Premix air heater

a technology of air heater and pre-mixing, which is applied in the direction of air heater, fluid heater, lighting and heating apparatus, etc., can solve the problems of over-pressurization of combustion fan in combustion chamber and heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009]The following detailed description refers to the accompanying drawings. The same reference numbers in different drawings may identify the same or similar elements. Also, the following detailed description does not limit the invention.

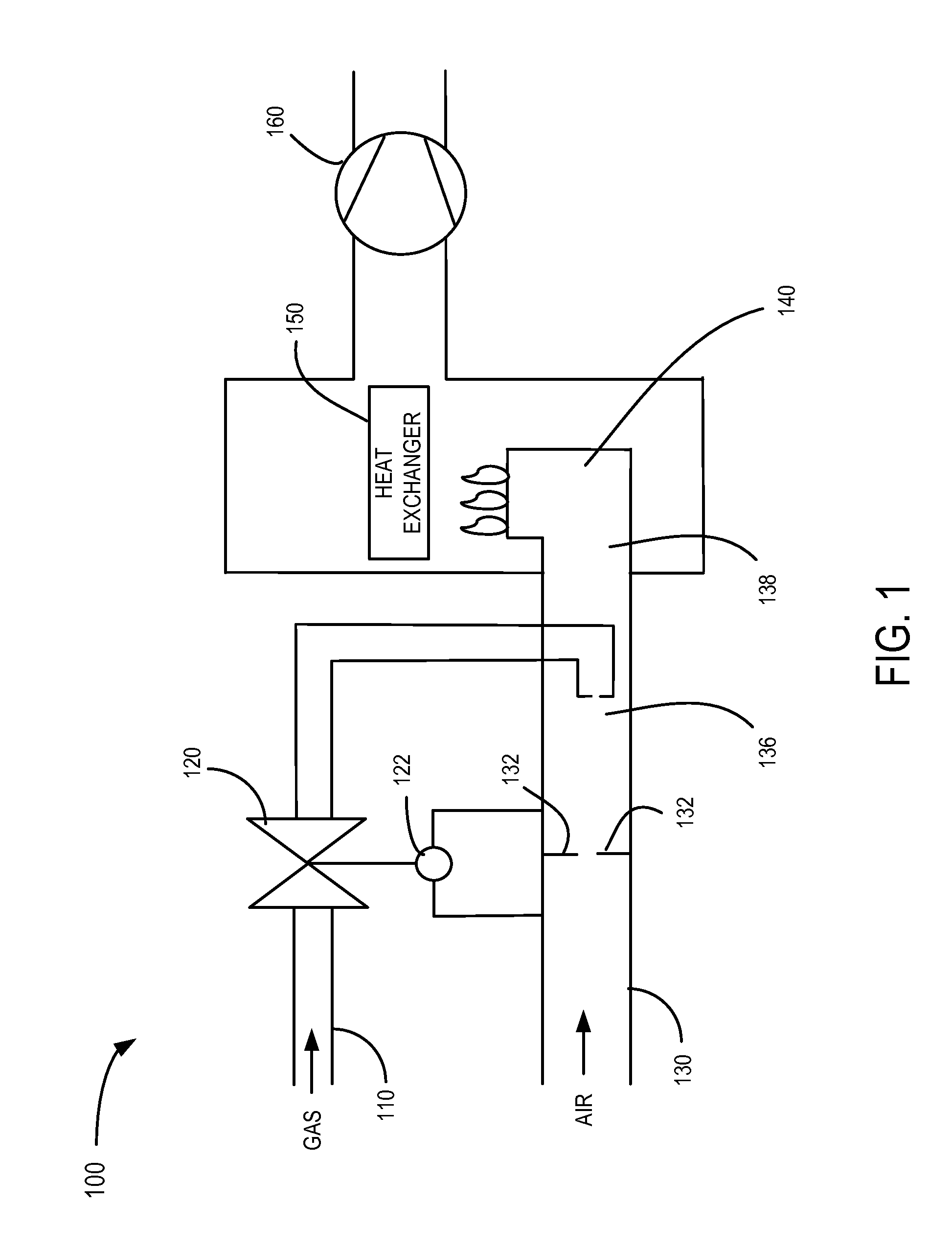

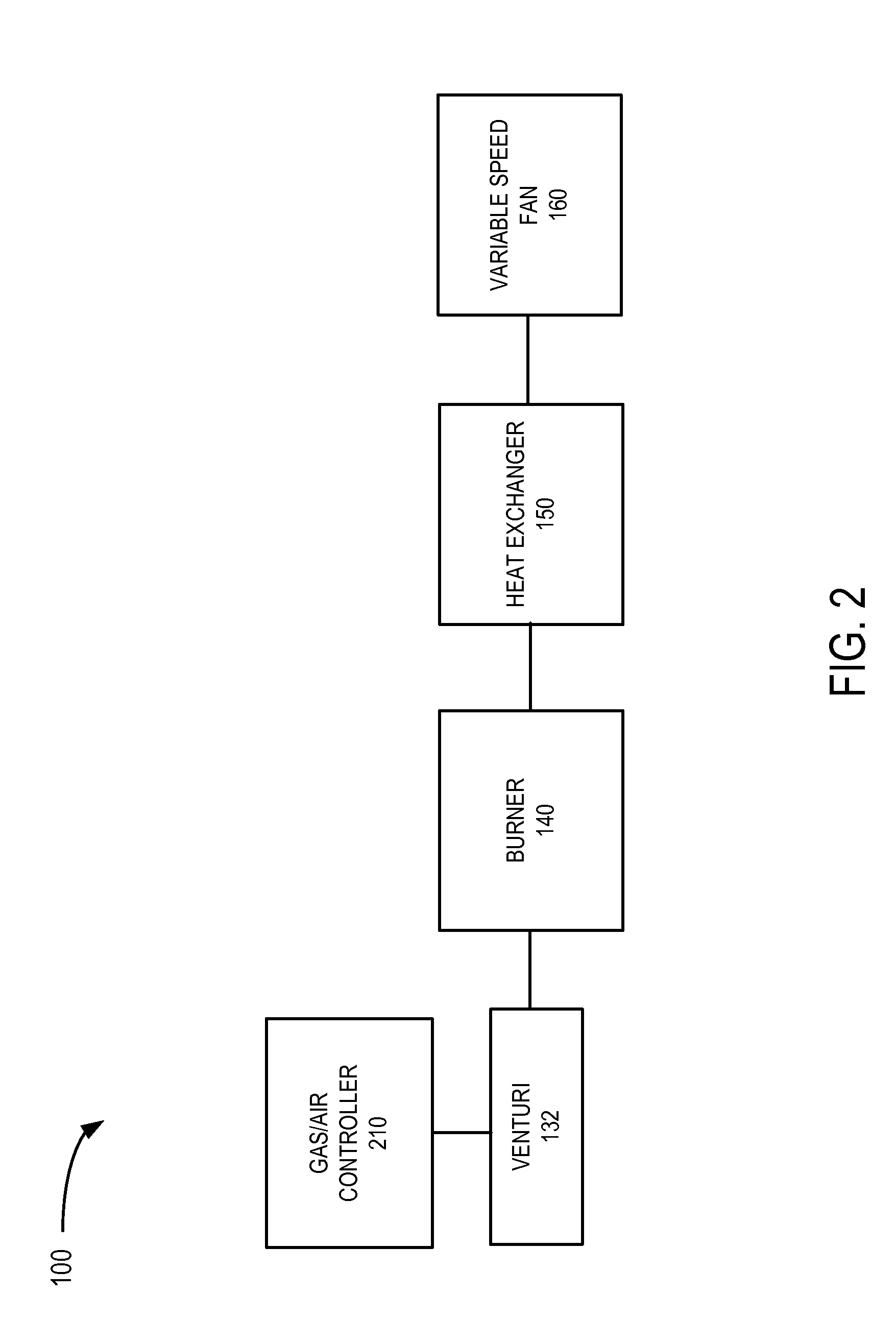

[0010]Embodiments described herein provide a premix air heater that includes a downstream fan that pulls or draws air through a heat exchanger. As a result of the location of the fan, the heat exchanger is effectively under a negative pressure, which helps prevent introduction of flue gases into an interior space. For example, a small leak in the combustion chamber or heat exchanger will not result in flue gases being expelled into the interior space. The fan may also be a variable speed fan that does not affect the gas-air mixture provided to the combustion chamber, which allows the air heater to achieve high efficiency at all loads.

