Design method of natural gas pipeline compressor standby unit

A technology for natural gas pipelines and backup units, which is applied to the design of backup units for natural gas pipeline compressors, can solve the problems of not being able to reflect the reliability of the pipeline system as a whole, and failing to comprehensively consider the influence of line valve chamber failures on the reliability of the pipeline system, thereby improving the reliability of the pipeline system. Utilization rate, the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

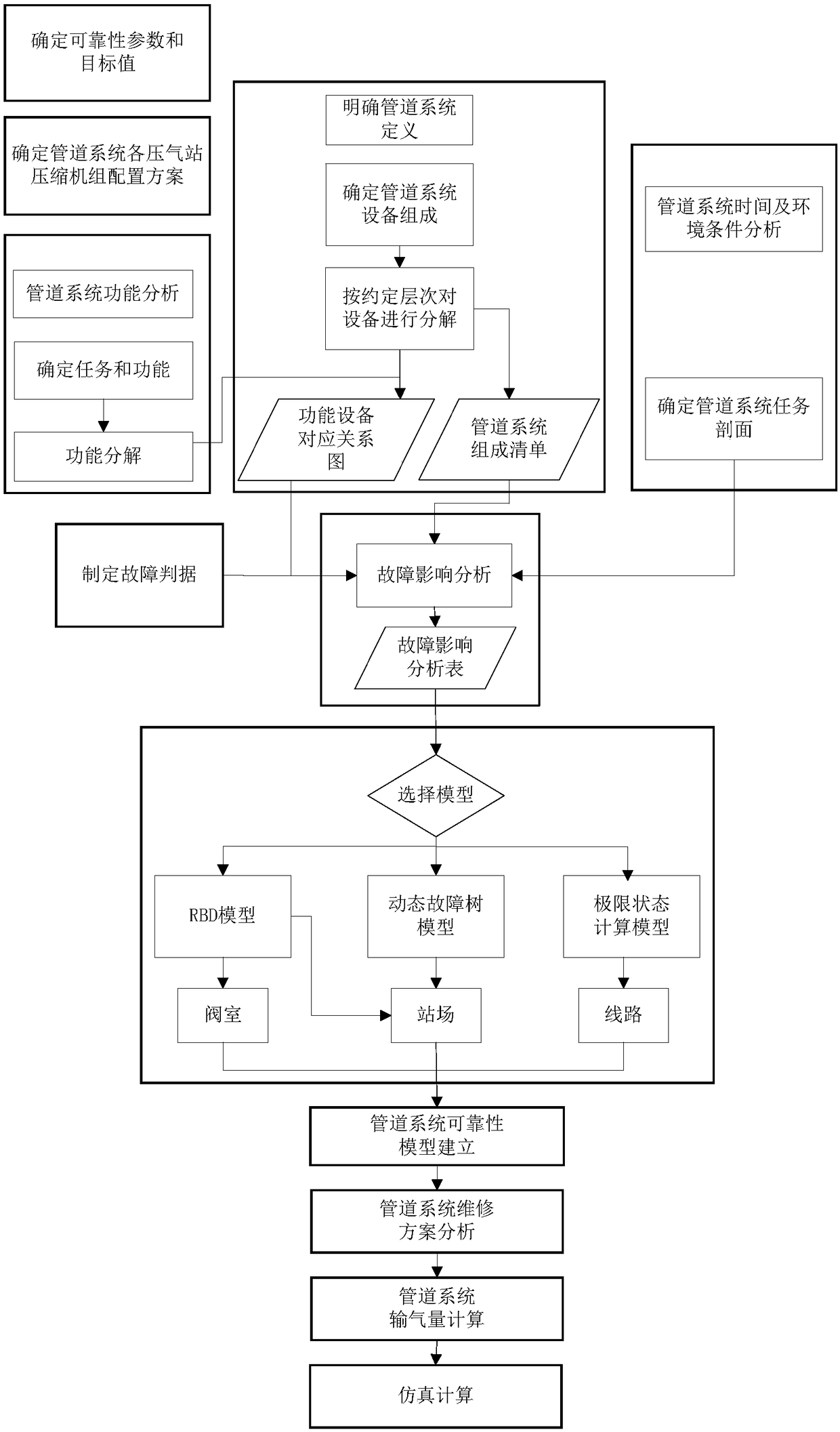

Method used

Image

Examples

Embodiment 1

[0053] Example 1, taking the design output of 22 billion cubic meters per year as an example, the configuration scheme of the compressor units of each compressor station in the pipeline system is shown in Table 1.

[0054] Table 1 The unit operation plan and backup comparison and selection plan with a design output of 22 billion cubic meters per year

[0055]

[0056] The specific calculation process is as follows:

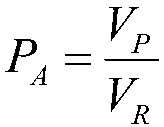

[0057]Step 1. The production availability is taken as the reliability parameter, and the target value is ≥1.

[0058] Step 2. According to the design output of 22 billion cubic meters per year, determine the configuration scheme of the pipeline compressor unit through the hydraulic calculation results, see Table 1.

[0059] Step 3. Analyze the task functions of the China-Russia Eastern Route Pipeline System. The main functions are as follows:

[0060] Line: connect the station and the valve room, and play the role of airtight transportation at the same time; ...

Embodiment 2

[0142] Example 2, taking the output volume of 30 billion cubic meters per year as an example, the configuration scheme of the compressor units of each compressor station in the pipeline system is shown in Table 10.

[0143] Table 10 Unit operation scheme and backup comparison scheme with a design output of 30 billion cubic meters per year

[0144]

[0145] After calculation using the above steps, the calculation results are shown in Tables 11-13.

[0146] Table 11 Calculation results of the pipeline system drop after the output volume is 30 billion cubic meters per year and one unit fails in one compressor station

[0147] serial number

Failure station

Gas transmission volume (billion cubic meters / year)

Decrease percentage / %

1

1# compressor station

322

15.3

[0148] serial number

Failure station

Gas transmission volume (billion cubic meters / year)

Decrease percentage / %

2

3# compressor station

320

...

Embodiment 3

[0158] Example 3, taking the transportation volume of 38 billion cubic meters per year as an example, the configuration scheme of the compressor units of each compressor station in the pipeline system is shown in Table 16.

[0159] Table 16 The number of units in operation with a design output of 38 billion cubic meters per year and the backup comparison and selection scheme

[0160]

[0161] Under the design output volume of 38 billion cubic meters per year, all compressor stations are fully in use, respectively for the full-line equipment scheme and no equipment scheme, and the unit scheme for separate station equipment (separate station equipment scheme 1 and separate station equipment scheme) 2) Carry out calculations, among which the equipment machine scheme 1 of the station separation is 1# compressor station, 3# compressor station, 5# compressor station, and 7# compressor station to set up spare unit scheme equipment machines, and the equipment machine scheme 2 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com