Method for performing circulating washing on lubricating oil of compressor station by using parallel pipeline

A technology of compressor station and lubricating oil, which is applied in the directions of cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

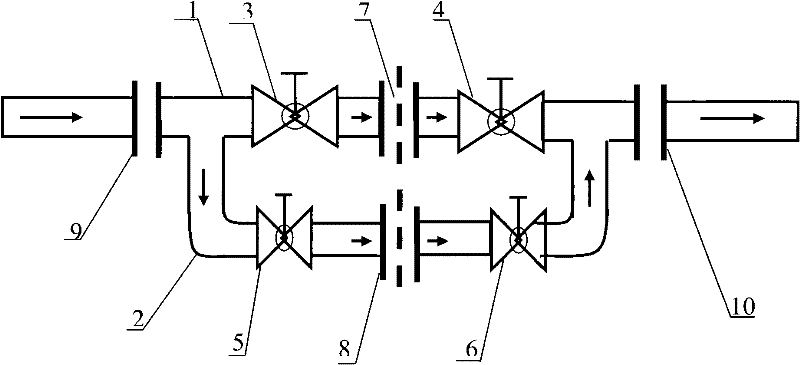

[0039] Embodiment. This example is a test device and method, and the constitution of device is as figure 1 shown. It is to install a parallel temporary bypass pipeline 2 by connecting the temporary pipeline flange (2″) I 9 and connecting the temporary pipeline flange II (2″) 10 beside the main pipeline 1; when connecting the temporary pipeline flange In each pipeline between I 9 and connecting temporary pipeline flange II 10, install two main pipeline filter screens before installing two main pipeline filter screens on both sides of the flange with main pipeline filter screen 7 and bypass pipeline filter screen 8 respectively. Valve 3, manual valve behind the main line filter 4, manual valve in front of the side line filter 5, manual valve 6 behind the side line filter; that is, install the manual valve in front of the main line filter in sequence from the front of the main line 1 oil flow 3. The flange of the filter screen 7 of the main line, the manual valve 4 behind the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com