High-efficiency intelligentized heating furnace control method

An intelligent control system and heating furnace technology, applied in the direction of furnace control devices, lighting and heating equipment, furnaces, etc., can solve the problems of uneven control of exhaust gas temperature, failure to meet modern requirements, imperfect control aspects and processes, etc. , to achieve the best heat utilization rate and energy-saving effect, and to maintain the effect of furnace temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

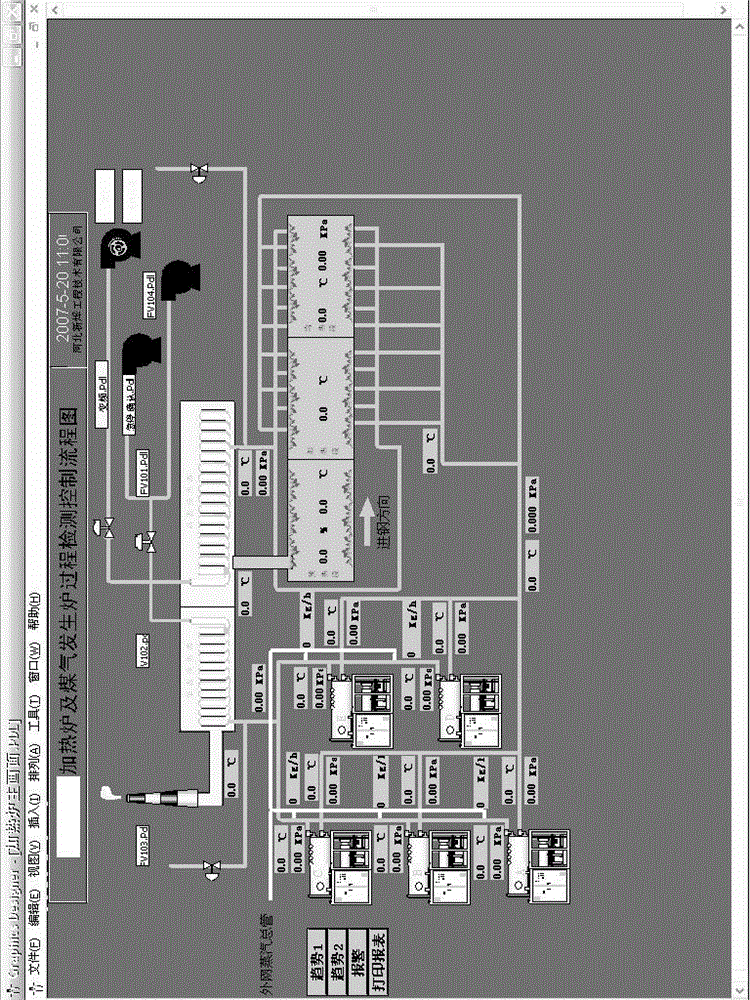

Image

Examples

Embodiment Construction

[0023] The method of the present invention is specifically described below by a certain company's heating furnace example:

[0024] When the method of the present invention is implemented, the intelligent control system is composed of a Siemens S7-300 field control system and a computer upper operating system. The computer is an Advantech industrial computer, configured as P4 2.0G, 256M, and has an industrial Ethernet processor CP5611. The computer communicates with the PLC by means of CP5611. The on-site control system is composed of CPU and input and output modules, and completes the collection of on-site thermal parameter data, equipment status acquisition and adjustment control output of important thermal parameters. The upper computer operating system completes the programming and online monitoring of equipment status, real-time control, and online adjustment of process parameters to ensure that production is carried out in an economical, safe and reasonable state at any...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com