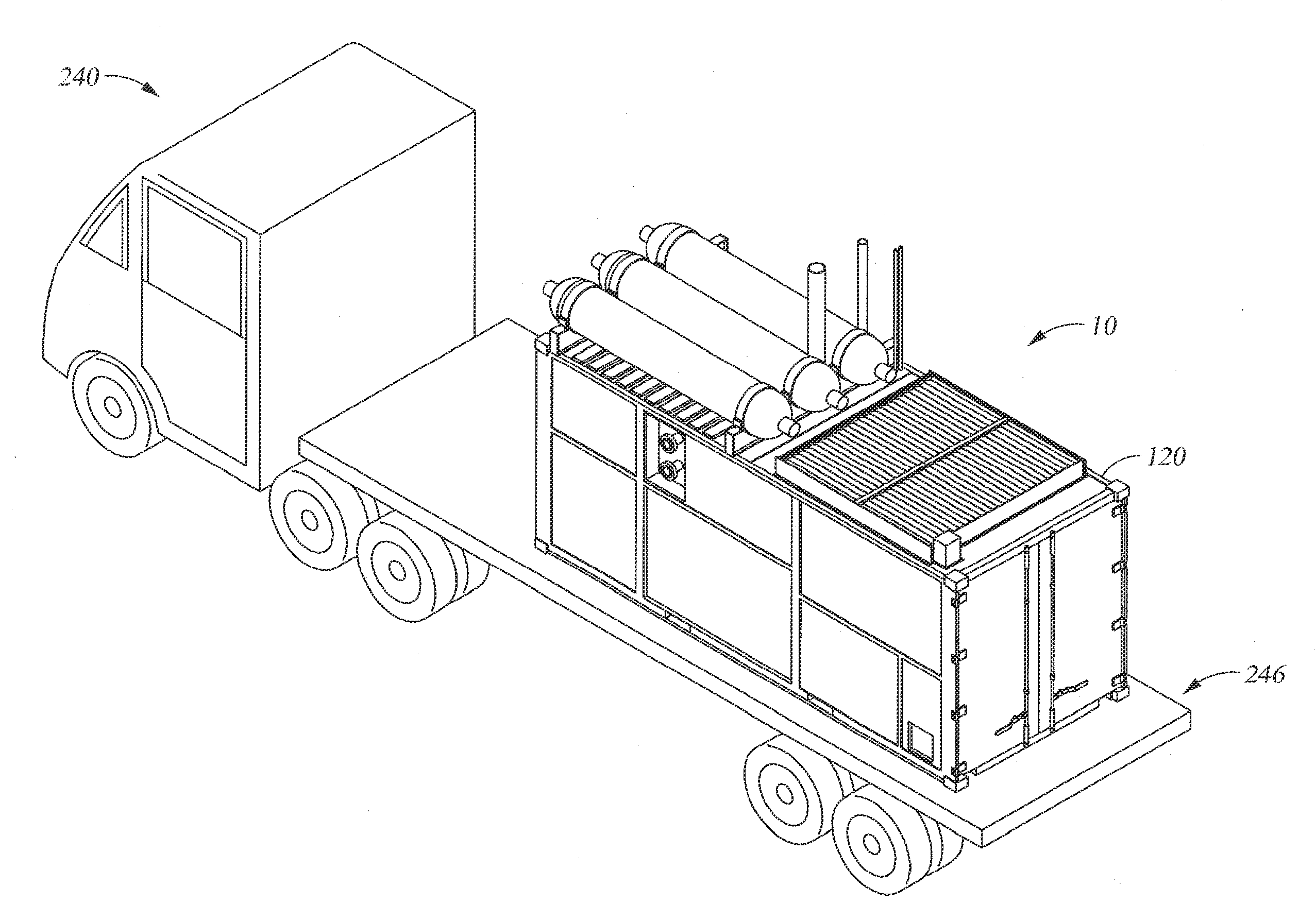

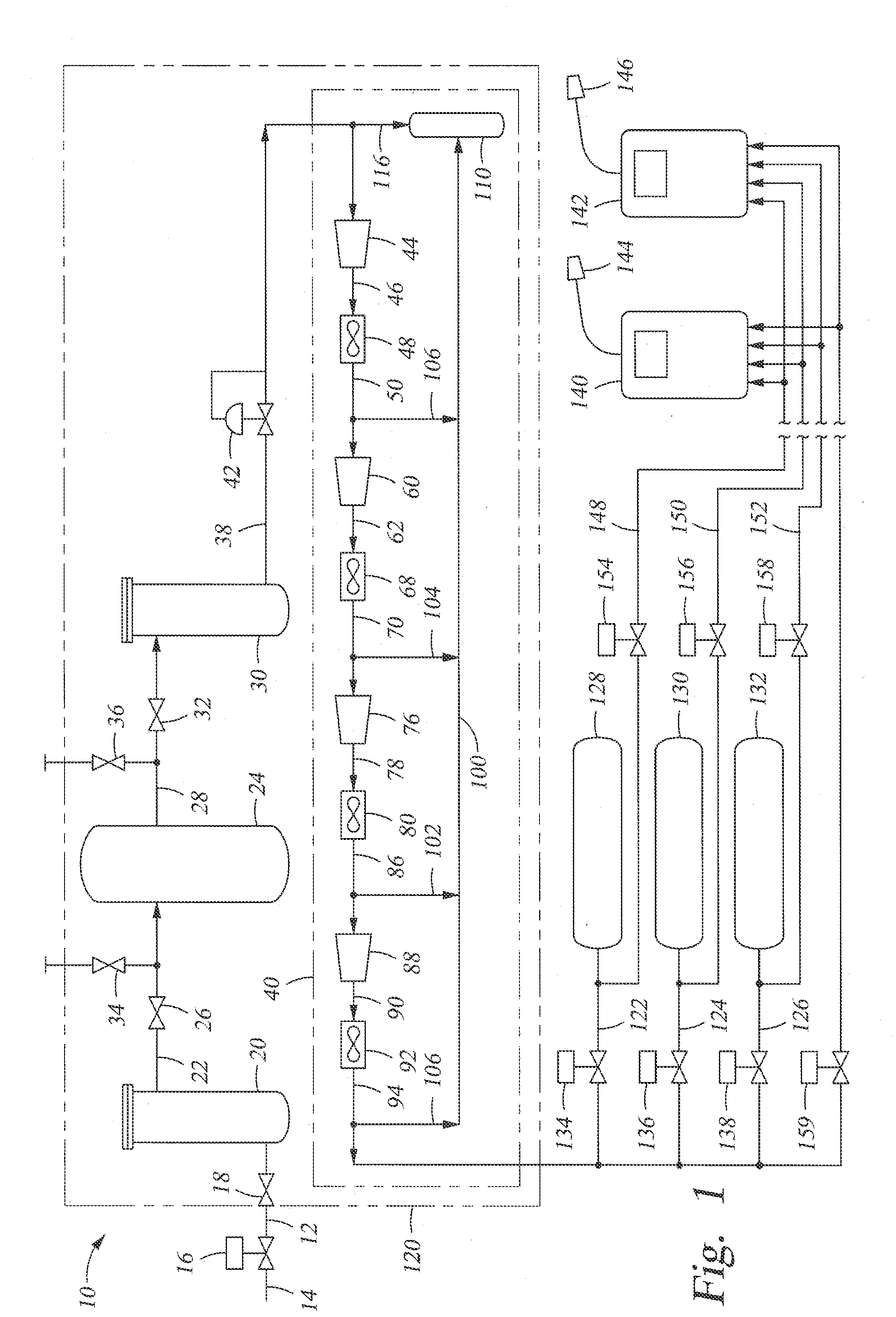

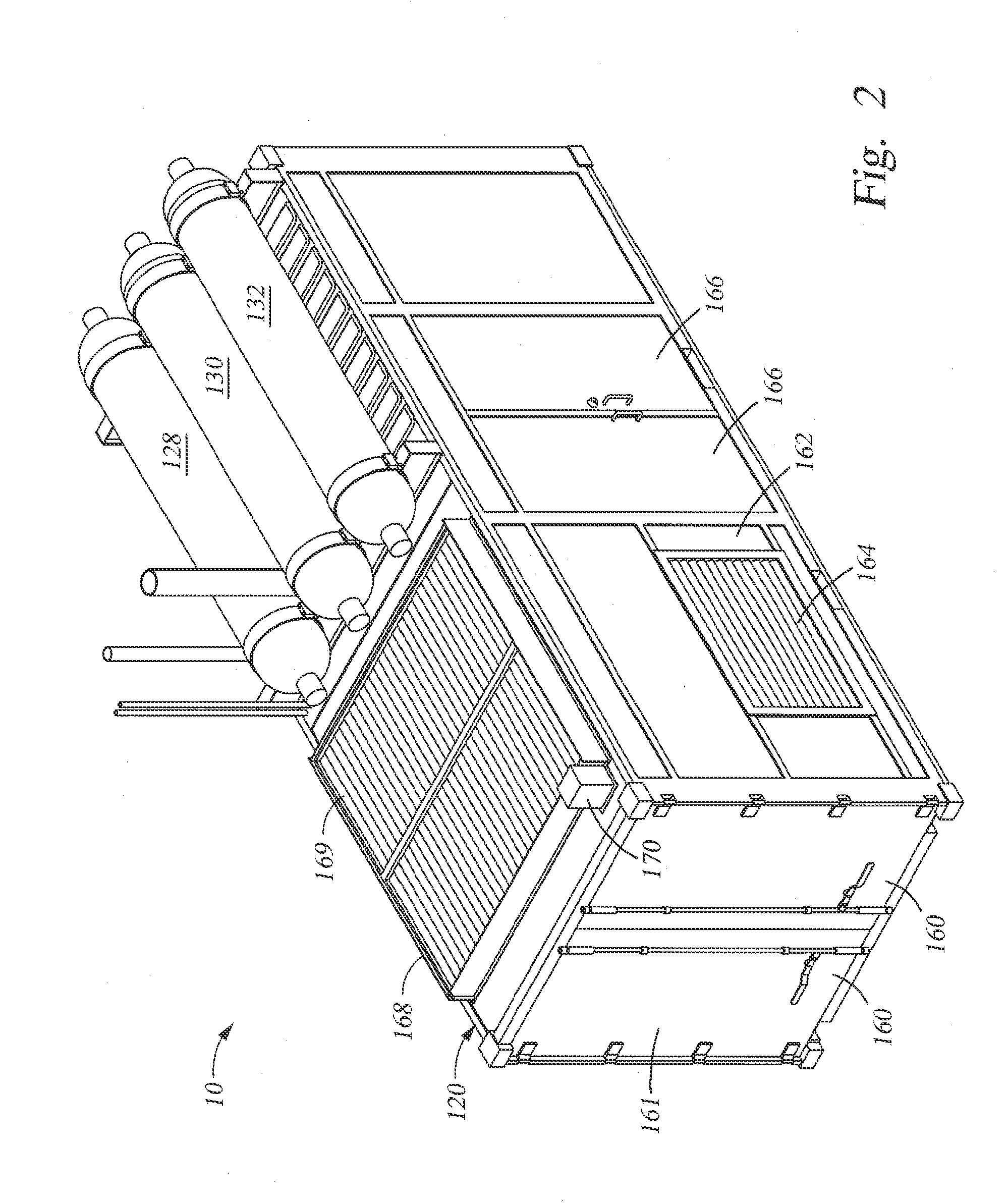

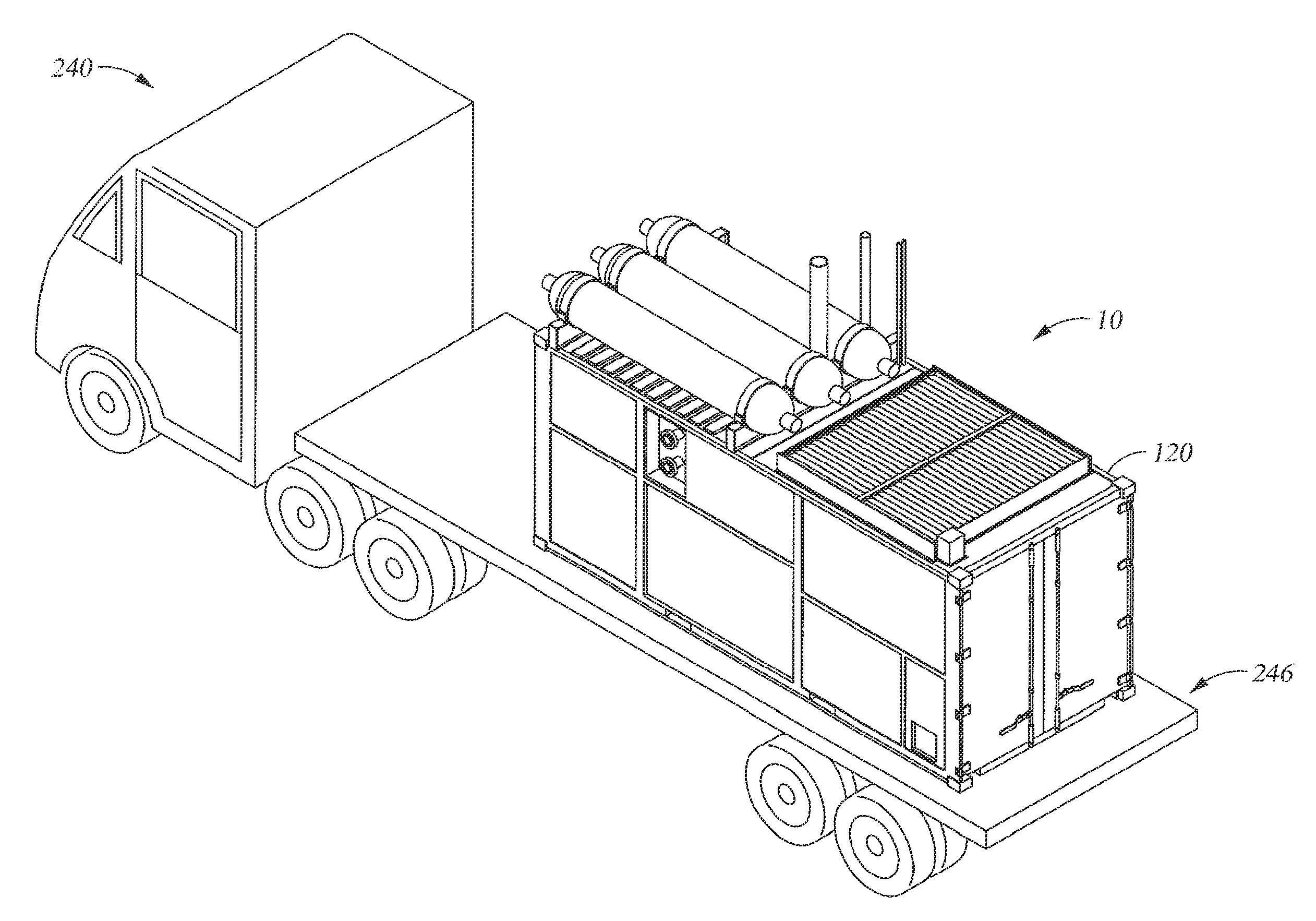

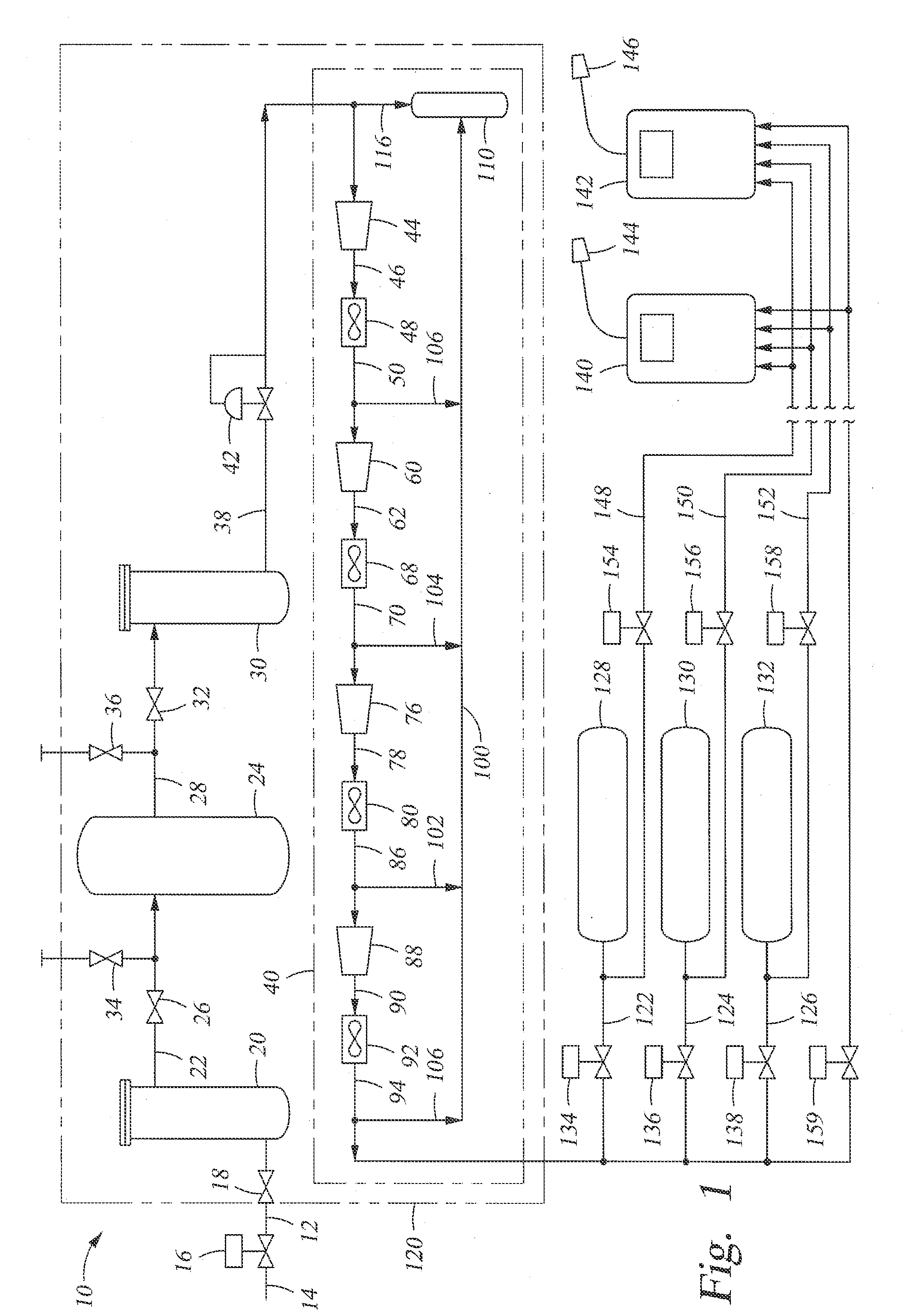

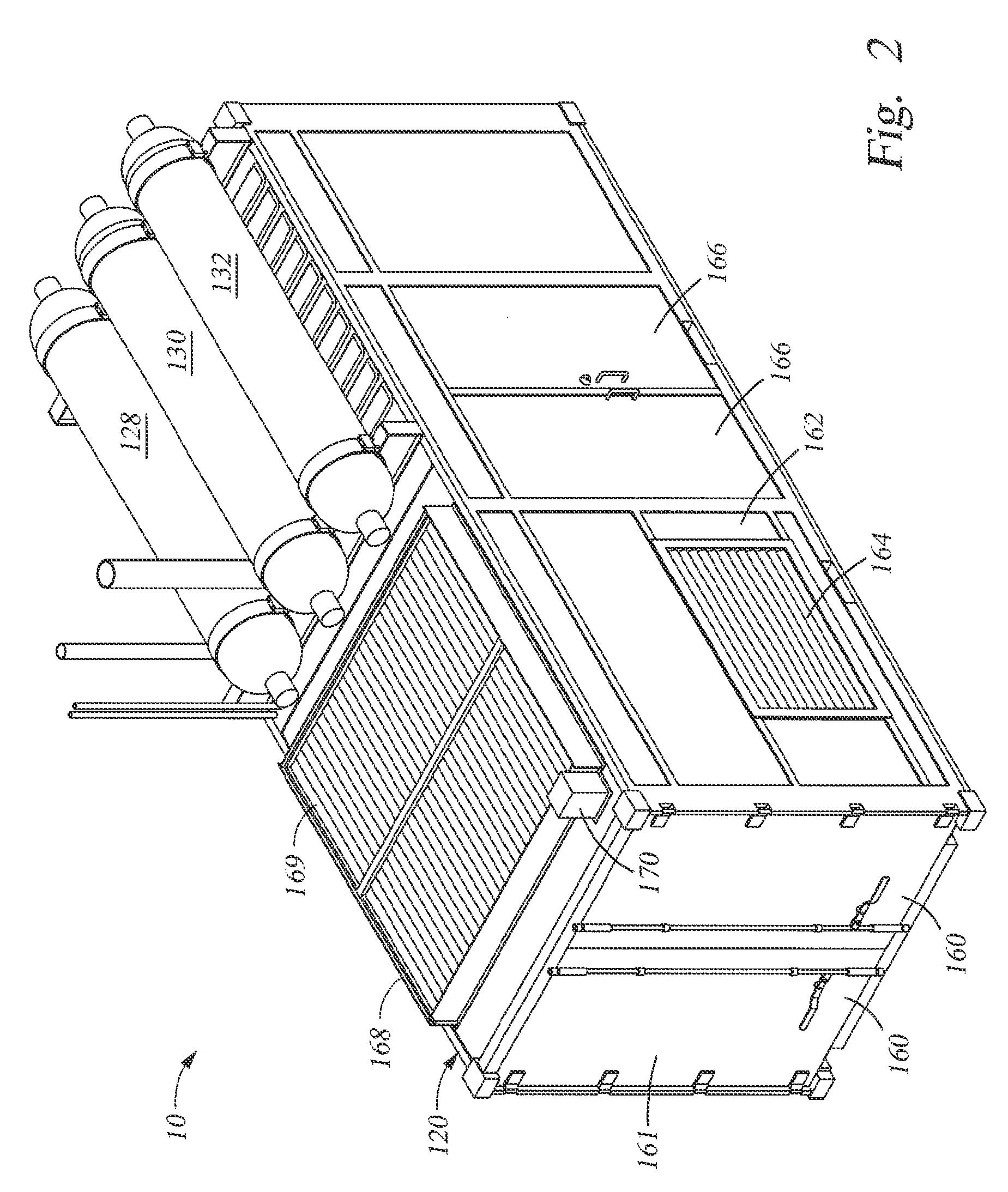

Modular Compressed Natural Gas System for Use at a Wellsite

ActiveUS20150240996A1Using liquid separation agentGas handling applicationsCompressed natural gasEngineering

A system and method of receiving field gas from a compressor station pipeline, and compressing the gas at a remote location with a modular compressor. The compressed gas is collected in a container and transported to a wellsite for use at the wellsite. The gas from the pipeline is directed to the container, and diverted to the modular compressor when pressure in the container approaches pressure in the pipeline. The modular compressor discharge is piped to the container, so that the container is filled with additional gas and at the discharge pressure of the modular compressor.

Owner:BAKER HUGHES INC

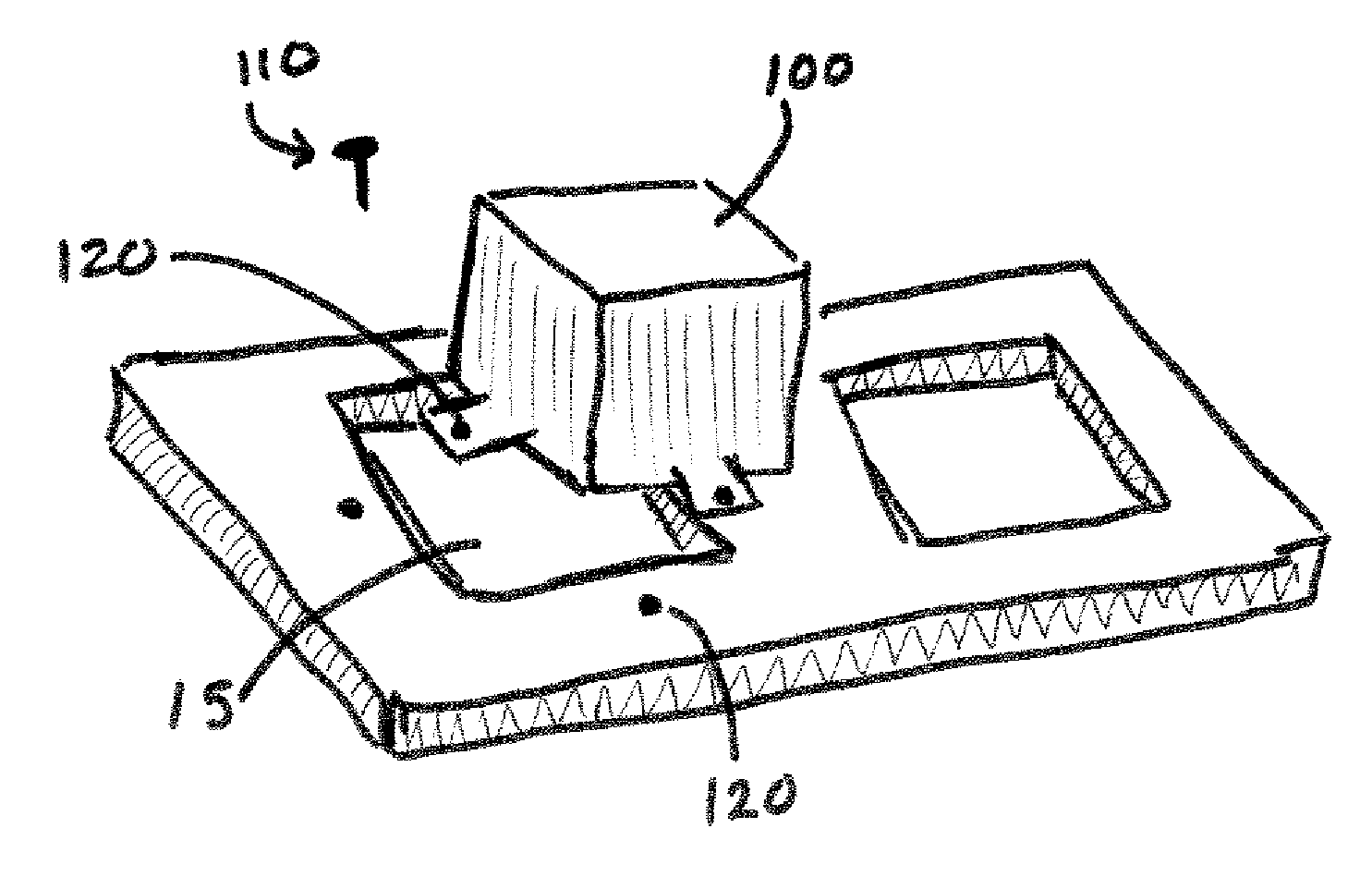

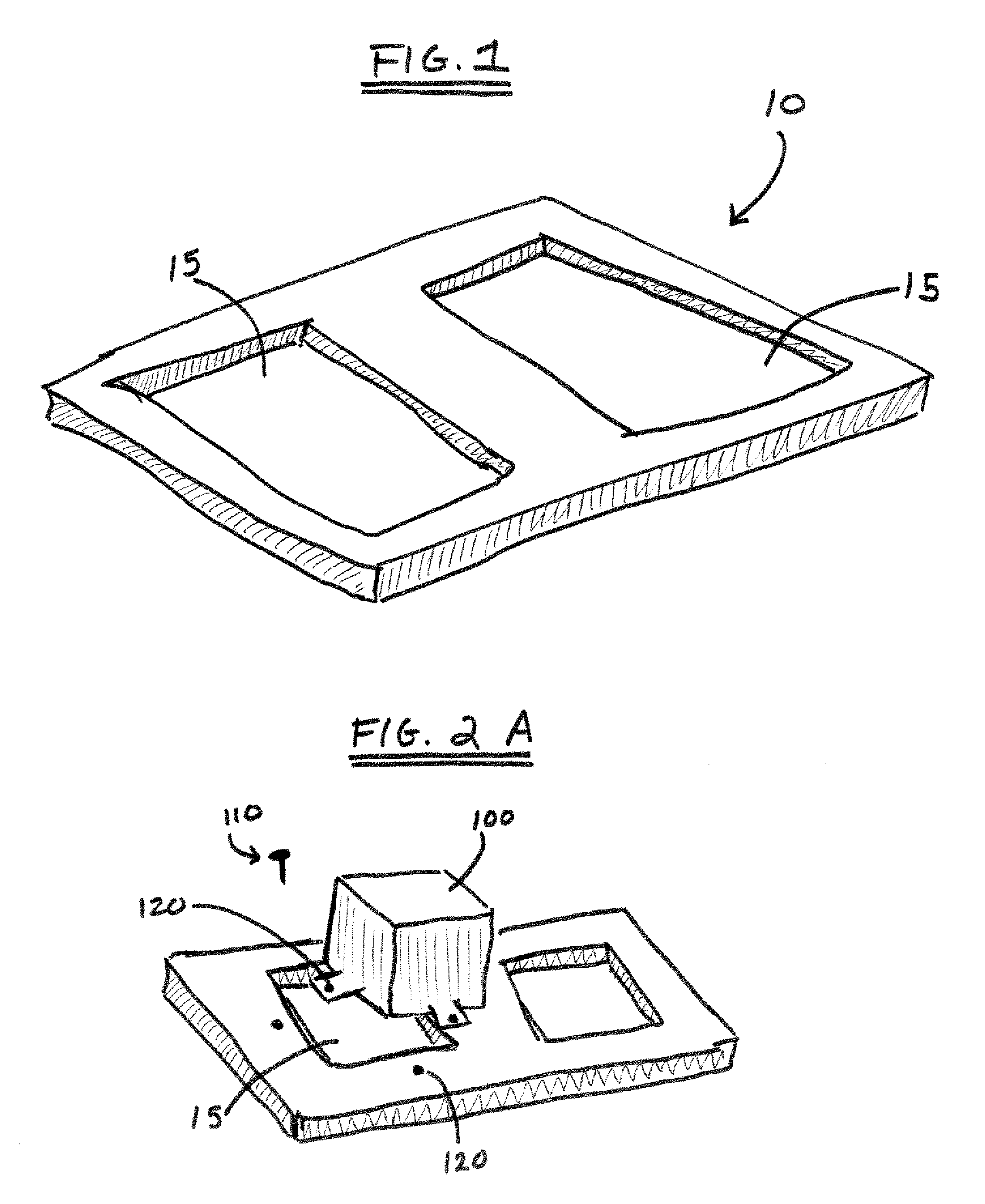

Modular production design of compressed natural gas compressor and multi-saturation liquefied natural gas dispenser systems

The present invention provides a modular natural gas compressor system for compressing natural gas so that it can be used to refuel motor vehicles. This system permits easy assembly and disassembly of compressor stations, as each individual compressor unit is shaped so that it will fit on a base structure. Specifically, the modular system is comprised of a prefabricated, mass produced base skid having at least one allowed space of standardized dimensions and at least one natural gas compressor unit, the base of which is shaped to fit in a allowed space of the base skid. Additional compressed natural gas compressor units or booster units, the bases of which are also shaped to fit in the allowed spaces of the base skid, may be added to increase the efficiency or functionality of the system. Liquefied natural gas dispenser units may also be designed to have bases that fit in the allowed spaces of the base skid, and can be added to the base skid to create a CNG compressor / LNG dispenser hybrid system. These liquefied natural gas dispenser units allow the user to select (automatically or manually) the level of saturation of the liquefied natural gas product to be dispensed by the dispenser.