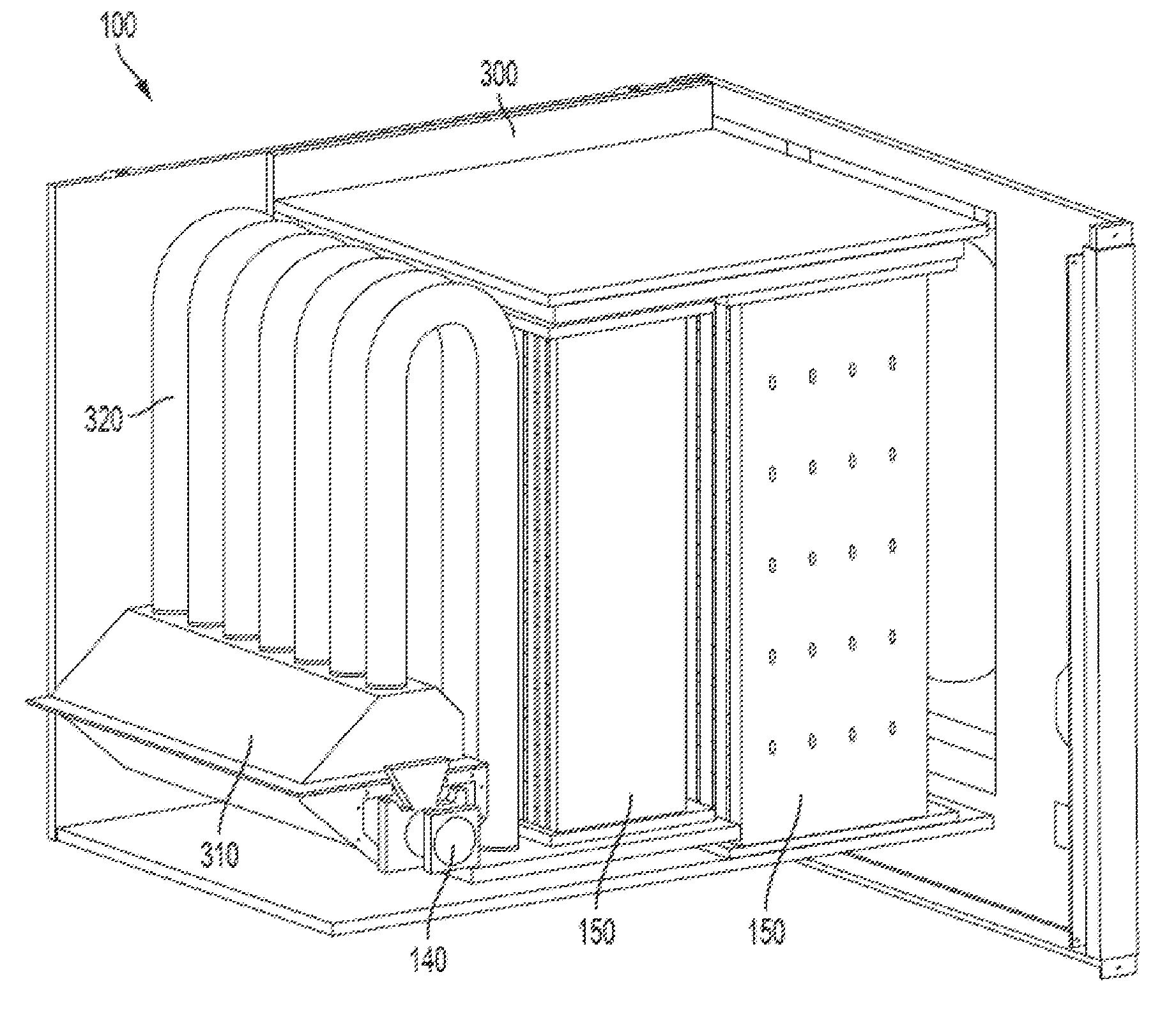

[0011]FIG. 1 is a schematic view of a premix heater unit 100 in accordance with an exemplary implementation. Referr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com