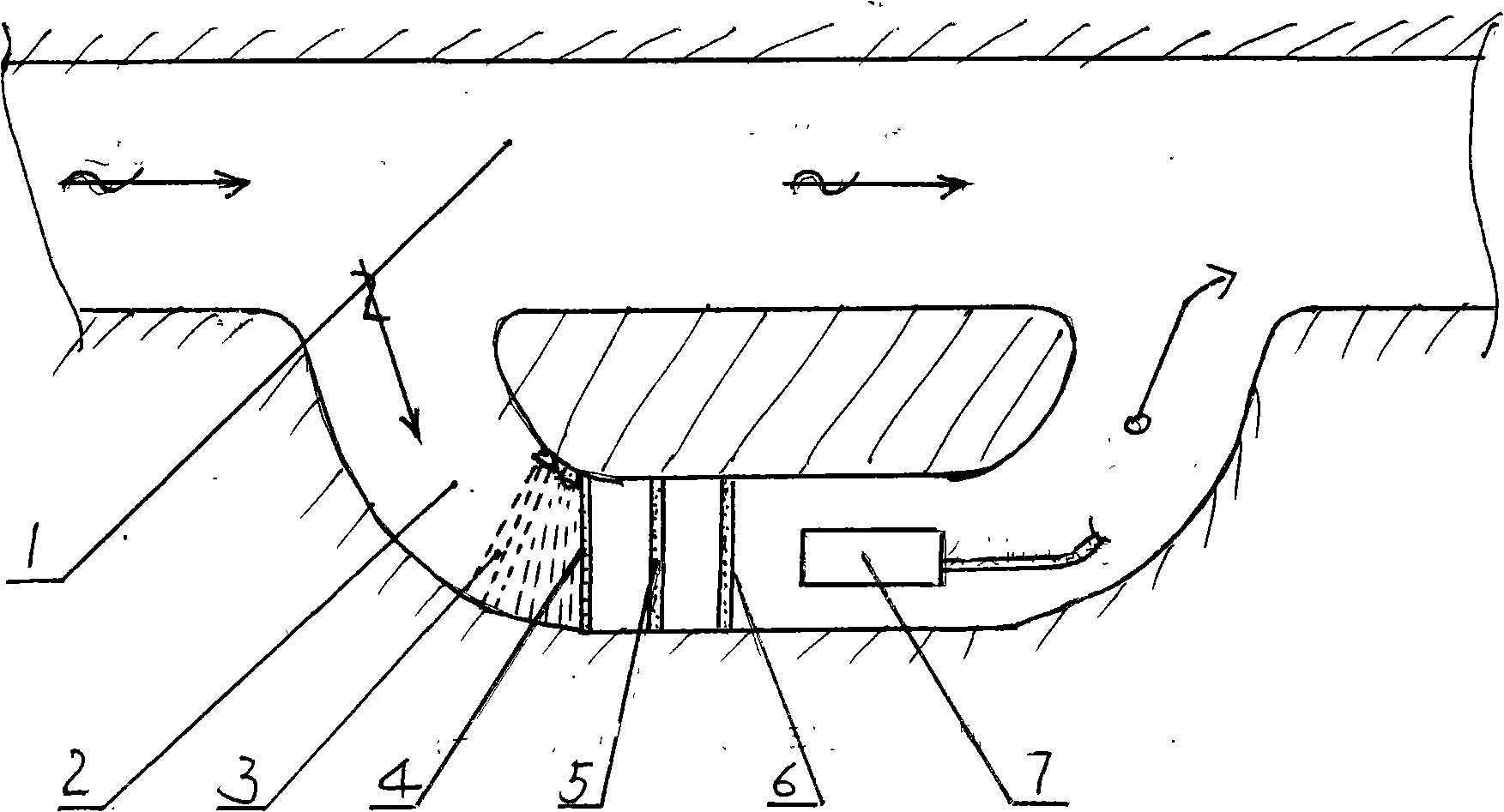

Wind pressuring arrangement method of deep well and mine

A layout method and mine technology, applied in mine/tunnel ventilation, mining equipment, earthwork drilling and mining, etc., can solve the problems of increased mechanical wear of the compressor, poor working environment, high dust content, etc., to reduce the temperature of the working environment , improve efficiency and avoid the effect of pressure wind loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A certain coal mine is taken as an example below to illustrate the specific embodiment of the present invention.

[0019] A coal mine currently has three production working faces and 15 tunneling heads. The compressed air used for the mining face was originally supplied by the ground compressed air station. Due to the low efficiency of the compressed air, the compressed air station was moved underground. A compressor room supply. Mine No. 1 depot compressor room (2 compressors), fourth mining compressor room (1 compressor), eight mining compressor room (3 compressors), the air between the three is connected by air ducts to ensure The whole mine uses wind. Mine-used explosion-proof mobile screw compressor is used underground, the model is SM5110-A, the rated pressure is 0.7MPa, and the displacement is 20m 3 / min. The original compressor is placed in the air inlet tunnel with good ventilation, less dust and no water accumulation. The working air of the compressor is fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com