Owner:CLEAN ENERGY FUELS CORP

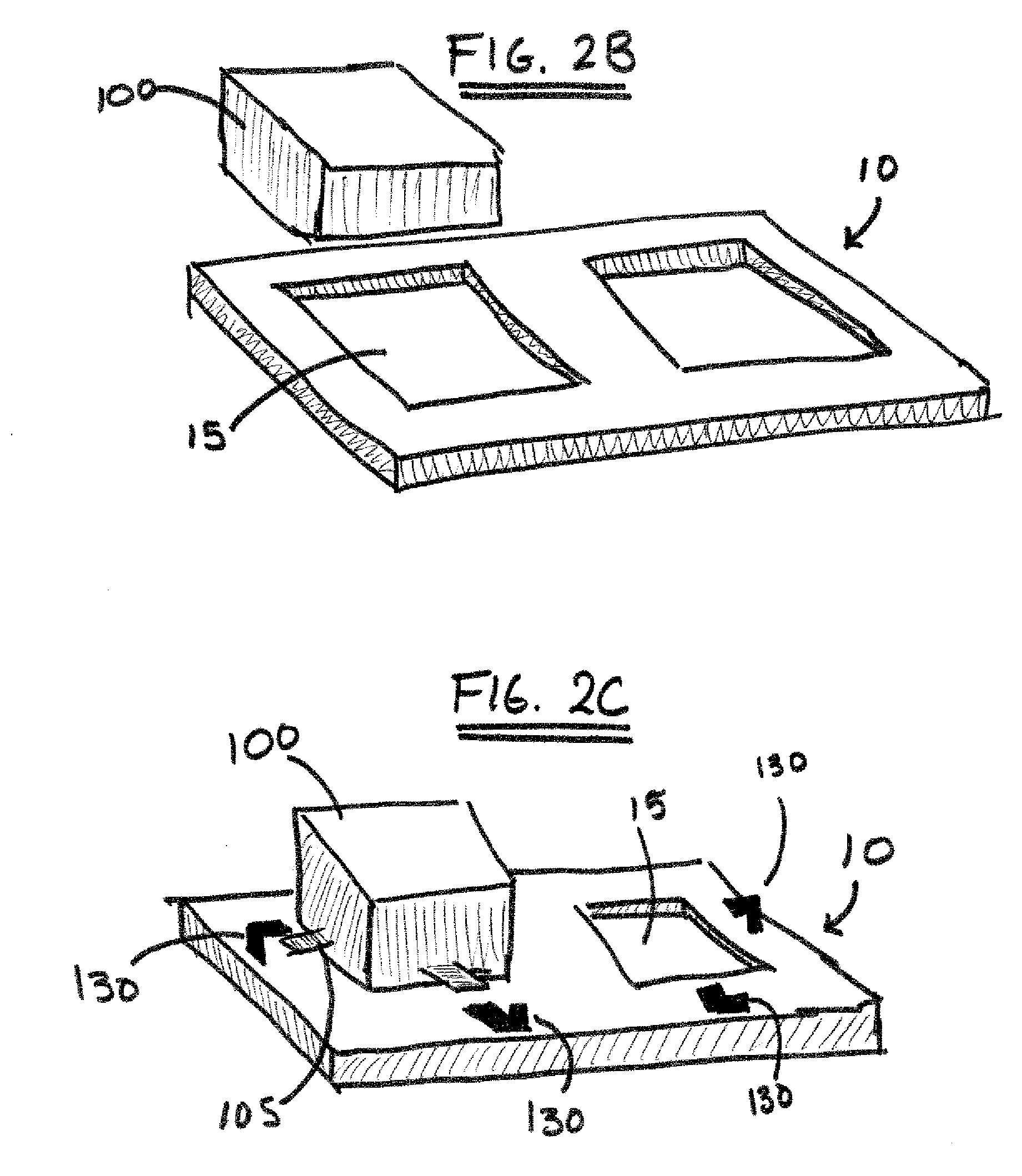

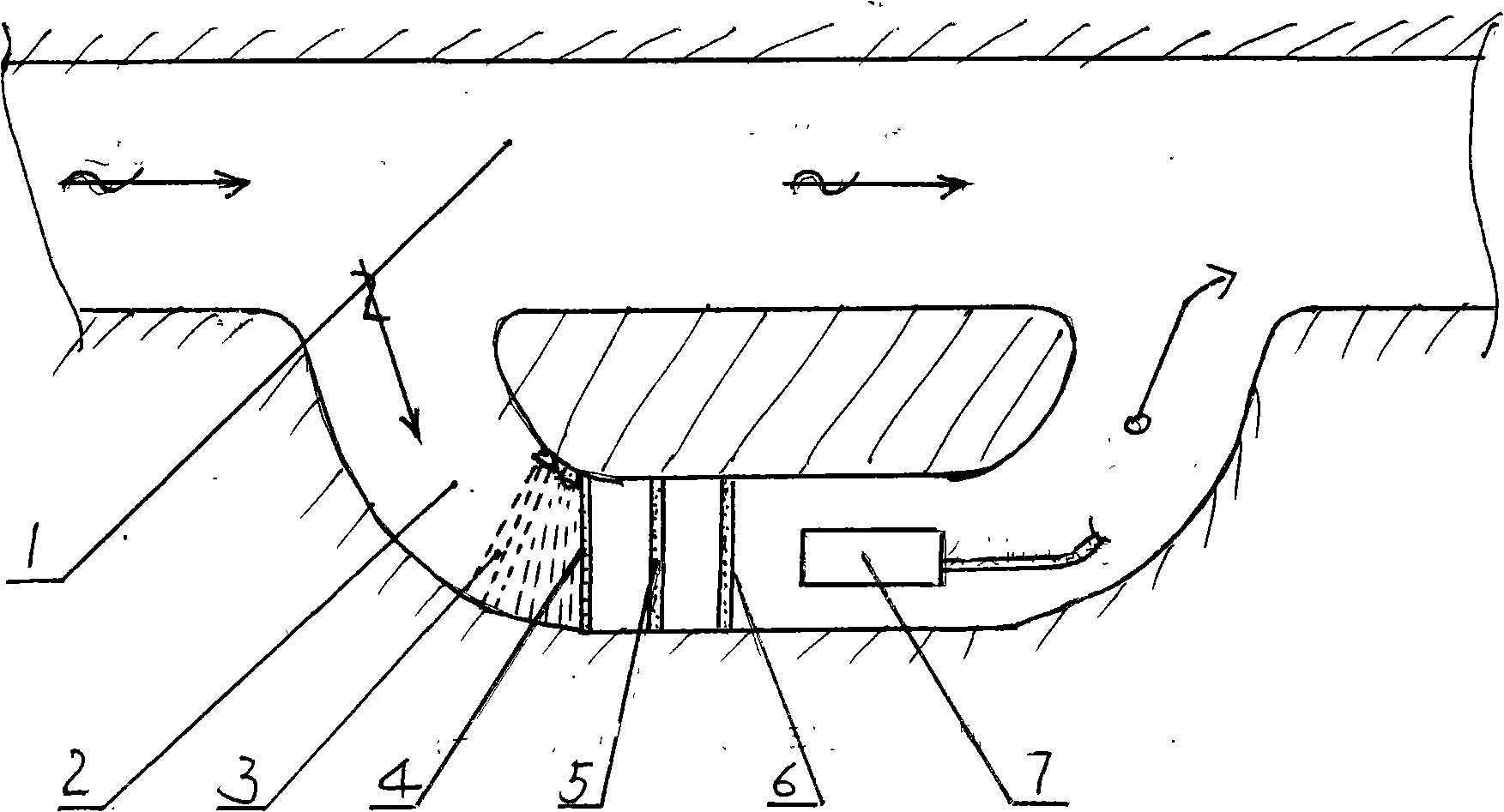

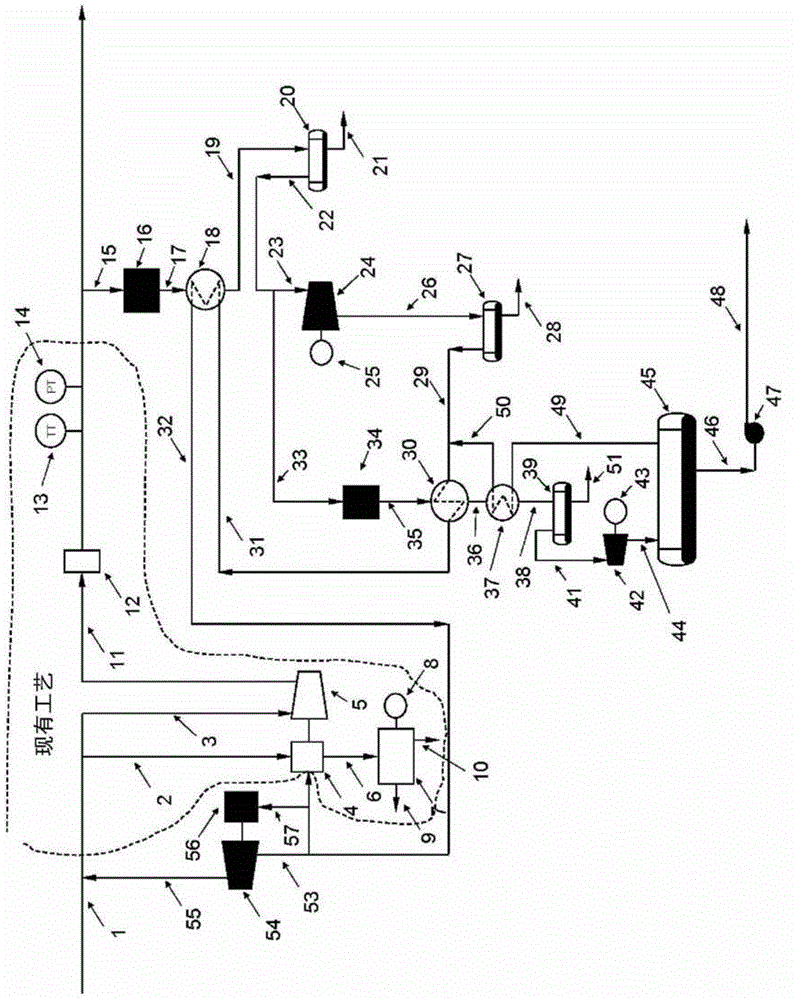

Method for performing circulating washing on lubricating oil of compressor station by using parallel pipeline

InactiveCN102451826AShort construction periodQuality improvementHollow article cleaningProcess engineeringLubrication

The invention discloses a method for performing circulating washing on lubricating oil of a natural gas large-scale compressor station by using a parallel pipeline, and relates to the technical field of lubrication and pipeline systems of variable capacity machines and common machines. A parallel pipeline structure is adopted by the washing method, a main pipeline filter screen front hand valve (3), a flange of a main pipeline filter net (7), and a main pipeline filter net rear hand valve (4) are sequentially arranged on the front part of a main pipeline (1) in an oil flowing direction; a side pipeline filter net front hand valve (5), a flange of a side pipeline filter net (8), and a side pipeline filter net rear handle valve (6) are arranged on the front part of a side pipeline (2) sequentially in an oil flowing direction; and the method comprises the following steps of: (1) installing a parallel pipeline and detecting the filter net; (2) washing oil of a system in a partitioned way; (3) performing circulating washing by using the parallel pipeline; and (4) recovering the pipeline. The method is short in washing duration, high in quality, small in lubricating oil loss, low in cost, high in efficiency, and easy to operate and control and slightly pollutes environment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

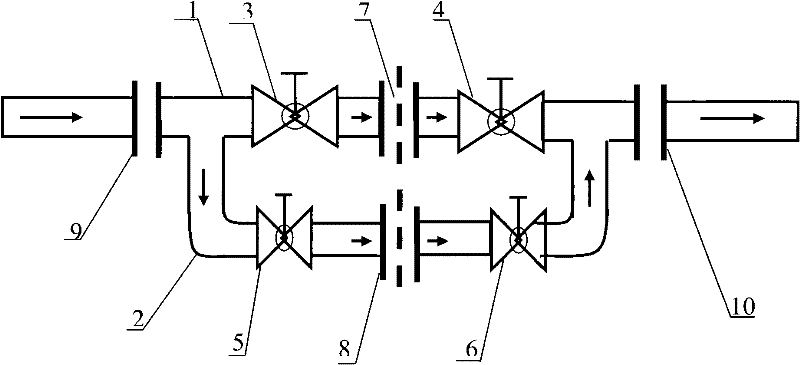

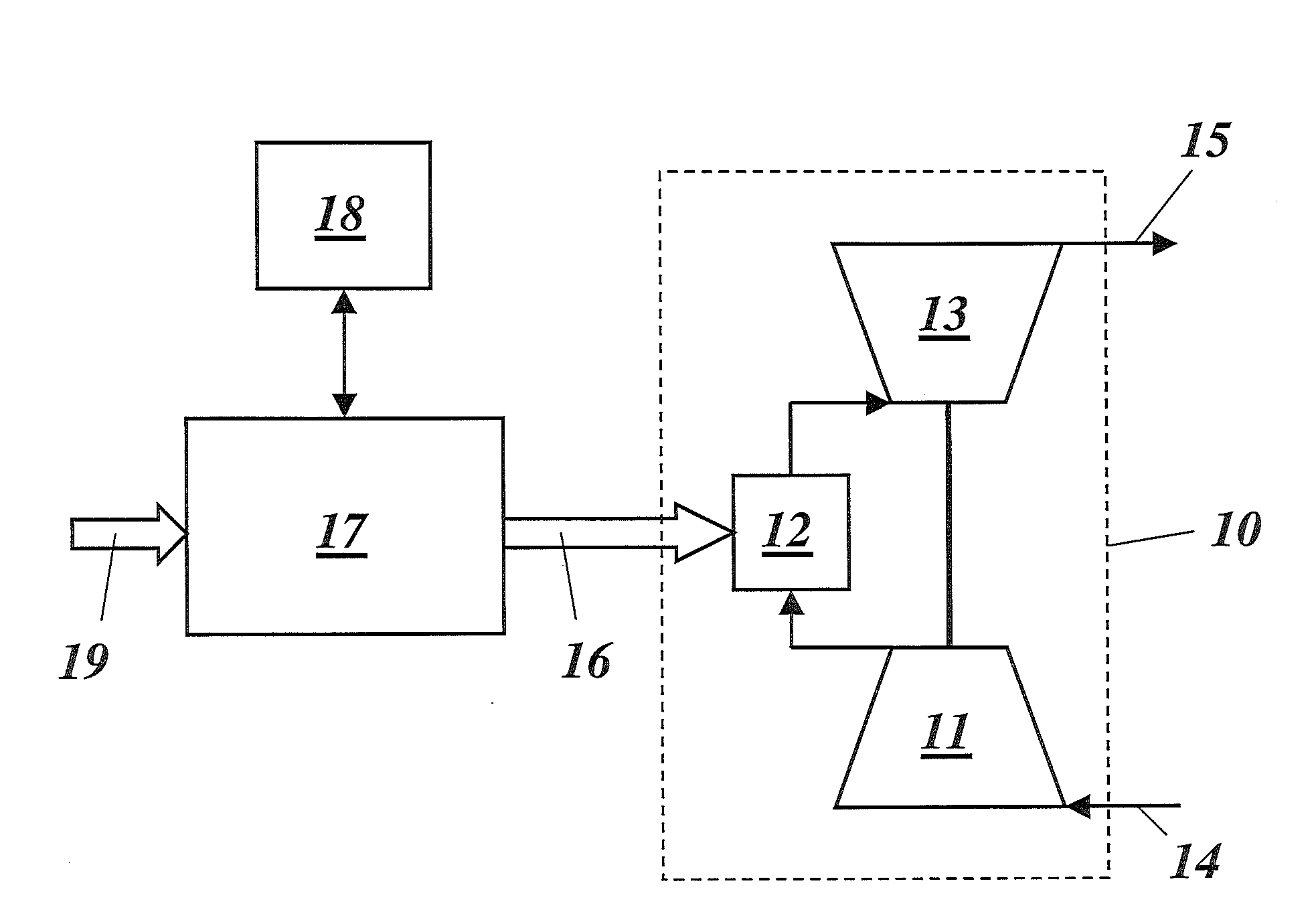

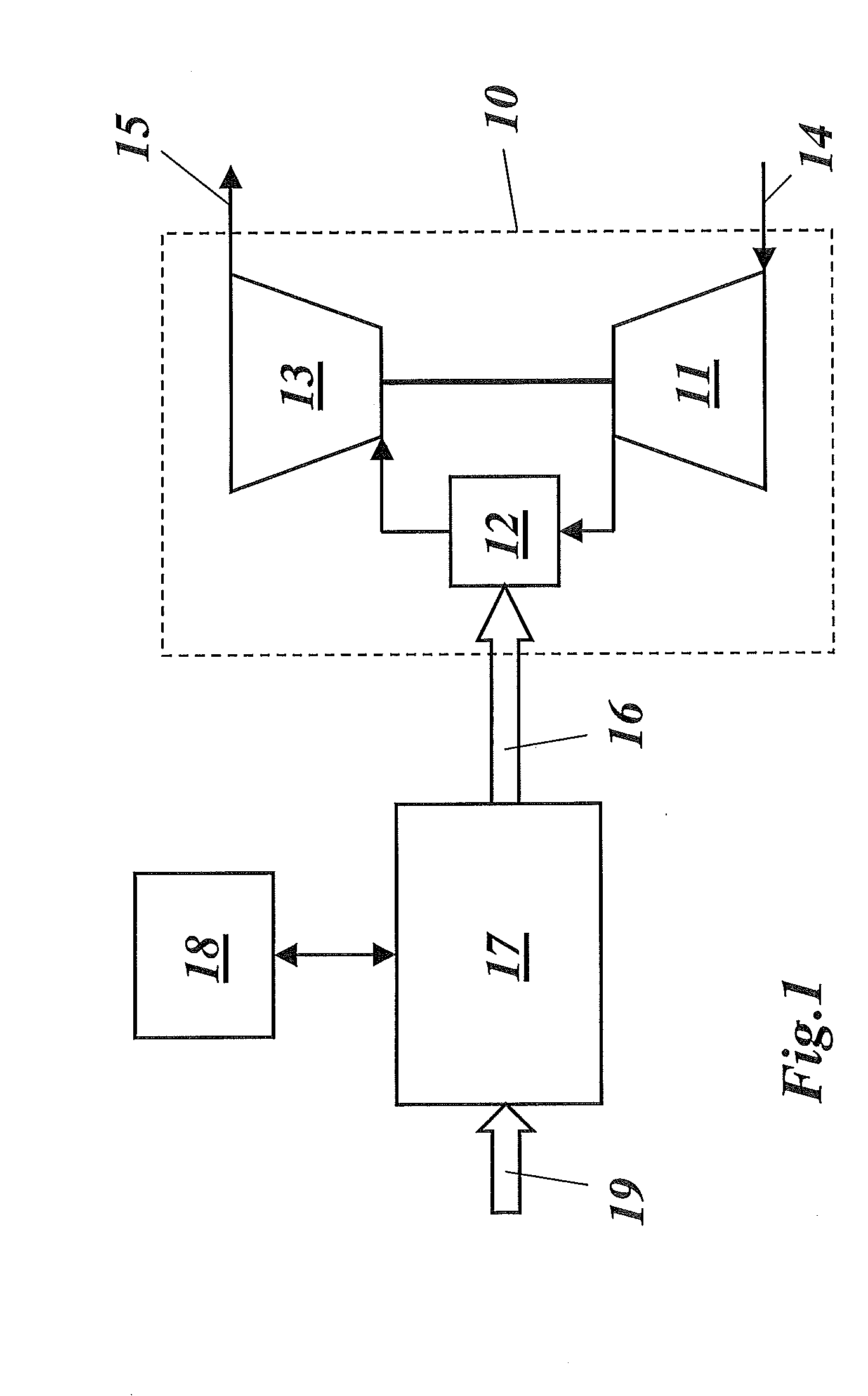

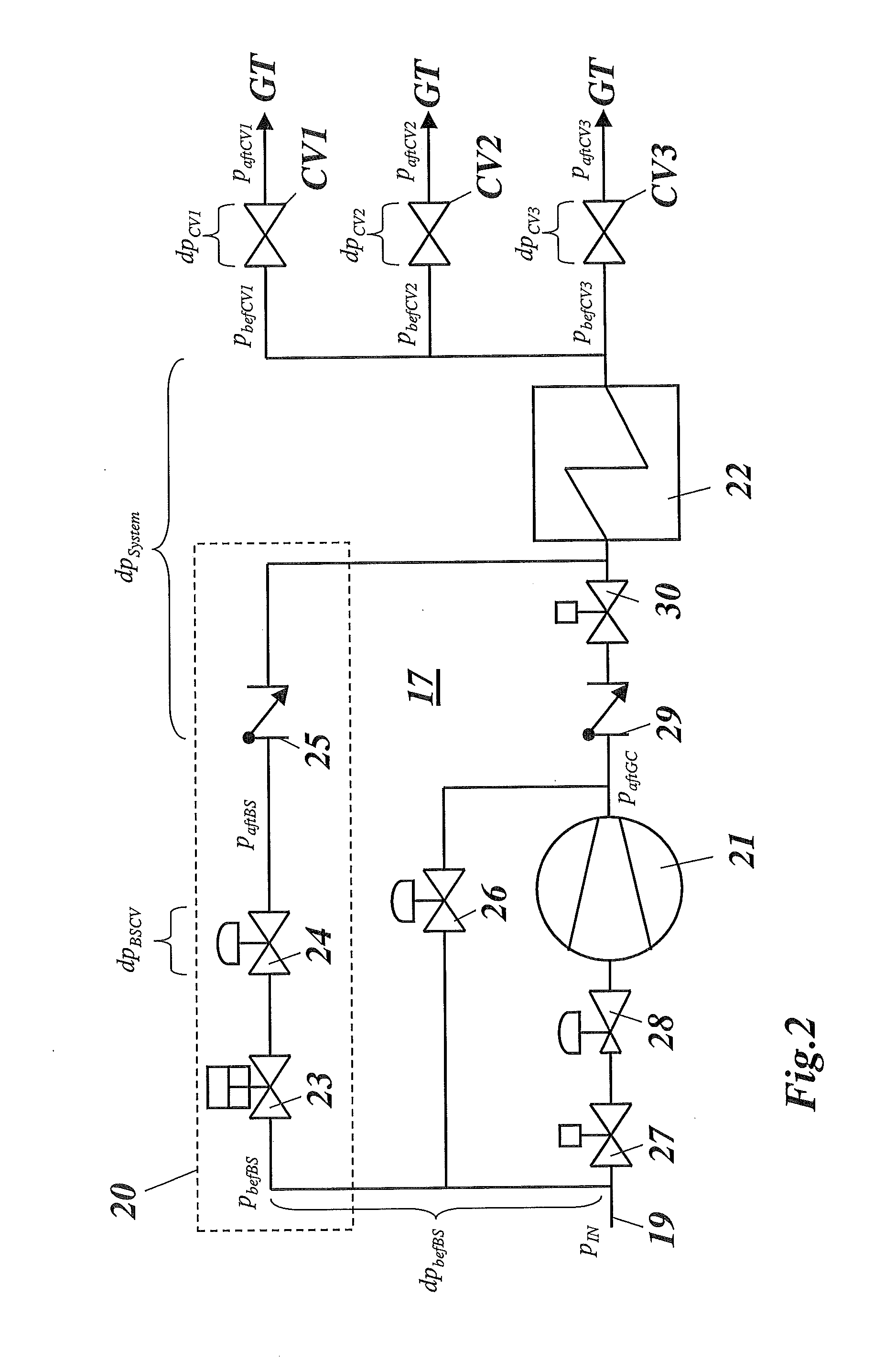

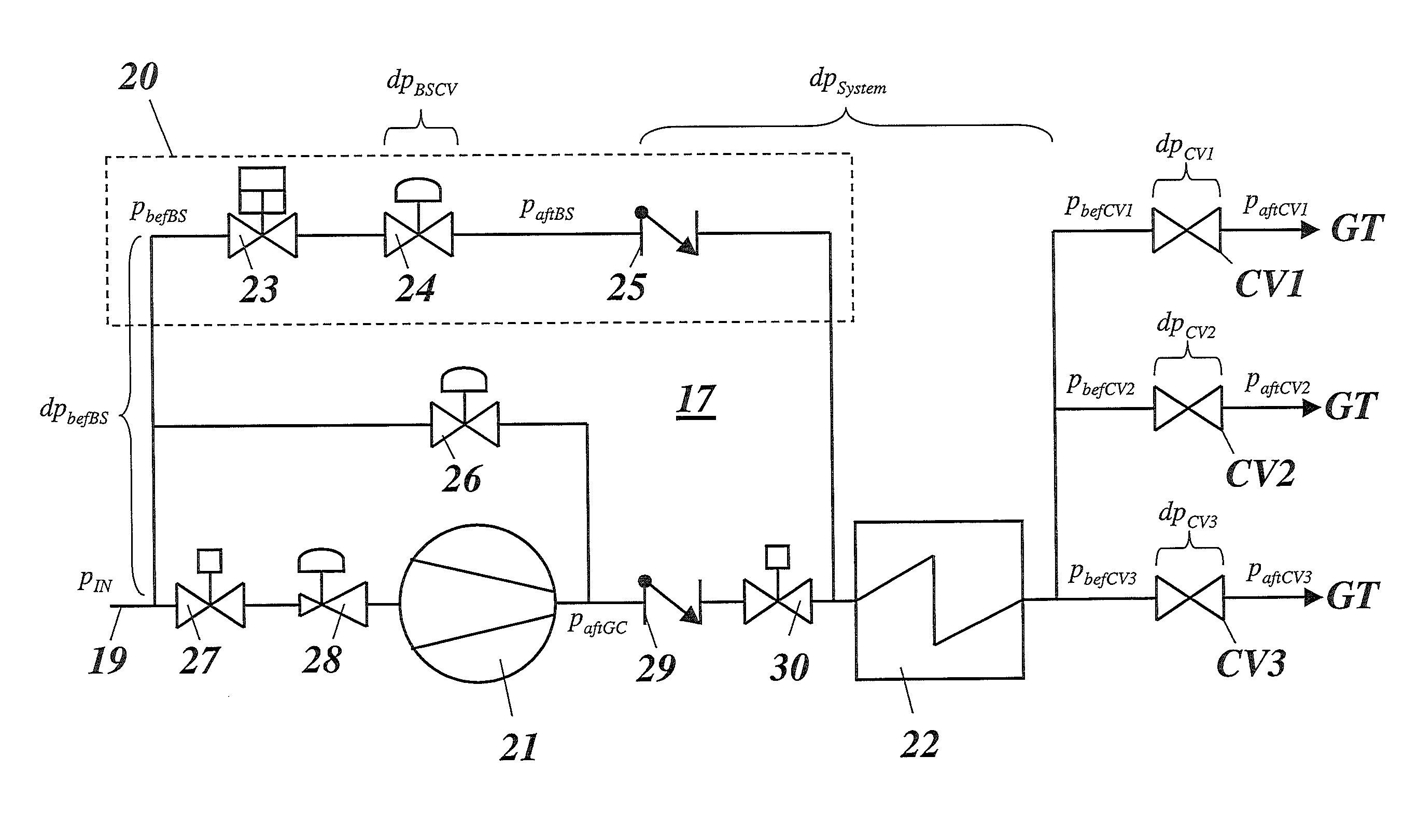

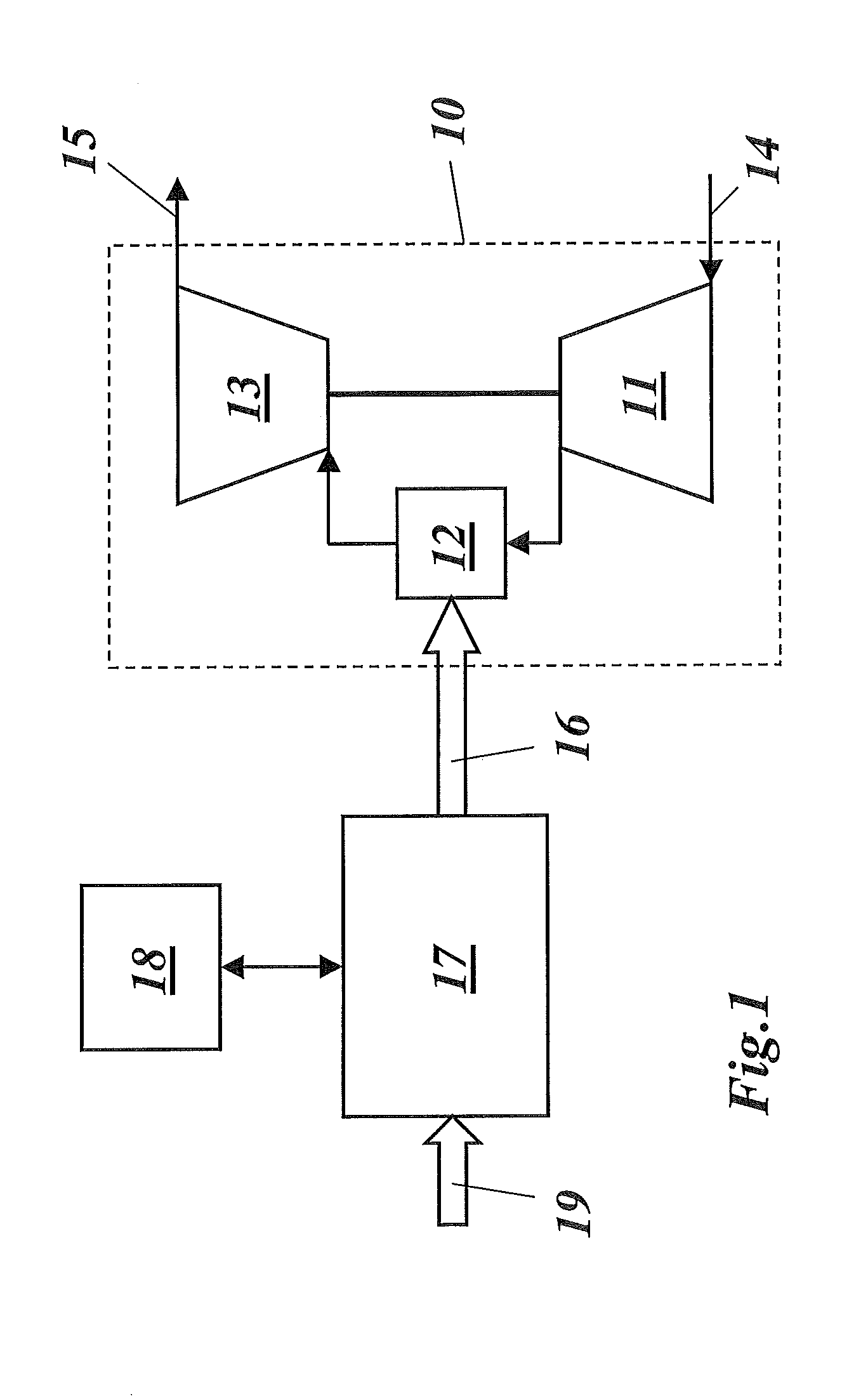

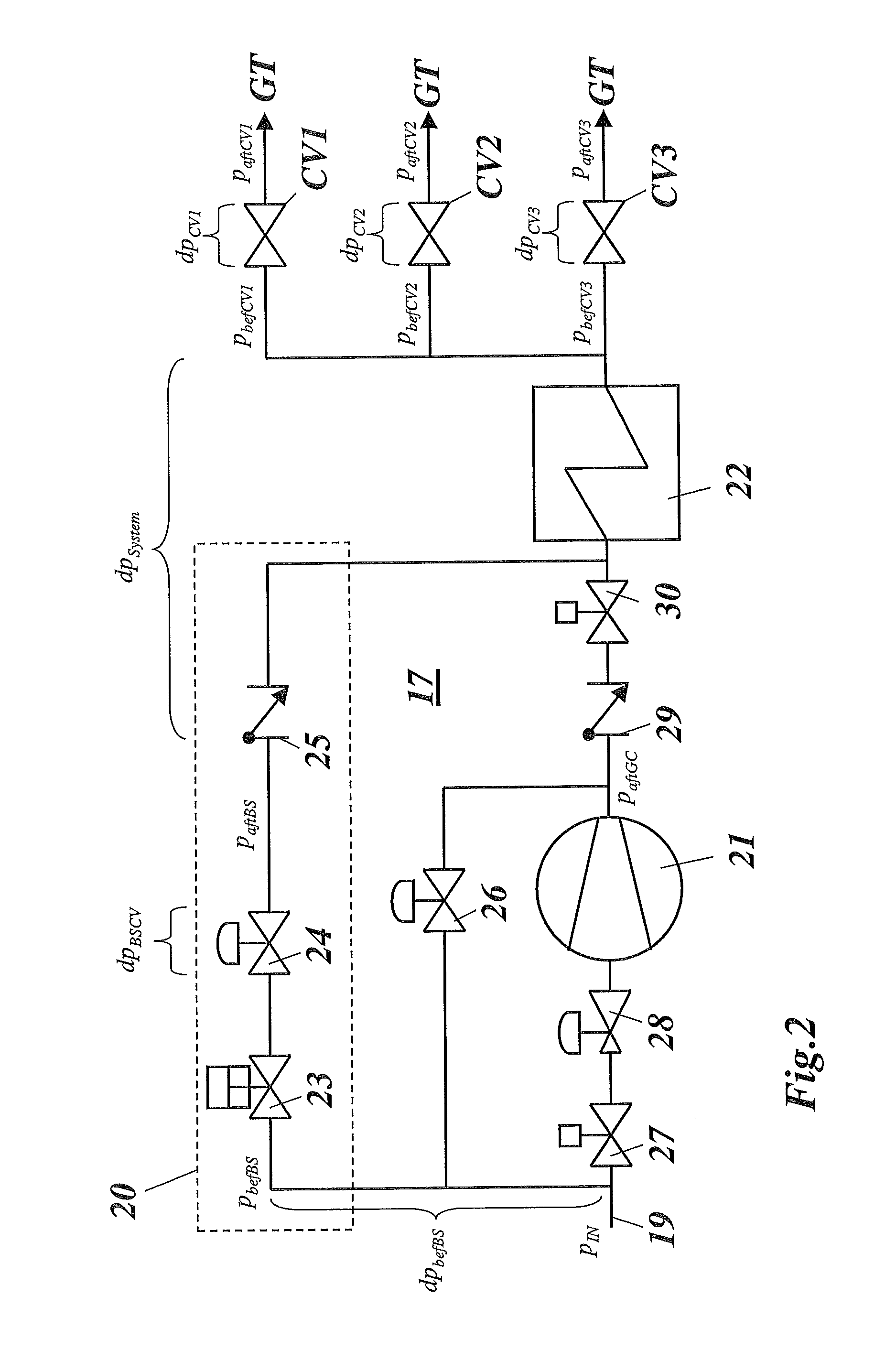

Method for operating a gas turbine plant with a compressor station for gaseous fuel

InactiveUS20100287945A1Fuel supply regulationTurbine/propulsion fuel supply systemsCombustion chamberProduct gas

The disclosure relates to a method for operating a gas turbine plant which is supplied with a fuel gas via a compressor station. The compressor station includes a compressor which compresses the fuel gas which is fed via a gas feed line and delivers it via at least one control valve to a combustion chamber of the gas turbine plant. A bypass system is arranged in parallel to the compressor via which fuel gas can be directed in a switchable manner past the compressor to the at least one control valve. An energy-saving operation can be achieved in a simple manner by continuously measuring the fuel gas pressure at the outlet of the at least one control valve. A minimum fuel gas pressure, which is desired (e.g., necessary) for operation of the gas turbine, at the inlet of the at least one control valve is determined from the measured pressure values in each case. The compressor station can be switched over to bypass operation when the fuel gas pressure which reaches the inlet of the at least one control valve via the bypass system is greater than or equal to the minimum fuel gas pressure.

