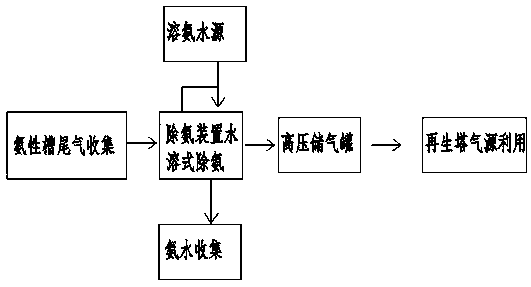

Method and device for treating tail gases of ammonia tanks of coking plant

A tail gas treatment and tail gas technology, applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve problems such as increased cost burden, waste, complex process equipment, etc., and achieve the effect of improving the level of governance and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

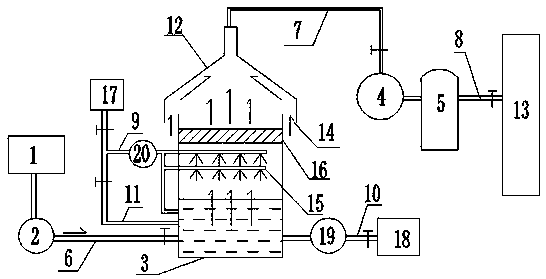

[0025] A coking plant ammonia tank tail gas treatment device as shown in the figure, it includes tail gas collection port 11, fan 2, water-soluble ammonia gas collection tank 3, gas compressor 4, high-pressure storage tank 5, water-soluble ammonia gas collection The bottom of the tank 3 is provided with an air inlet connected to the fan 2, and the tail gas collection port 1 is connected to each ammonia tank to collect ammonia tail gas, and the tail gas is introduced into the bottom of the water-soluble ammonia gas-collecting tank 3 through the fan 2 and the pipeline I6 for water-soluble ammonia removal. The upper part of the water-soluble ammonia gas collection tank 3 is provided with a gas collector 12, and the gas released after the water-soluble ammonia gas collection tank 3 dissolves ammonia is mixed with the gas collector 12 and air, and then connected to the gas compressor 4 through the pipeline II7, and the gas compressor 4 The gas is compressed into the high-pressure st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com