Owner:ANSALDO ENERGIA IP UK LTD

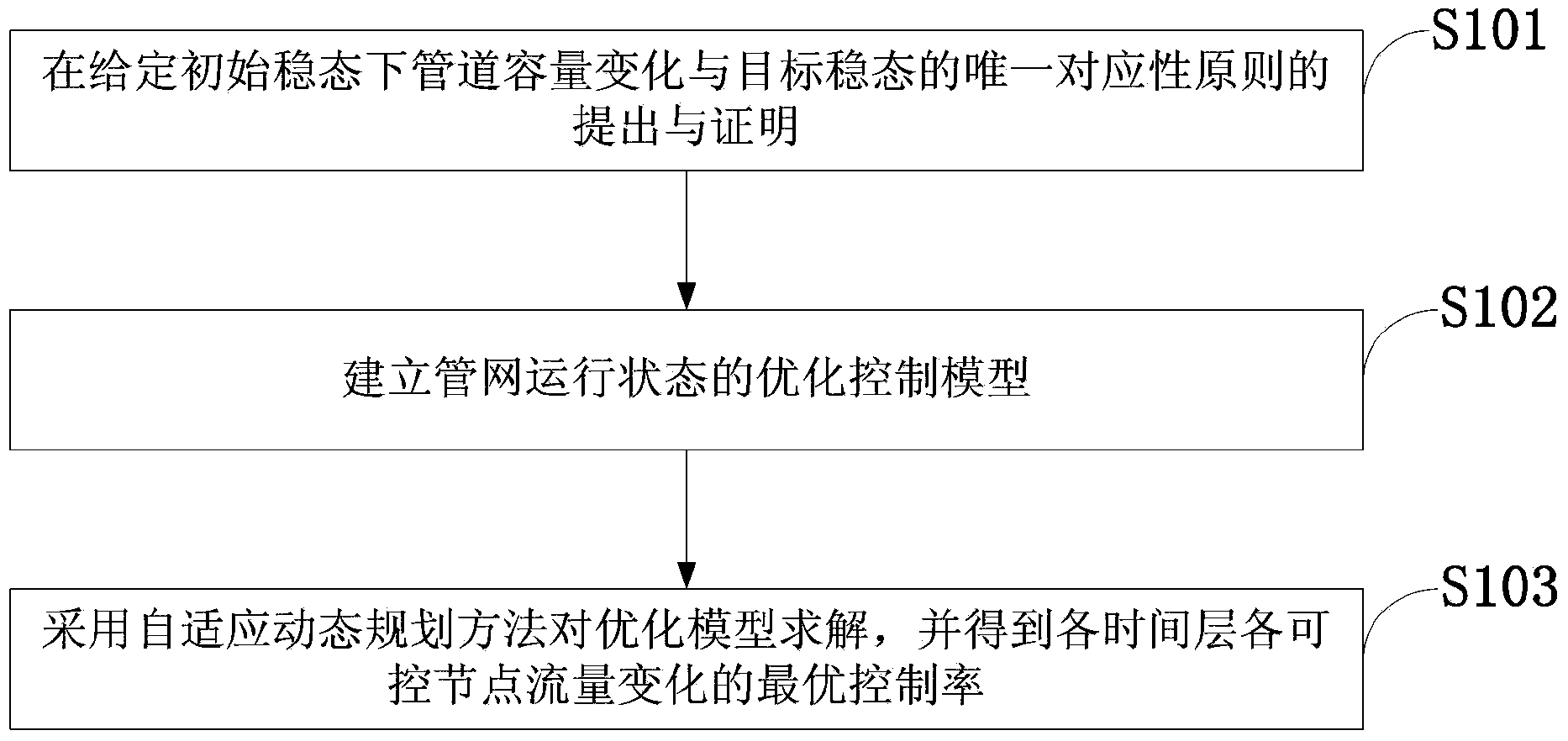

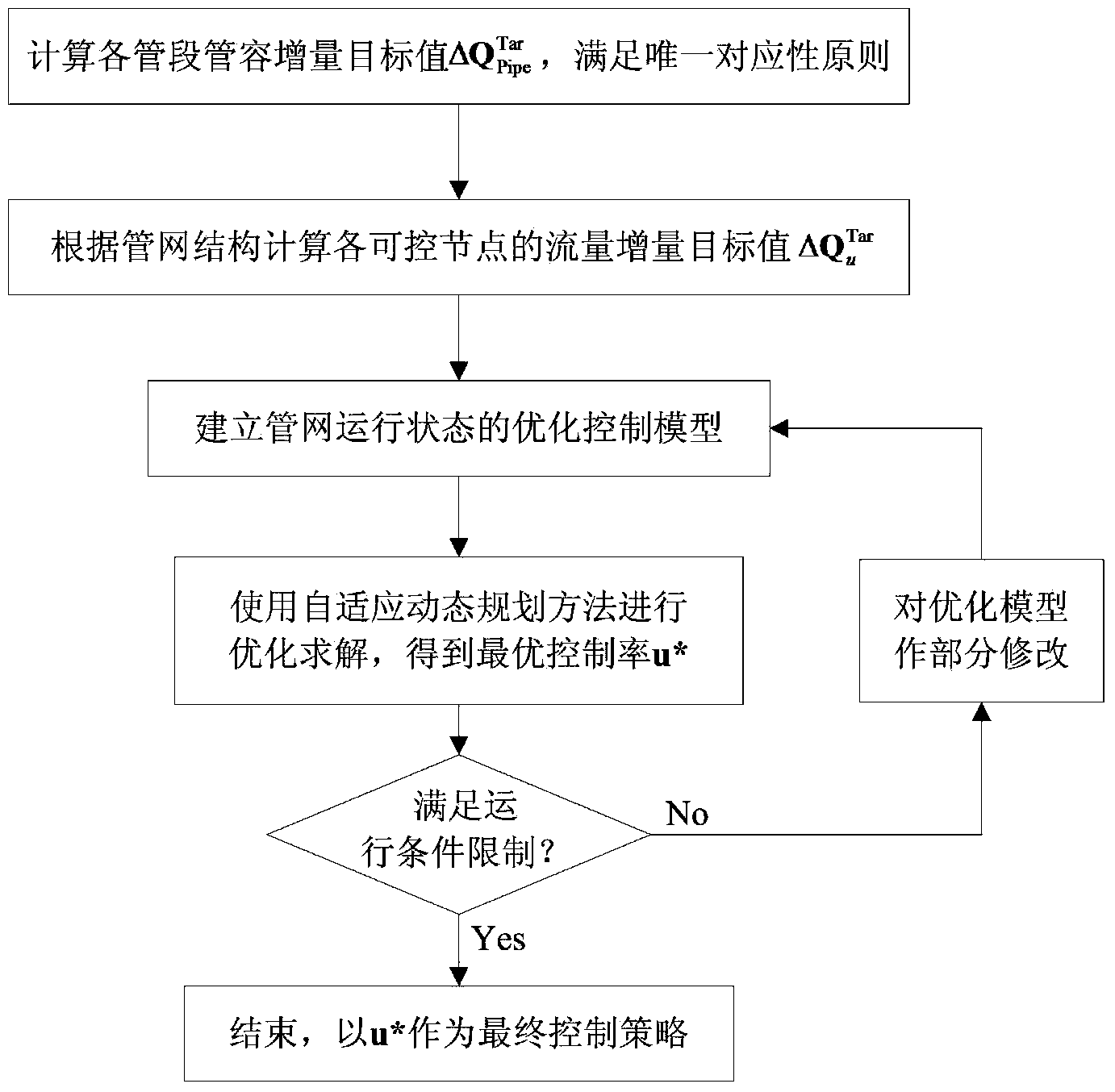

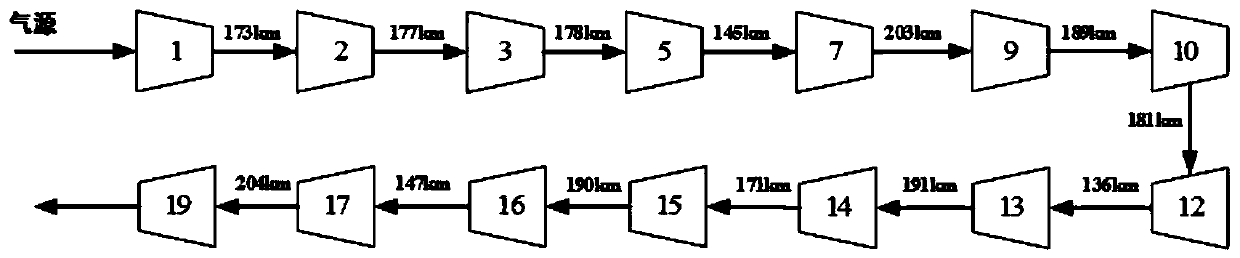

Natural gas pipeline network operation regulation and control method based on self-adaptive dynamic planning

The invention discloses a natural gas pipeline network operation regulation and control method based on self-adaptive dynamic planning. The natural gas pipeline network operation regulation and control method based on self-adaptive dynamic planning includes the steps of: putting forward and proving a principle of unique correspondence of a pipe capacity change and a target steady state in a given initial steady state; establishing an optimization control model of a pipeline network operating state; and adopting a self-adaptive dynamic planning solving algorithm. The natural gas pipeline network operation regulation and control method in the invention considers both operating conditions and technological operation constraints of compressor stations in a process of determining a control strategy, satisfies the unique correspondence principle that is put forward, and thus is feasible. The natural gas pipeline network operation regulation and control method based on self-adaptive dynamic planning in the invention considers the overall situation, considers pipe capacity variation of all pipe sections in the pipeline network system, and formulates a flow control strategy of all compressor stations in a unified manner, and thus does not need to consider mutual influence of the compressor stations in a regulation process.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

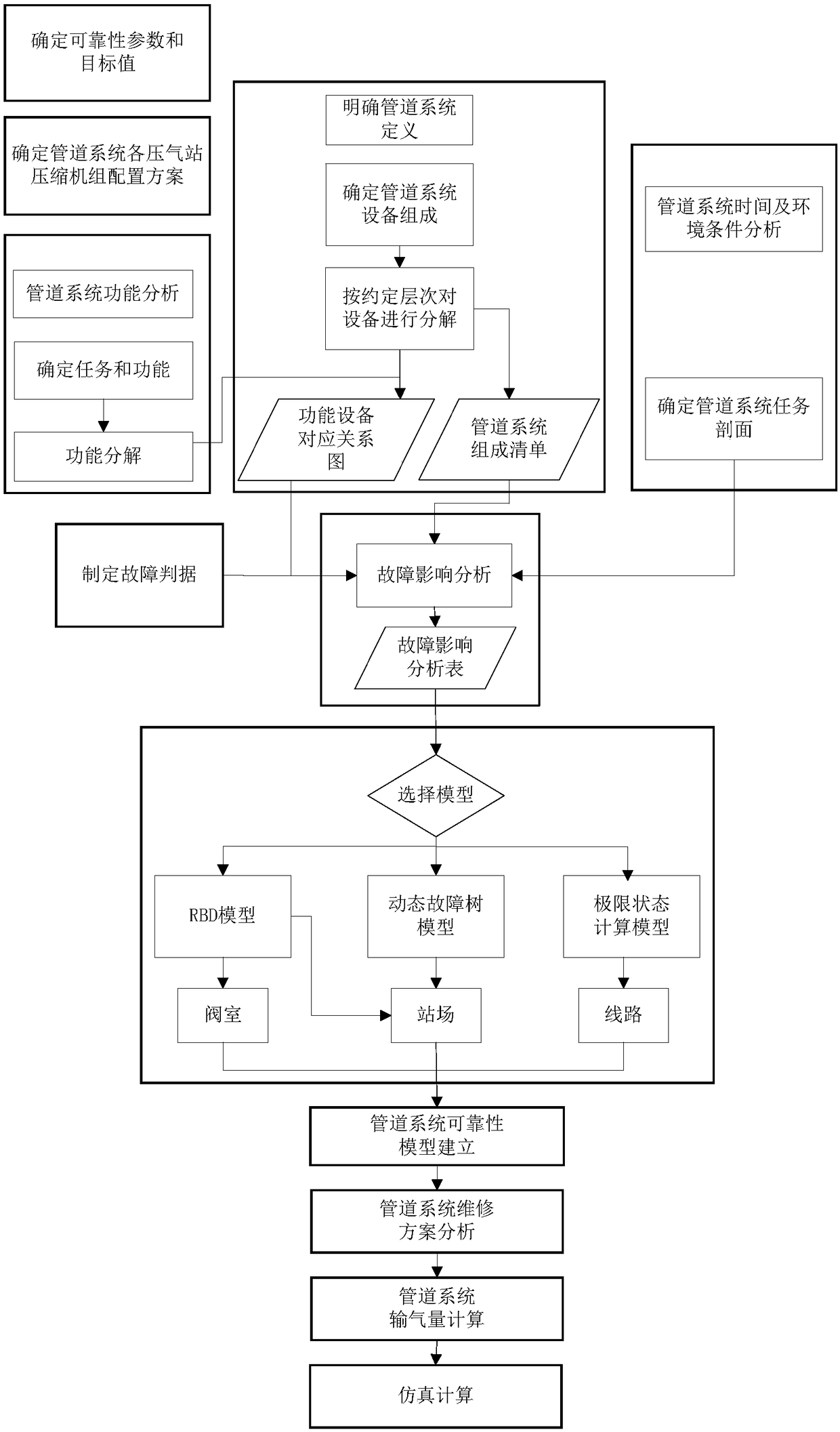

Design method of natural gas pipeline compressor standby unit

InactiveCN108090304AIncrease profitLess investmentProbabilistic CADSpecial data processing applicationsDecompositionReliability model

The invention discloses a design method of a natural gas pipeline compressor standby unit. The method includes the steps of firstly, determining the reliability parameter of a pipeline system and thetarget value of the reliability parameter of the pipeline system; secondly, determining the configuration scheme of each compressor station compressor unit of the pipeline system; thirdly, analyzing the tasks and functions of the pipeline system; fourthly, determining the equipment composition of the pipeline system, and performing level decomposition on equipment according to set level to obtaina pipeline system composition list; fifthly, analyzing the working time and environment conditions of the pipeline system, and determining the task profile of the pipeline system; sixthly, making fault criteria; seventhly, acquiring a fault influence analysis table; eighthly, building the reliability model of a valve chamber, a station field and a circuit part; ninthly, building the reliability model of the pipeline system; tenthly, analyzing a maintenance scheme; eleventhly, calculating the gas delivery capacity of the pipeline system; twelfthly, performing reliability simulation. The methodhas the advantages that the reliability indexes of the pipeline system are comprehensively reflected, investment is reduced, and unit utilization rate is increased.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

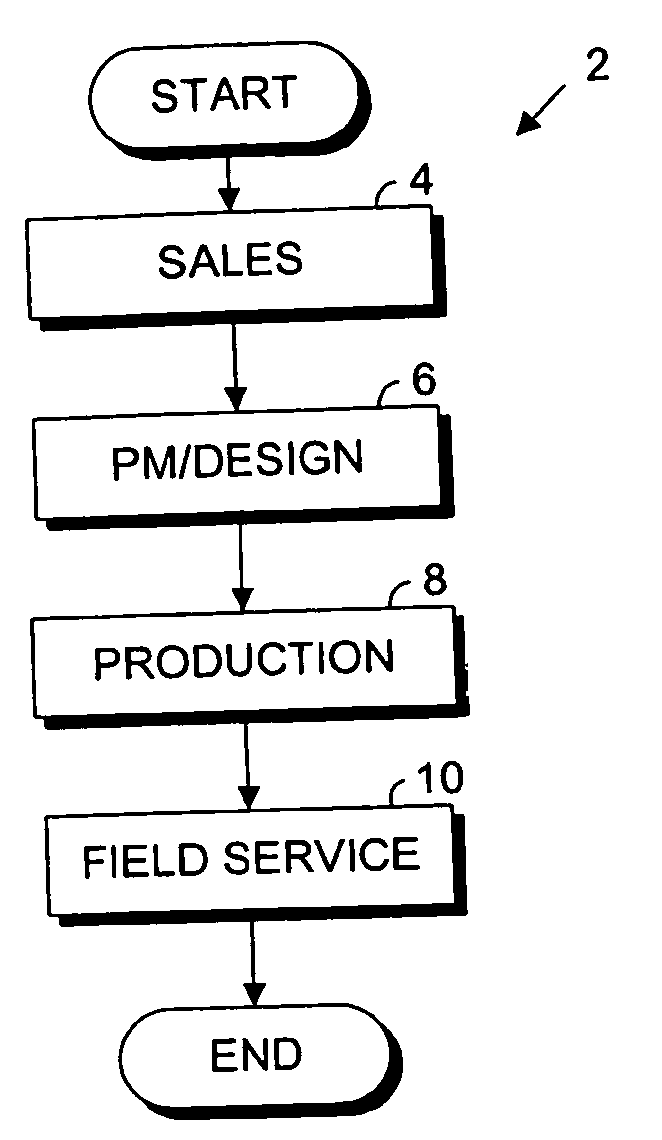

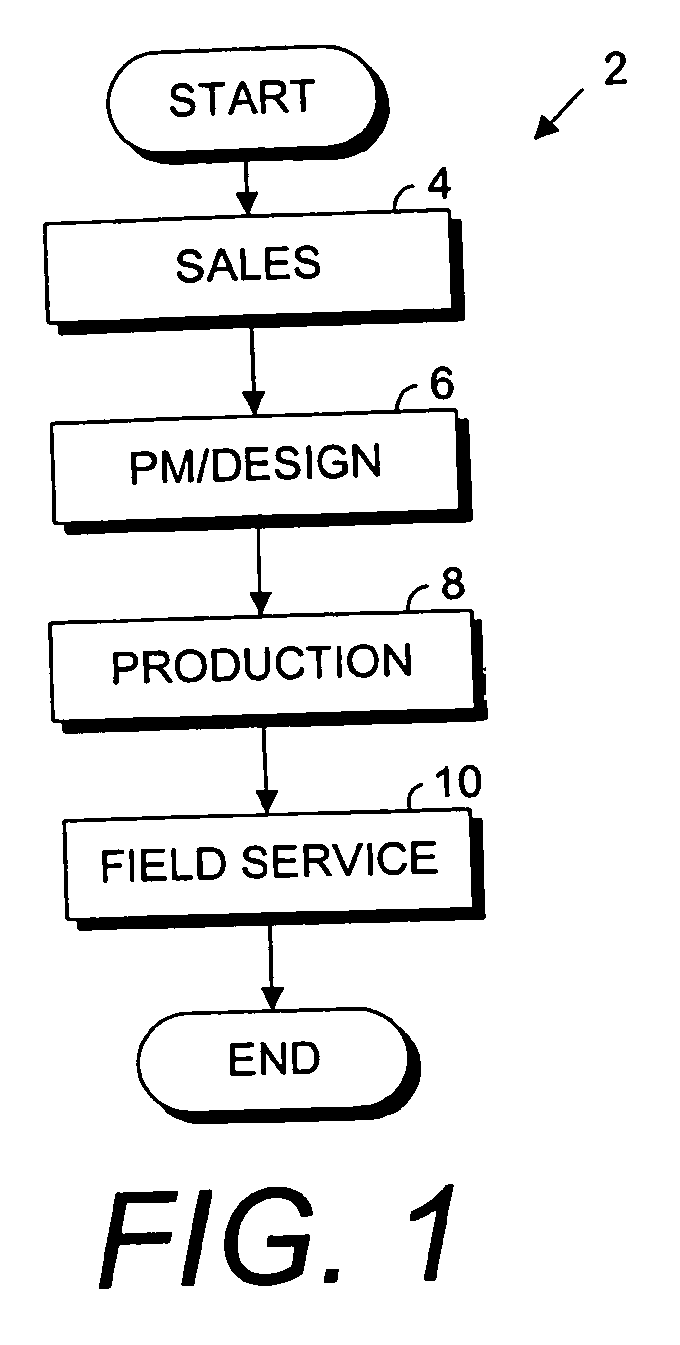

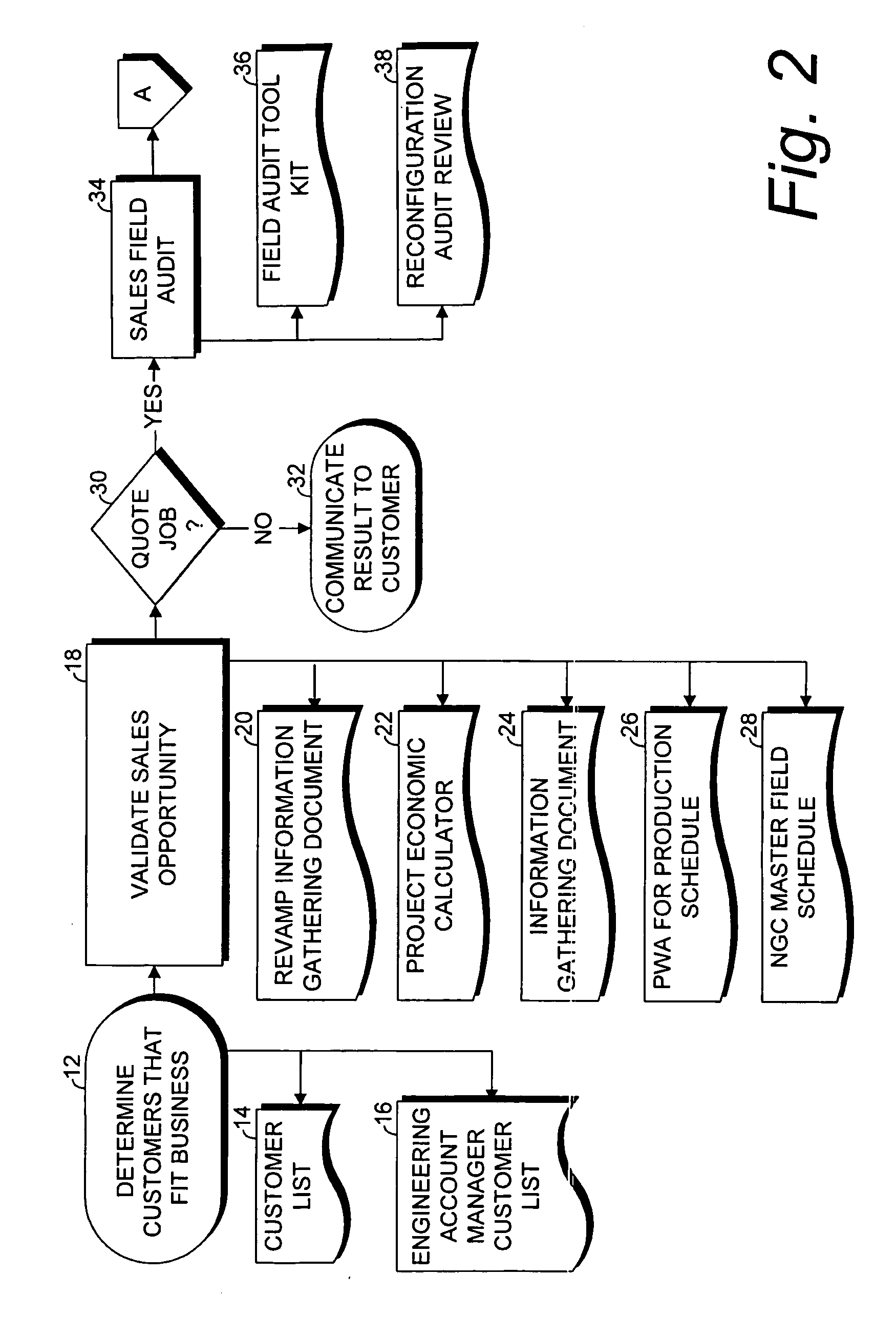

Equipment retrofitting project method

InactiveUS20090319308A1Minimize on-site activityImprove accuracyResourcesDesign phaseProject management

An equipment retrofitting project method includes the steps of conducting sales, project management (PM) / design, production and field service phases. The PM / design phase includes the steps of providing a coordinate measuring machine (CMM) and measuring spatial and dimensional coordinates of natural gas compressor station components with the CMM at the compressor station location. The coordinates are related to a reference at the compressor station location. Output is provided from the CMM in the form of part coordinate system (PCS) data comprising the spatial and dimensional data associated with the components and a 3-D model is created from the PCS data. In the production phase new and / or refurbished components are produced utilizing the PCS data at a location remote from the equipment. In the field service phase the new or refurbished components are installed in the equipment.

Owner:NGC COMPRESSIONS SOLUTIONS

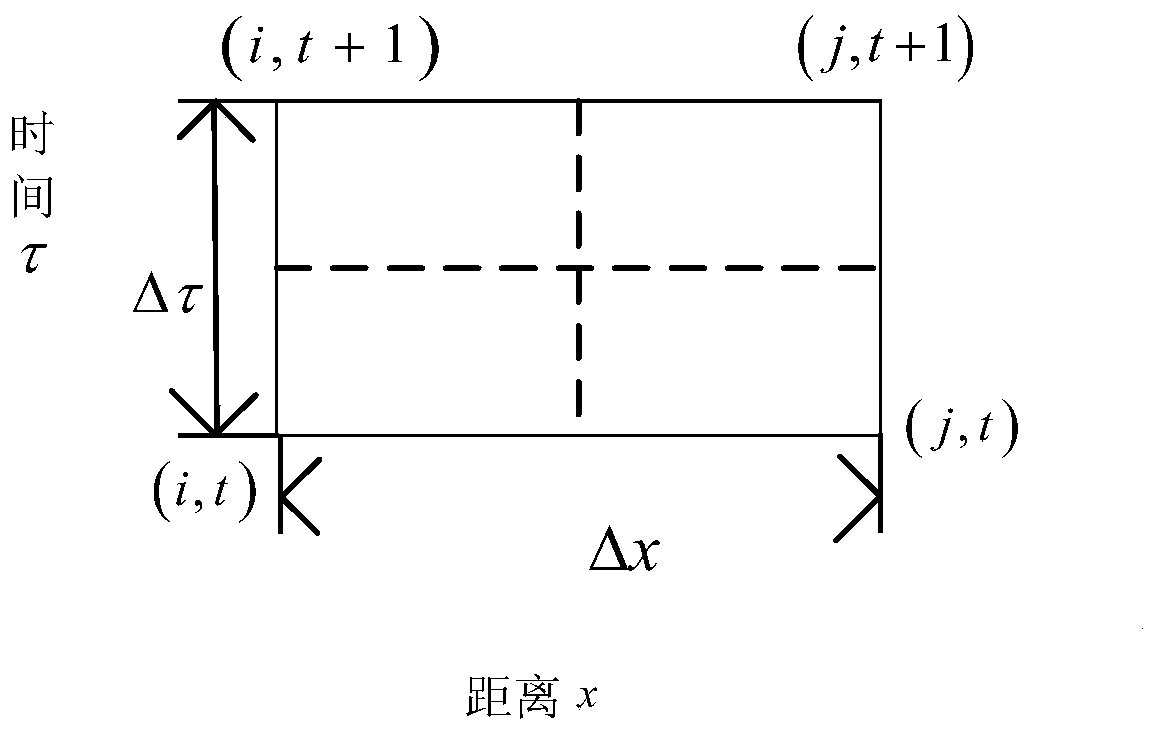

Natural gas pipeline transient operation optimization method

InactiveCN110717632AFast solutionAvoid frequent switchingForecastingControl engineeringProcess engineering

The invention discloses a natural gas pipeline transient operation optimization method, which comprises the steps of establishing a transient optimization model comprising compressor operation energyconsumption and compressor switch cost, and selecting compressor station outlet pressure changing with time and the number of started compressor stations as optimization variables by the transient optimization model; establishing constraint conditions of the transient optimization model, wherein the constraint conditions comprise transient natural gas pipeline constraints, node constraints, compressor and station yard constraints and terminal conditions; solving the transient optimization model through a heuristic algorithm to obtain an optimal feasible solution; and the natural gas pipeline operating by utilizing the optimal feasible solution to realize transient optimization. The transient optimization model is high in solving speed, frequent opening and closing of the compressor can beavoided, and the opening and closing cost of the compressor is reduced. The problem that in order to reduce energy consumption, the pipe stock is excessively utilized, and the output is reduced is avoided, and stable operation of the natural gas pipeline system is guaranteed.

Owner:SOUTHWEST PETROLEUM UNIV

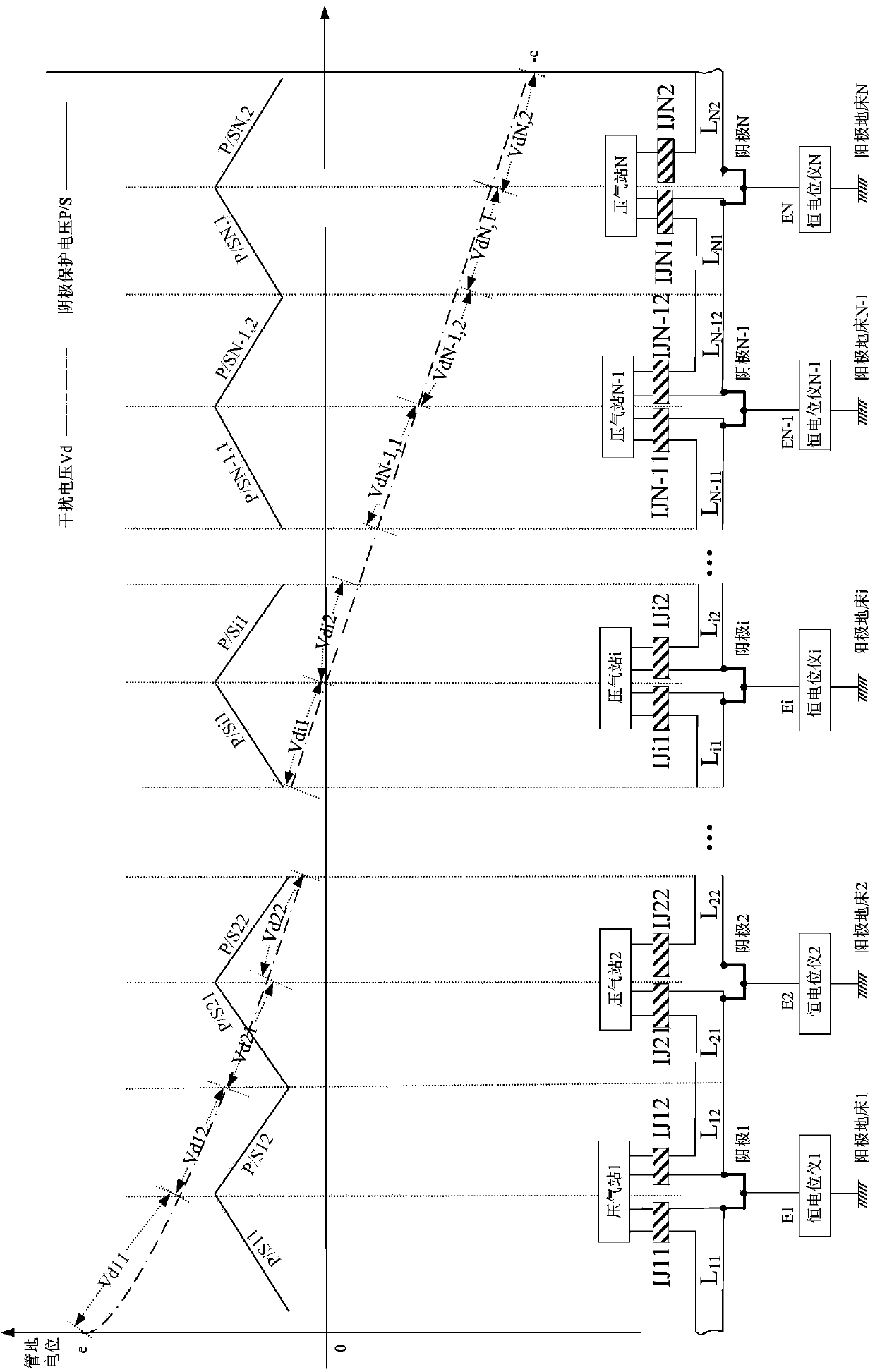

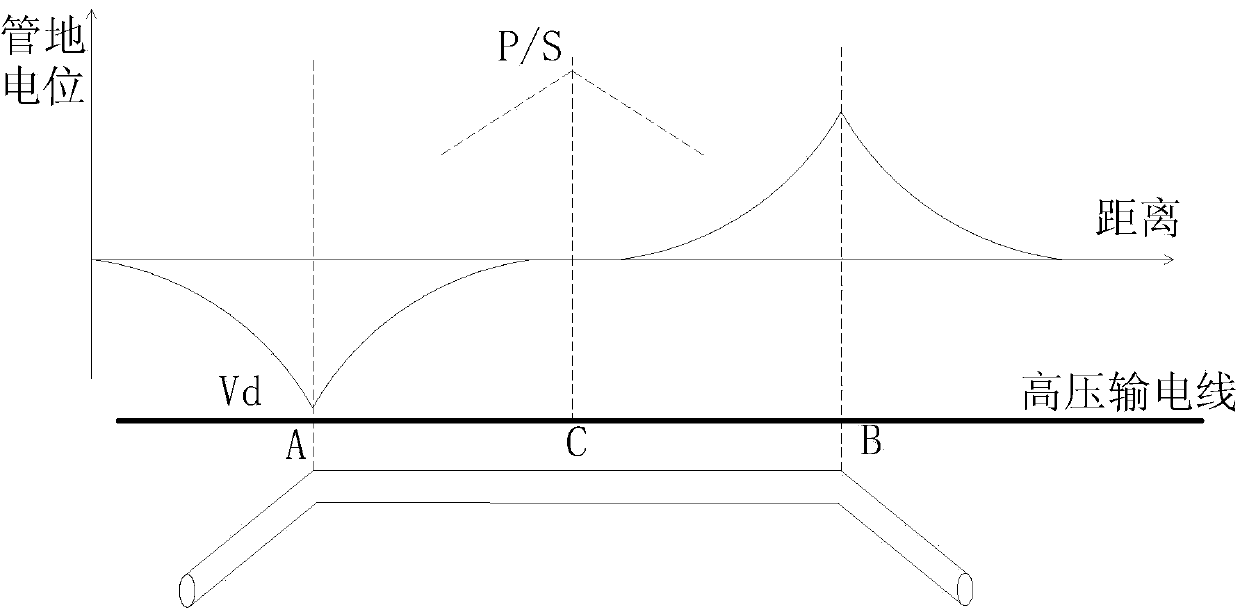

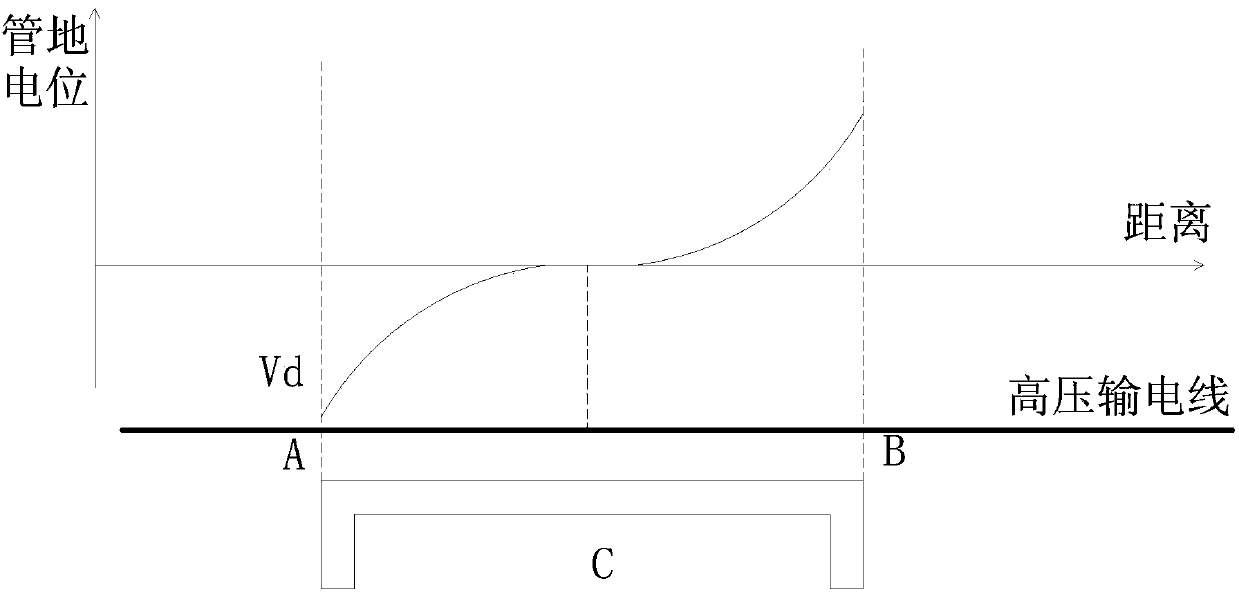

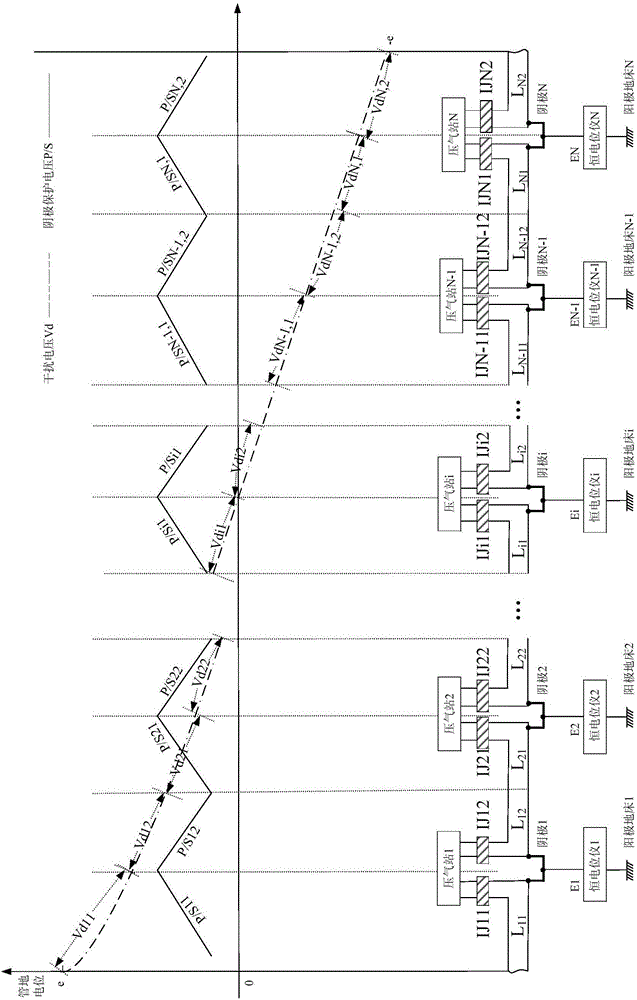

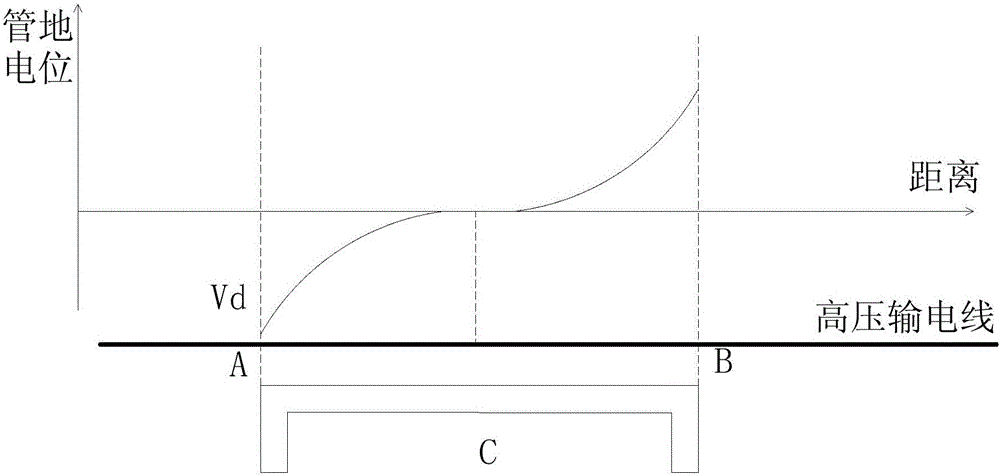

Generalized impulse cathodic protection system and generalized impulse constant potential rectifier thereof

The invention provides a generalized impulse cathodic protection system and a generalized impulse constant potential rectifier thereof. The generalized impulse constant potential rectifier comprises a pipe-to-soil potential measurement unit, a controller, an adjustable direct current power supply, an impulse output control unit and an impulse polarity control unit, wherein the impulse polarity control unit converts direct current impulse voltage output by the impulse output control unit into direct current impulse voltage output which is opposite to the polarity of an interfering pipe-to-soil potential. The system comprises the generalized impulse constant potential rectifiers, wherein two output ends of every two generalized impulse constant potential rectifiers are electrically connected with the external surfaces at the two ends of inlet and outlet buried metal pipeline sections of a compressor station respectively and correspondingly; two earthing terminals of every two generalized impulse constant potential rectifiers are connected with a generalized anodic groundbed; and the buried metal pipeline sections are electrically insulated with the adjacent buried metal pipeline sections. The system can exert an external stray current interference resistance effect, and can convert the impulse polarity to adapt to eliminate external stray current interference in any polarity.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Wind pressuring arrangement method of deep well and mine

InactiveCN101328812AAvoid lostGuaranteed air supply needsTunnel/mines ventillationAir filterDistribution method

The invention discloses a distribution method of underground high-pressure air, which is applicable to the distribution of high-pressure air needed by pneumatic devices and tools in the operations of underground excavation and passageway reconstruction, etc. The invention adopts a proposal that a compressor station is arranged inside a branch return airway which is connected in parallel to a main return airway, and a filtering apparatus is arranged at the intake side of the compressor to filter the ventilation air methane to change the ventilation air methane into clean air which meets the standards required by the compressor. The filtering apparatus is provided with three air valves which are arranged in the intake airway of the compressor, wherein, the space between the air valves is 3 to 5 meters; a water curtain is arranged at the first air valve; each air valve is provided with an air filter screen. The distribution method of underground high-pressure air in the invention is capable of improving the efficiency of the underground air compressor system, improving the working environment of the compressor, and ensuring the supply of the high-pressure air without consuming the fresh air underground.

Owner:滕广林 +1

Modular compressed natural gas system for use at a wellsite

A system and method of receiving field gas from a compressor station pipeline, and compressing the gas at a remote location with a modular compressor. The compressed gas is collected in a container and transported to a wellsite for use at the wellsite. The gas from the pipeline is directed to the container, and diverted to the modular compressor when pressure in the container approaches pressure in the pipeline. The modular compressor discharge is piped to the container, so that the container is filled with additional gas and at the discharge pressure of the modular compressor.

Owner:BAKER HUGHES INC

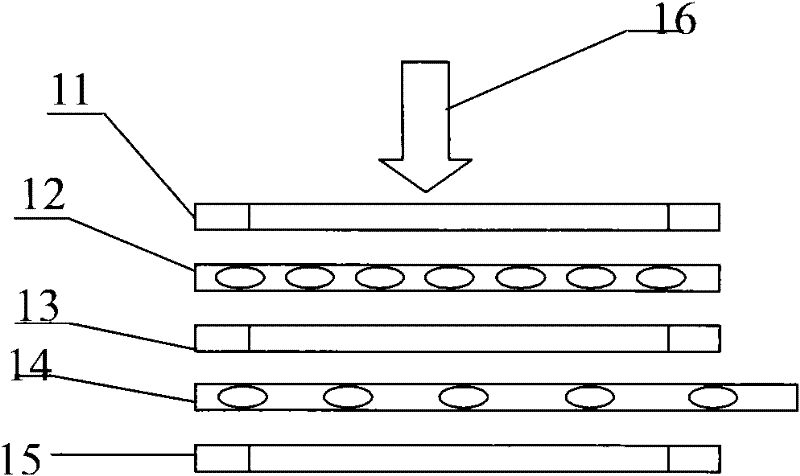

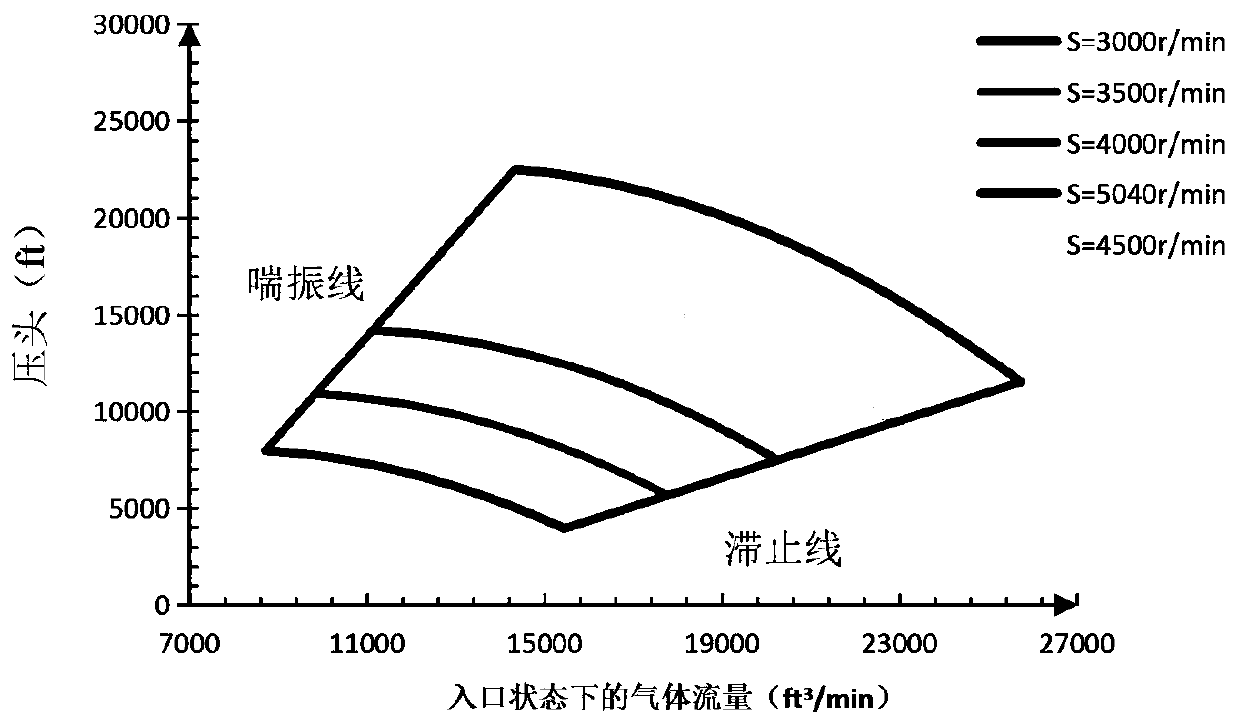

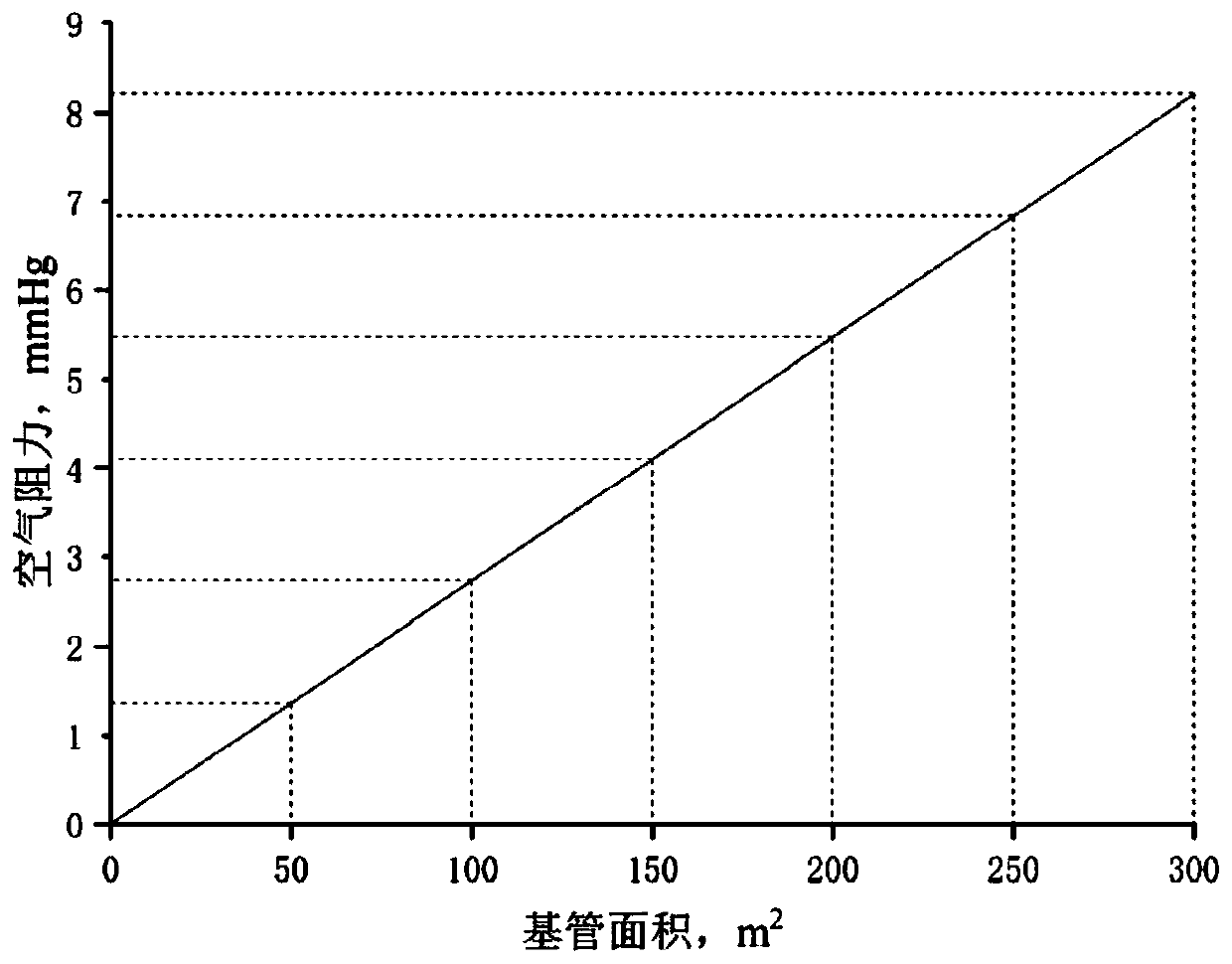

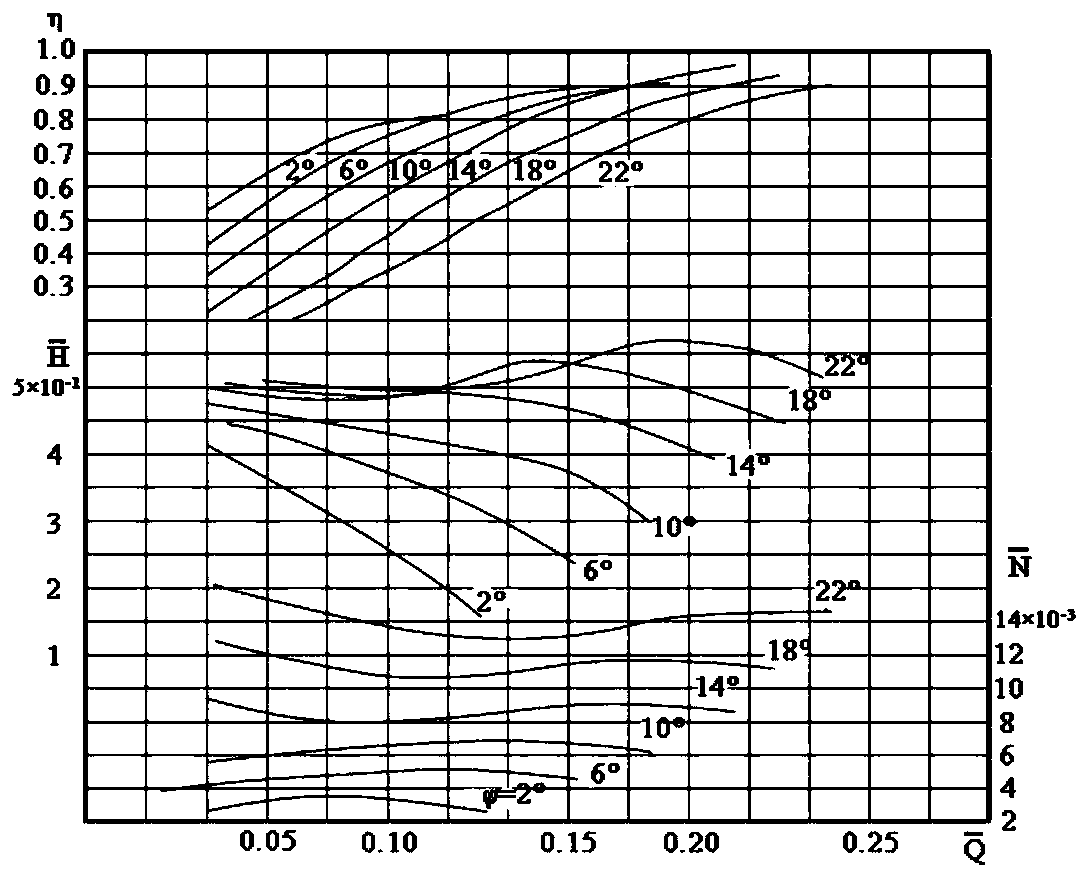

Natural gas pipeline steady-state operation optimization method considering influence of air cooler

ActiveCN110489708AIncrease the number of bootsIncrease the difficulty of solvingPipeline systemsComplex mathematical operationsAir compressionProcess engineering

The invention discloses a natural gas pipeline steady-state operation optimization method considering the influence of an air cooler. The minimum sum of the energy consumption of a compressor unit andthe energy consumption of an air cooler unit is taken as an objective function. The sum of the energy consumption of the compressor unit and the energy consumption of starting the air cooler unit ineach air compression station is taken as the energy consumption of each station. The total number of the air compression stations is set to be n, and the total energy consumption of the whole long-distance pipeline is the sum of the energy consumption of each station. According to the method, the energy consumption of the air cooler is added into the optimization model for the first time. The coupling relation among the air cooler. The compressor and the pipeline system is considered. The method is more suitable for on-site practice. Meanwhile, the number of started air coolers is increased toserve as an optimization variable. The performance constraint of the air coolers is increased. The model solving difficulty is greatly increased. The optimization scheme obtained according to the model can greatly reduce the energy consumption of the whole line compressor station.

Owner:SOUTHWEST PETROLEUM UNIV +1

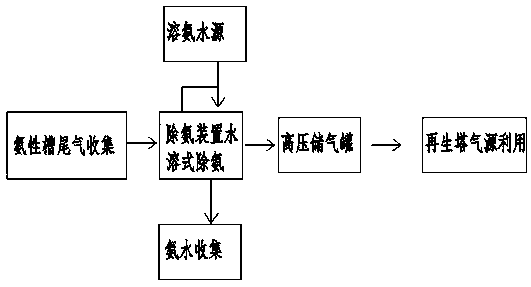

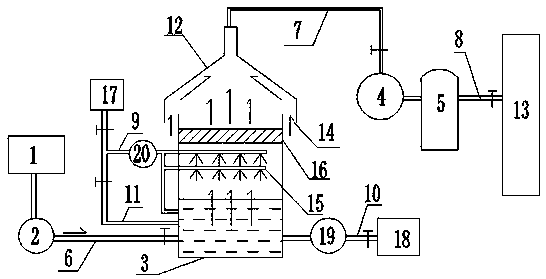

Method and device for treating tail gases of ammonia tanks of coking plant

PendingCN109173615AGood governanceReduce manufacturing costGas treatmentDispersed particle separationEngineeringProcess engineering

The invention discloses a method and a device for treating tail gases of ammonia tanks of a coking plant. All tail gases of ammonia tanks of the coking plant are treated and then are directly used ina regeneration tower for production. The device comprises a tail gas collection port, a fan, a water dissolving and ammonia collecting gas tank, a gas compressor and a high-pressure storage tank whichare sequentially connected, a gas inlet is arranged at the bottom of the water dissolving and ammonia collecting gas tank and is connected with the fan, the tail gases are introduced to the bottom ofthe water dissolving and ammonia collecting gas tank through the fan and a pipeline and undergo water dissolving ammonia removal, a gas collector is arranged at the upper part of the water dissolvingand ammonia collecting gas, a gas released after dissolving ammonia in the tail gases with water in the water dissolving and ammonia collecting gas tank rises to the gas collector, is mixed with air,and then is connected with the gas compressor through a pipeline II, the gas compressor compresses the gas into the high-pressure storage tank for storage, and the high-pressure storage tank substitutes an compressor station to supply the gas to the regeneration tower. The whole method and the device have the advantages of reasonable constitution, maximal utilization of resources of the coking plant without or slightly increasing the energy consumption, effectiveness in treatment of the tail gases of the ammonia tanks, and achieving of the purposes of energy saving and consumption reduction.

Owner:山东环达环保科技有限公司

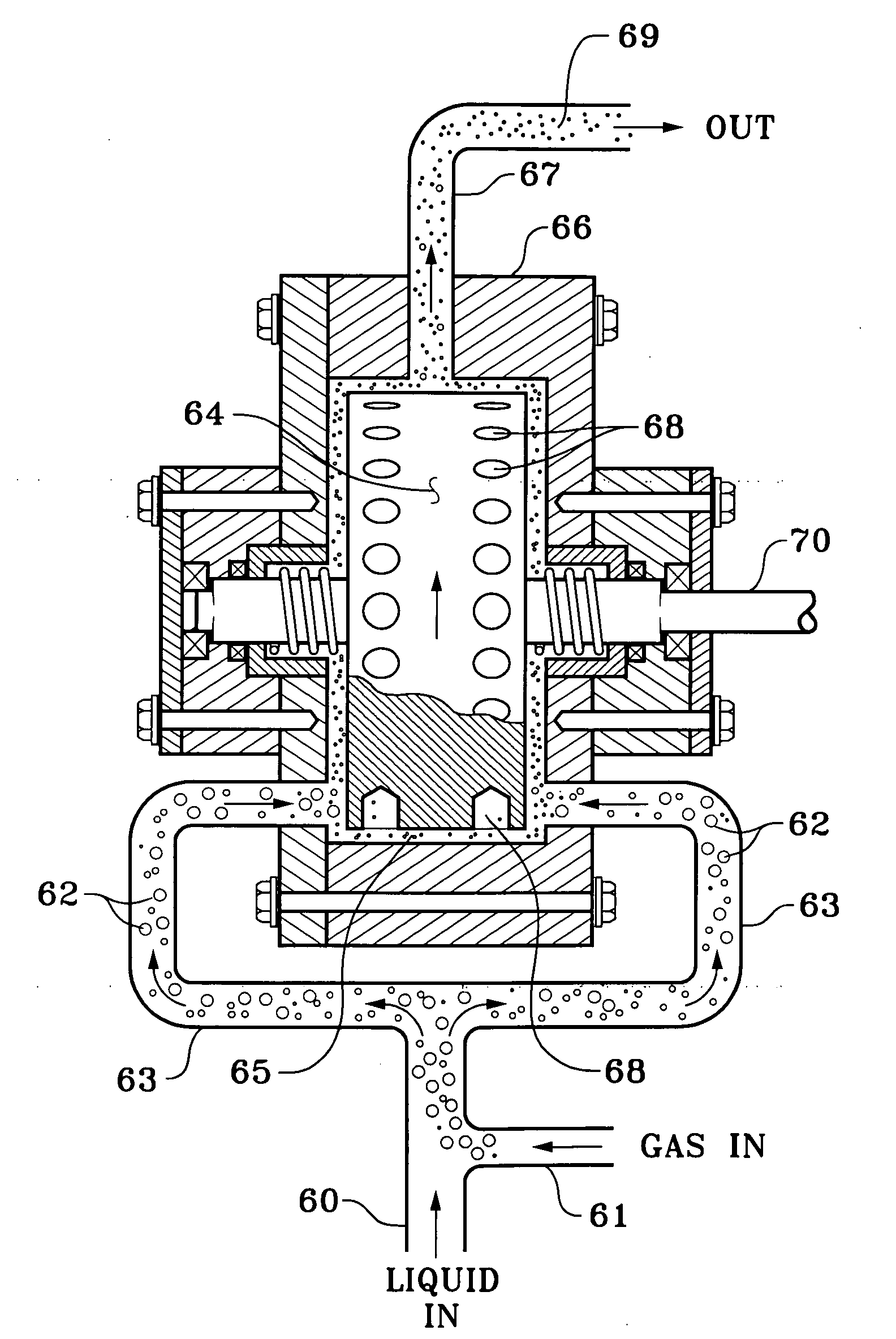

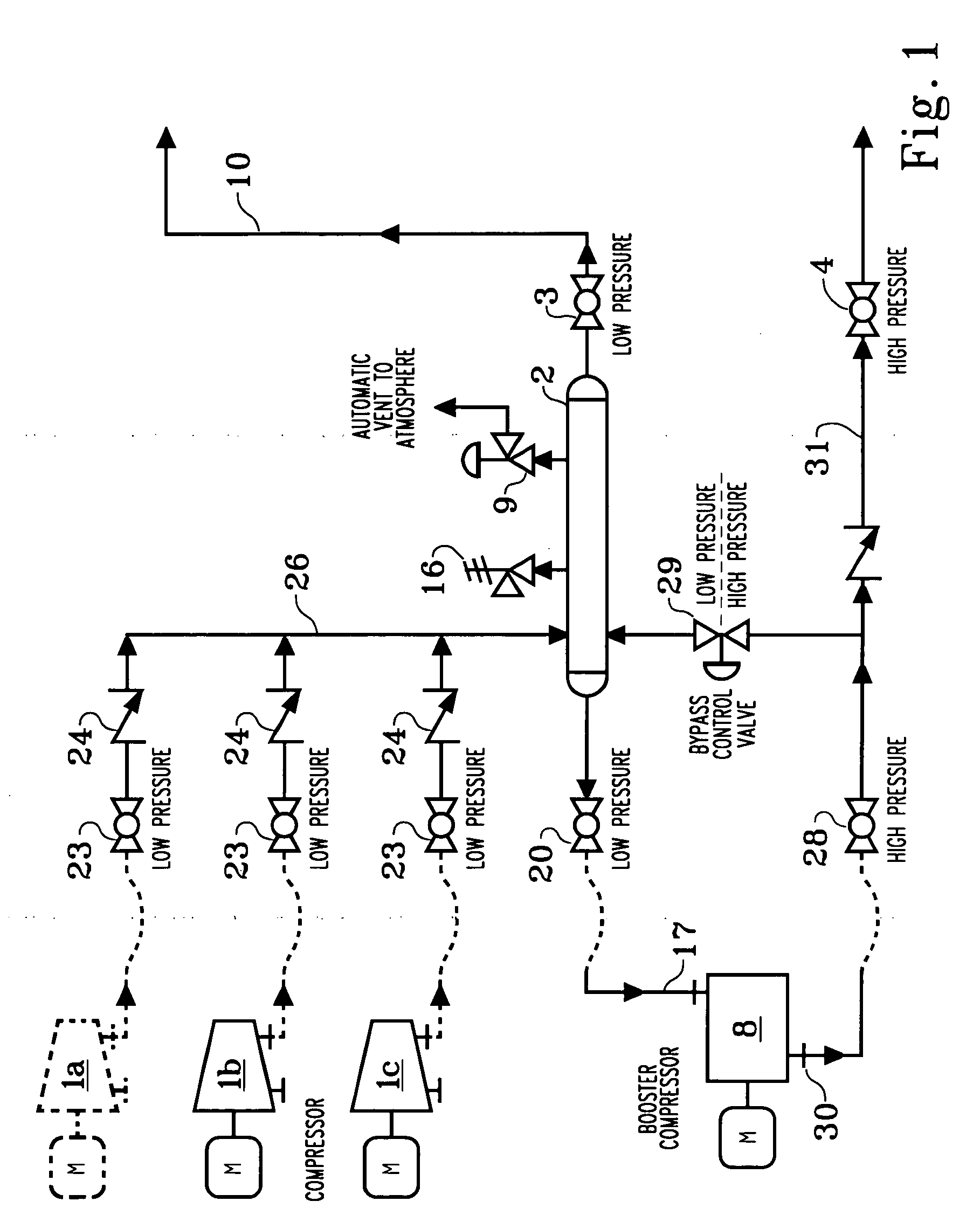

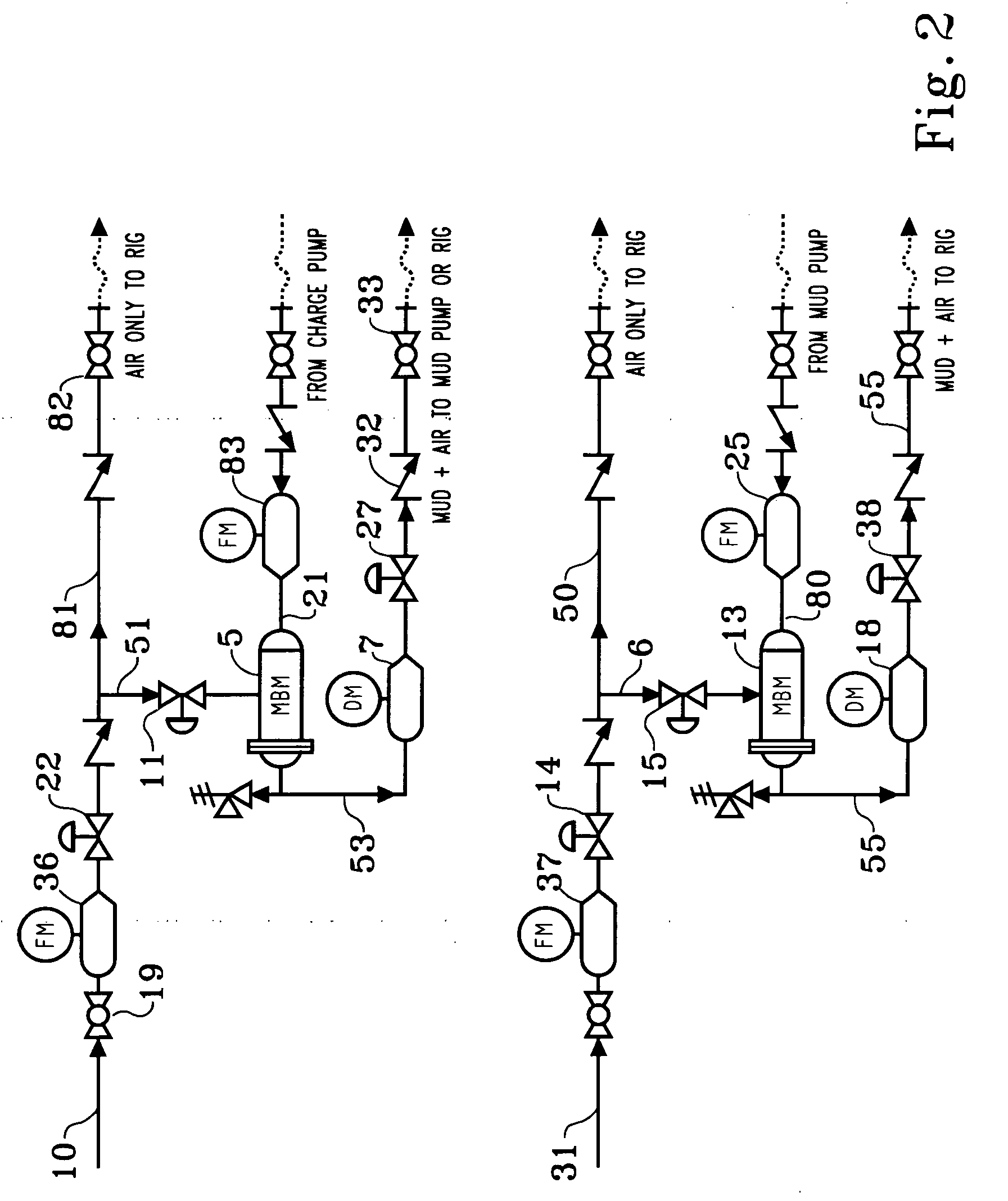

Compressed gas system useful for producing light weight drilling fluids

InactiveUS20090140444A1Economically and efficiently to respondLower energy requirementsCarburetting airFlow mixersReadiness findingMicrobubbles

A compressor station having at least one primary compressor and a booster compressor is controlled to conserve energy and air, and to respond quickly to sudden changes in demand for air, by employing a volume bottle to buffer changes in air pressure and by recycling already compressed air from the intake to the output of the booster compressor. The system may be used in air drilling and to provide compressed air for generating low density drilling fluid on site by injecting microbubbles into a base drilling fluid. Two different methods of generating microbubbles are illustrated. The primary and booster compressors are kept in a state of readiness during drill pipe connection time, providing for a rapid resumption of pressure and air flow after connection is completed. The system can utilize gases other than air.

Owner:TOTAL SEPARATION SOLUTIONS

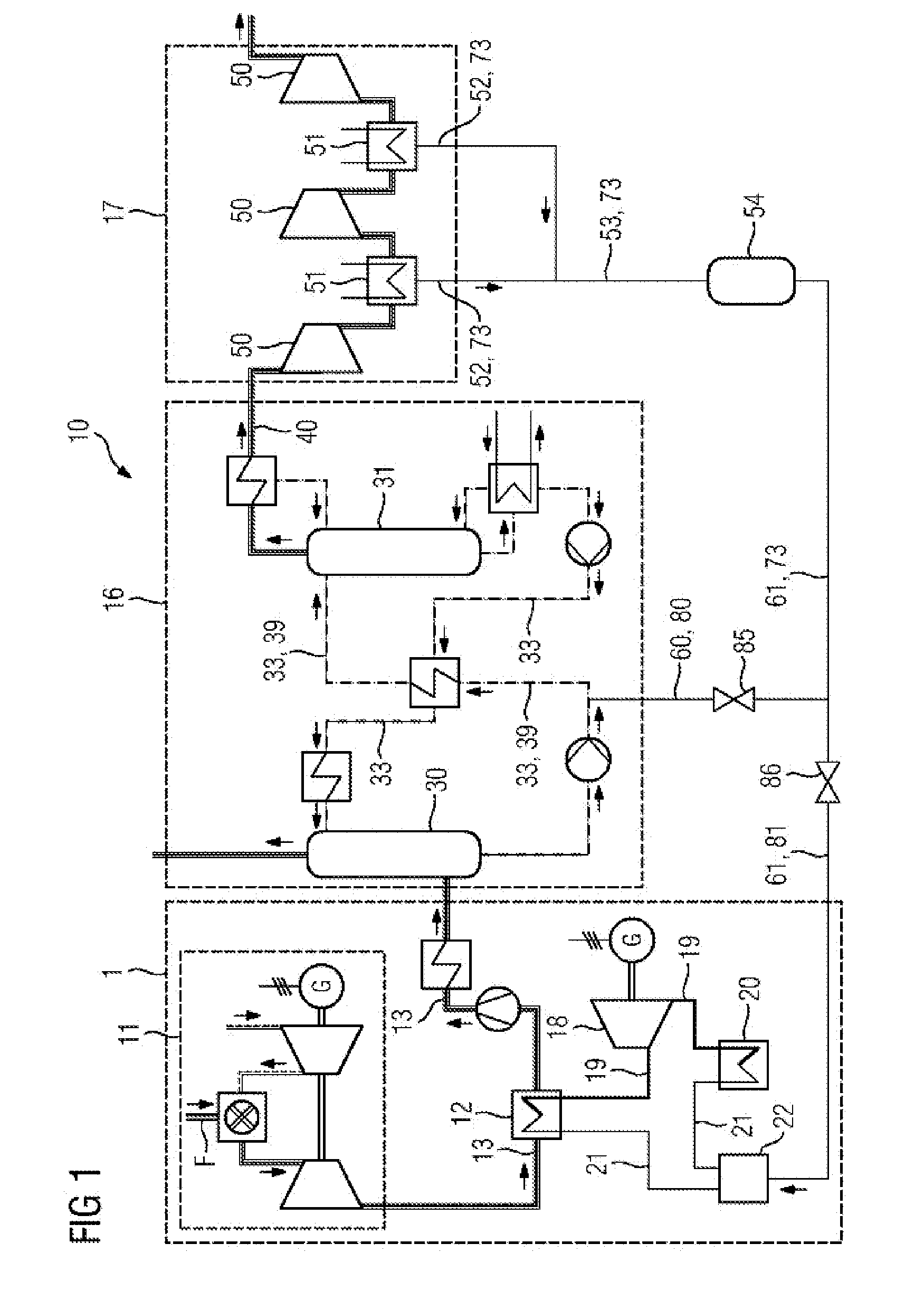

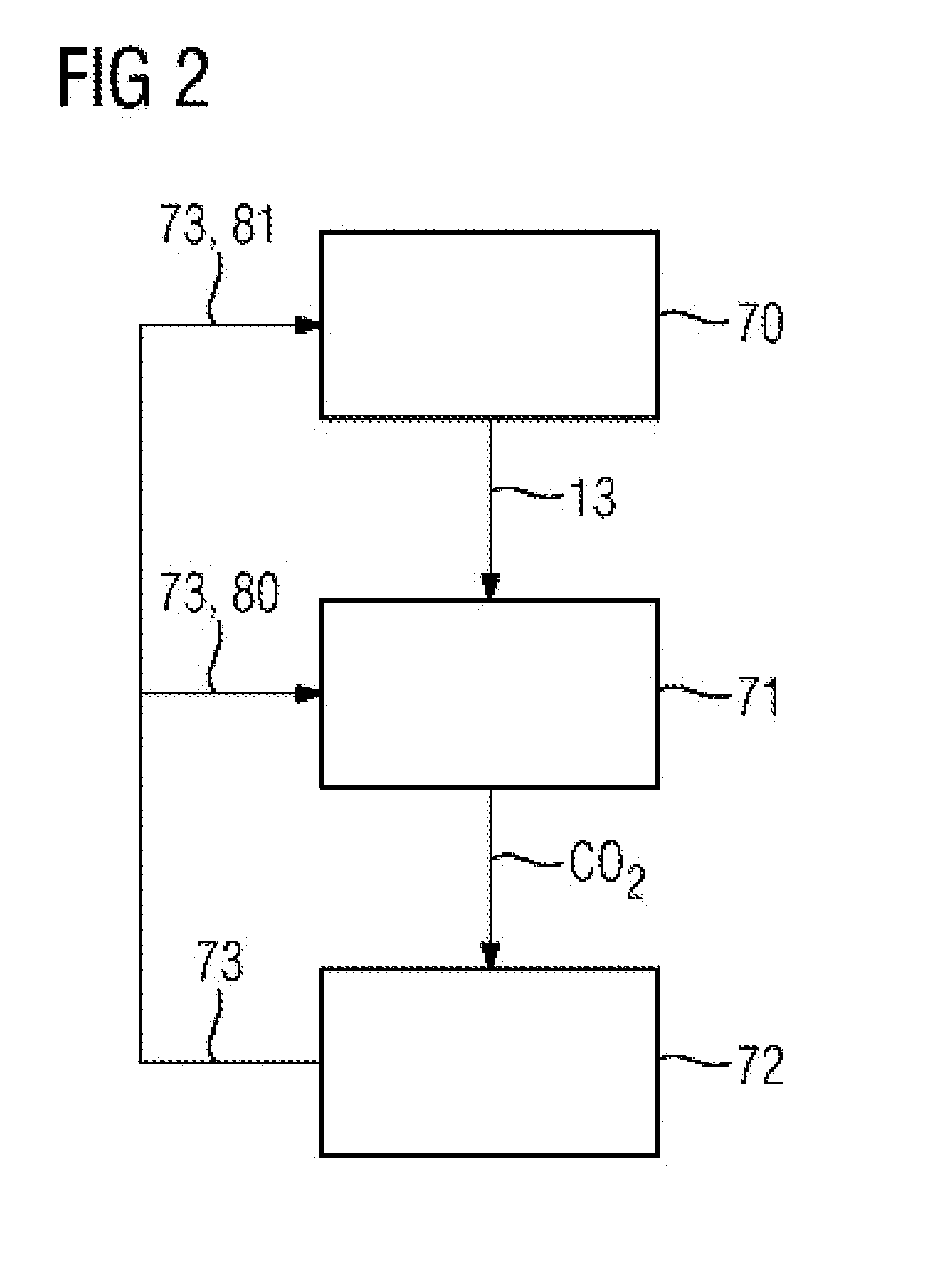

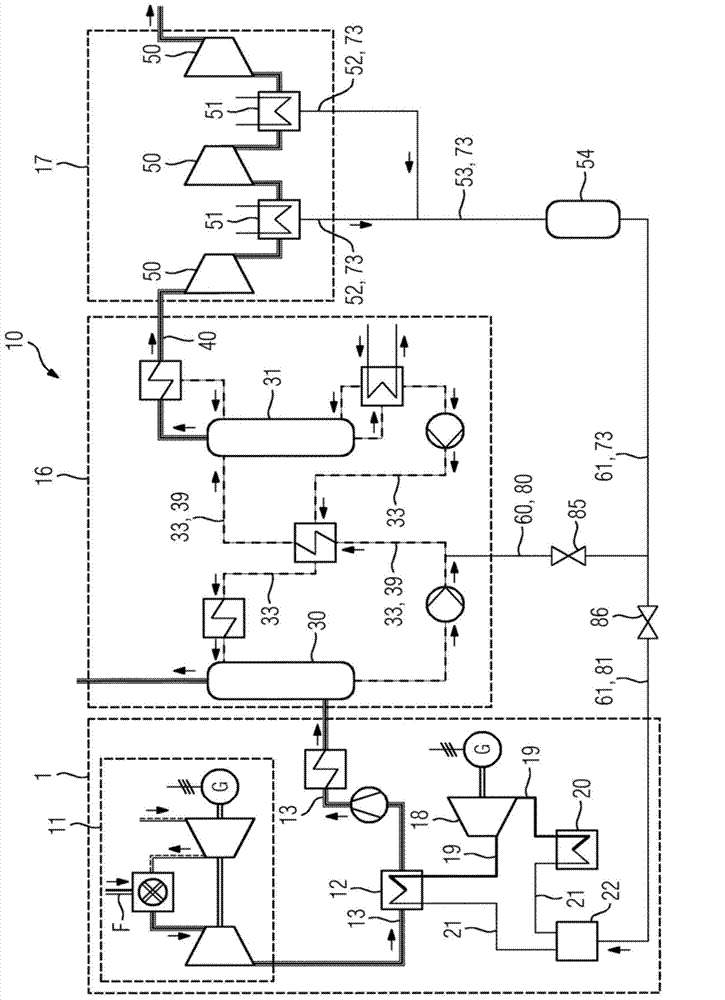

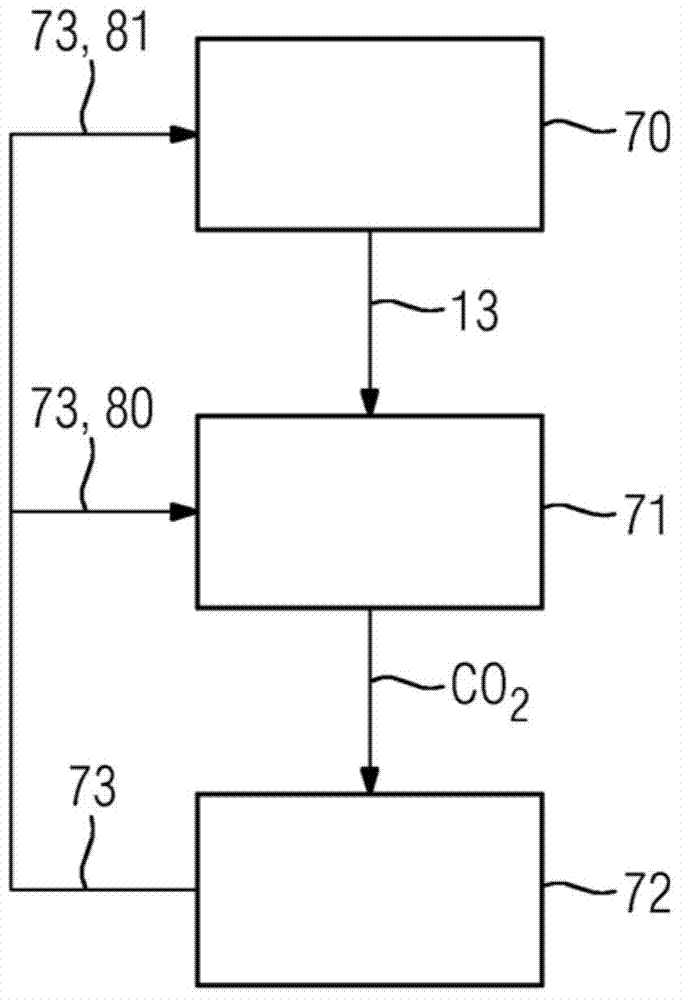

Method and fossil-fuel-fired power plant for recovering a condensate

InactiveUS20140150699A1Cost installationCost operationSolidificationLiquefactionCombustionProcess engineering

A fossil-fuel-fired power plant, having a combustion device, a CO2 separation device, which is arranged downstream of the fossil-fuel-fired power plant, for removing CO2, and a CO2 compressor station, which is arranged downstream of the CO2 separation device and which has a number of compressor stages and coolers for intermediate cooling is provided. The coolers are connected to the CO2 separation device or the fossil-fuel-fired power plant by means of a condensate line in order to recover condensate. A method for carrying out the condensate recovery is also provided.

Owner:SIEMENS AG

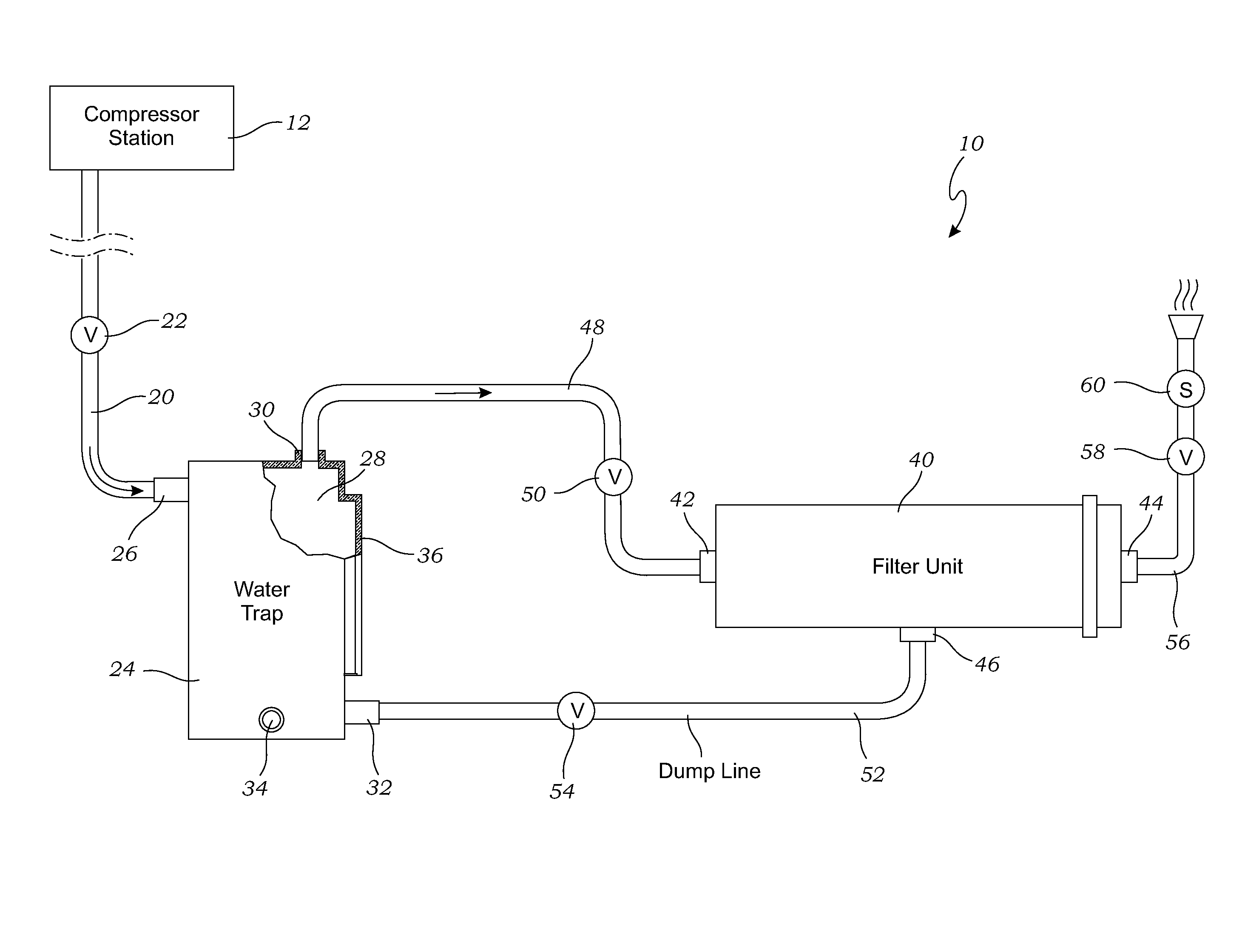

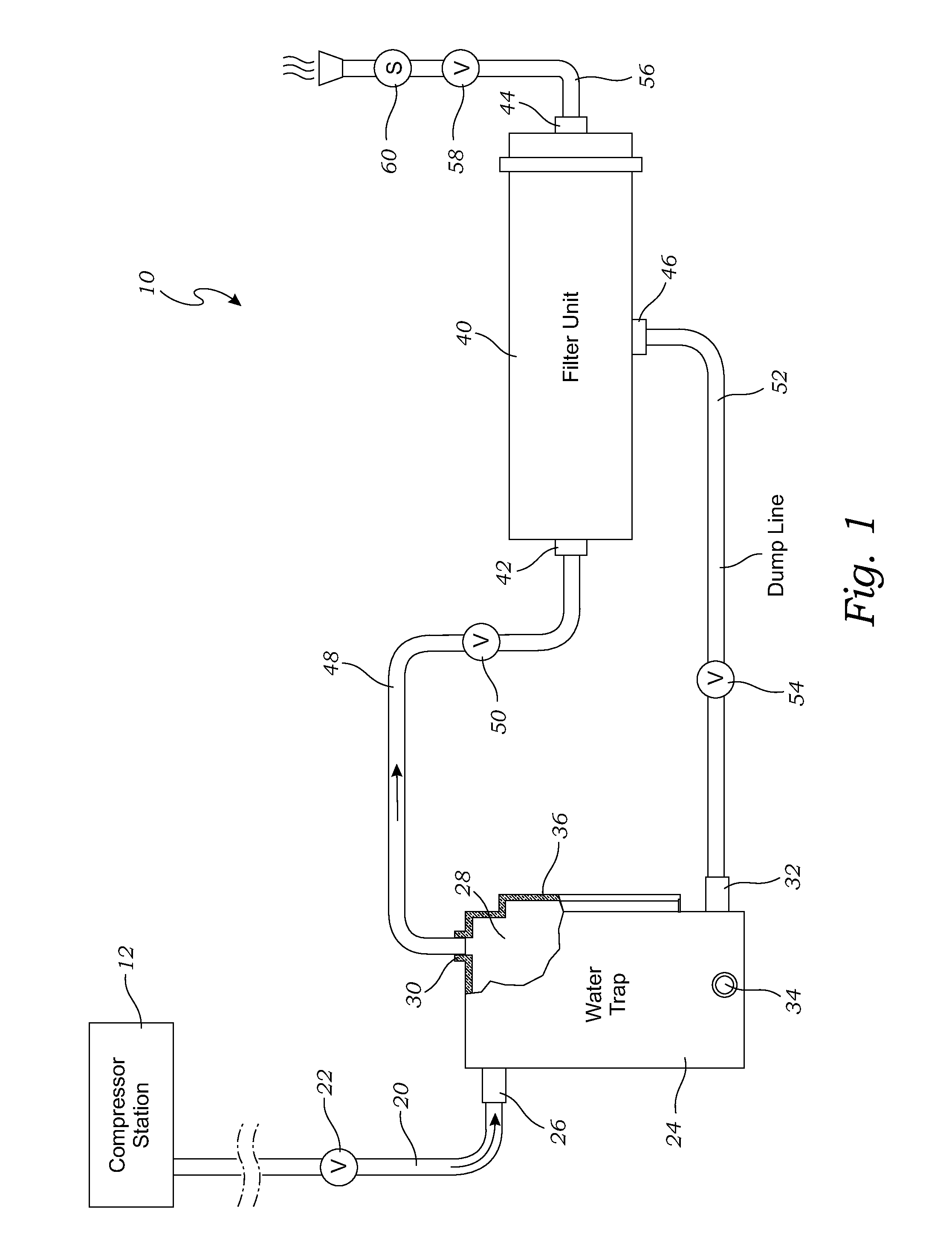

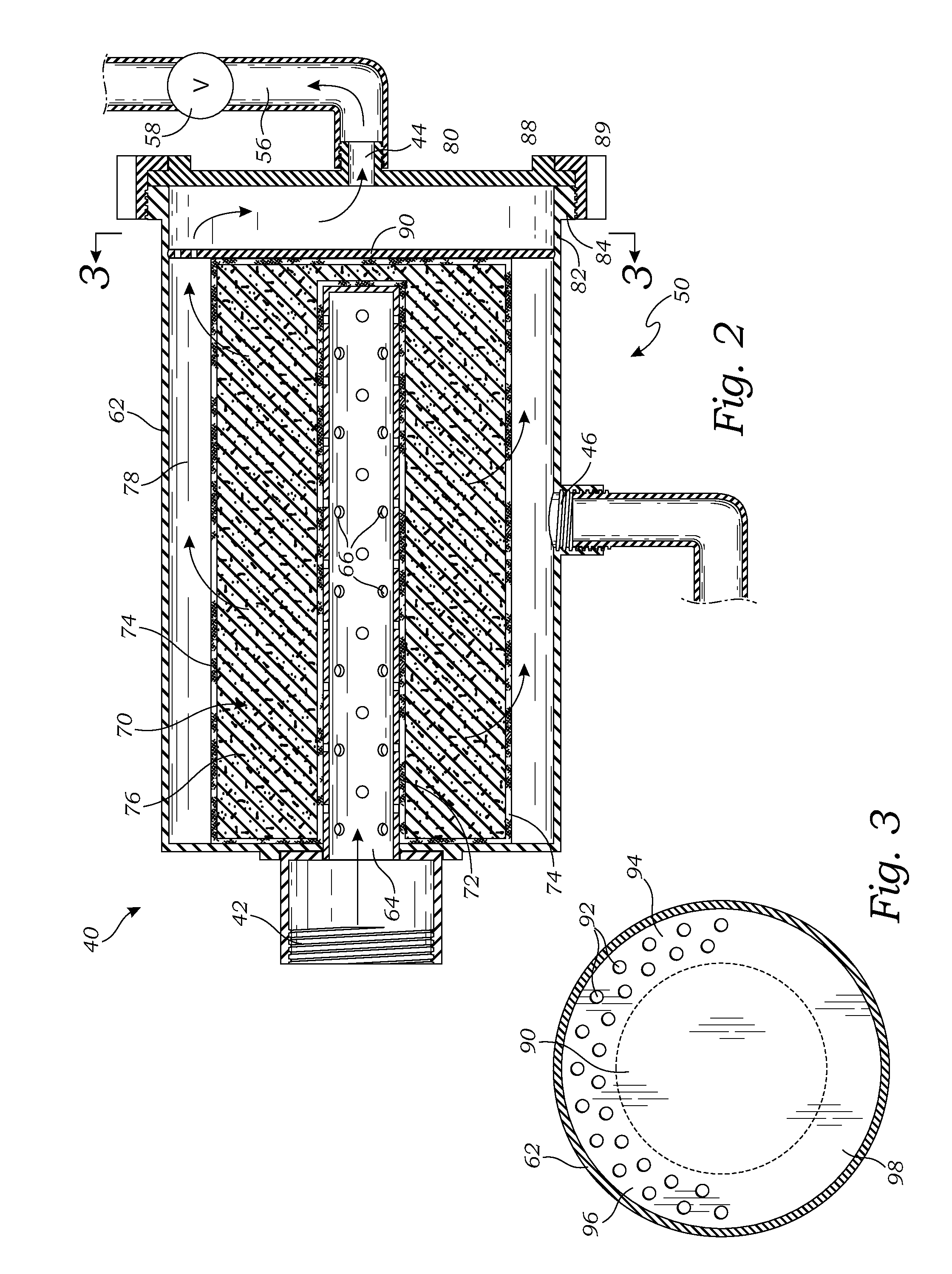

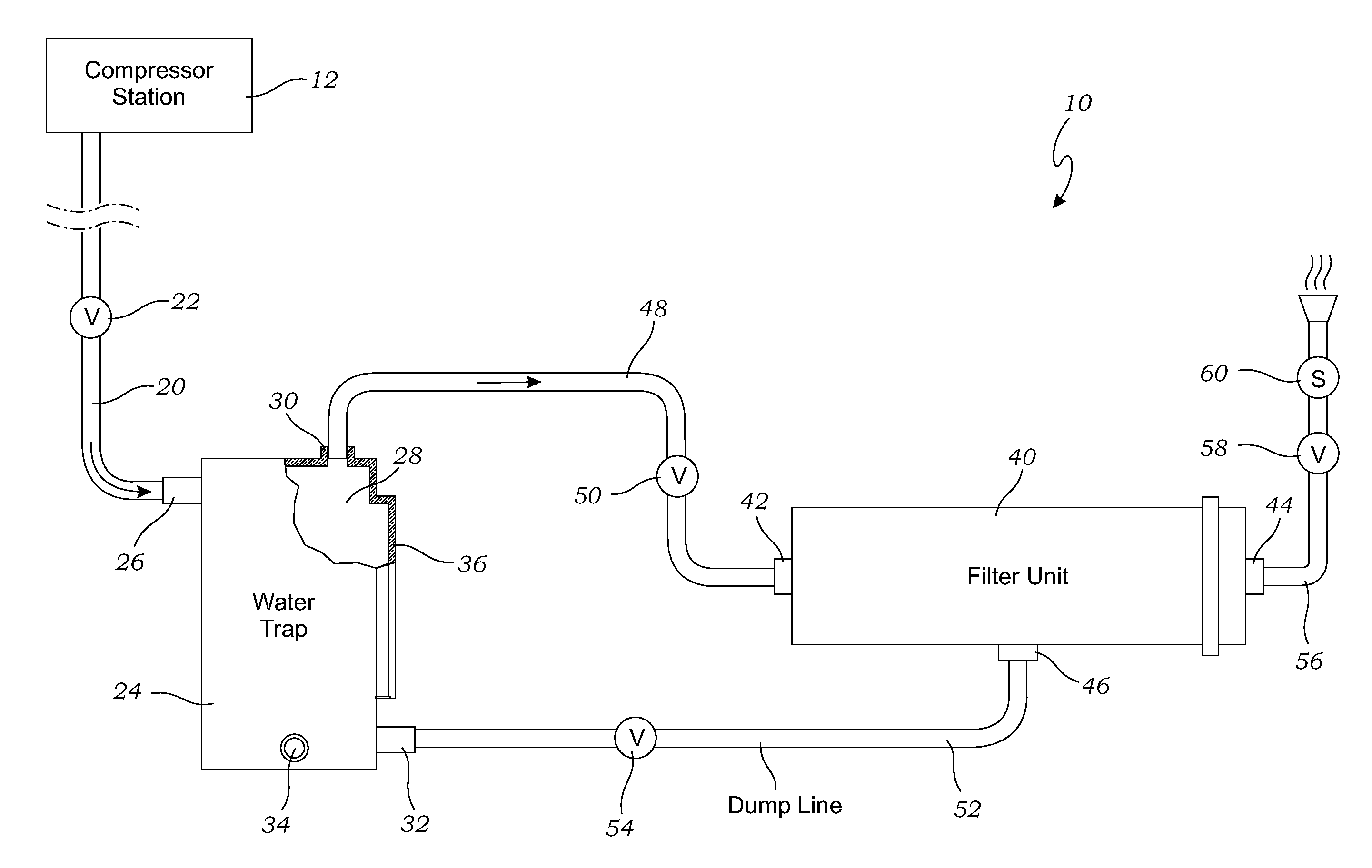

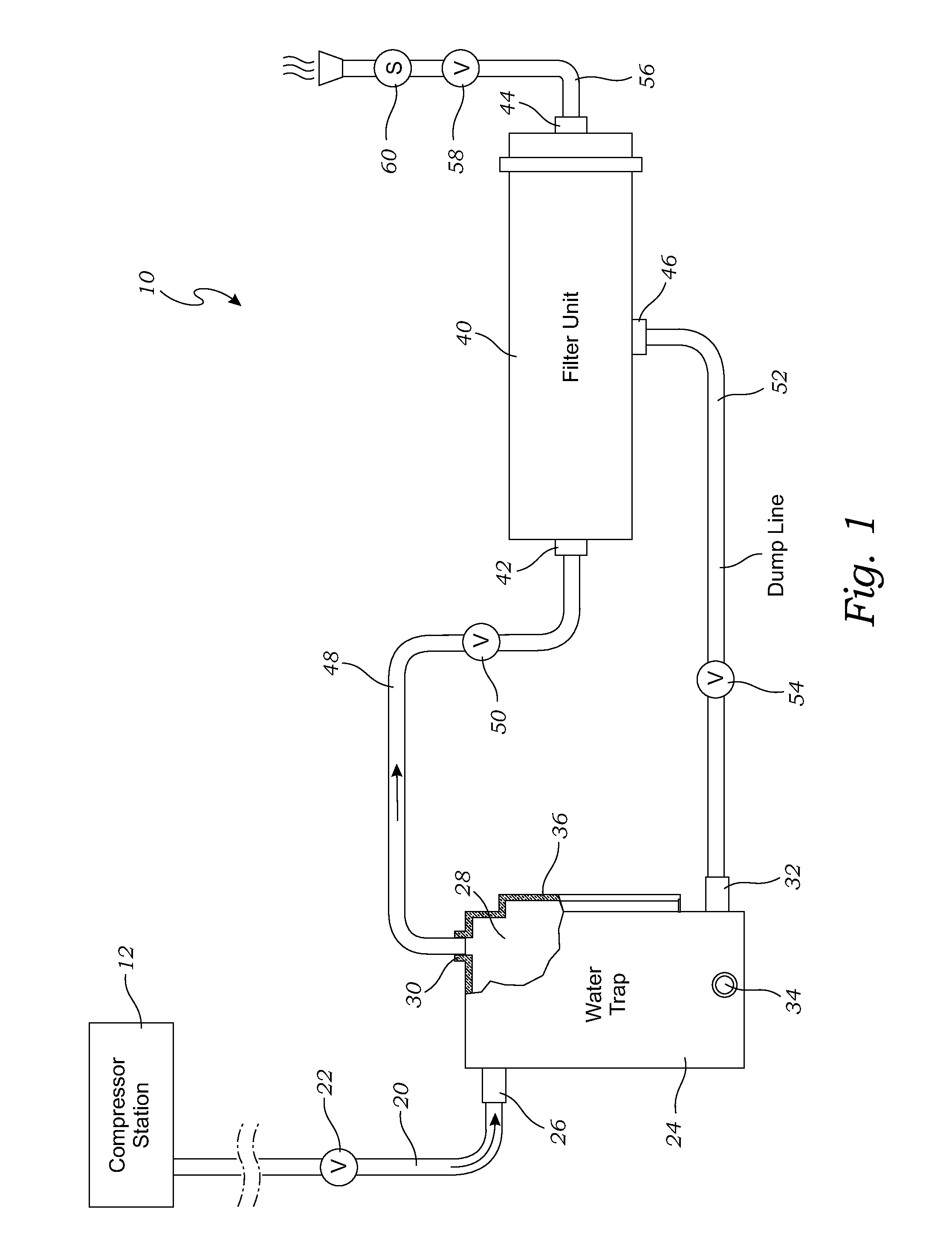

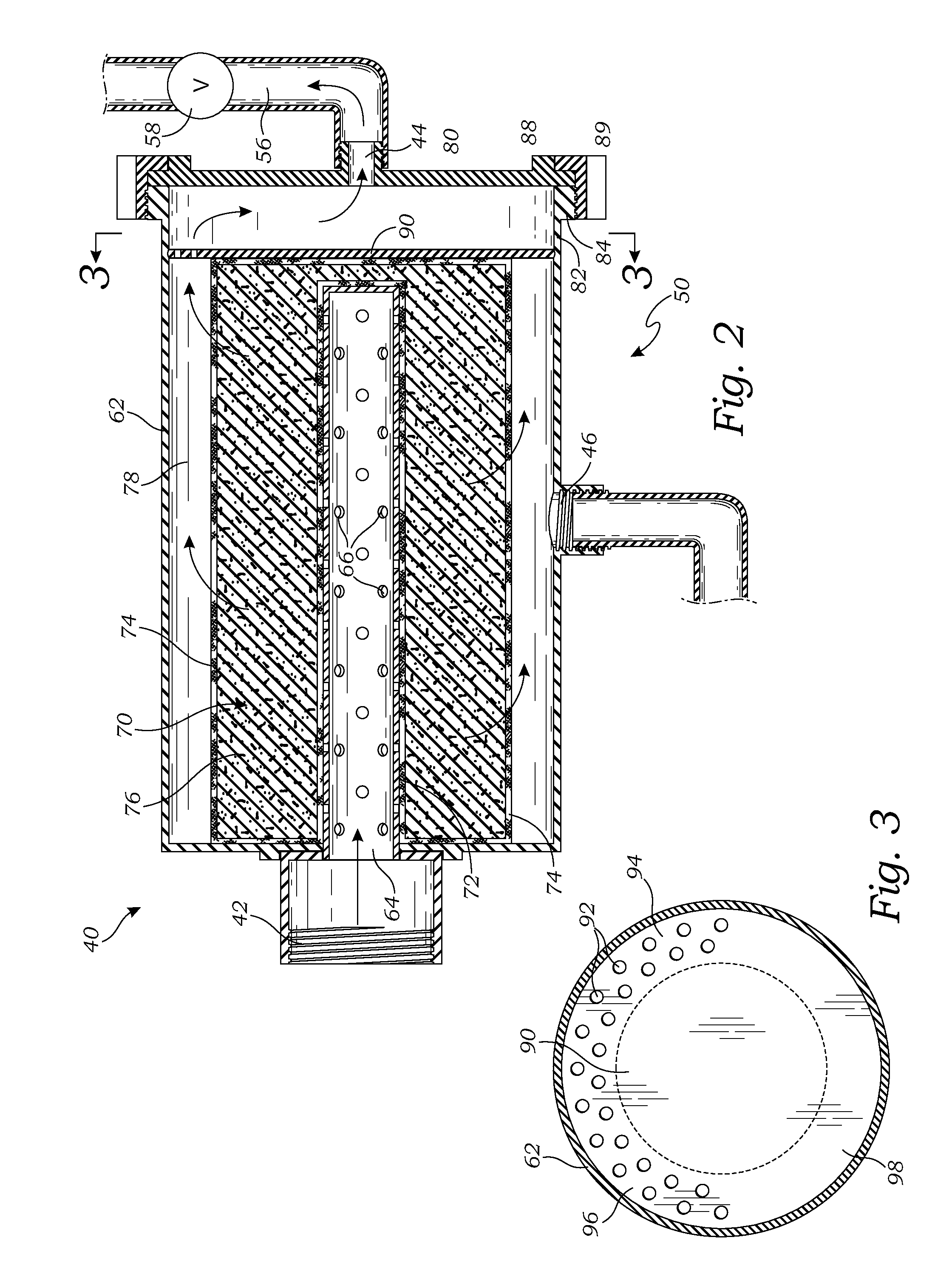

Filtration system for a compressor station

InactiveUS8388746B2Proper disposalEmission reductionCombination devicesAuxillary pretreatmentFiltrationPollution

A filtration system has a blowdown conduit and a filter unit. The blowdown conduit is adapted to be operably connected with a gas compressor station. The filter unit includes a filter housing, an inlet port, a pollution filter positioned within the filter housing to remove the pollutants from the vented gasses entering through the inlet port, and an exit port enabling the vented gasses to exit the filter housing once the pollutants have been removed by the pollution filter.

Owner:WARR 2 BROS

Method for operating a gas turbine plant with a compressor station for gaseous fuel

The disclosure relates to a method for operating a gas turbine plant which is supplied with a fuel gas via a compressor station. The compressor station includes a compressor which compresses the fuel gas which is fed via a gas feed line and delivers it via at least one control valve to a combustion chamber of the gas turbine plant. A bypass system is arranged in parallel to the compressor via which fuel gas can be directed in a switchable manner past the compressor to the at least one control valve. An energy-saving operation can be achieved in a simple manner by continuously measuring the fuel gas pressure at the outlet of the at least one control valve. A minimum fuel gas pressure, which is desired (e.g., necessary) for operation of the gas turbine, at the inlet of the at least one control valve is determined from the measured pressure values in each case. The compressor station can be switched over to bypass operation when the fuel gas pressure which reaches the inlet of the at least one control valve via the bypass system is greater than or equal to the minimum fuel gas pressure.

Owner:ANSALDO ENERGIA IP UK LTD

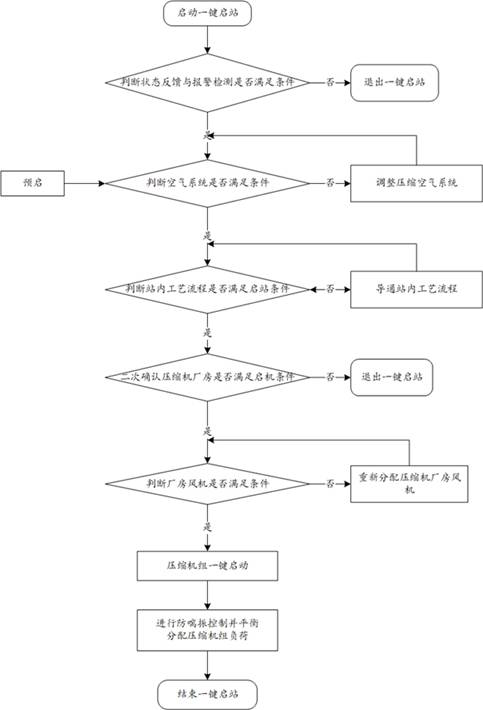

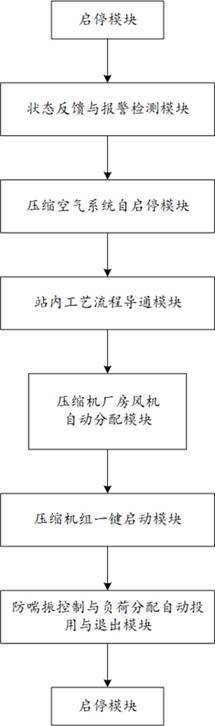

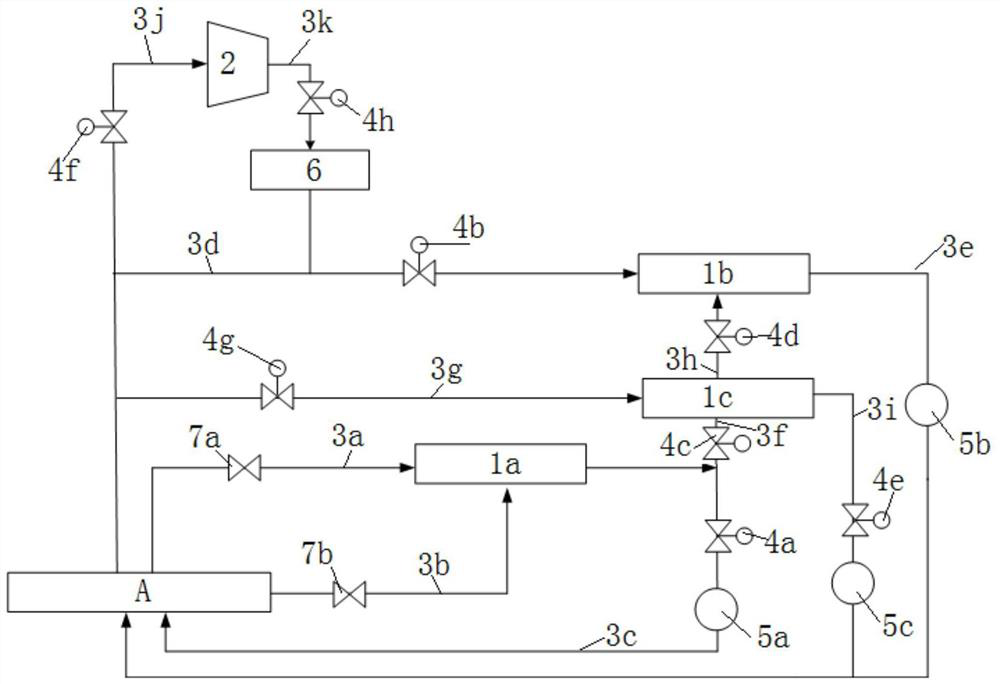

One-key start-stop method and system for compressor station

InactiveCN114776622AAvoid failureStable speedPump controlNon-positive displacement fluid enginesControl engineeringControl theory

The invention relates to the technical field of compressed air supply systems, and discloses a one-key start-stop method and system for a compressor station, and the method comprises the following steps: S1, starting a one-key start station; s2, judging whether state feedback and alarm detection meet conditions or not; s3, whether the air system meets the conditions or not is judged, and pre-starting is carried out while the step S3 is carried out; s4, whether the in-station technological process meets the station starting condition or not is judged; s5, secondary confirmation is conducted on whether the compressor plant meets the starting condition or not; s6, judging whether the plant fan meets conditions or not; s7, the compressor unit is started through one key; s8, anti-surge control is carried out, and the load distribution of the compressor unit is balanced; and step S9, ending one-key station starting. The problems that an existing compressor station cannot be started and stopped through one key, and efficient operation of a compressor unit is affected are solved. And through automatic operation, the problem that manual errors affect efficient operation of the compressor unit is avoided.

Owner:国家管网集团北方管道有限责任公司

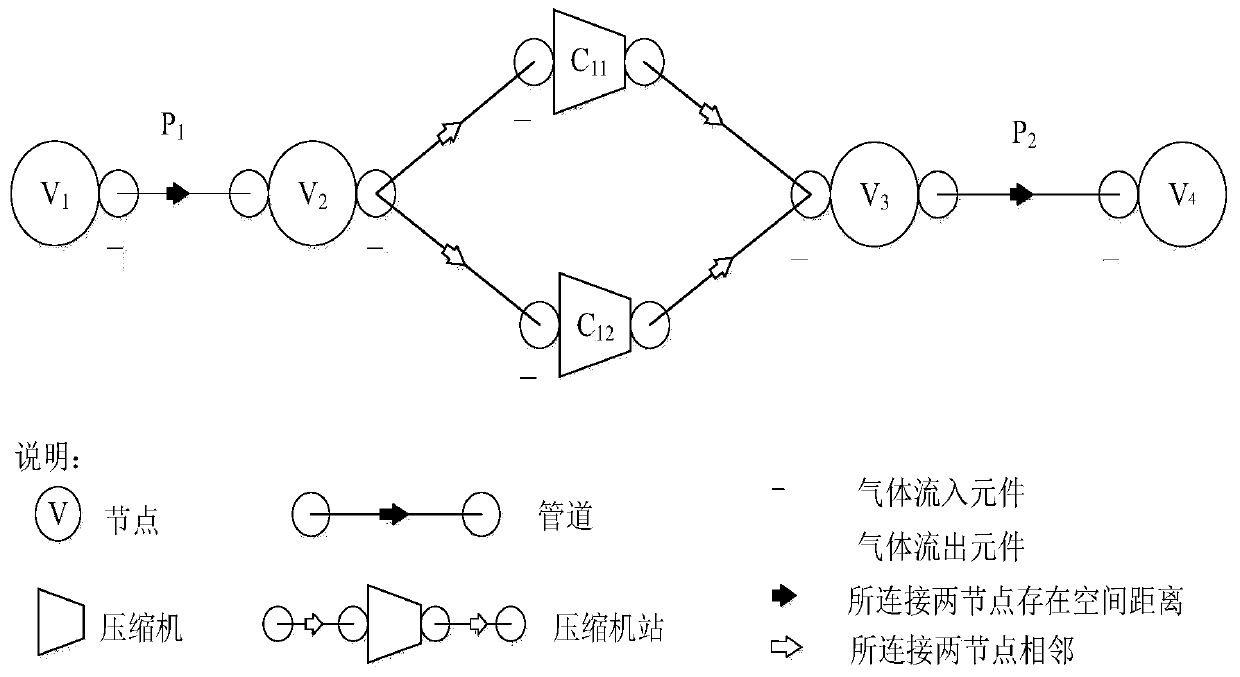

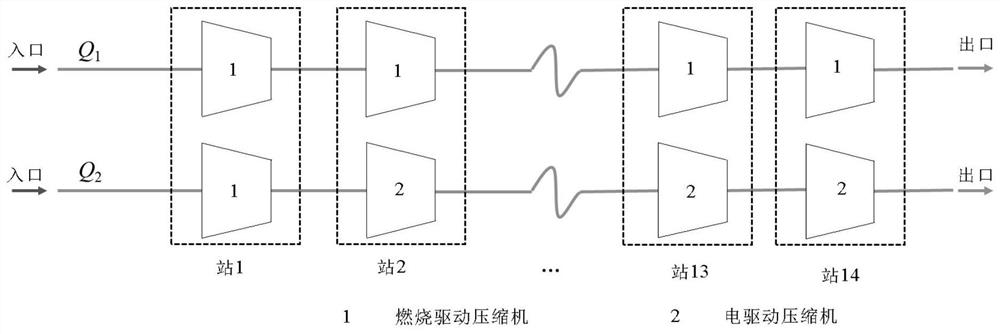

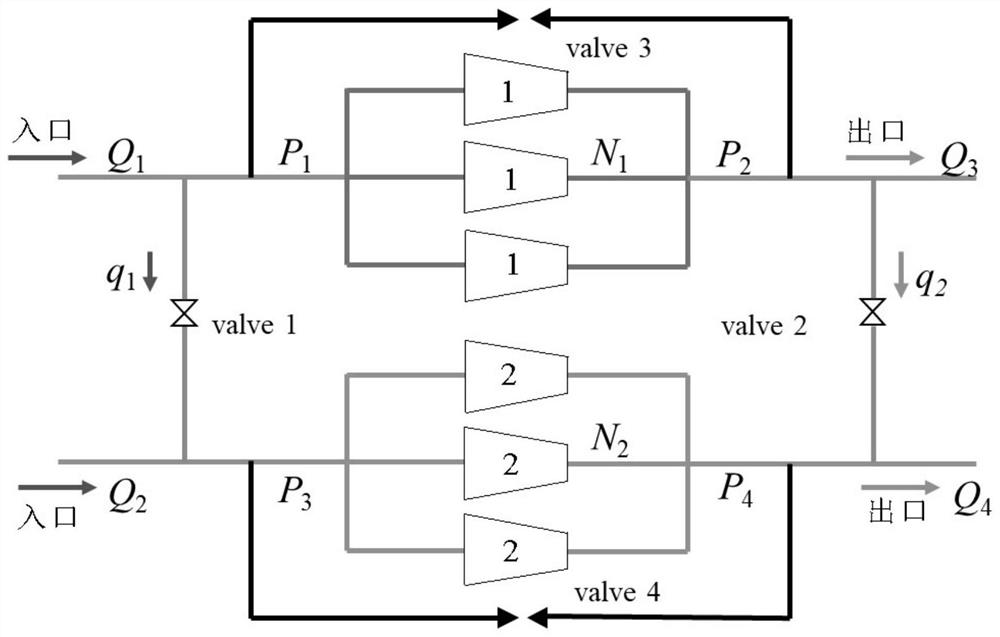

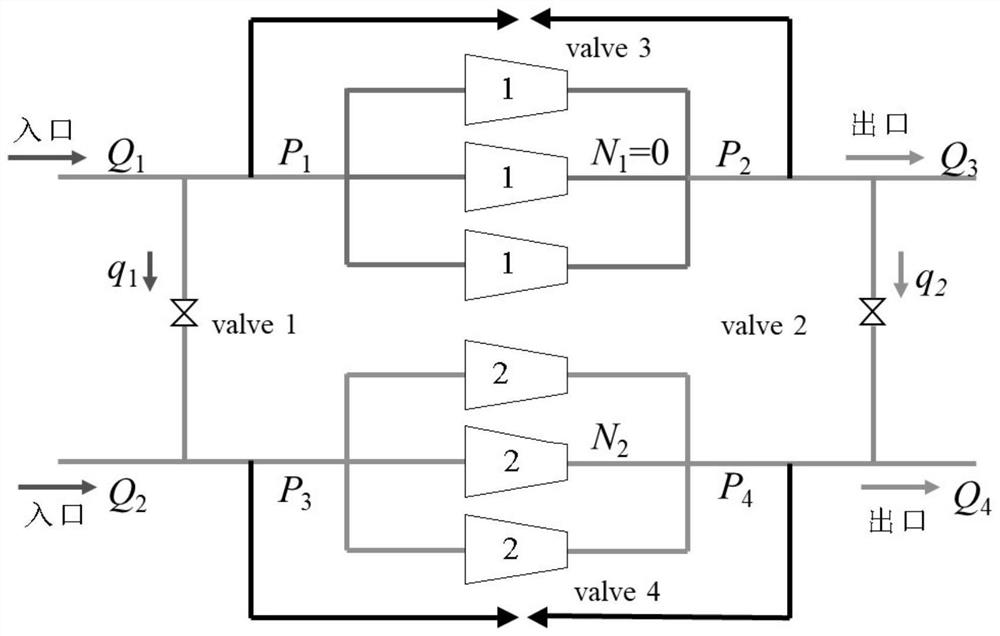

Large parallel natural gas pipeline network optimization operation model and solving method

ActiveCN113032935ACalculate pressure and temperature changesSimulation is accurateGeometric CADForecastingControl engineeringProcess engineering

The invention discloses a large parallel natural gas pipeline network optimization operation model and a solving method. The solving method comprises the following steps: step 1, constructing a compressor model and a pipeline model; 2, taking the minimum energy consumption sum of compressor units along the parallel pipe network as a target function, the total number of the compressor stations being n, and the total energy consumption of the whole long-distance pipeline being the sum of the energy consumption of the stations, and setting an optimization variable as Xi; 3, determining constraint conditions; According to the invention, the decision variables are introduced into the connection state between the pipelines in the established optimized operation model, the actual operation scheme is better met, and simulation is more accurate; the compressor model and the pipeline model are combined, so that the pressure and temperature change along the pipeline can be calculated; by adopting the phasor particle swarm algorithm, the convergence speed is high, and the number of times of obtaining the optimal scheme is maximum; the optimal scheme obtained through calculation is smaller than an actual scheme in the aspects of gas consumption, power consumption and total production energy consumption, and the total production energy consumption can be reduced by 26.62%.

Owner:SOUTHWEST PETROLEUM UNIV

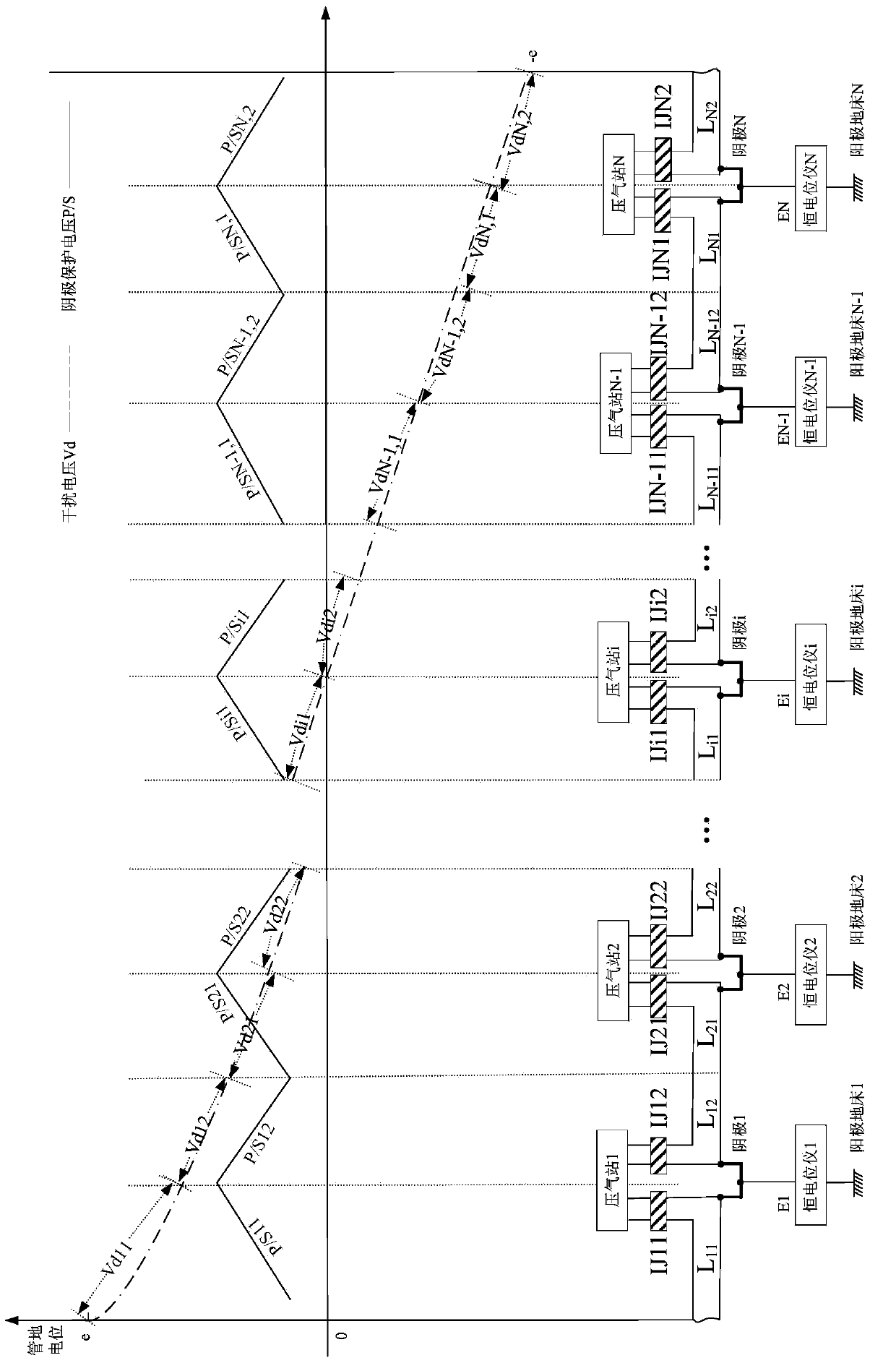

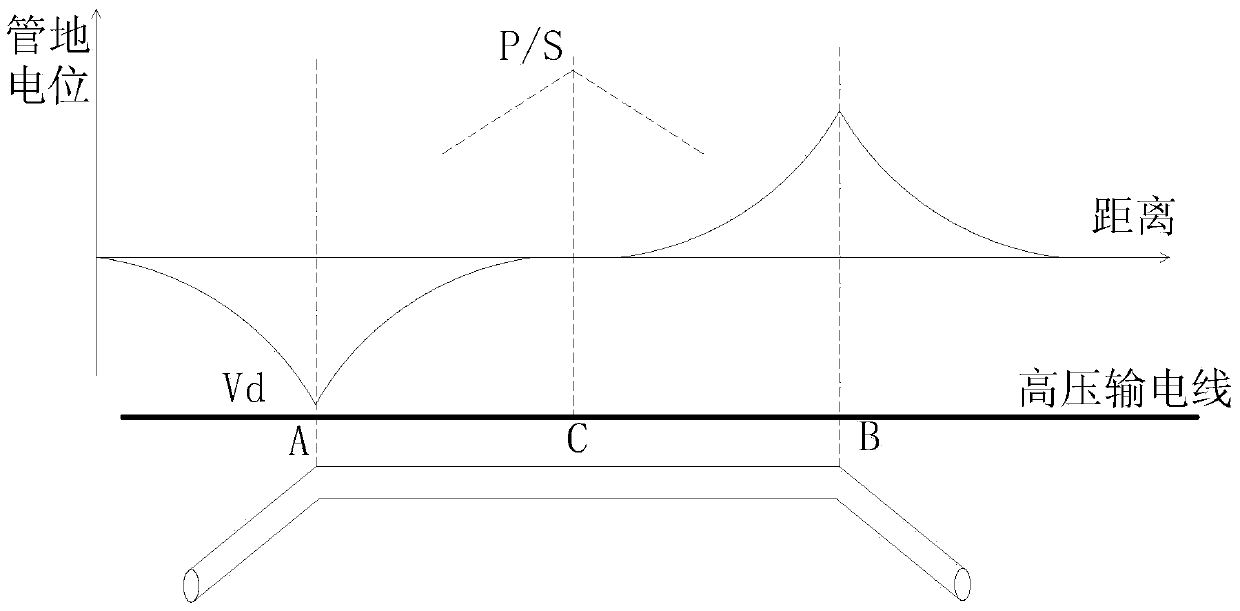

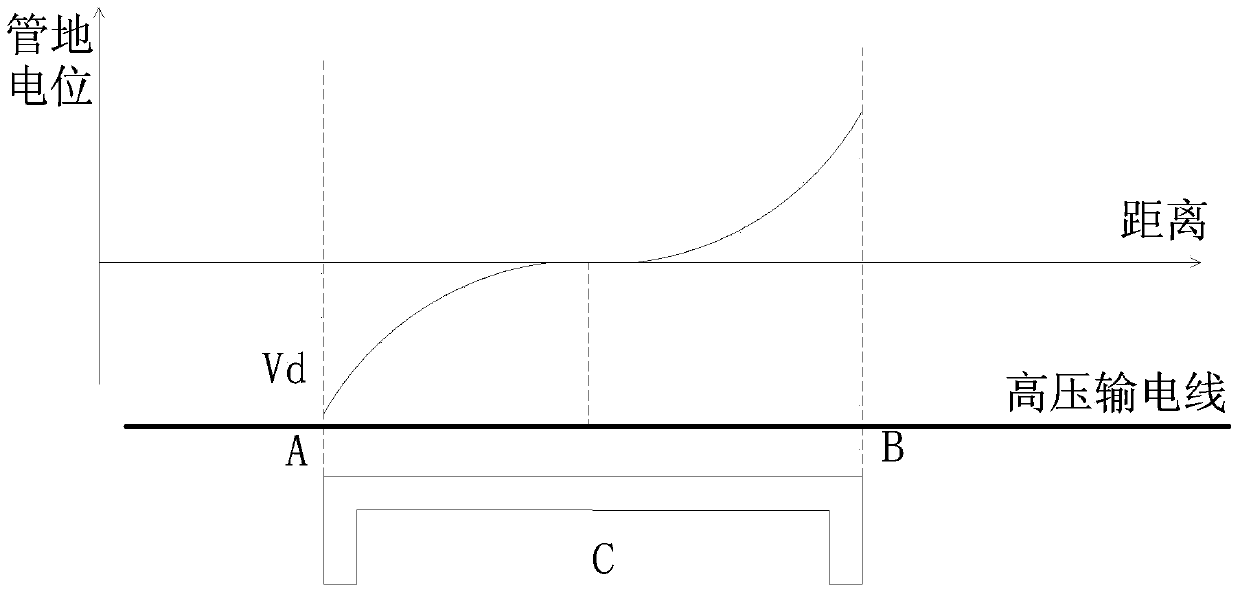

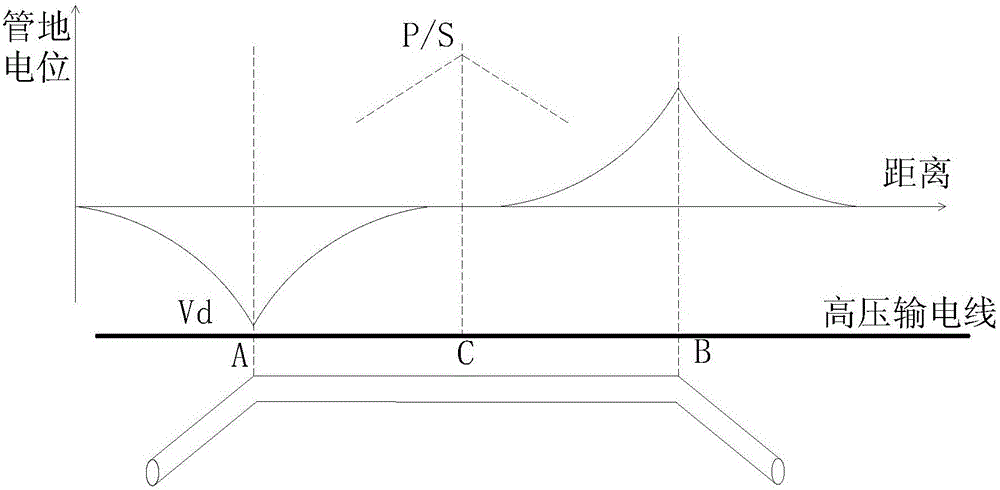

Generalized direct current cathodic protection system and generalized direct current constant potential rectifier thereof

InactiveCN103695937AEliminate distractionsPlay an inhibitory rolePotential measurementProtection system

The invention provides a generalized direct current cathodic protection system and a generalized direct current constant potential rectifier thereof. The generalized direct current constant potential rectifier comprises a pipe-to-soil potential measurement unit, a controller, an adjustable direct current power supply and a polarity control unit, wherein the polarity control unit can convert direct current voltage output by the adjustable direct current power supply into direct current voltage output which is opposite to the polarity of an interfering pipe-to-soil potential under control of the controller. The system comprises the generalized direct current constant potential rectifiers, wherein two output ends of every two generalized direct current constant potential rectifiers are electrically connected with the external surfaces at the two ends of inlet and outlet buried metal pipeline sections of a compressor station respectively and correspondingly; two earthing terminals of every two generalized direct current constant potential rectifiers are connected with a generalized anodic groundbed; and the buried metal pipeline sections are electrically insulated with the adjacent buried metal pipeline sections. The generalized direct current constant potential rectifier of the system can exert an external stray current interference resistance effect, and can convert the direct current polarity to adapt to eliminate external stray current interference in any polarity.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Filtration system for a compressor station

InactiveUS20120073444A1Proper disposalEmission reductionCombination devicesAuxillary pretreatmentFiltrationFilter system

A filtration system has a blowdown conduit and a filter unit. The blowdown conduit is adapted to be operably connected with a gas compressor station. The filter unit includes a filter housing, an inlet port, a pollution filter positioned within the filter housing to remove the pollutants from the vented gasses entering through the inlet port, and an exit port enabling the vented gasses to exit the filter housing once the pollutants have been removed by the pollution filter.

Owner:WARR 2 BROS

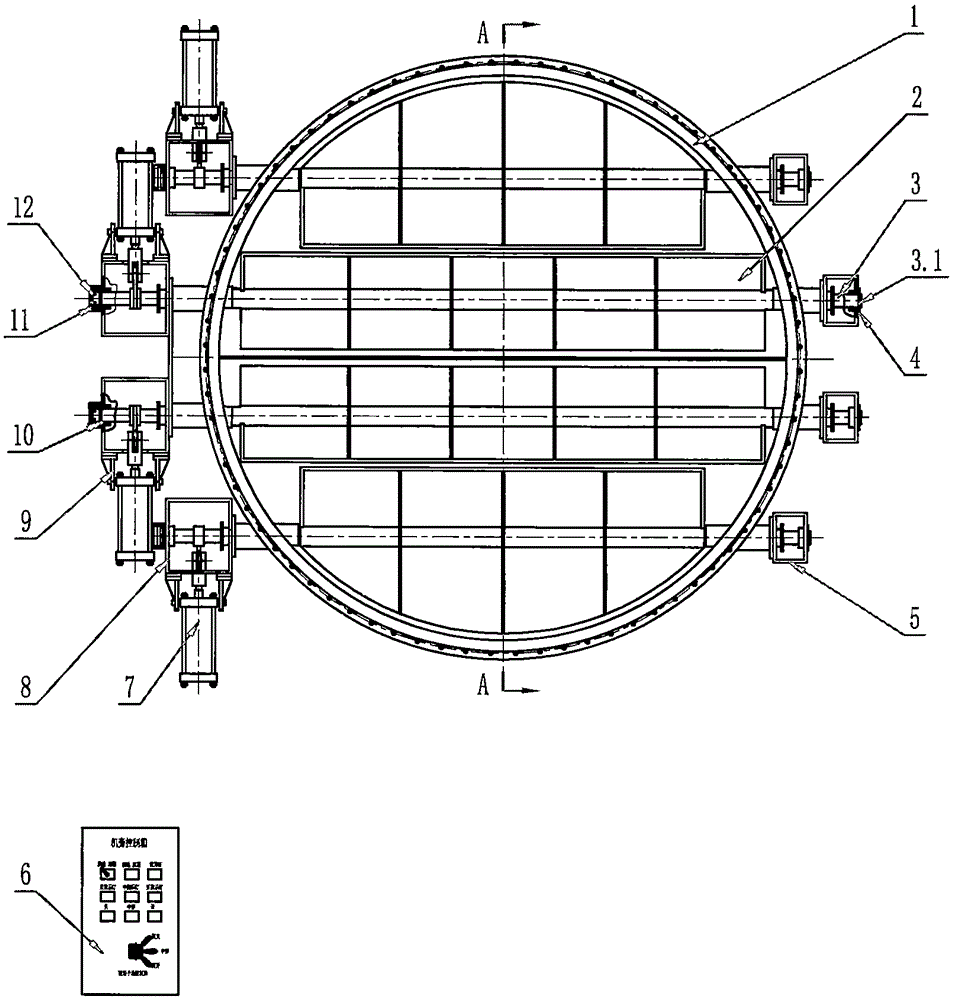

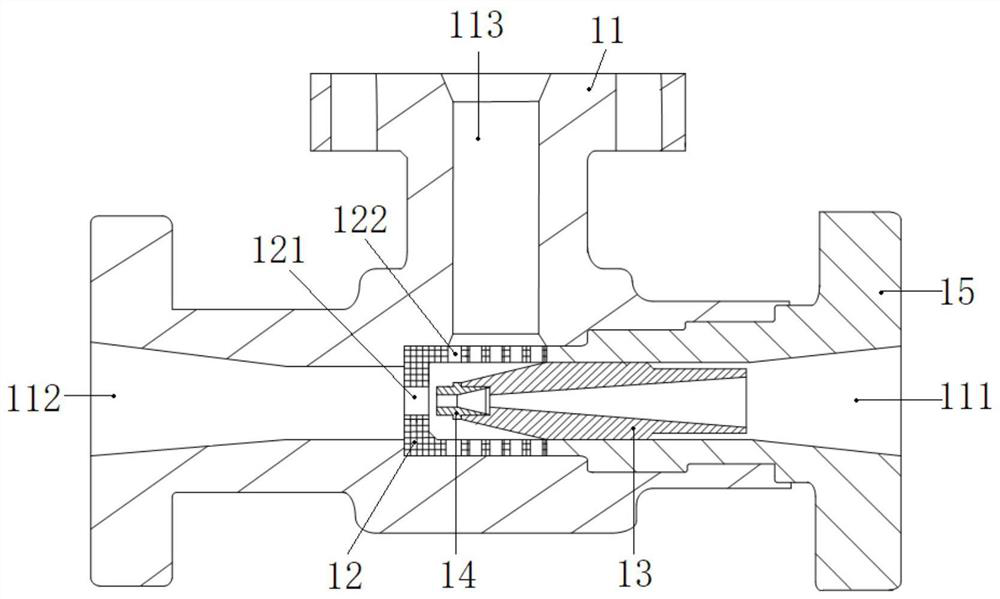

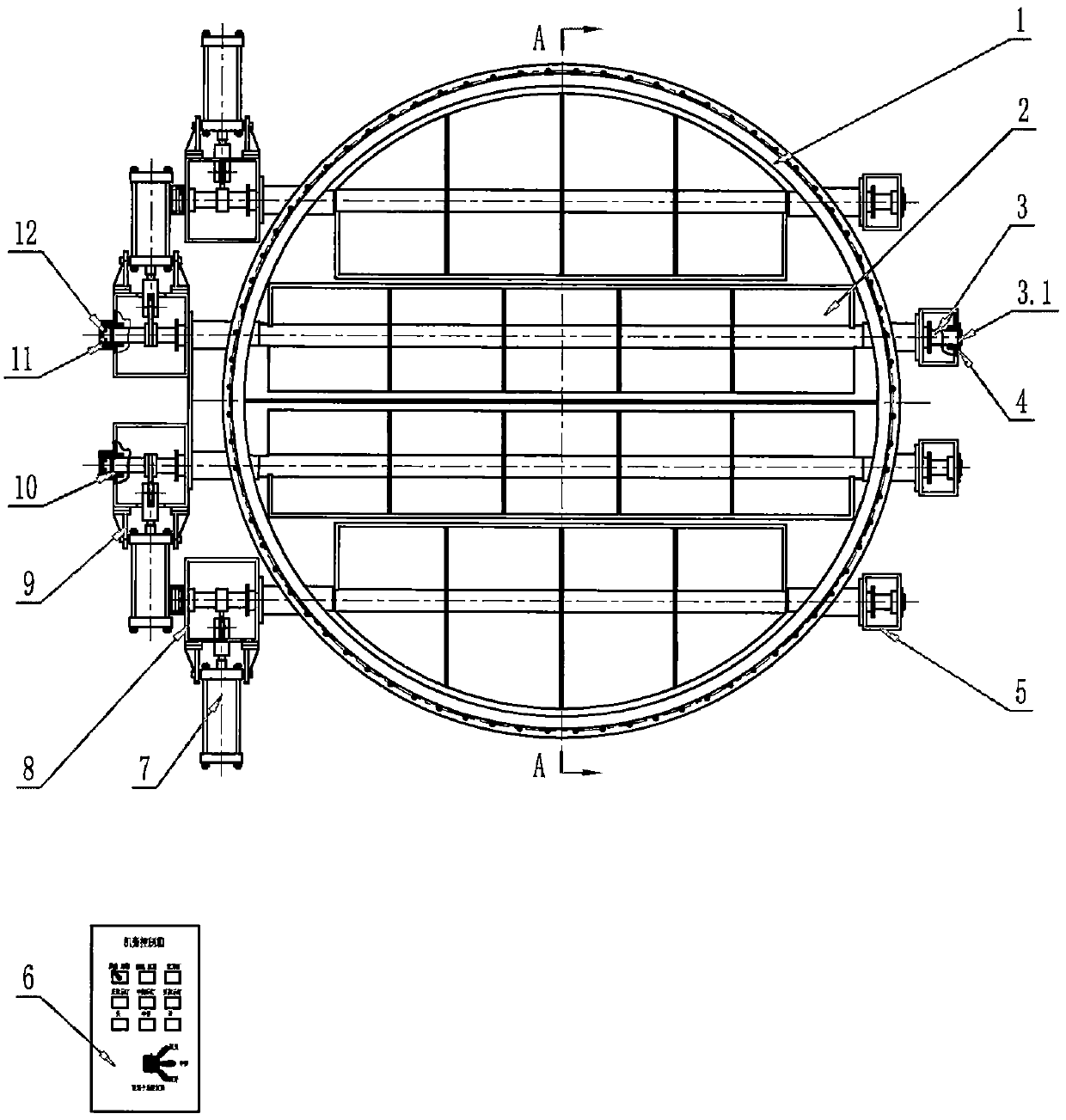

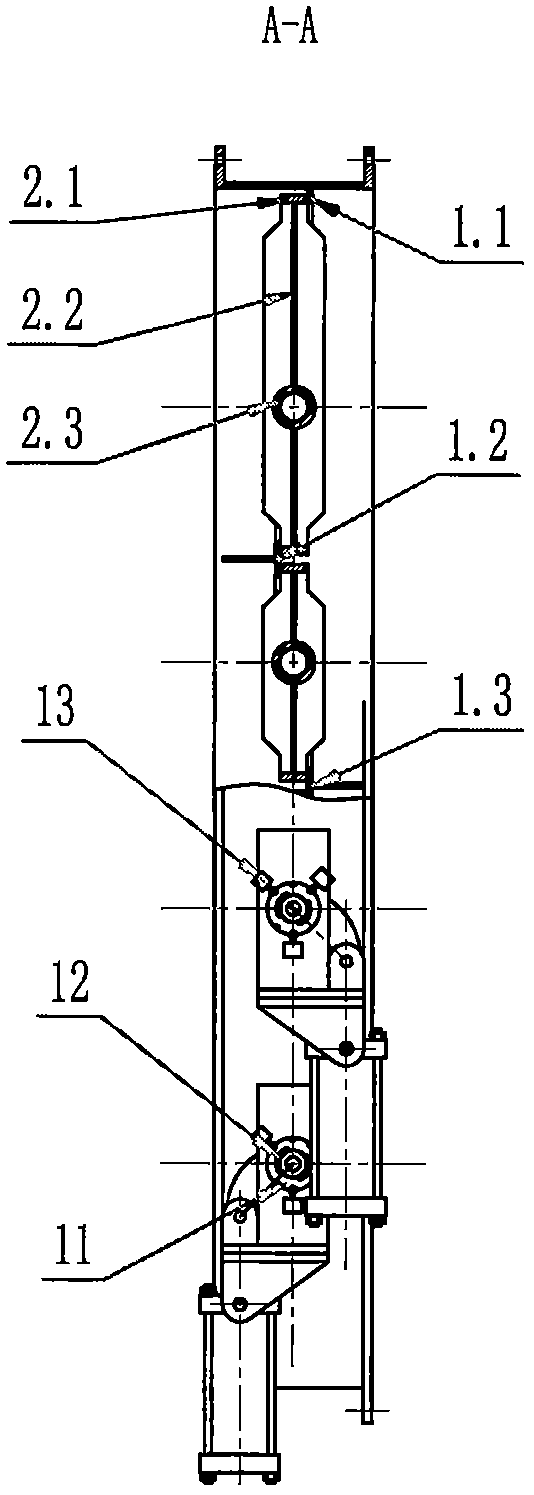

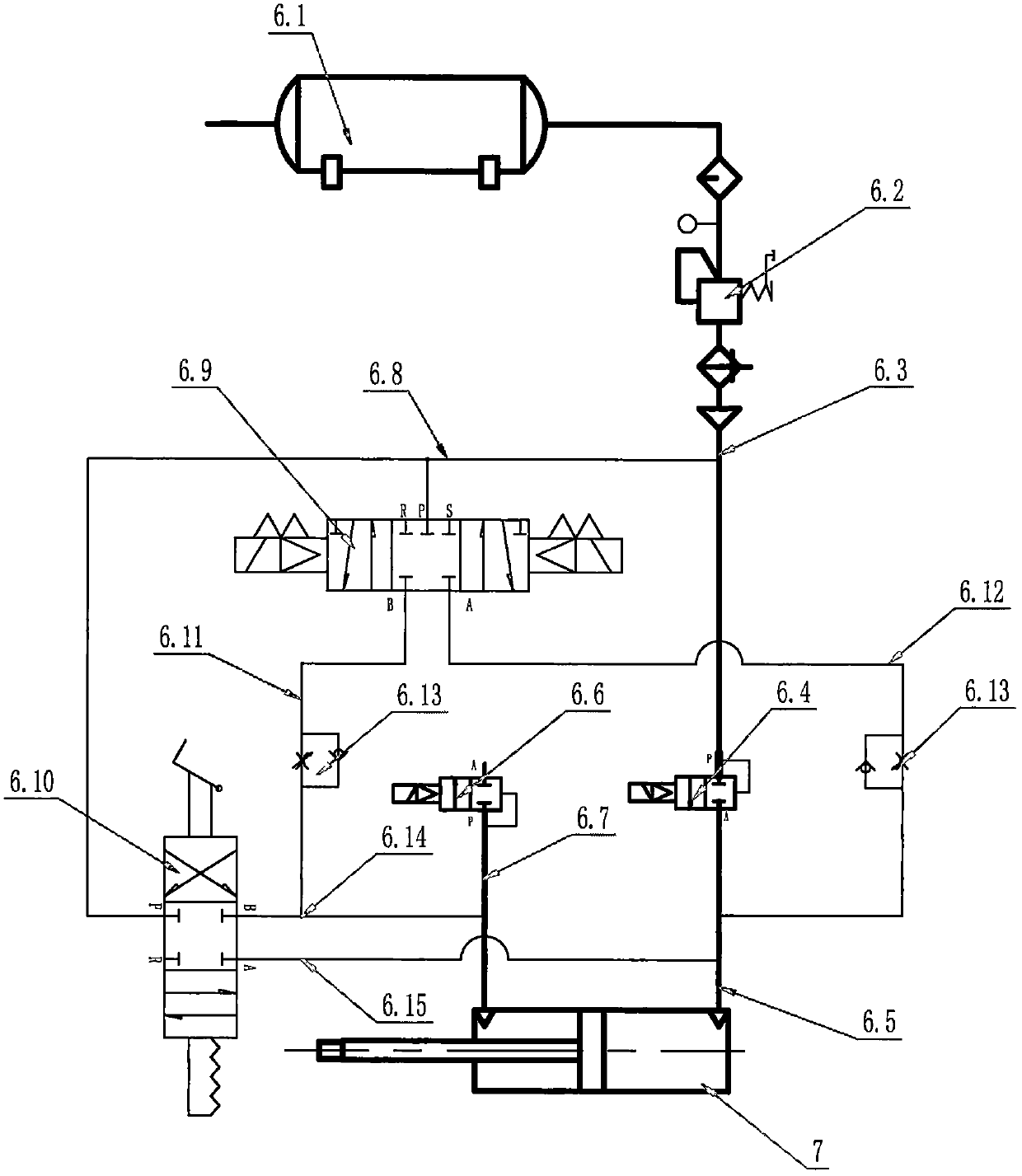

Pneumatic quick-opening shutter butterfly valve

ActiveCN105276202AHigh strengthAvoid deformationOperating means/releasing devices for valvesLift valveEngineeringButterfly valve

The invention relates to a pneumatic quick-opening shutter butterfly valve. A valve body is composed of a plurality of butterfly plates, each butterfly plate is provided with an independent driving device which is used for controlling the opening or closing motion of the butterfly plate, and the functions of adjustable speed of quick opening (or quick closing) and slow closing (or slow opening), stopping of closing (or opening) position and the like are achieved through the shutter butterfly valve with an air source as power; as a plurality of sets of independently-driven butterfly plates are arranged in the shutter butterfly valve, when one set of butterfly plate breaks down and cannot be normally started, and the other sets of butterfly plates are not influenced and can still normally used, the using reliability is improved, and the defect that in an original product, when one set of butterfly plate is damaged, the overall shutter butterfly valve is influenced and cannot be normally used is avoided. The pneumatic quick-opening shutter butterfly valve is suitable for quick exhausting under emergency conditions of West-East natural gas transmission compressor station tail gas waste heat power generation projects.

Owner:RUIAN FIRST VALVE FACTORY

Generalized DC cathodic protection system and its generalized DC potentiostat

The invention provides a generalized direct current cathodic protection system and a generalized direct current constant potential rectifier thereof. The generalized direct current constant potential rectifier comprises a pipe-to-soil potential measurement unit, a controller, an adjustable direct current power supply and a polarity control unit, wherein the polarity control unit can convert direct current voltage output by the adjustable direct current power supply into direct current voltage output which is opposite to the polarity of an interfering pipe-to-soil potential under control of the controller. The system comprises the generalized direct current constant potential rectifiers, wherein two output ends of every two generalized direct current constant potential rectifiers are electrically connected with the external surfaces at the two ends of inlet and outlet buried metal pipeline sections of a compressor station respectively and correspondingly; two earthing terminals of every two generalized direct current constant potential rectifiers are connected with a generalized anodic groundbed; and the buried metal pipeline sections are electrically insulated with the adjacent buried metal pipeline sections. The generalized direct current constant potential rectifier of the system can exert an external stray current interference resistance effect, and can convert the direct current polarity to adapt to eliminate external stray current interference in any polarity.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

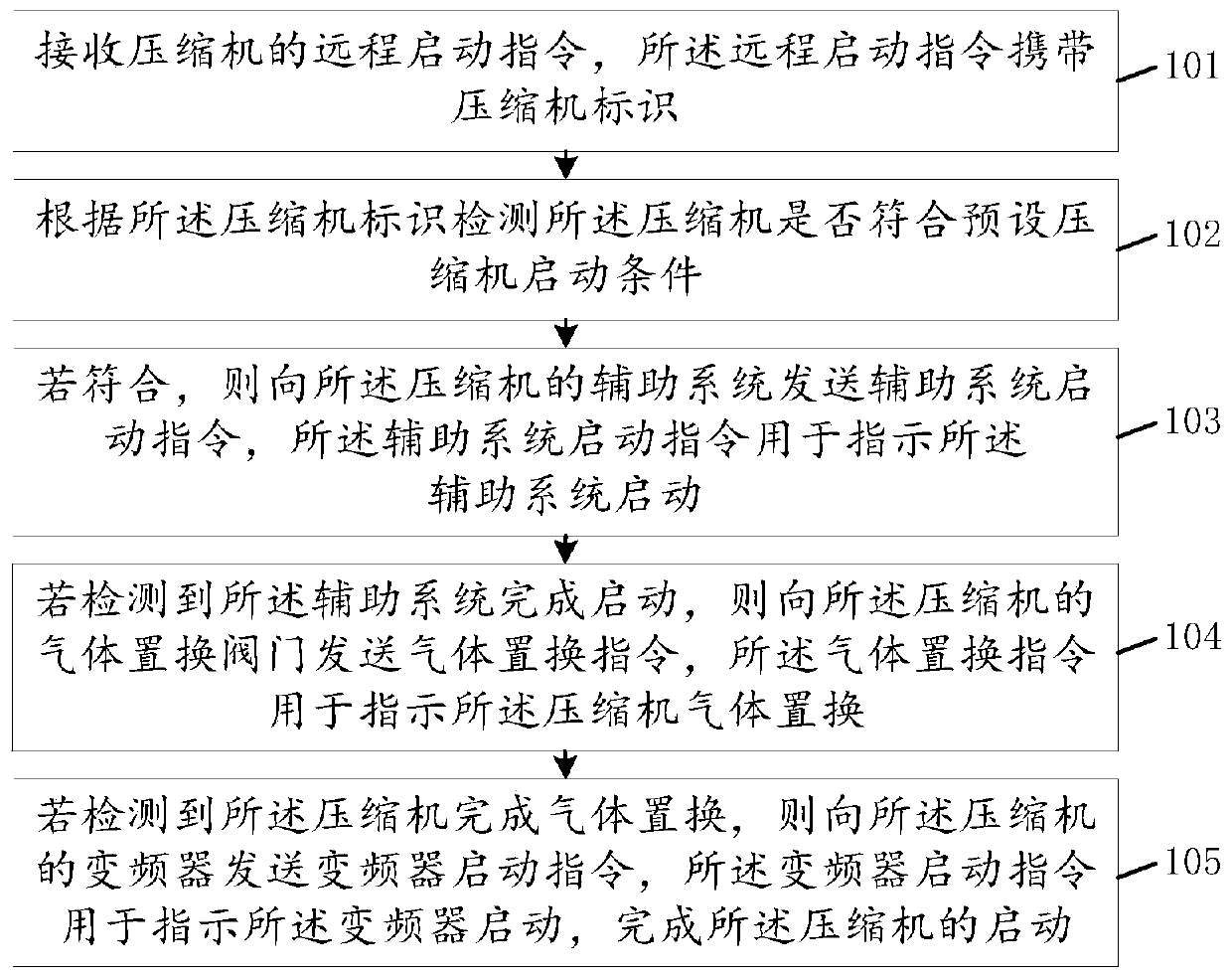

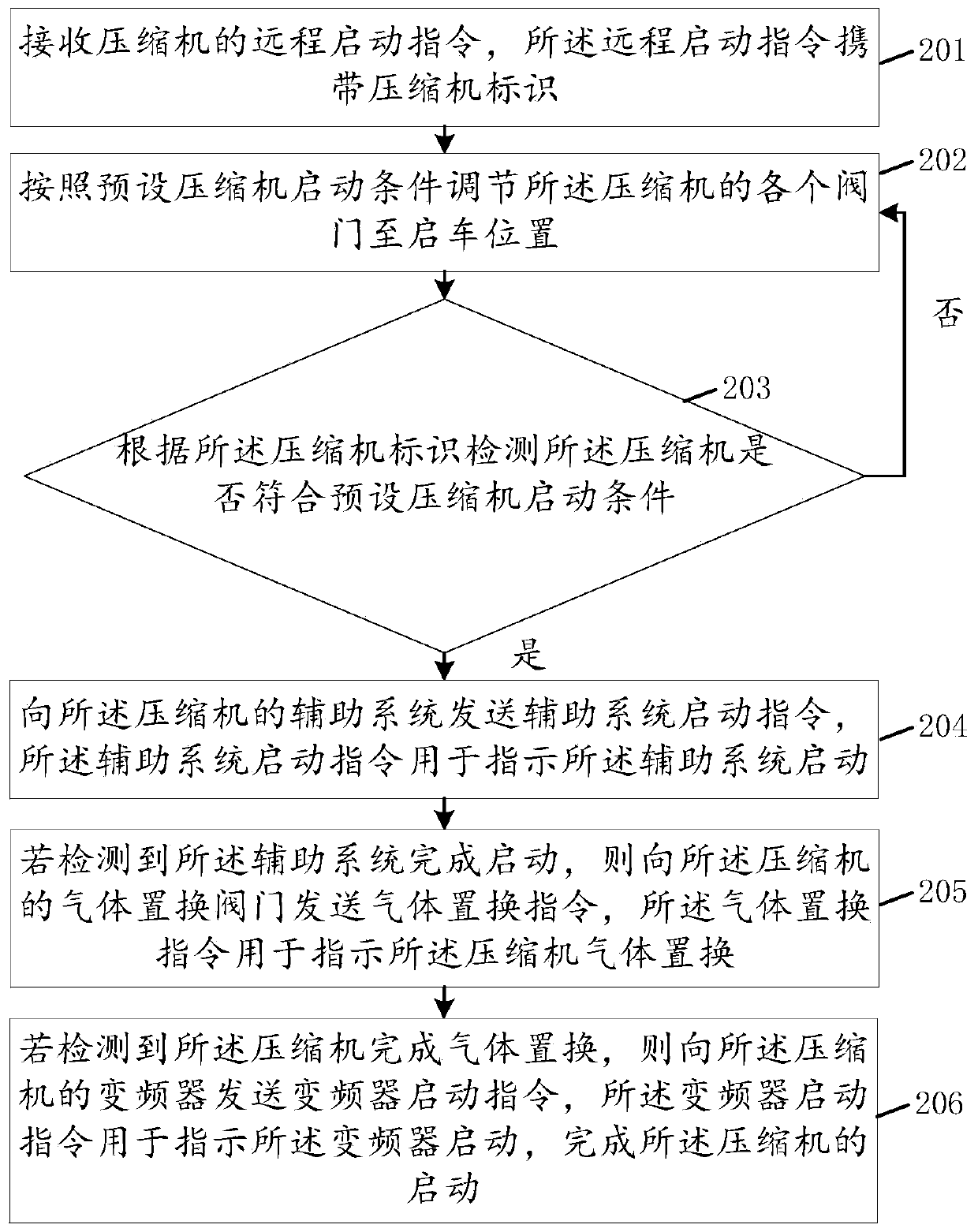

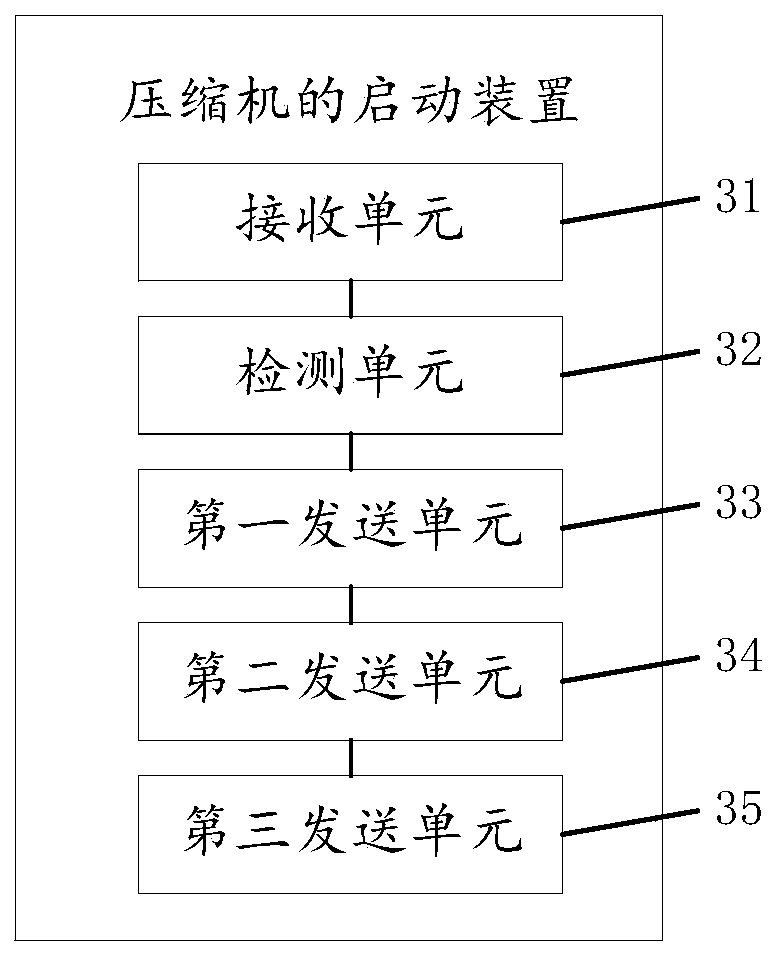

Method and device for starting compressor, storage medium and computer equipment

InactiveCN109989908AEasy to controlEasy to operatePump controlPositive-displacement liquid enginesFrequency changerVariable-frequency drive

The invention discloses a method and device for starting a compressor, a storage medium and computer equipment, relates to the technical field of compressors, and mainly aims to remotely operate and control a long-distance pipeline compressor station. The method comprises the following steps of receiving a remote starting instruction of the compressor, specifically, the remote starting instructioncarries compressor identification; detecting whether the compressor meets a preset compressor starting condition or not according to the compressor identification; if yes, sending an auxiliary systemstarting instruction to an auxiliary system of the compressor; if it is detected that the auxiliary system finishes starting, sending a gas replacement instruction to a gas replacement valve of the compressor; and if it is detected that the compressor completes gas replacement, sending a frequency converter starting instruction to a frequency converter of the compressor, specifically, the frequency converter starting instruction is used for instructing the frequency converter to start and completing the starting of the compressor. The method and the device are suitable for starting the compressor.

Owner:SHENYANG BLOWER WORKS GRP AUTOMATIC CONTROL SYST ENG

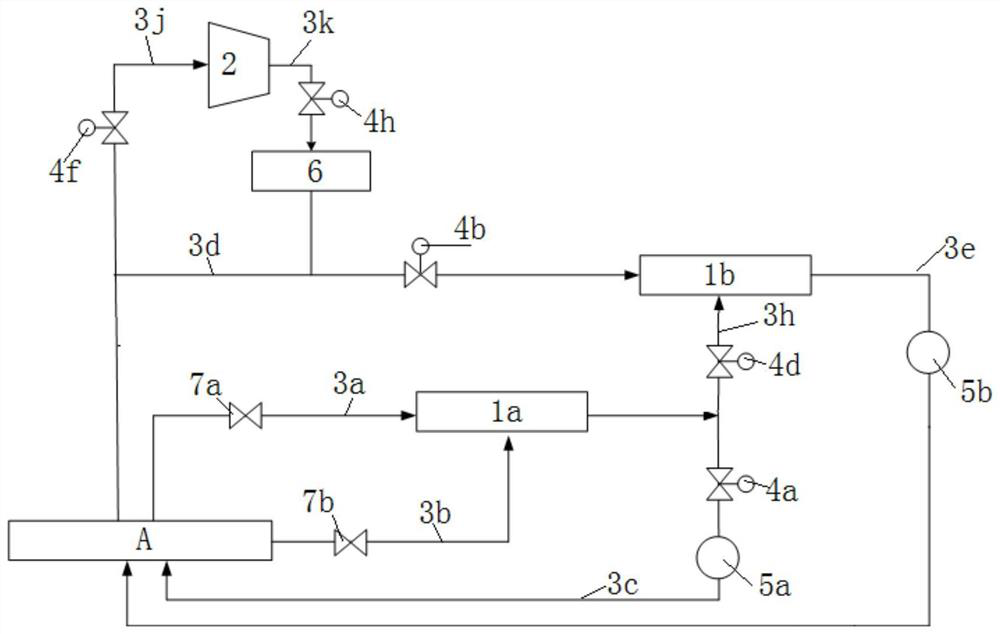

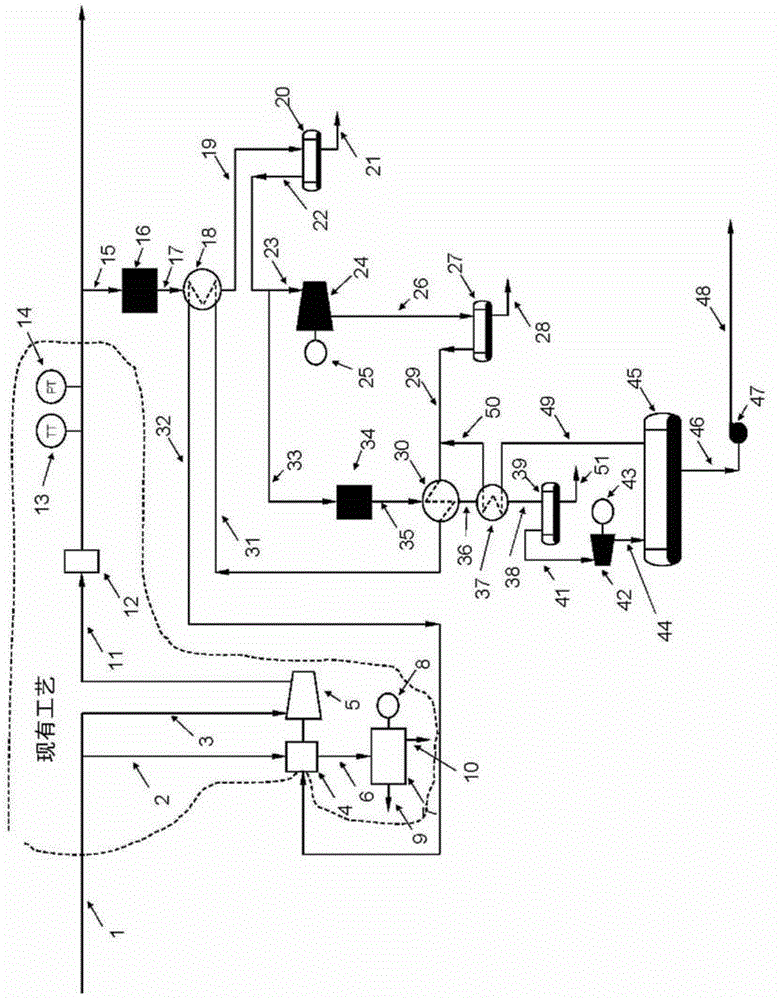

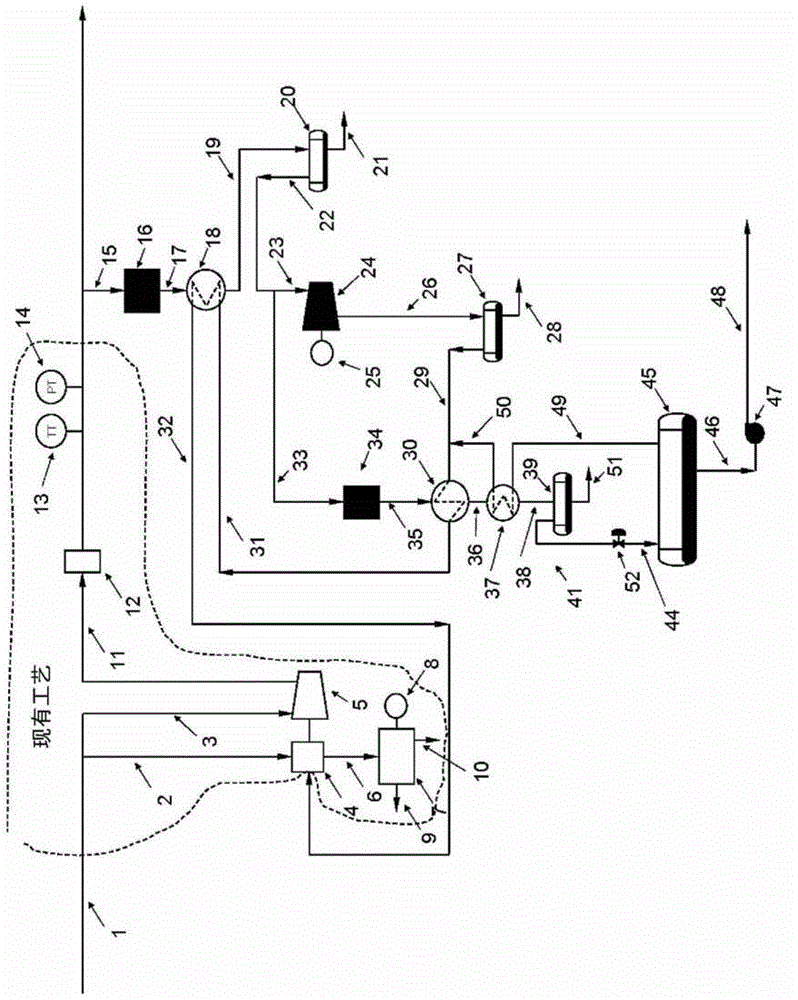

System for recycling vent natural gas in compressor station

PendingCN111623238AHigh recovery rateReduced impact on operational reliabilityJet pumpsPipeline systemsThermodynamicsEngineering

The invention discloses a system for recycling vent natural gas in a compressor station and belongs to the technical field of natural gas recycling. The system comprises a multilevel gas power compressor, a gas reciprocating compressor and a controller. According to the coordination of the multilevel gas power compressor and the gas reciprocating compressor, the controller is utilized to control the opening and closing of a first electromagnetic valve, a second electromagnetic valve, a third electromagnetic valve, a fourth electromagnetic valve, a fifth electromagnetic valve, a sixth electromagnetic valve and a seventh electromagnetic valve based on a detection result transferred by a first pressure transducer, a second pressure transducer, and a third pressure transducer. Gas of differentpressure and different capacity discharged from a vent end of a pipeline compressor can be effectively supercharged in time so that the supercharged pressure can reach the requirement of predetermined recoverable pressure, and the recovery rate of vent natural gas in the compressor station is improved.

Owner:PETROCHINA CO LTD

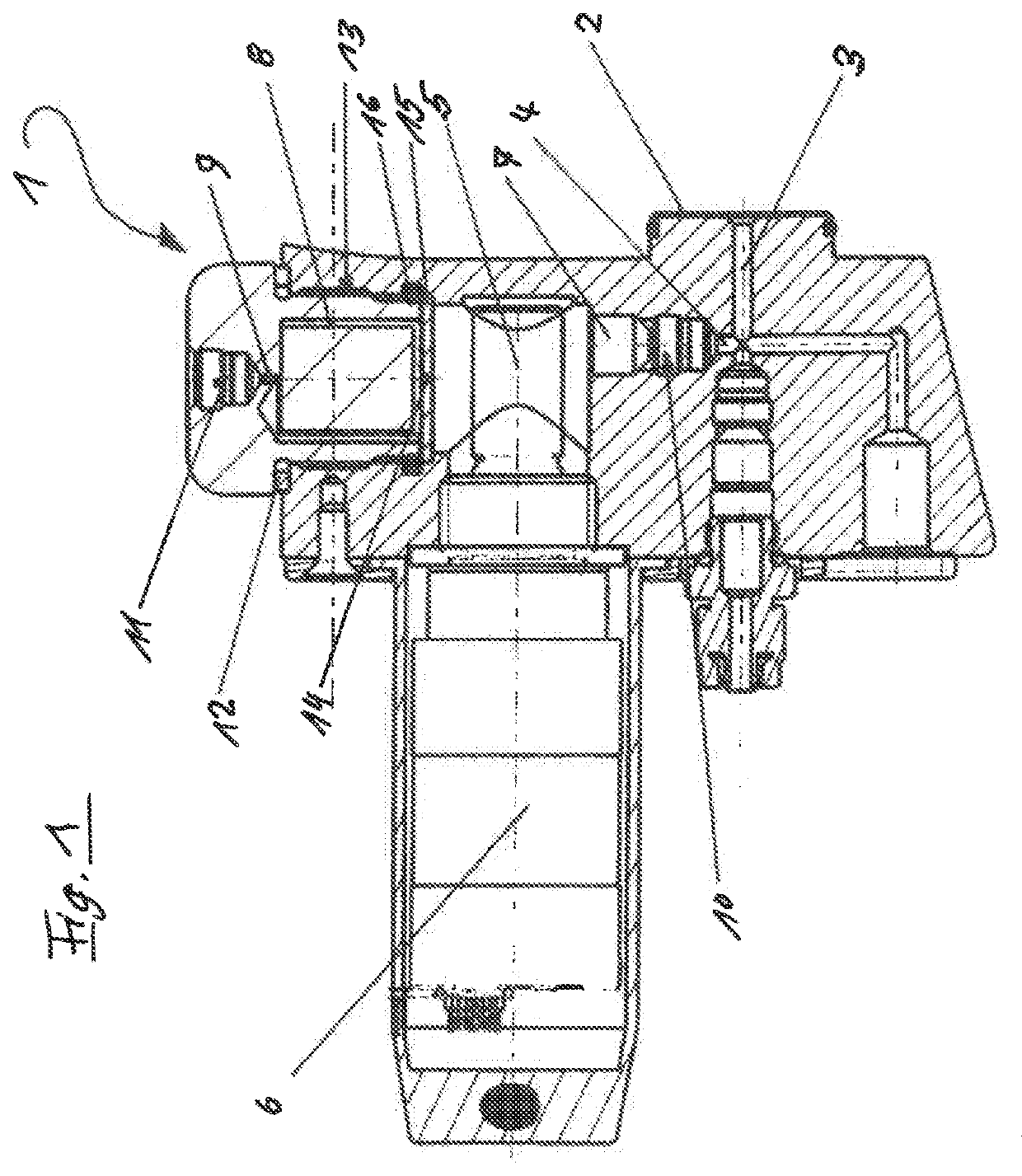

Moisture measuring device for gases

PendingUS20200141887A1Reliable detectionPrecise and reliable moisture contentPositive displacement pump componentsWithdrawing sample devicesHermetic sealEnvironmental engineering

A moisture measuring device for gases, in particular compressed gases, compressed air and the like, for moisture content detection in a gas supply system, includes a gas sampling input for the test gas which is connected to the gas supply system. A separate gas channel used only for the moisture measurement branches off from the gas sampling input. The separate gas channel is connected with a measuring cell in which a dew point sensor is arranged. A drying cell with a drying agent is connected downstream of the measuring cell. The drying cell is substantially hermetically sealed against the outside environment. Lastly, the output side of the drying cell is connected to an outlet channel leading to the outside environment. A gas supply system may have the form of a compressed gas system, a compressor station, a storage system and the like.

Owner:BAUER KOMPRESSOREN

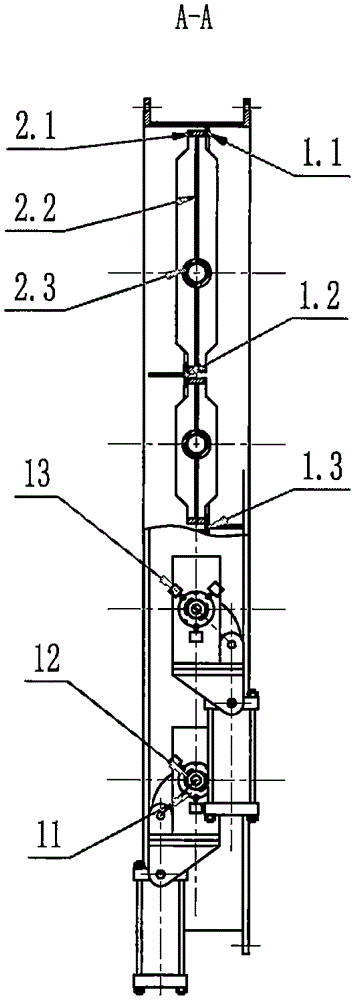

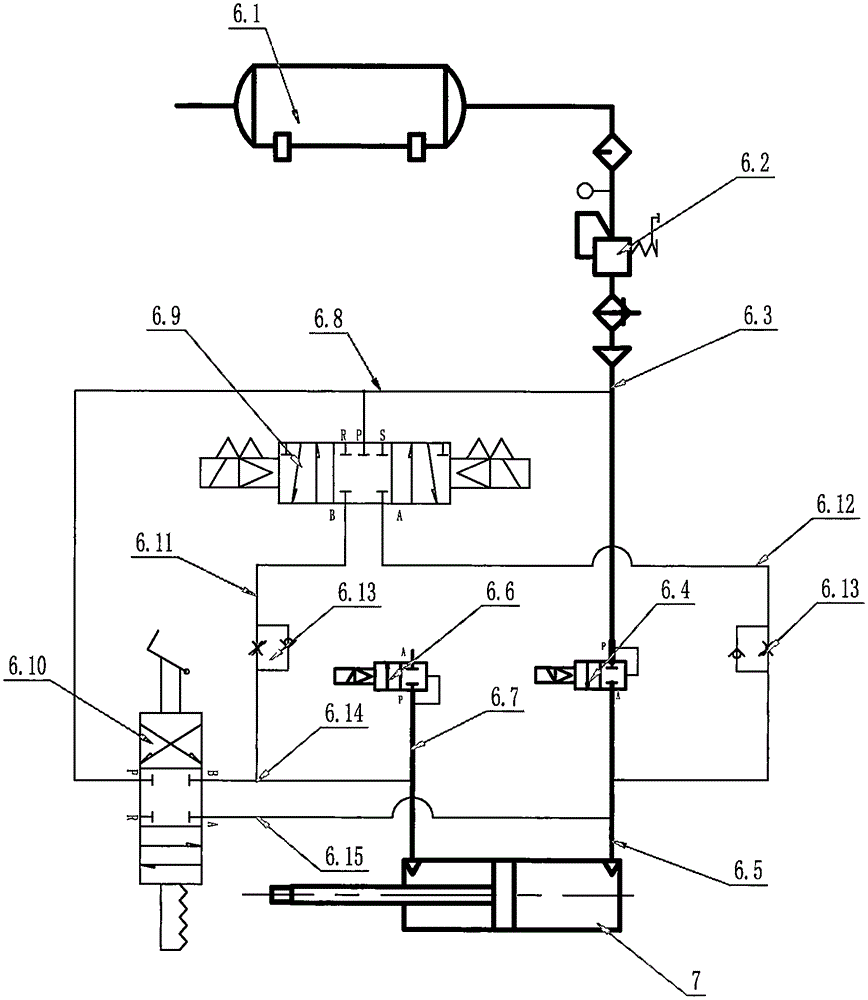

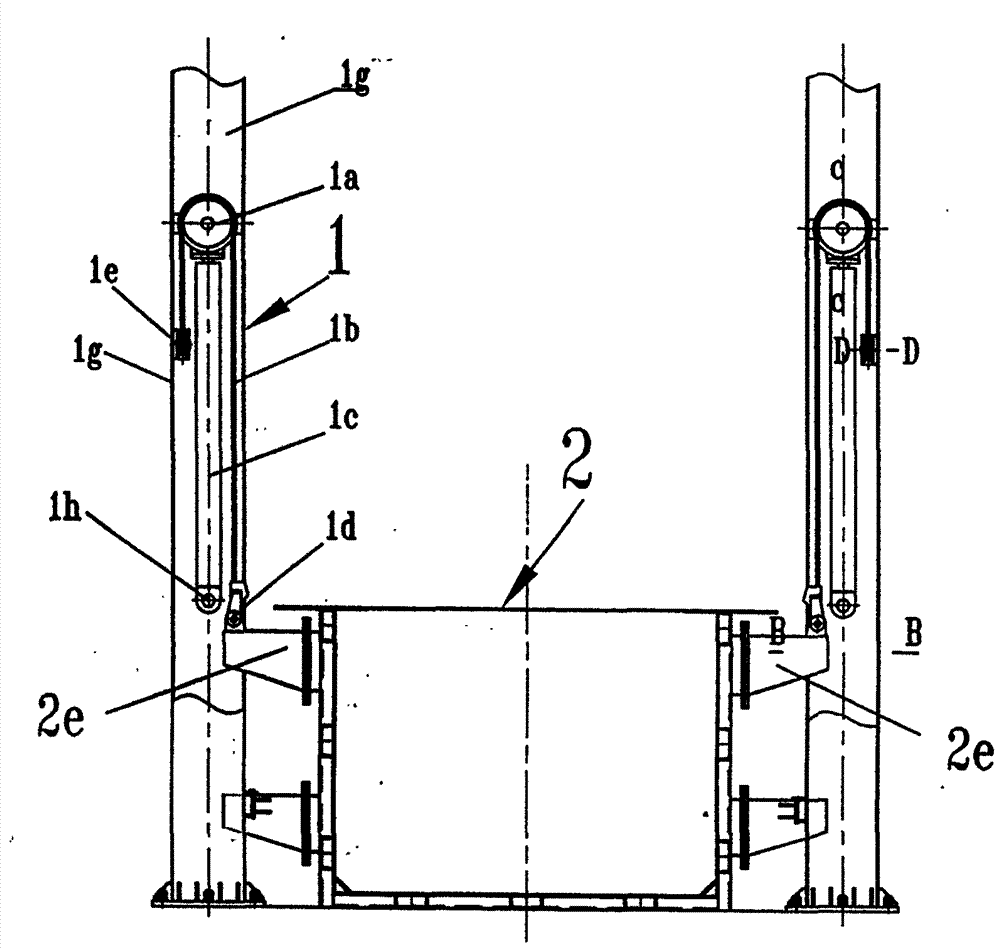

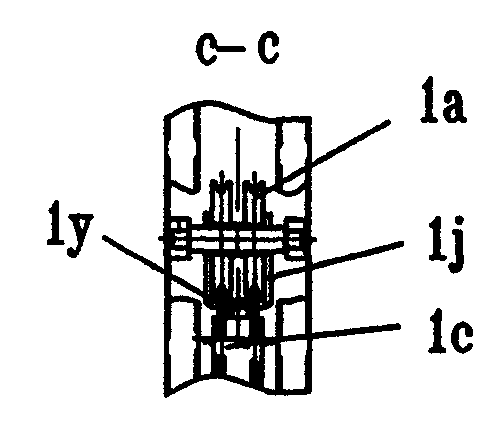

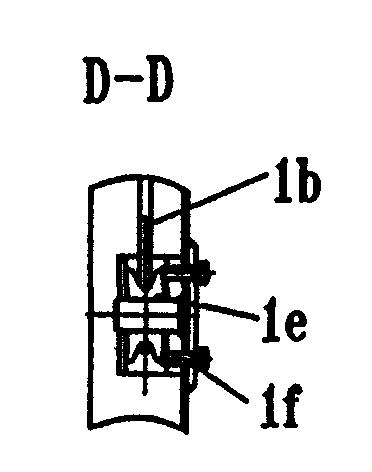

Lifting device used on rubbish compression machine (station)

InactiveCN101691169BLower the altitudeReduce building heightRefuse transferringLoading/unloadingCantilevered beamClassical mechanics

The invention particularly relates to a lifting device used on a rubbish compression machine (station), which comprises a lifting device 1 and a rubbish volume box 2, and is characterized in that: a cantilever beam 2e is fixed on the rubbish volume box 2; the lifting device 1 comprises a stand column 1g, an oil cylinder lifting mechanism, a pulley and sliding rope transmission gear; the cross section of the stand column 1g is in a sunken shape and hollow and provided with an opening, and the oil cylinder lifting device and the pulley and sliding rope transmission gear are arranged in the stand column 1g; the lifting mechanism consists of a lifting oil cylinder 1c, a piston 1y, a pulley base 1j and an oil cylinder base 1h, the pulley and sliding rope transmission gear is composed of a driven pulley 1a, a sliding rope 1b, a bearing pulley 1e and a bearing support 1f; the middle of the sliding rope is wound in a bearing pulley, two sides are wound on the driven pulley, two ends are hinged on the cantilever beam 2e by a rope clip 1d. The lifting height and lifting speed of the invention is twice as that of the oil cylinder, the height of the stand column and factory buildings is reduced by more than 15%, the structure is simple and the efficiency is high.

Owner:吉林前沅专用汽车制造股份有限公司

Pneumatic quick opening louver butterfly valve

ActiveCN105276202BHigh strengthAvoid deformationOperating means/releasing devices for valvesLift valveButterfly valveEmergency condition

The invention relates to a pneumatic quick-opening shutter butterfly valve. A valve body is composed of a plurality of butterfly plates, each butterfly plate is provided with an independent driving device which is used for controlling the opening or closing motion of the butterfly plate, and the functions of adjustable speed of quick opening (or quick closing) and slow closing (or slow opening), stopping of closing (or opening) position and the like are achieved through the shutter butterfly valve with an air source as power; as a plurality of sets of independently-driven butterfly plates are arranged in the shutter butterfly valve, when one set of butterfly plate breaks down and cannot be normally started, and the other sets of butterfly plates are not influenced and can still normally used, the using reliability is improved, and the defect that in an original product, when one set of butterfly plate is damaged, the overall shutter butterfly valve is influenced and cannot be normally used is avoided. The pneumatic quick-opening shutter butterfly valve is suitable for quick exhausting under emergency conditions of West-East natural gas transmission compressor station tail gas waste heat power generation projects.

Owner:RUIAN FIRST VALVE FACTORY

Method of producing and distributing liquid natural gas

A method for producing liquid natural gas (LNG) includes the following steps. Compressor stations forming part of existing natural-gas distribution network are identified. Compressor stations that are geographically suited for localized distribution of LNG are selected. Natural gas flowing through the selected compressor stations is diverted to provide a high pressure first natural gas stream and a high pressure second natural gas stream. A pressure of the first natural gas stream is lowered to produce cold temperatures through pressure let-down gas expansion and then the first natural gas stream is consumed as a fuel gas for an engine driving a compressor at the compressor station. The second natural gas stream is first cooled with the cold temperatures generated by the first natural gas stream, and then expanded to a lower pressure, thus producing LNG.

Owner:1304338 ALBERTA

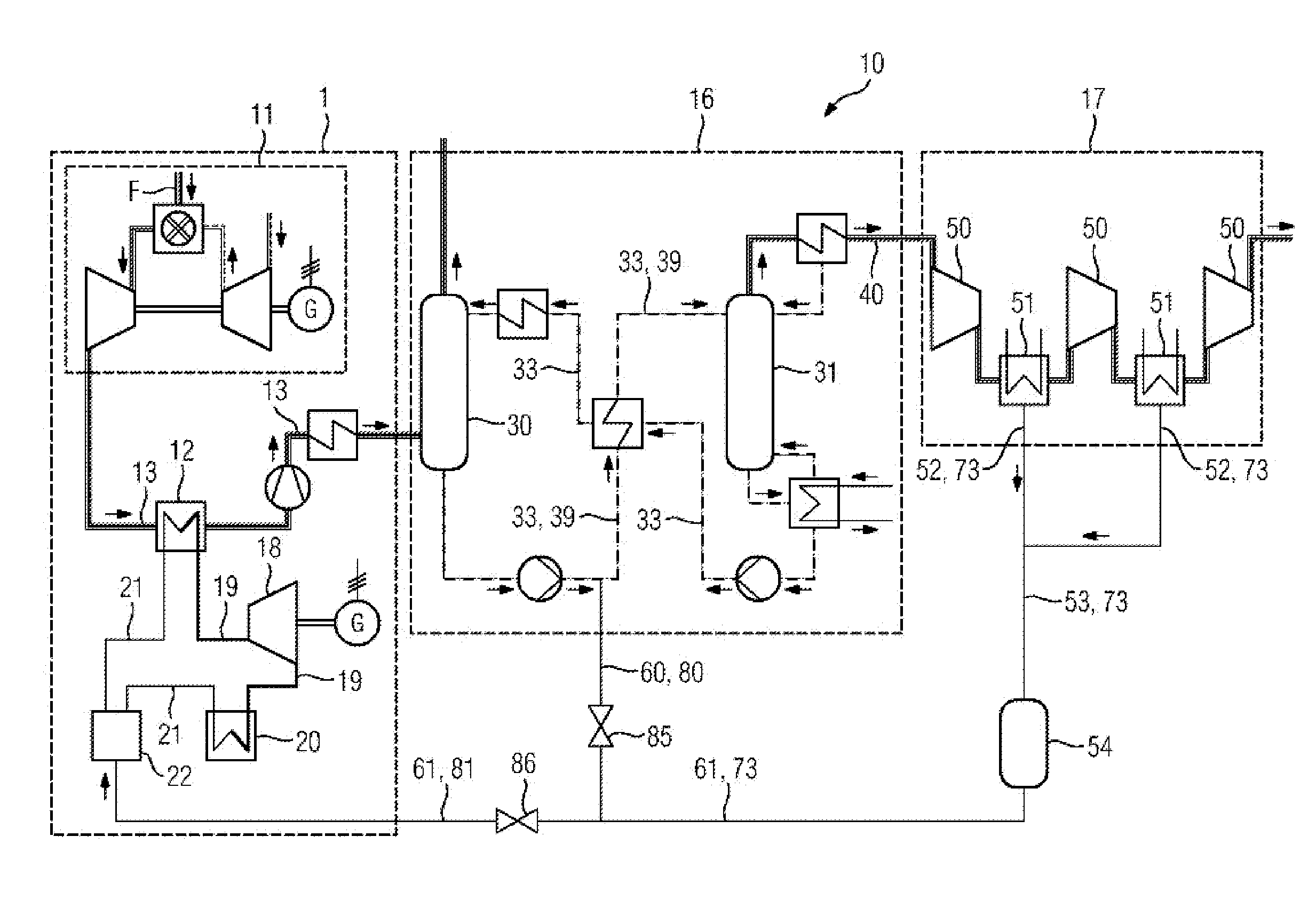

Method and fossil-fuel-fired power plant for recovering a condensate

InactiveCN103717847ALighting and heating apparatusDispersed particle separationCombustionProcess engineering

The invention relates to a fossil-fuel-fired power plant (10), comprising a combustion device (11), a CO2 separation device (16), which is arranged downstream of the fossil-fuel-fired power plant (10), for removing CO2, and a CO2 compressor station (17), which is arranged downstream of the CO2 separation device (16) and which has a number of compressor stages (50) and coolers (51) for intermediate cooling. According to the invention, the coolers (51) are connected to the CO2 separation device (16) or the fossil-fuel-fired power plant (10) by means of a condensate line (52, 53, 60, 61) in order to recover condensate. The invention further relates to a method for carrying out the condensate recovery.

Owner:SIEMENS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com